Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about "Understructures" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

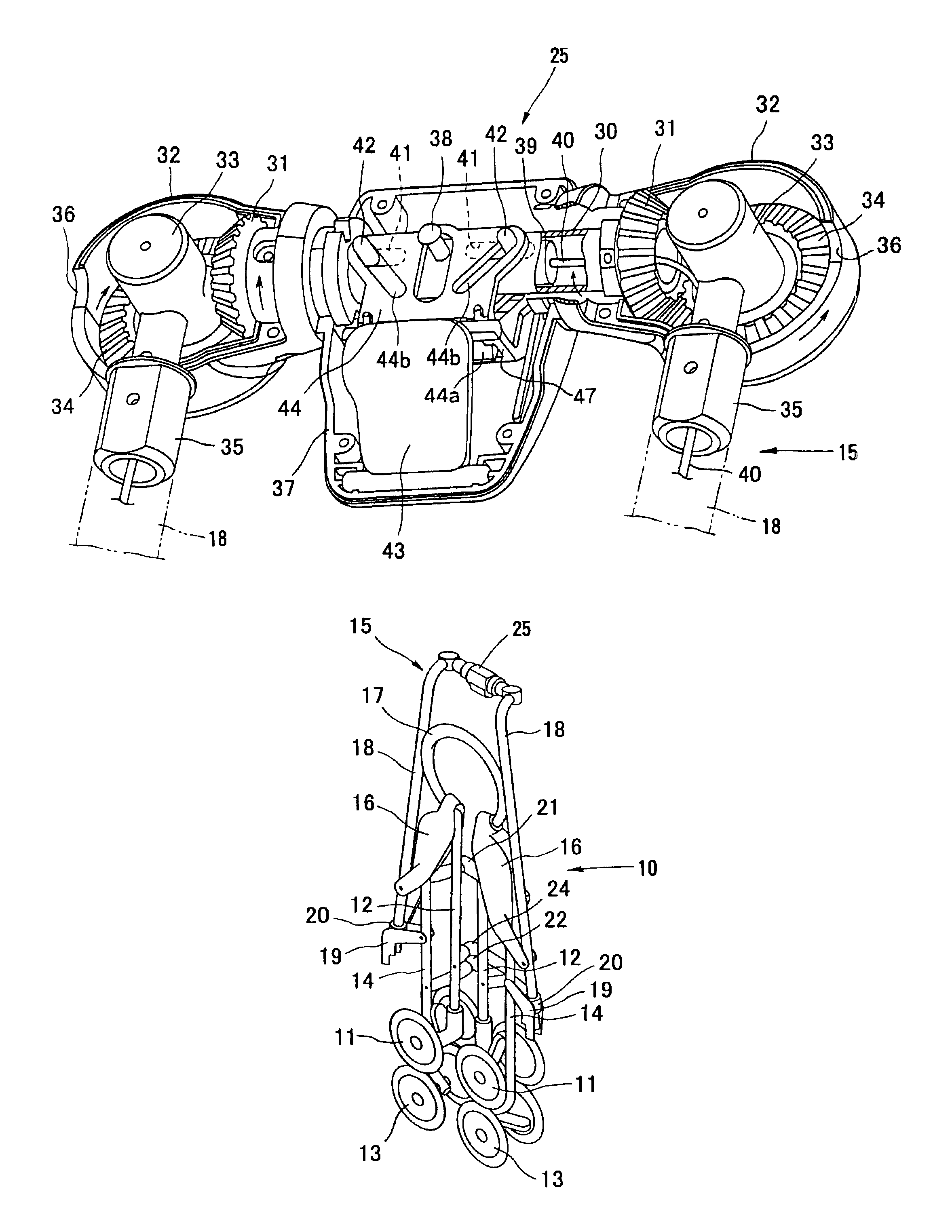

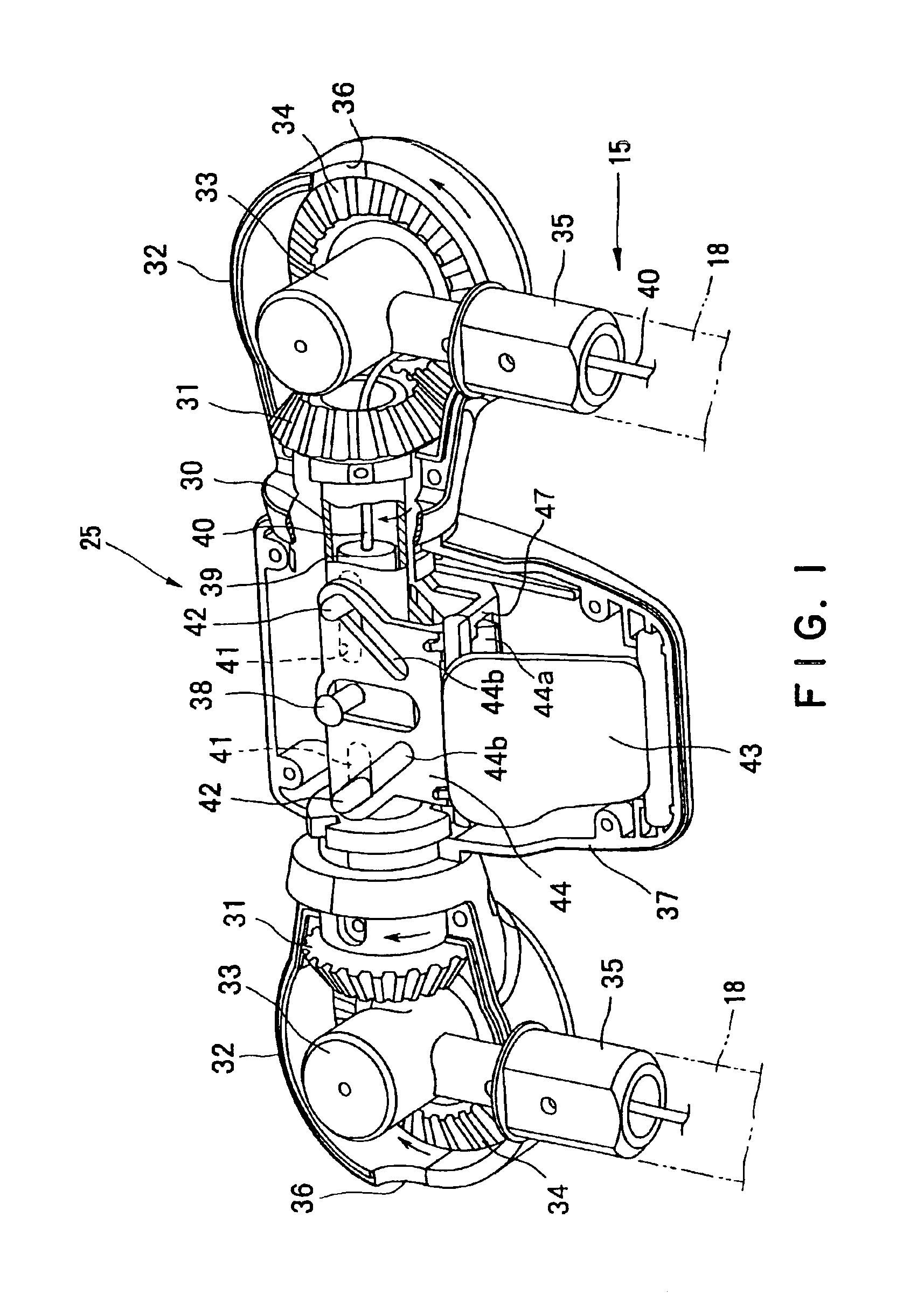

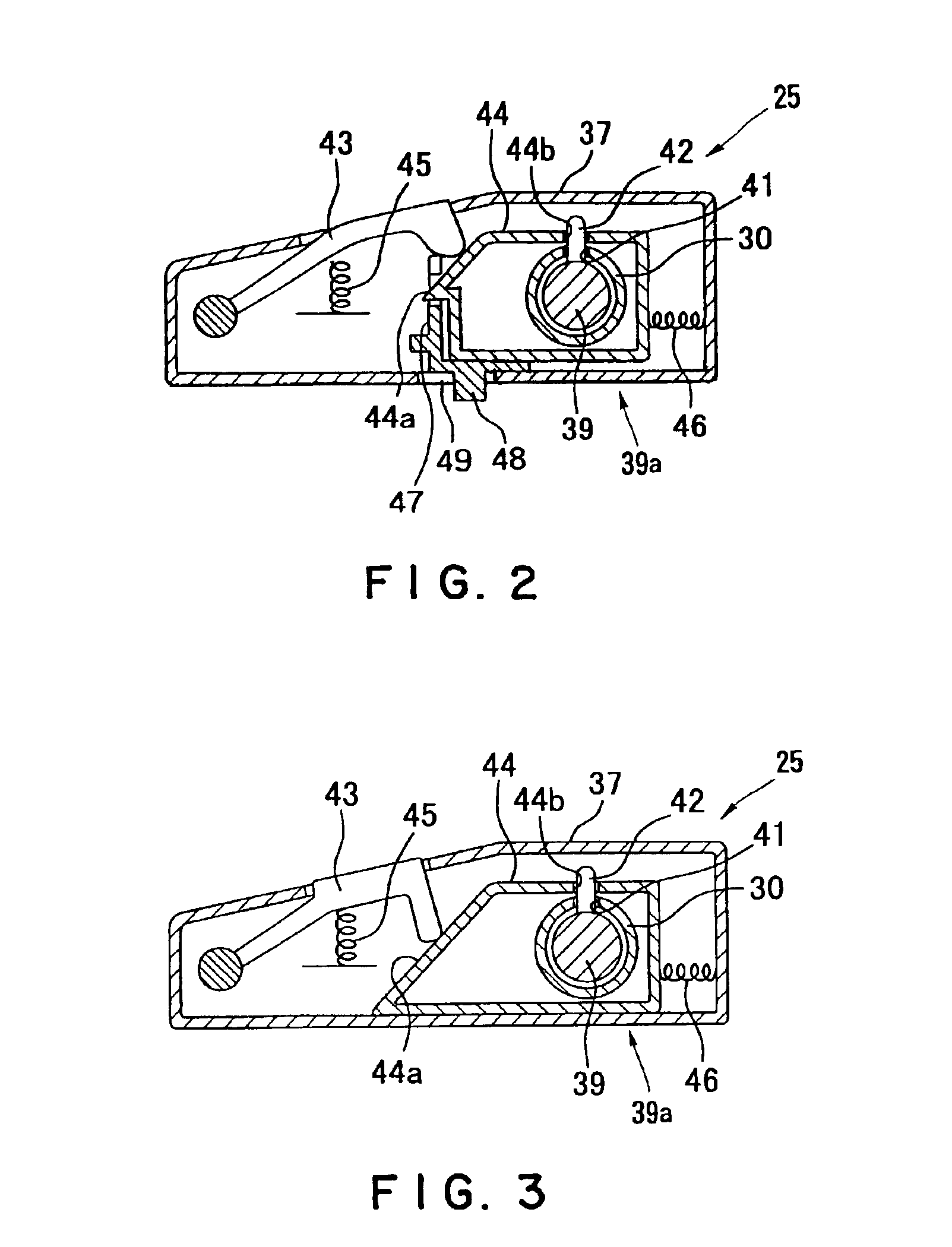

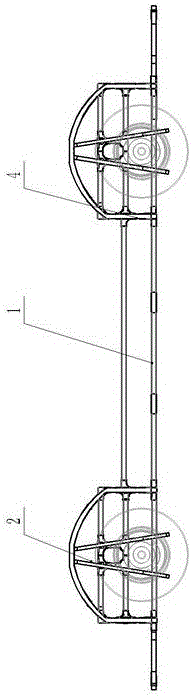

Stroller foldable in three

Owner:COMBI CORP

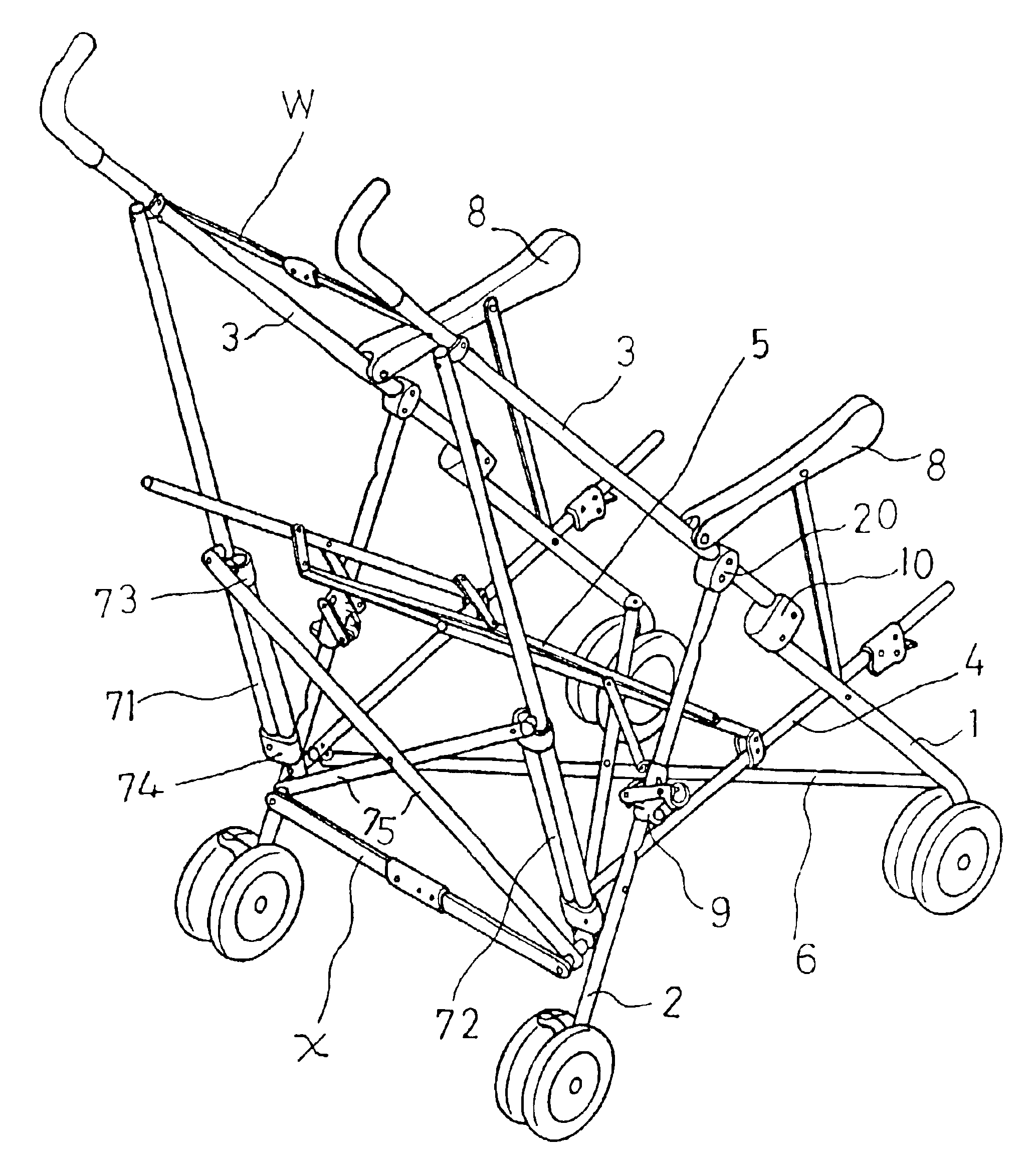

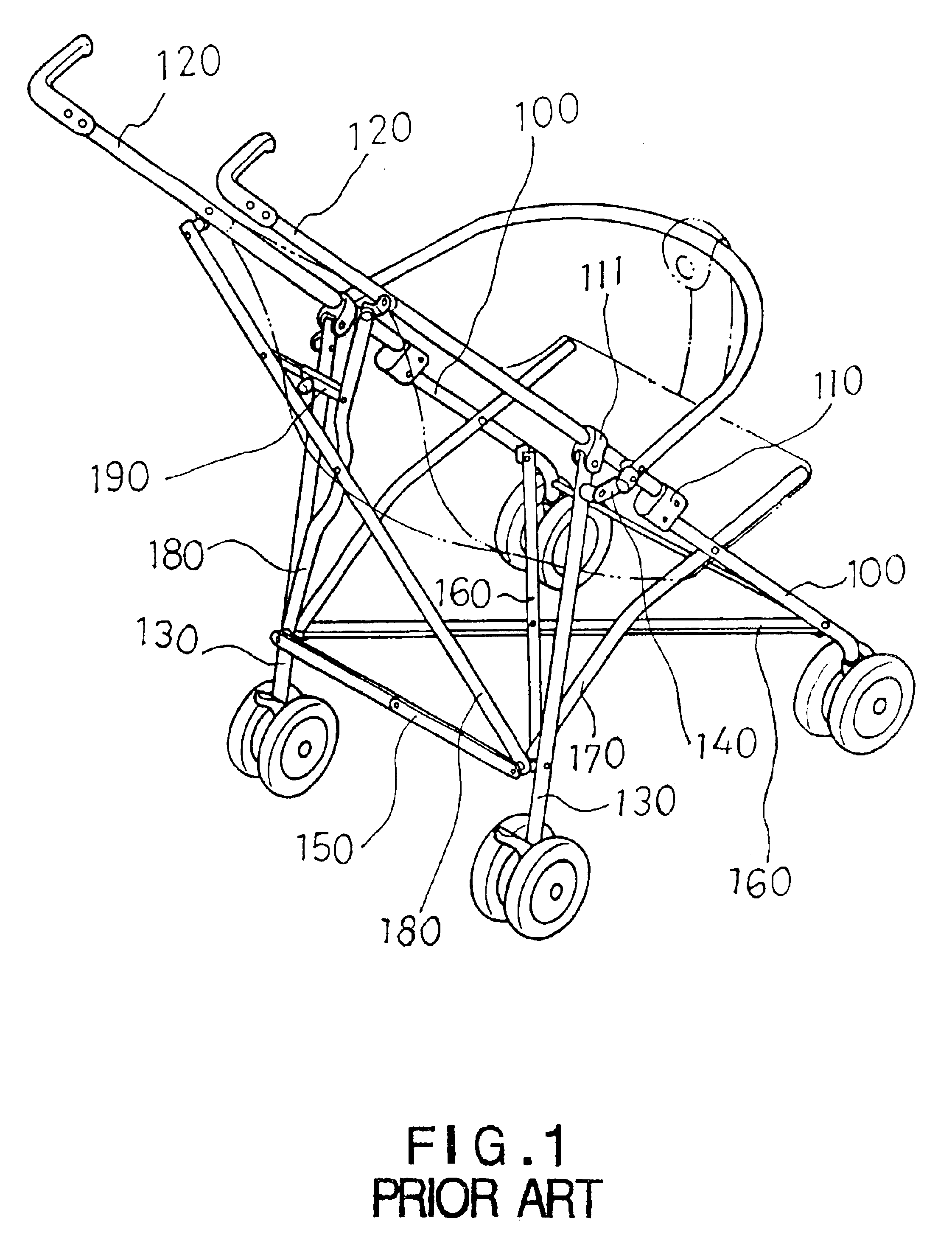

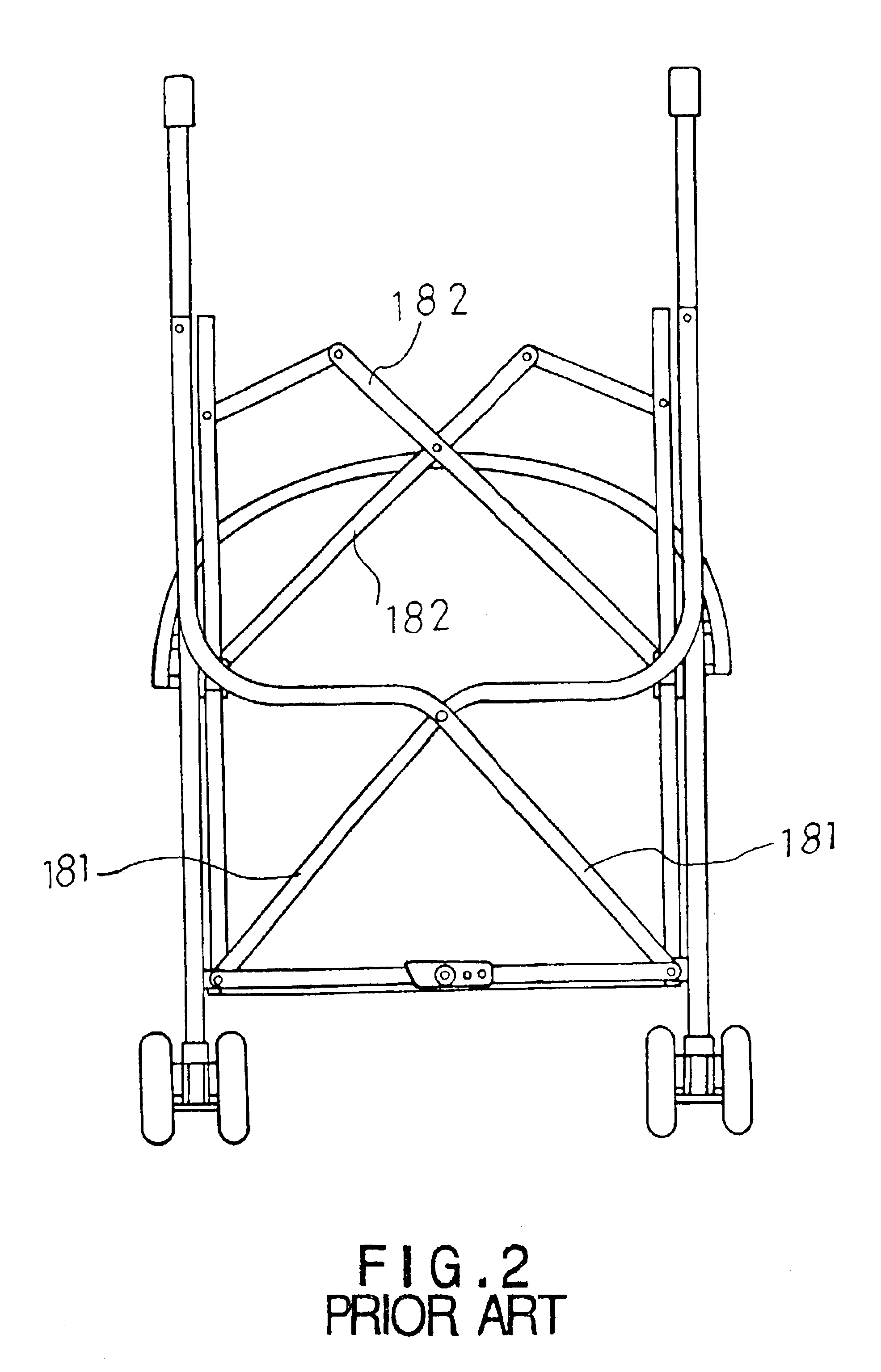

Foldable baby stroller

A stroller includes two rear upright tubes and two assist tubes which are respectively connected to the rear upright tubes in parallel by two joint members. At least one folding assembly is connected between the two upright tubes. The rear upright tubes and the two assist tubes reinforce the structure of the stroller. Two adjusting members are mounted to the rear leg tubes and a handle is biased by torsion springs and a pin connected to the handle extends through the adjusting member so as to engage a notch defined in the rear leg tube. A backrest is pivotably connected to the adjusting members which is positioned by engaging the pin with the notch in the rear leg tubes so that the backrest can be leaned in a stable status.

Owner:GUO JYAN TSAI

Impact Features

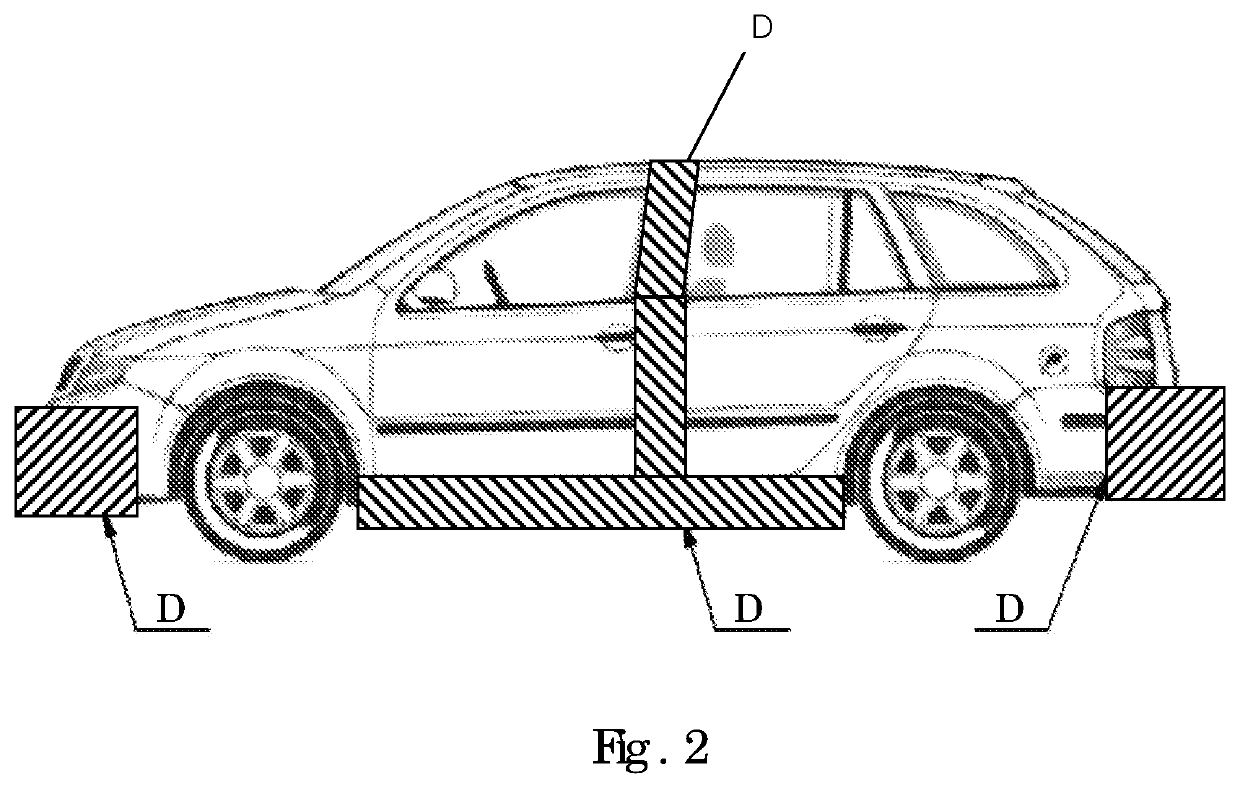

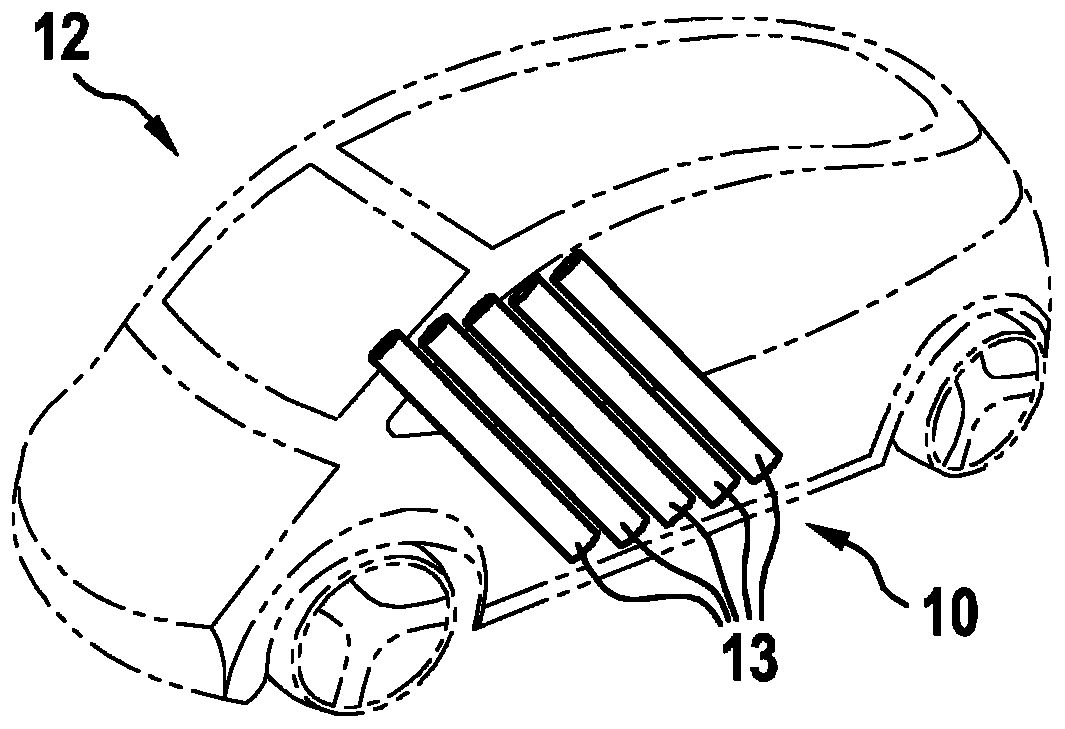

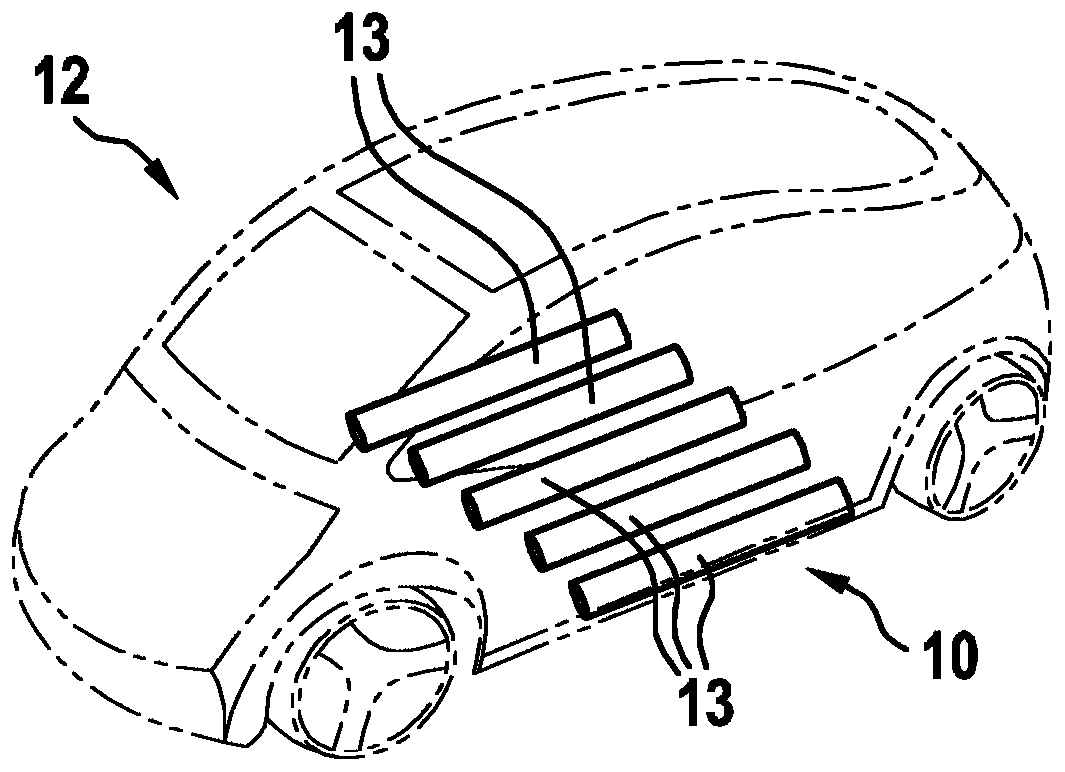

ActiveUS20210001924A1Reduce the amount requiredHigh levelElectric propulsion mountingUnderstructuresElectrical batteryEnergy absorption

A vehicle platform with a variety of impact safety features including front and rear impact features as well as side impact features designed to protect the passenger compartment as well as the battery compartment and vehicle chassis components. Some features may include crumple zone components, deflectors and modular energy absorption units.

Owner:CANOO TECHNOLOGIES INC

Body frame component for a motor vehicle and method of producing it

InactiveUS6155634AReduce weightNo significant manufacturing toleranceVehicle seatsUnderstructuresMobile vehicleStress conditions

A body frame component is designed so that it absorbs at least one force acting on it. The specific shape of the body frame component results in differing load or stress conditions within different regions of the body frame component when the force is being absorbed. In particular, high load or stress conditions occur in a first region and low load or stress conditions occur in a second region of the component. A reduction in the weight of the body frame component is achieved by forming at least one through hole in a region of the low load or stress conditions for the purpose of reducing the amount of material in the body frame component. In producing the body frame component, the through hole is formed either before or during the shaping of flat material to produce the specific shape of the body frame component.

Owner:VOLKSWAGEN AG

Adjustable display base

Owner:TUSAVITZ DANIEL J

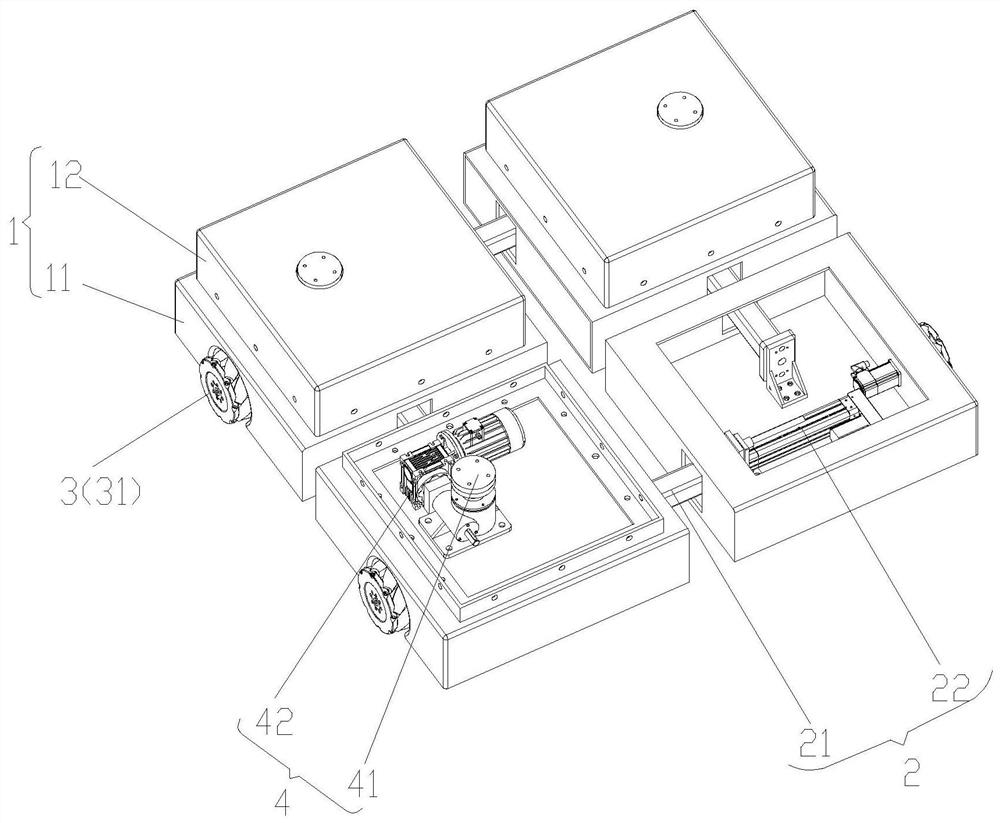

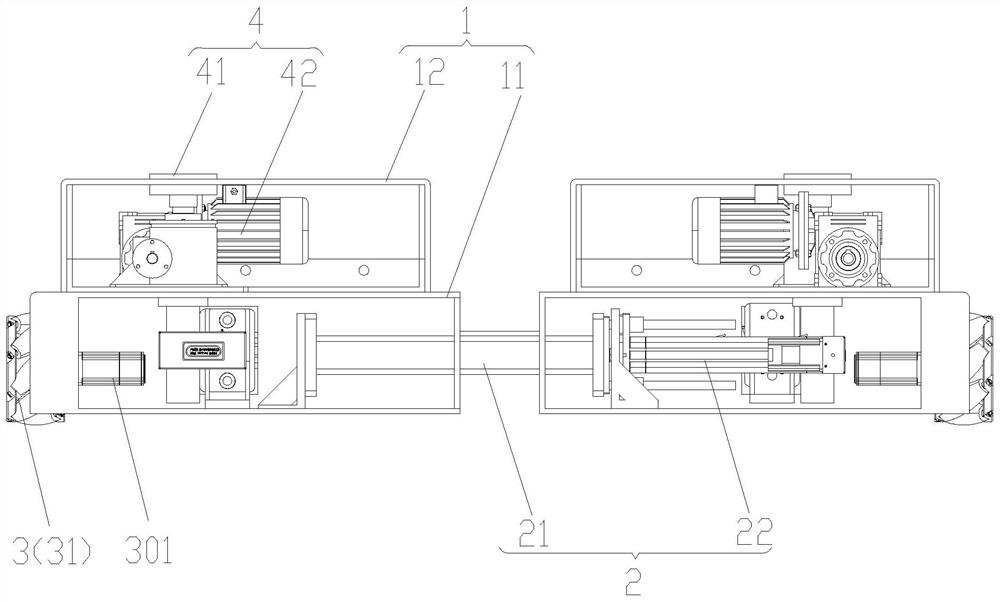

Three-freedom-degree hinge-joint chassis of engineering machinery and obstacle-navigation control method

InactiveCN106080781AImprove passabilityAvoid scratchesUnderstructuresTerrainThree degrees of freedom

The invention discloses a three-freedom-degree hinge-joint chassis of engineering machinery and an obstacle-navigation control method. The chassis comprises a front car body, a rear car body and a three-freedom-degree hinge-joint device, wherein the front end of the three-freedom-degree hinge-joint device is connected to the front car body, and the rear end is connected to the rear car body; the front car body has a yaw freedom degree, a lateral inclination freedom degree and a pitching freedom degree relative to the rear car body; and because of the added pitching freedom degree, pitching motion can be generated between the front car body and the rear car body. In this way, when a car meets a large-scale obstacle, the pitching angle between the front car body and the rear car body is adjusted to form an inverse V-shaped, so that the large-scale obstacle can be prevented from scraping or colliding the chassis; and when the car passes a deep V-shaped terrain, the pitching angle between the front car body and the rear car body is adjusted to form a V-shaped, so that the front end of the car is prevented from colliding the V-shaped terrain, and thus trafficability of the car is increased.

Owner:JILIN UNIV

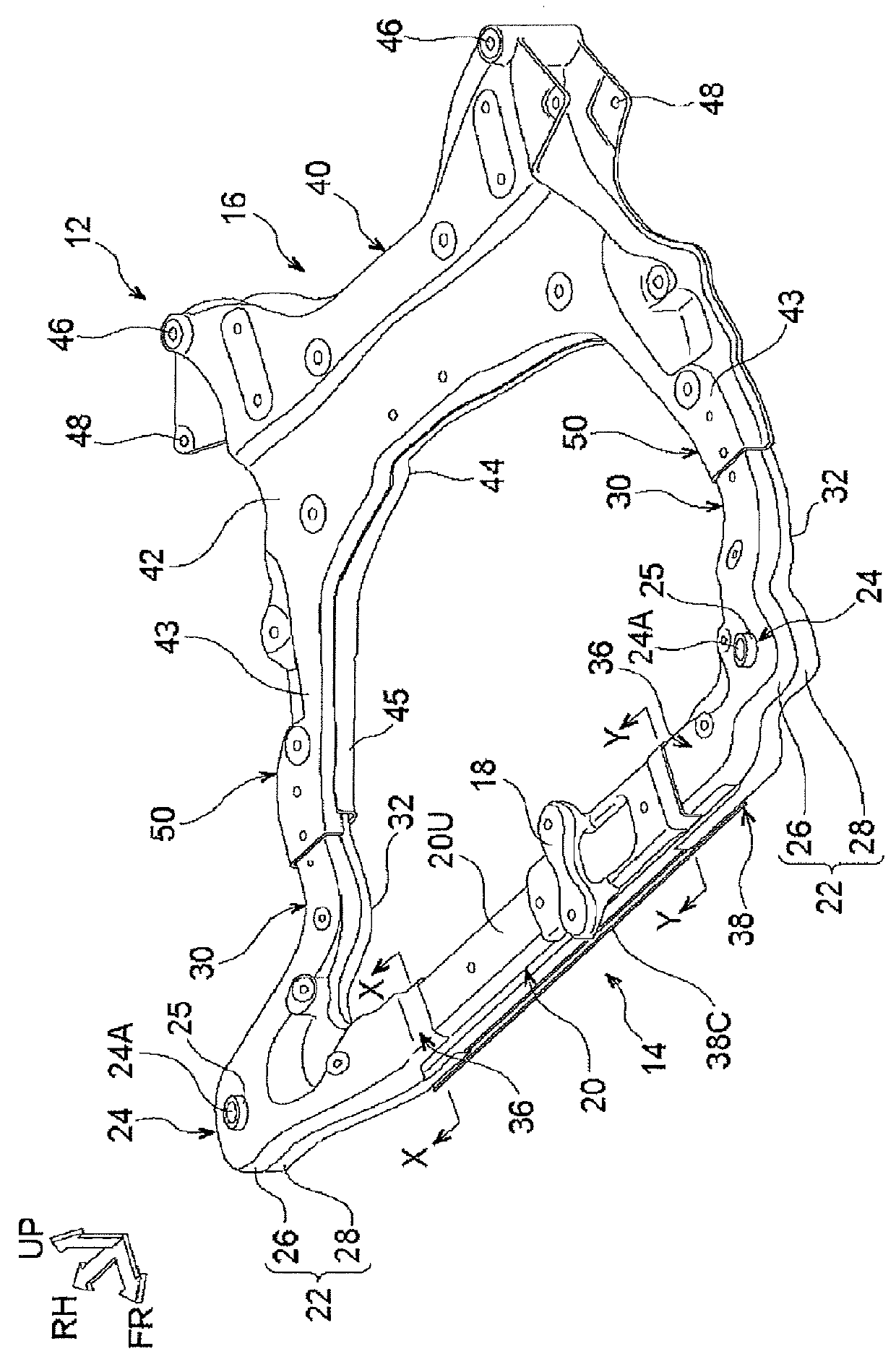

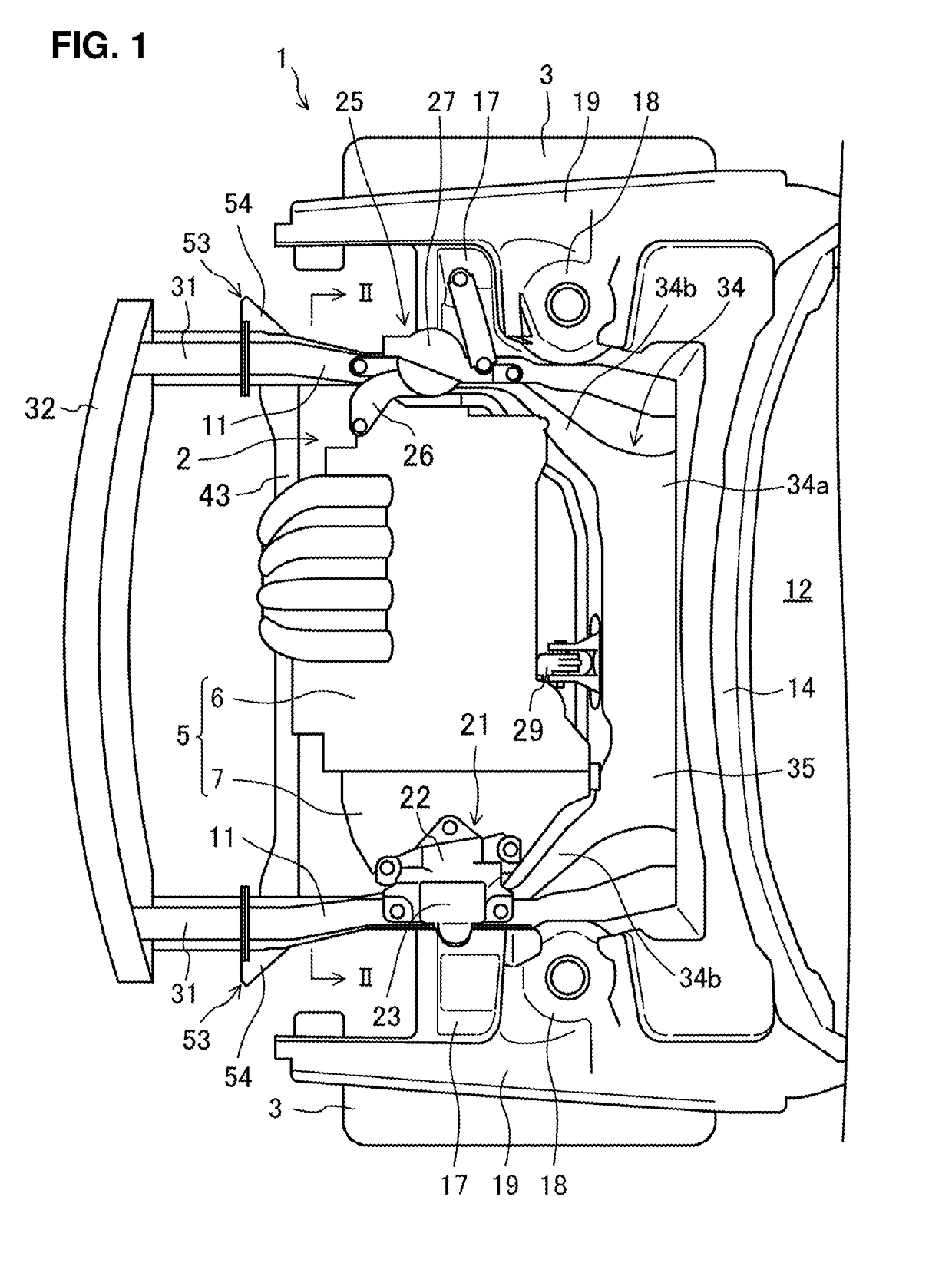

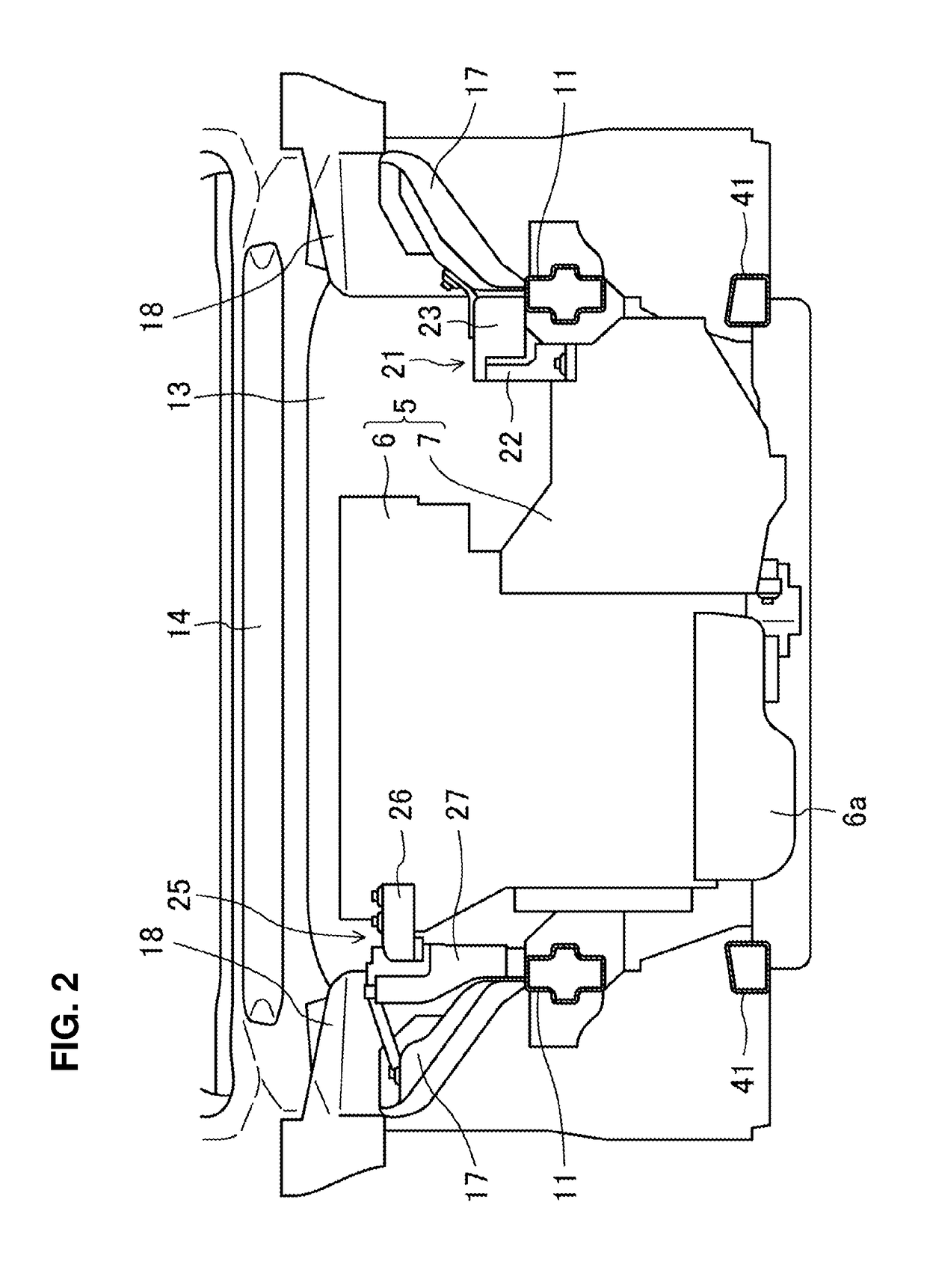

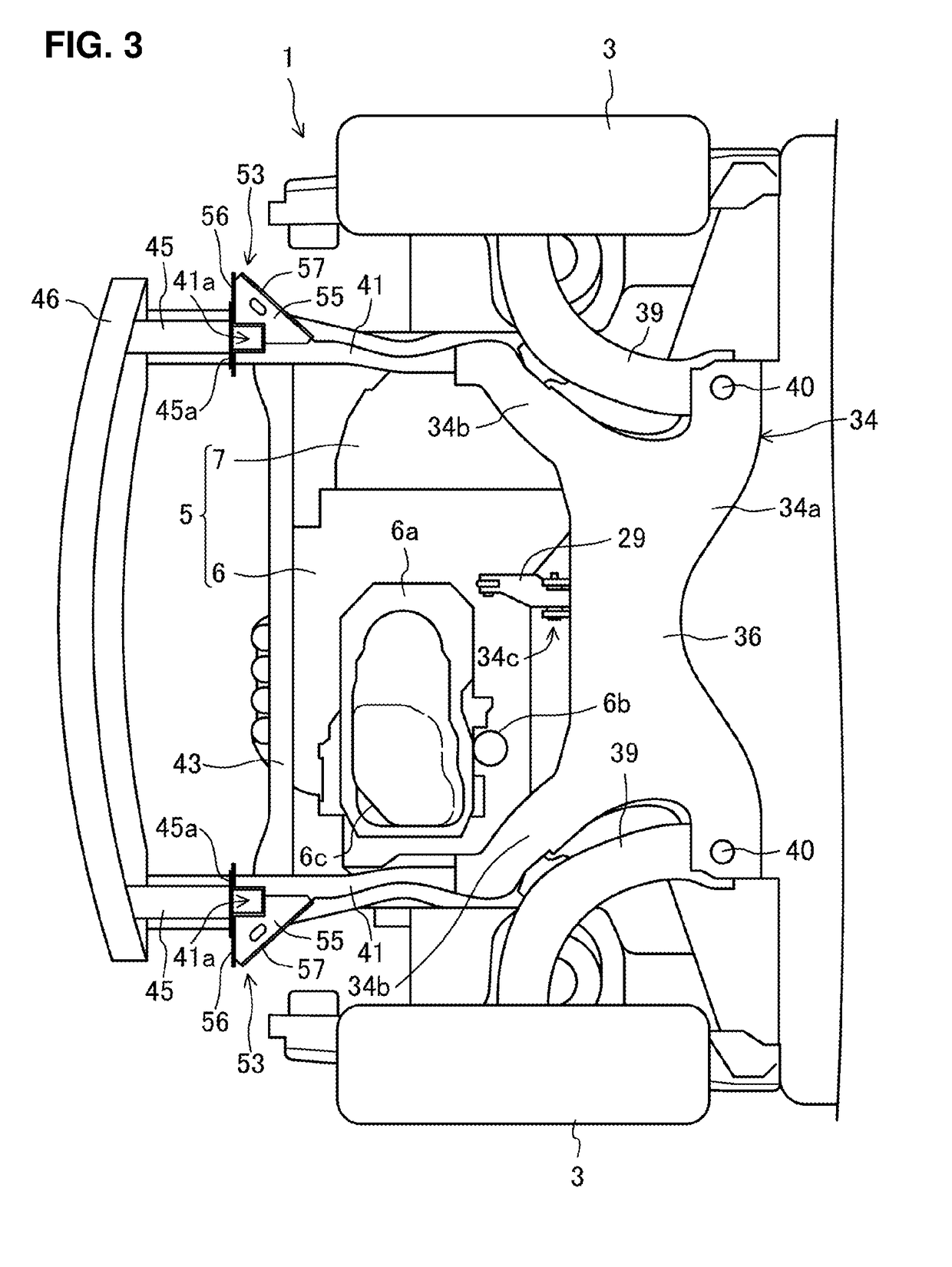

Vehicle front portion structure

ActiveUS20190126983A1Avoid deformationElectric propulsion mountingUnderstructuresEngineeringMechanical engineering

Owner:TOYOTA JIDOSHA KK

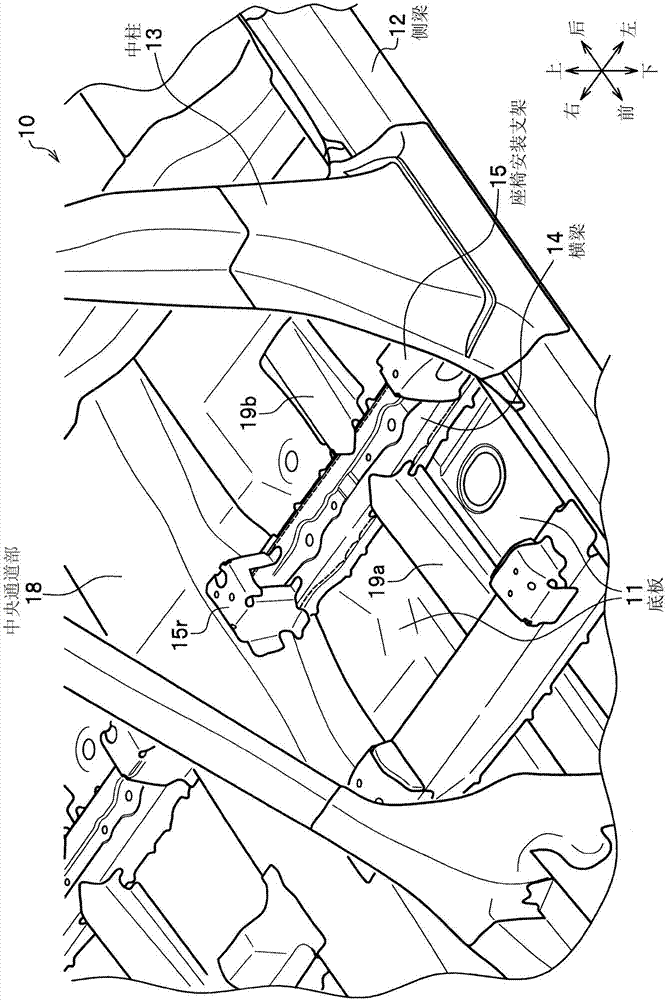

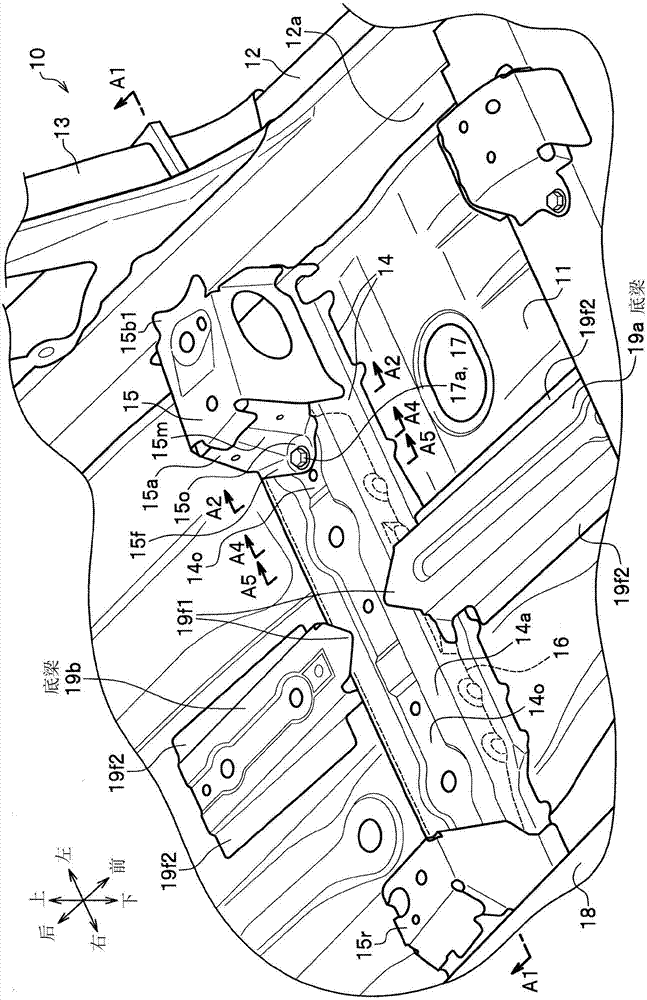

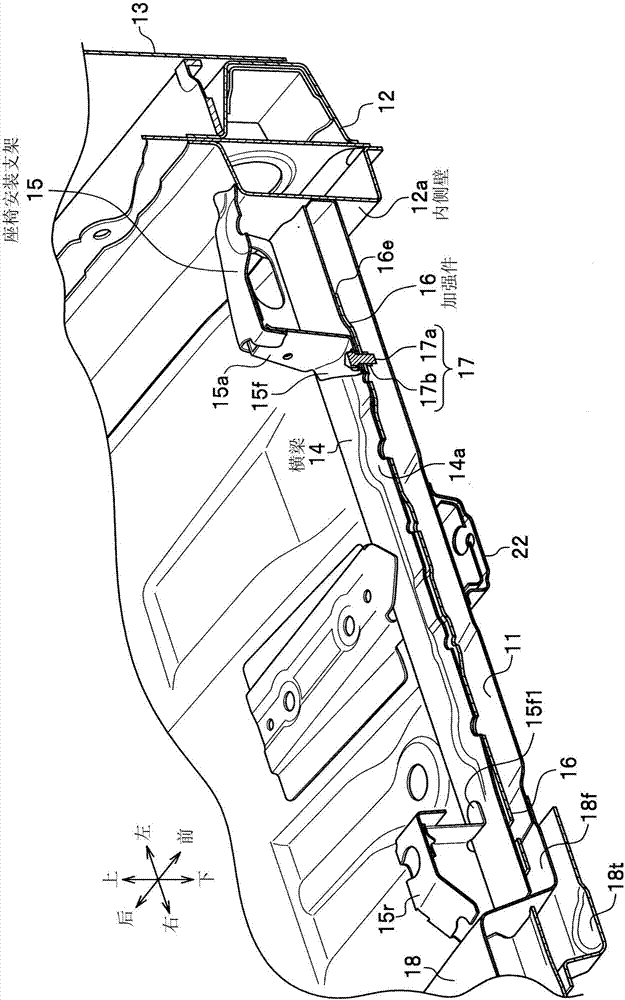

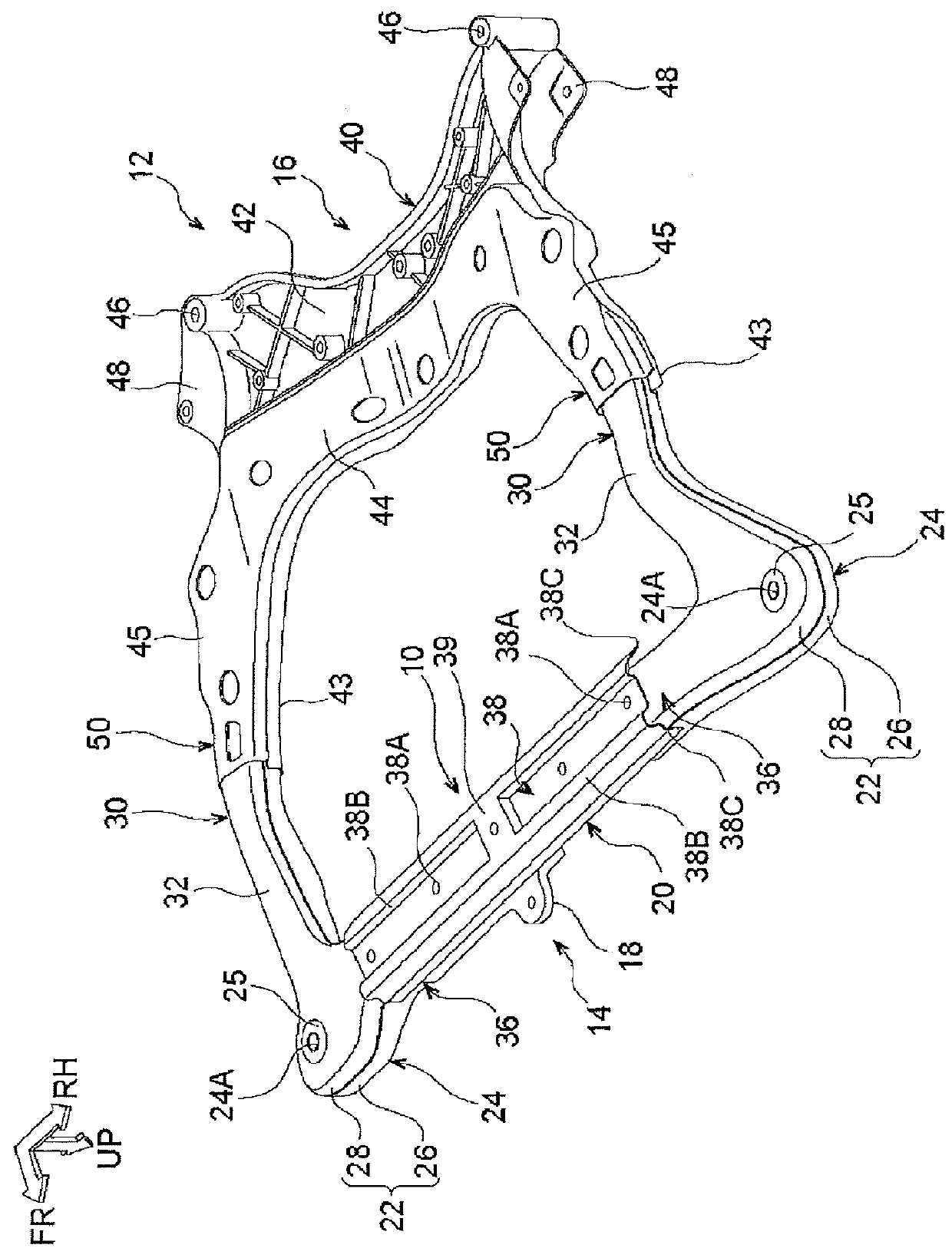

Car body structure

Owner:HONDA MOTOR CO LTD

Suspension member

ActiveUS20180105213A1Improve rigidityAdd partsUnderstructuresSuperstructure subunitsMechanical engineering

Owner:TOYOTA JIDOSHA KK

Automobile Collision Impact Reducer with Spring, Plate and Cushioning materials

PendingUS20200173519A1Reduce the impact of collisionNon-rotating vibration suppressionUnderstructuresCushioningRecoil effect

Owner:S DHANYA R

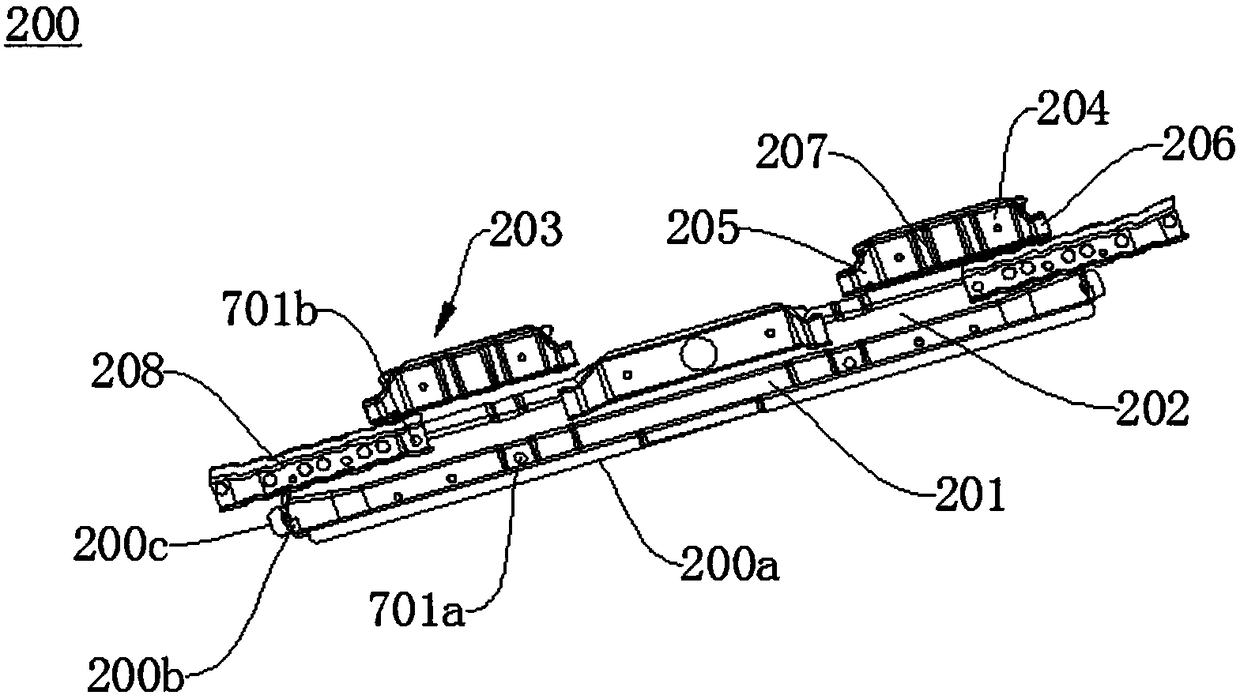

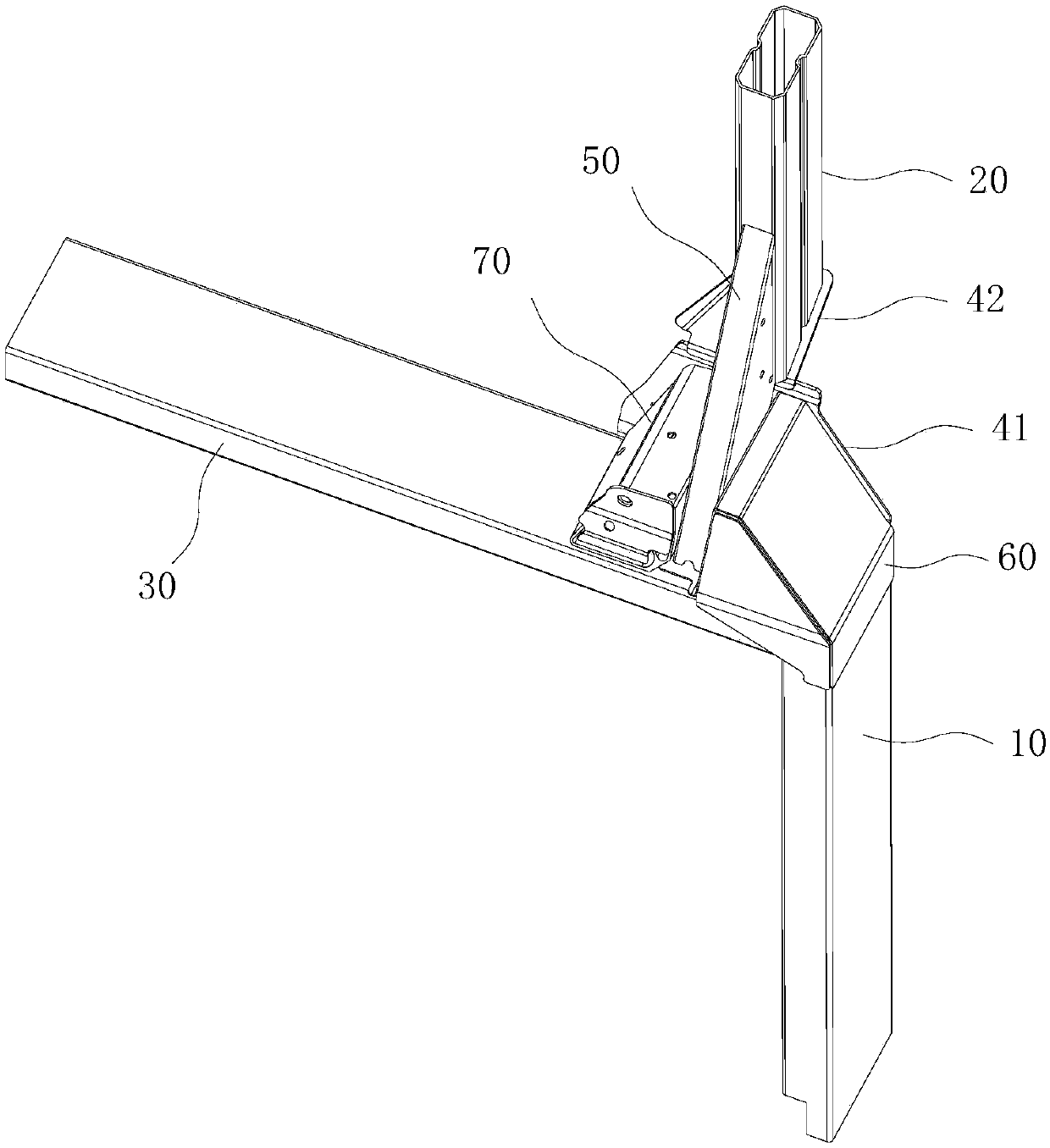

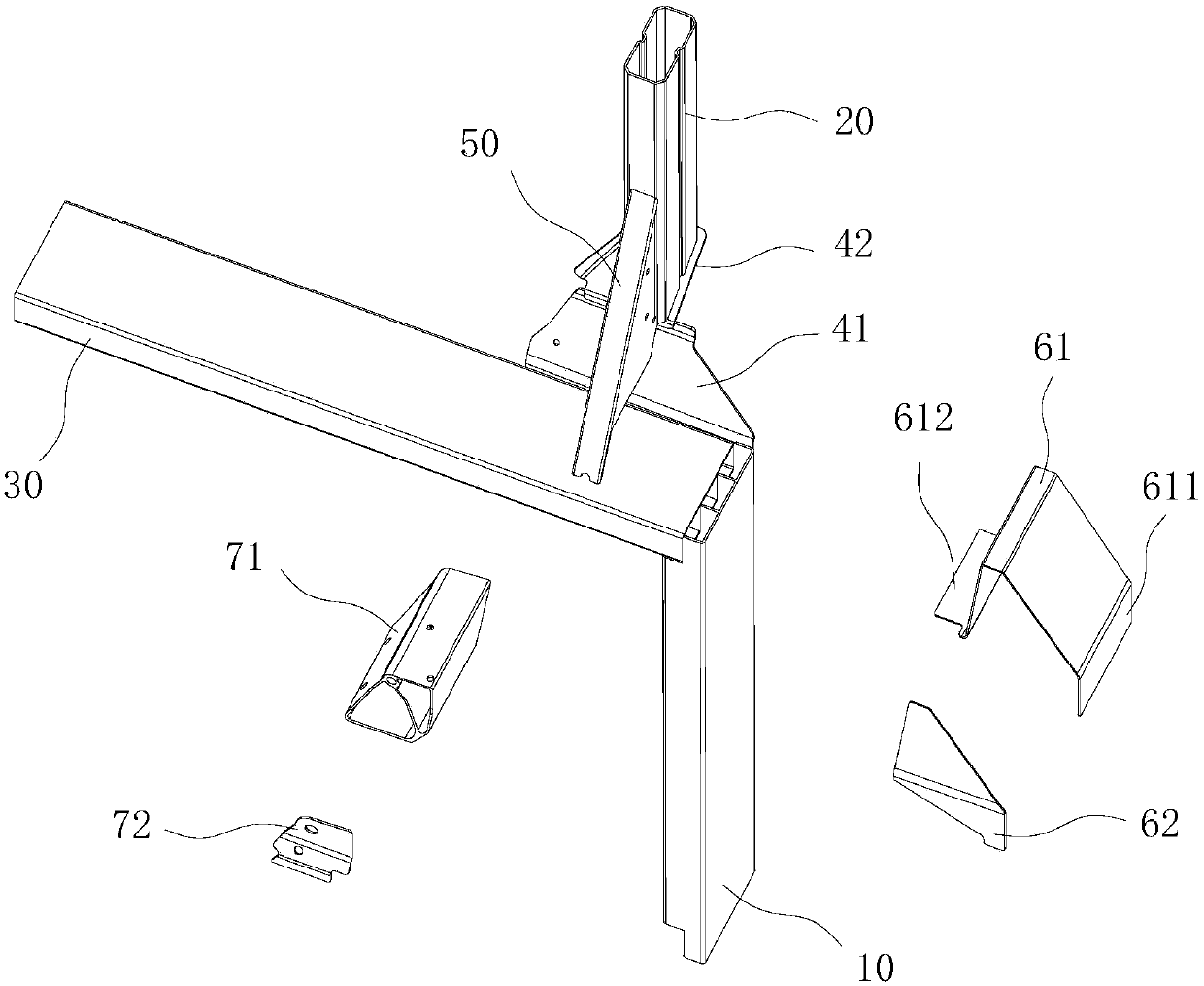

Car frame connecting piece for electric car, car frame assembly and electric car

Owner:NIO ANHUI HLDG CO LTD

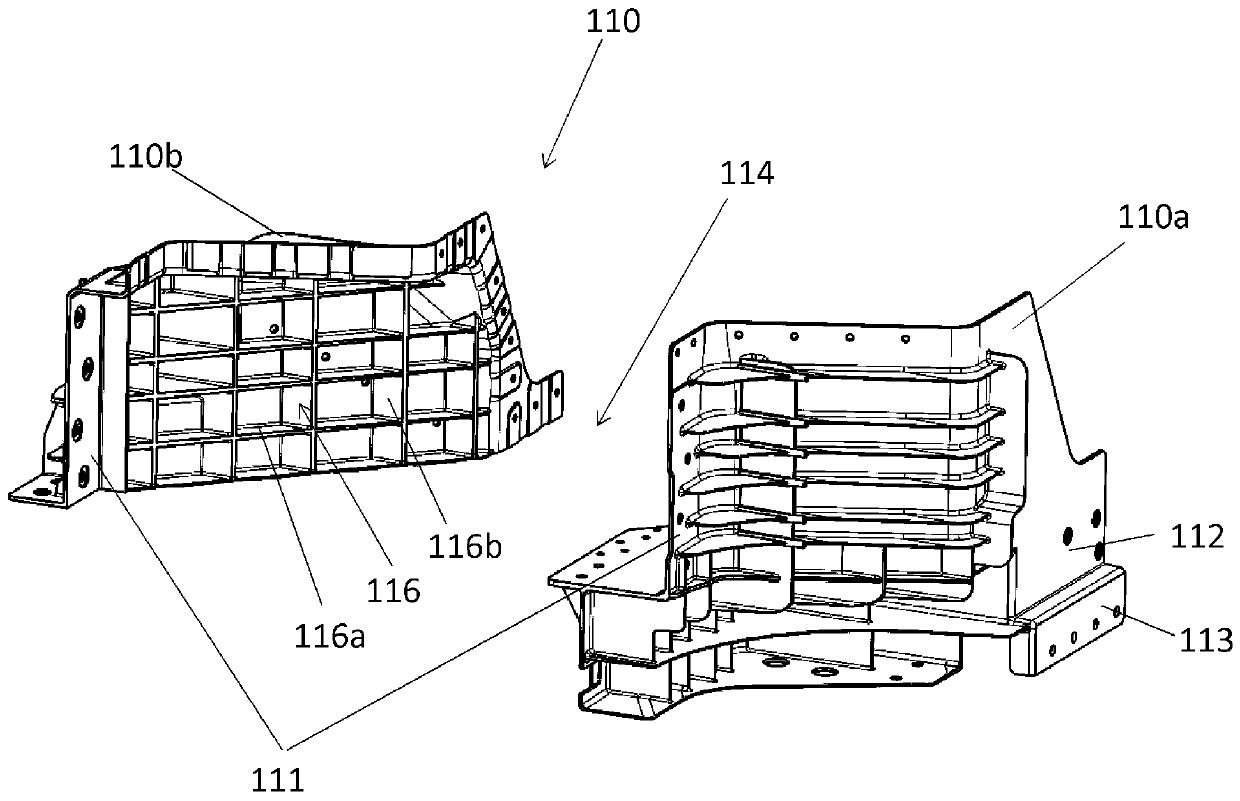

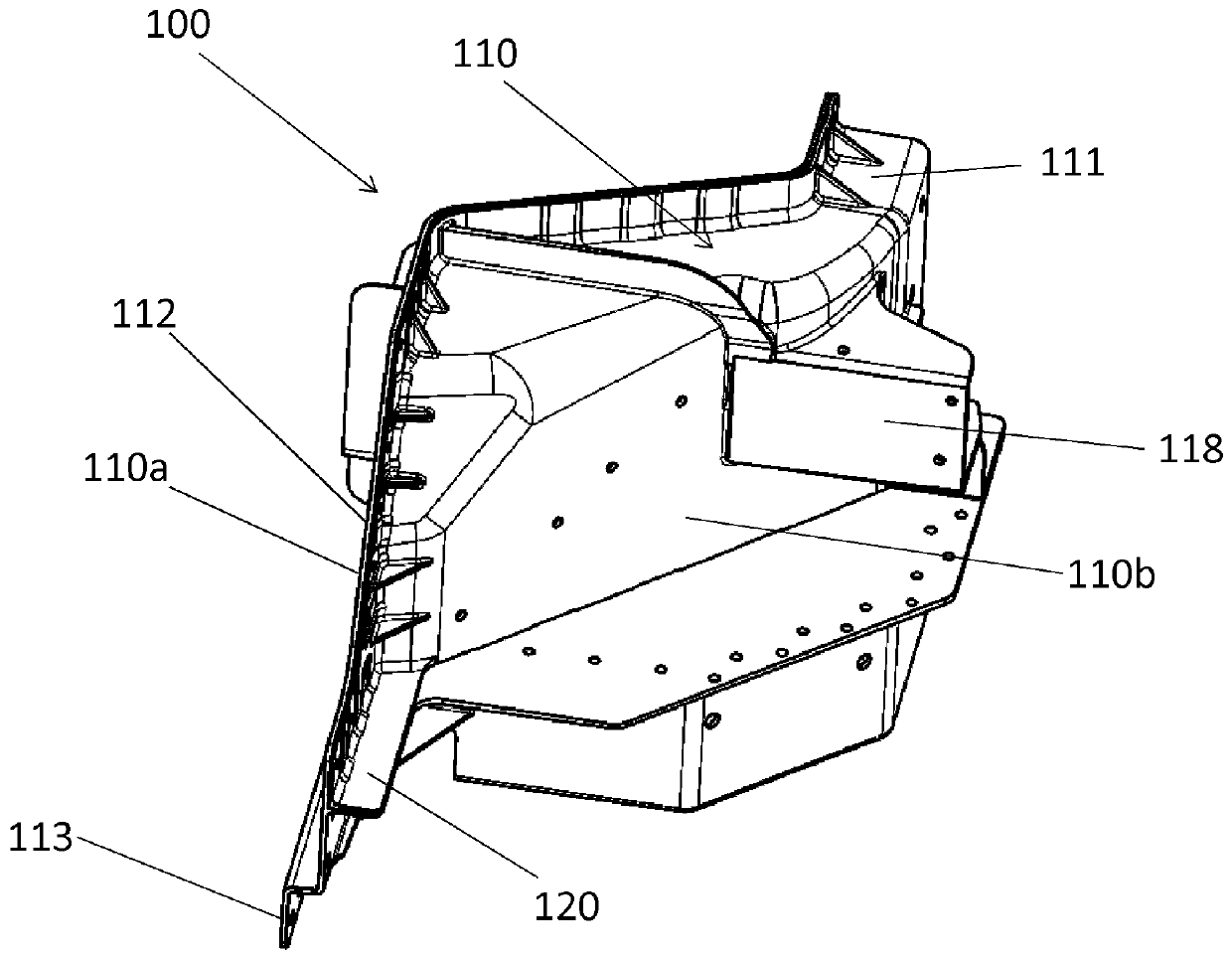

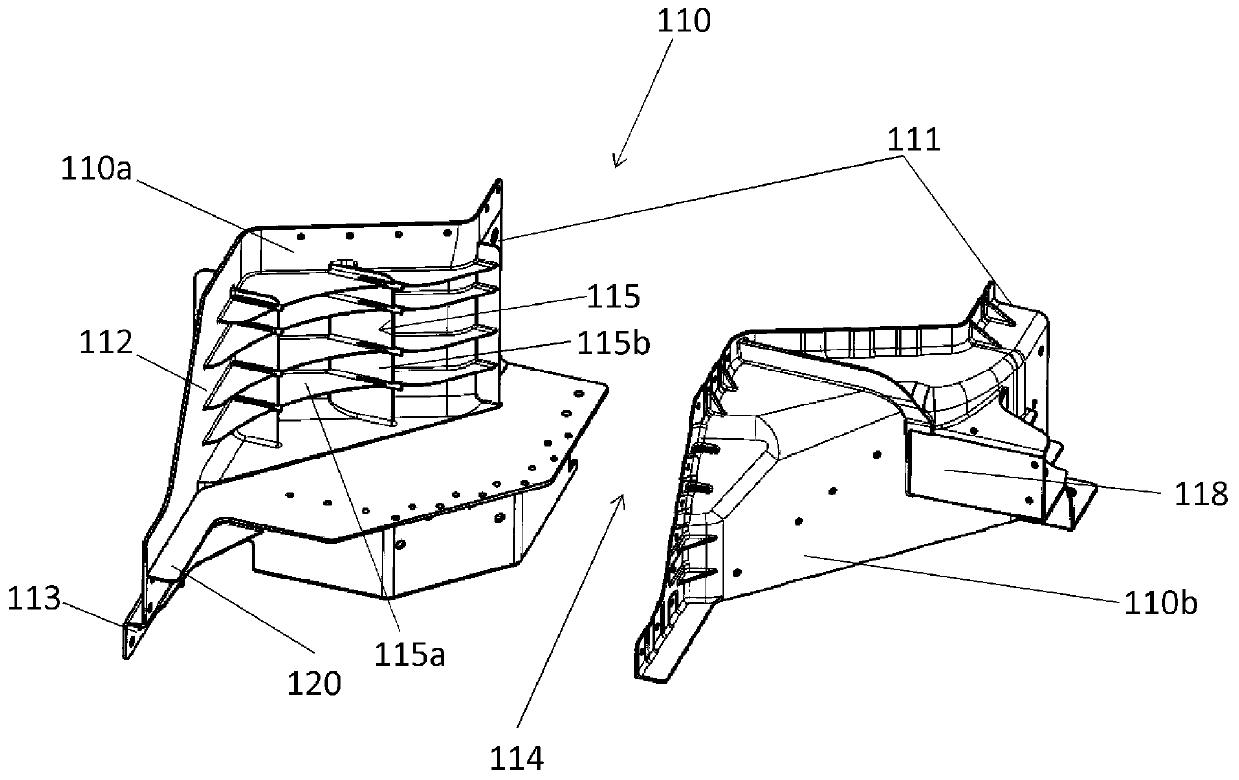

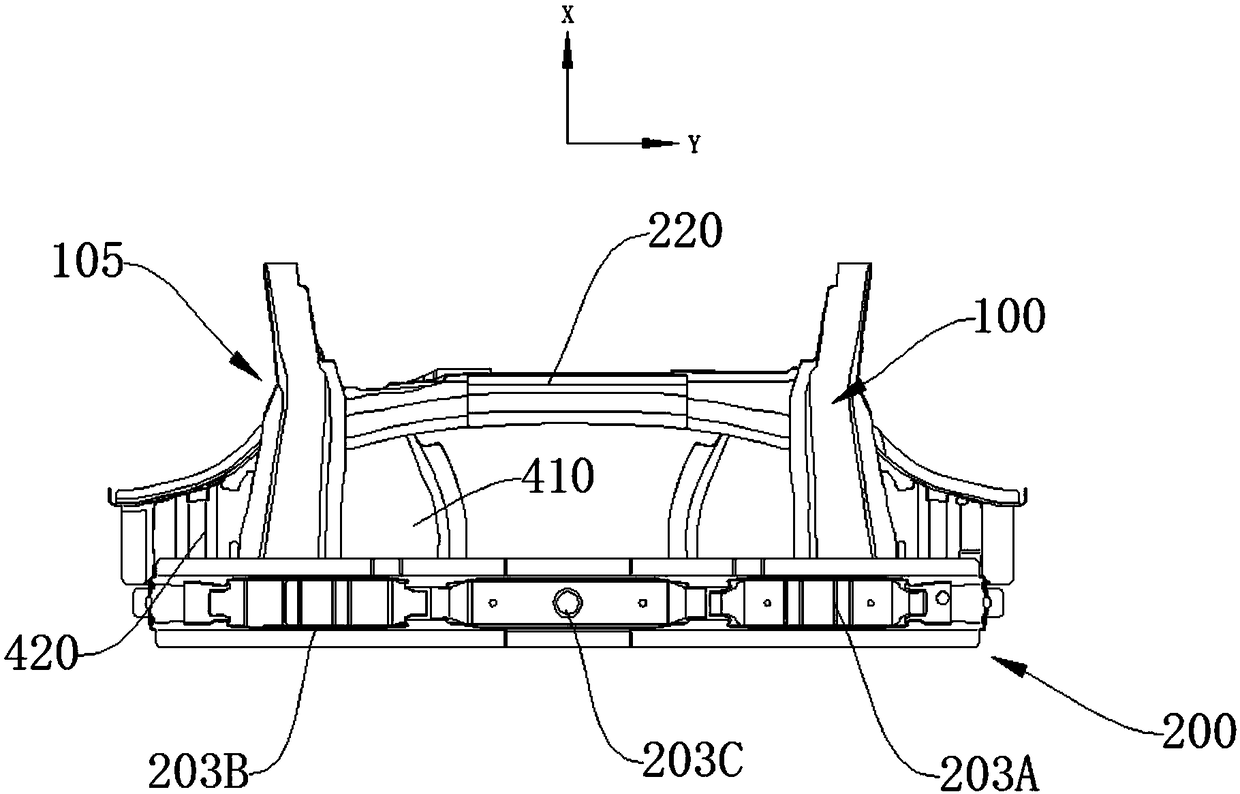

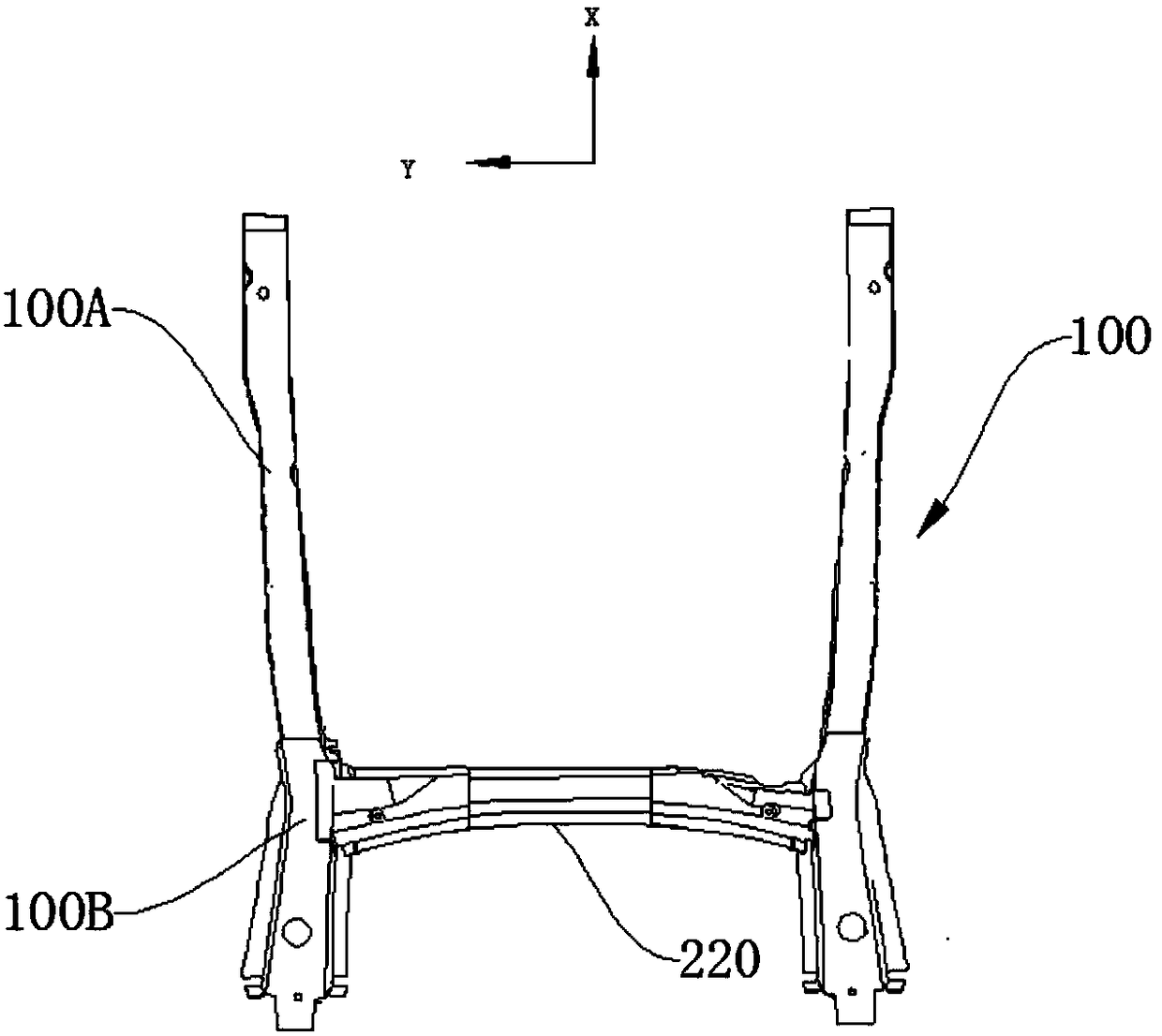

A body structure and a vehicle

Owner:BYD CO LTD

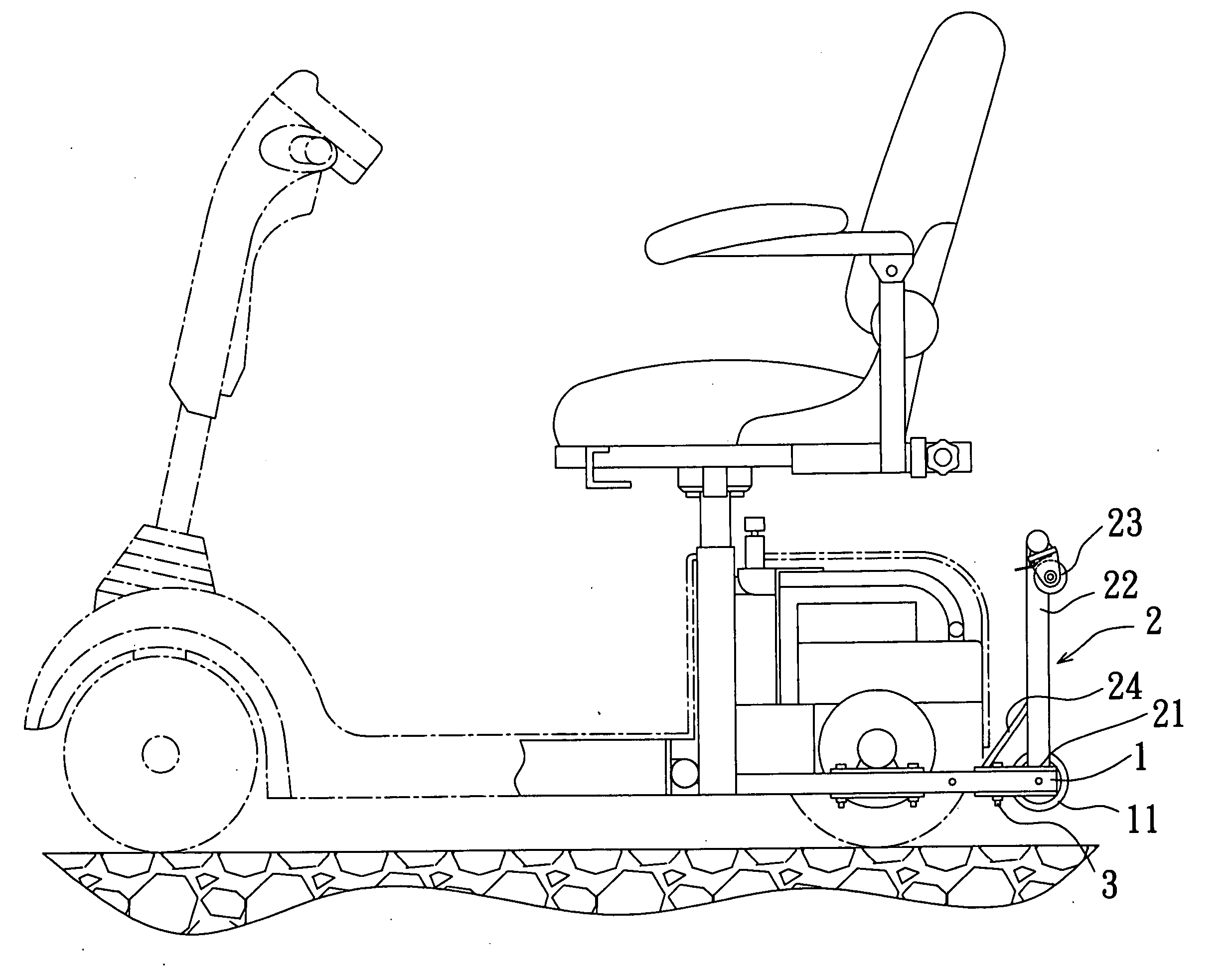

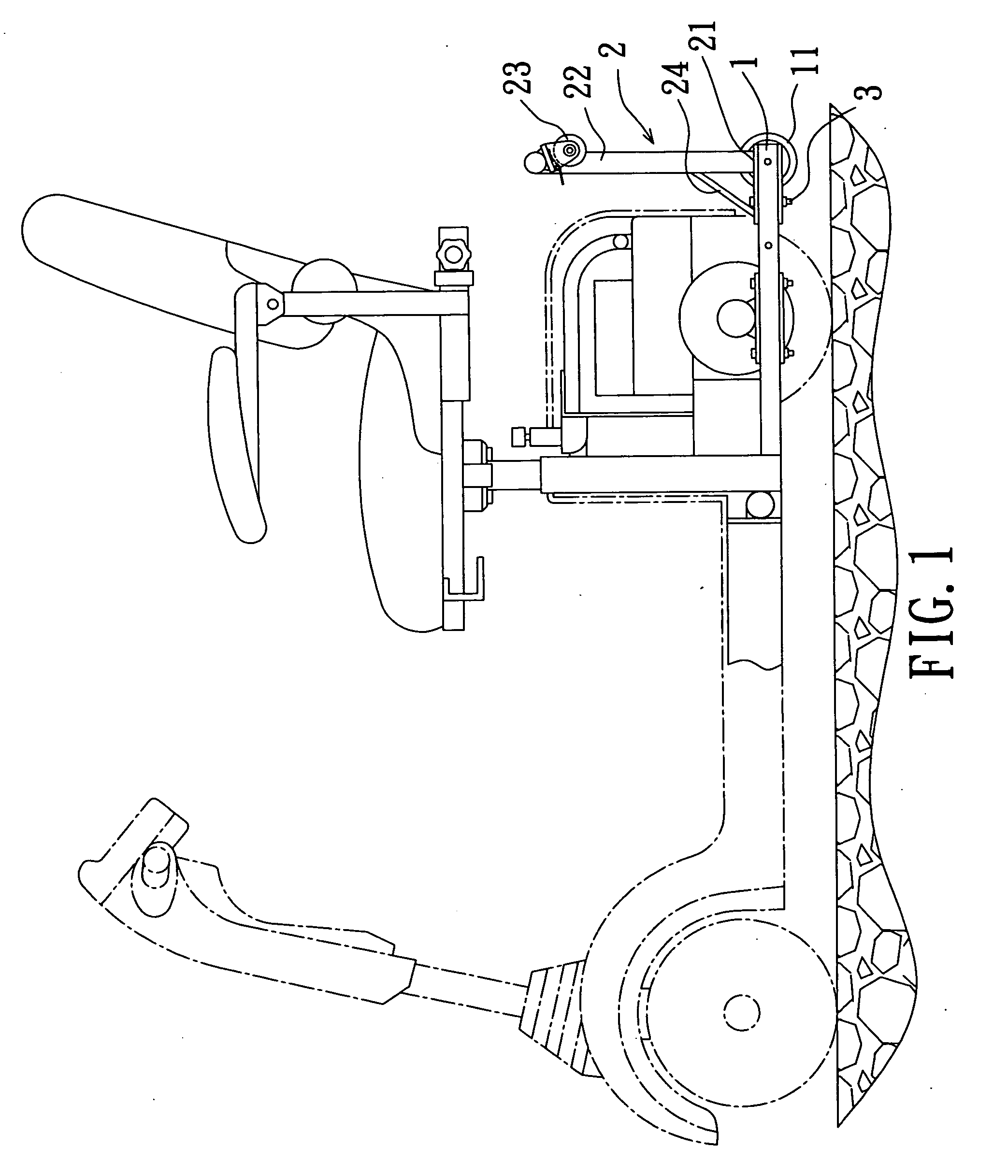

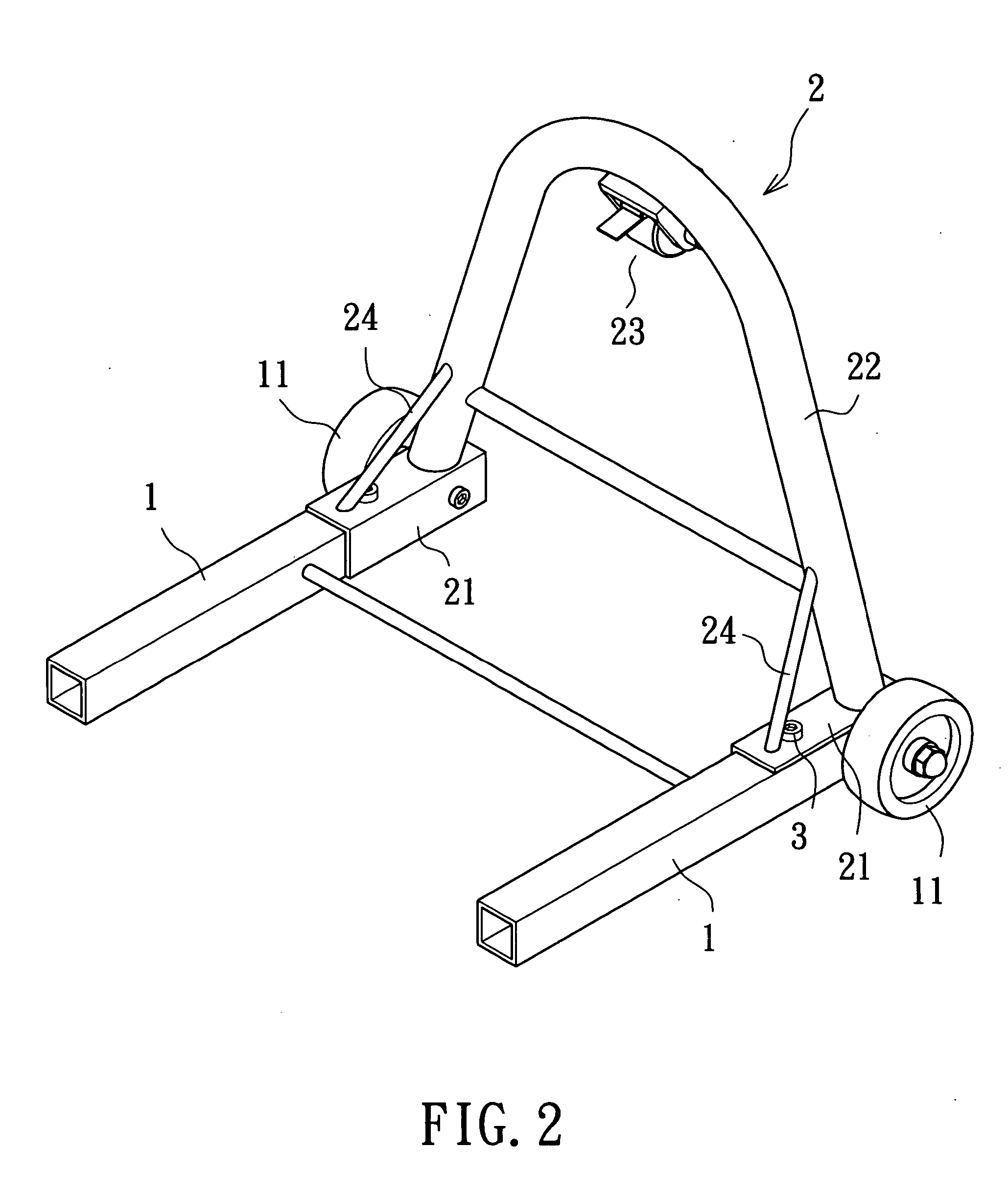

Assistant stand mechanism of a cart for people to ride on

ActiveUS20060175780A1Promote repairEasy maintenanceUnderstructuresWheelchairs/patient conveyanceEngineeringCaster

Owner:FREERIDER CORP

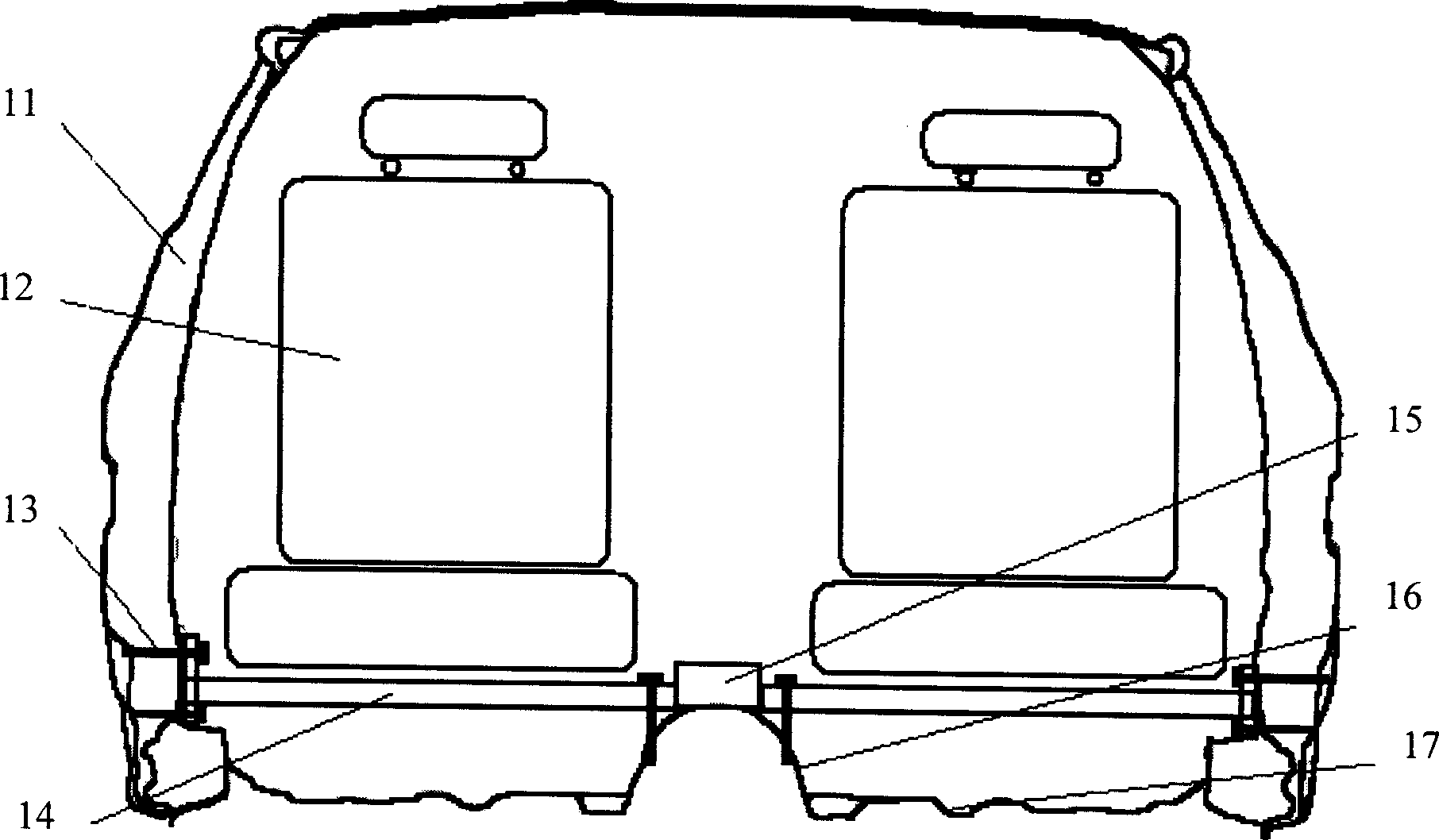

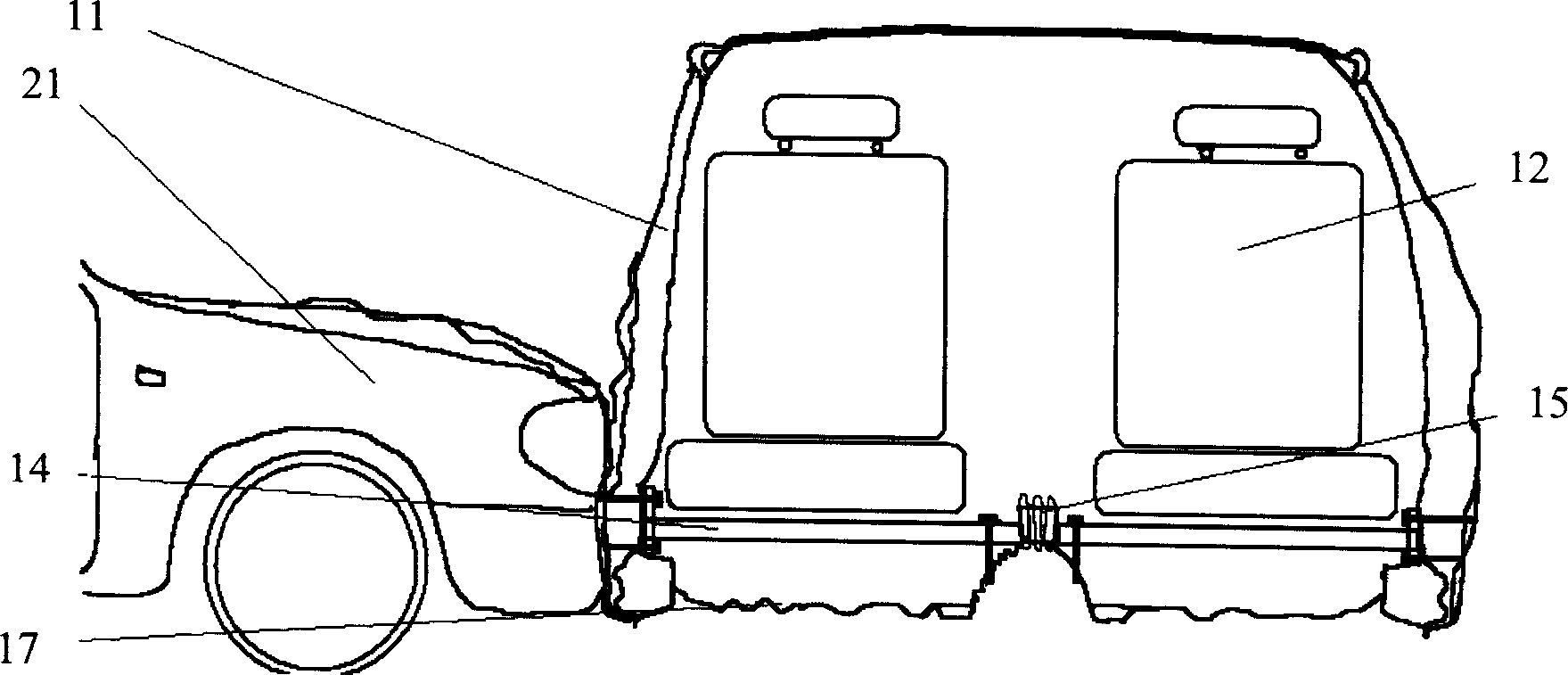

Deformation set for anti-collision on side of manned vehicle, and manned vehicle with the set

ActiveCN1760075ASmall amount of deformationReduce deformation speedUnderstructuresMonocoque constructionsEnergy absorptionEngineering

Owner:叶子青 +1

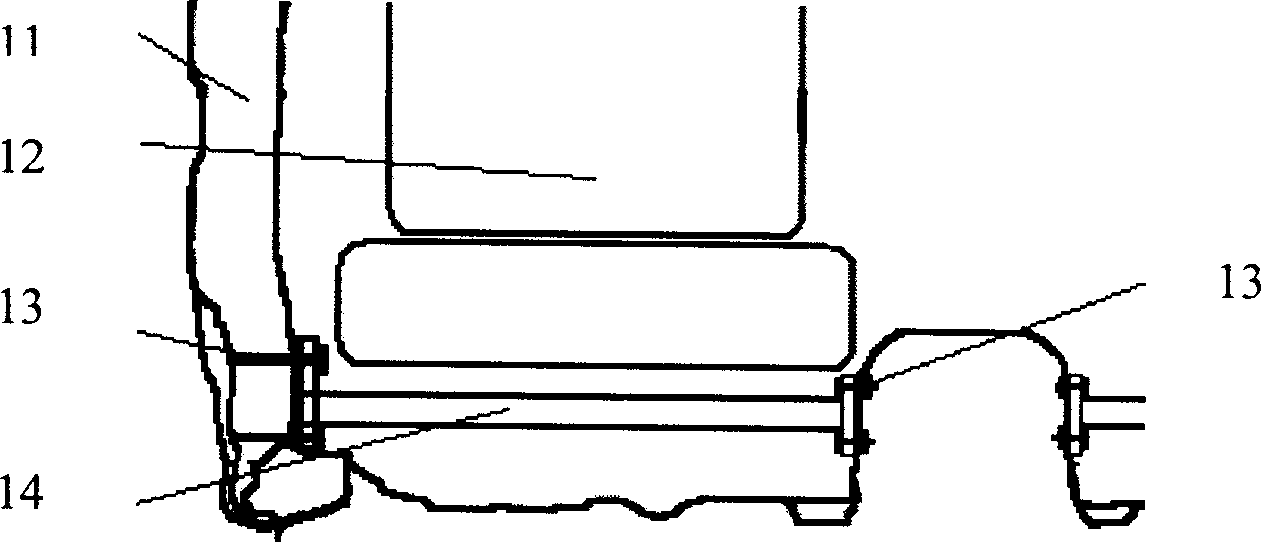

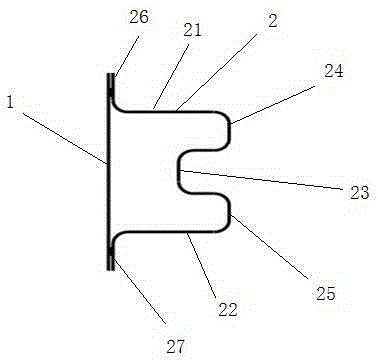

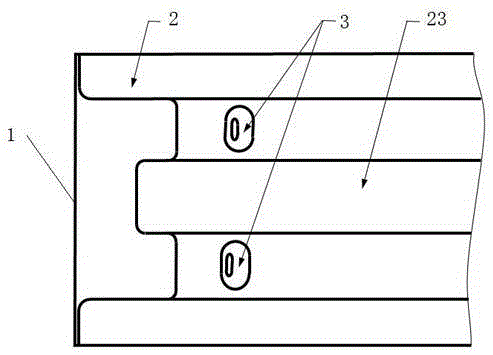

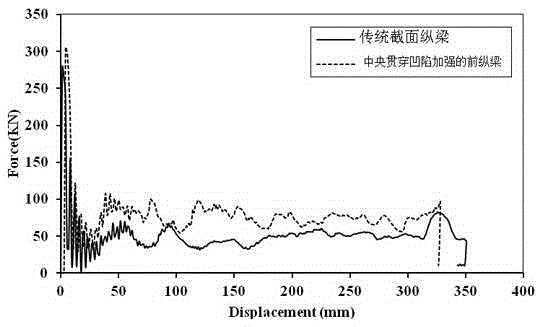

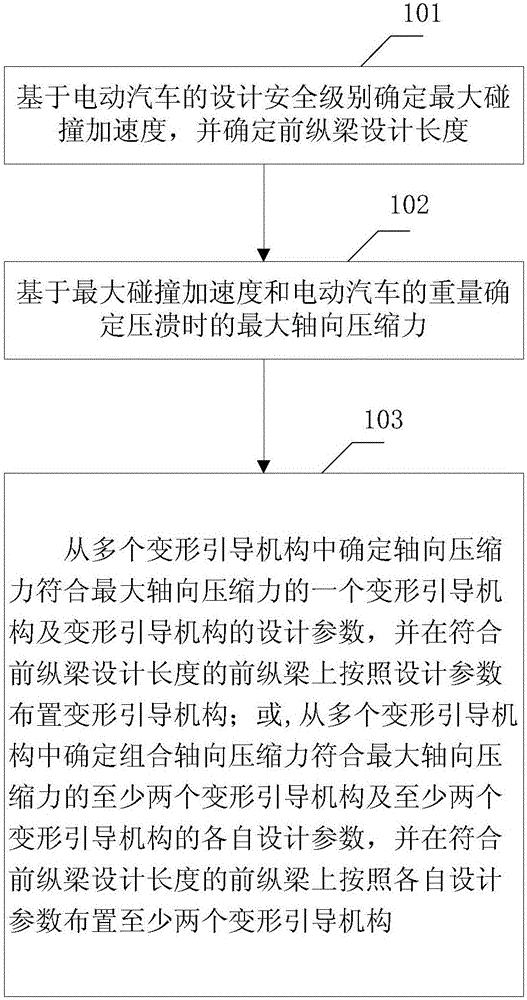

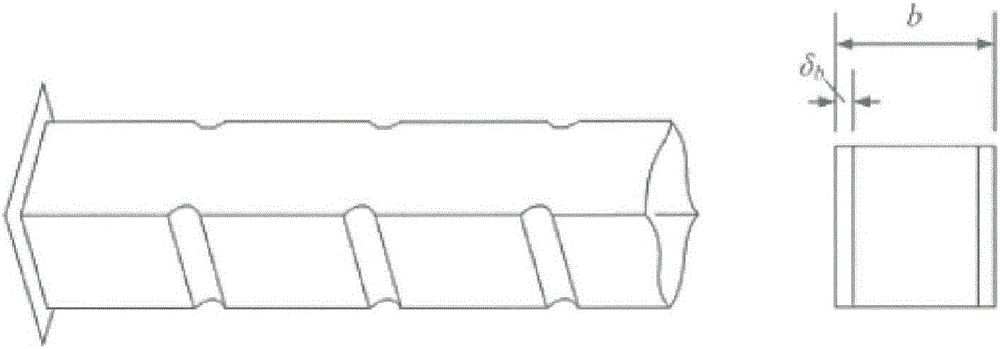

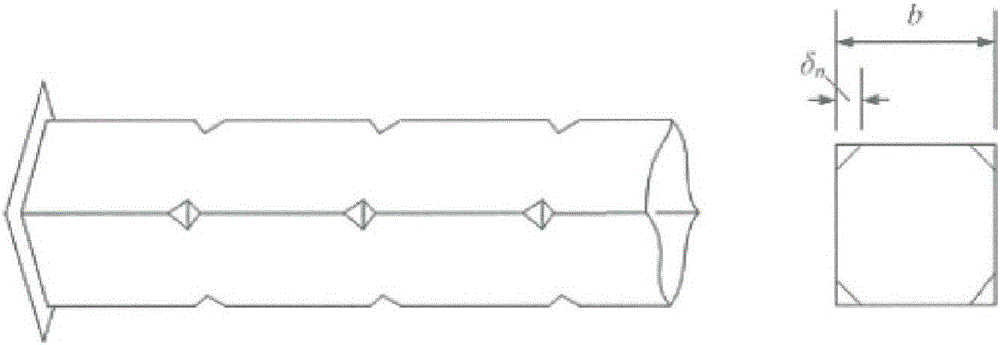

Central-through-sunken-part-reinforced front longitudinal beam

InactiveCN105383564AImprove the problem of unstable deformation formSatisfy the requirements of safe collision energy absorptionUnderstructuresEnergy absorptionClosed cavity

The invention provides a central-through-sunken-part-reinforced front longitudinal beam. The central-through-sunken-part-reinforced front longitudinal beam comprises a main side plate and a sunken side plate. A closed cavity is defined by the main side plate and the sunken side plate, a central sunken groove is formed in the sunken side plate, and the sinking direction of the central sunken groove faces the main side plate. The central-through-sunken-part-reinforced front longitudinal beam has the advantages that as the central-sunken-groove cross section design is adopted, the problem that a deformation form of a front longitudinal beam with a traditional cross section is instable is effectively solved; as the cross section form of the front longitudinal beam is changed, under the conditions of the same material and the same mass, the safe collision energy-absorption requirement of the front longitudinal beam is effectively met, the crushing force and the energy absorption index are effectively increased, and the light-weight requirement of a car body is met.

Owner:SAIC-GM-WULING AUTOMOBILE CO LTD

Front longitudinal beam structure

Owner:SUZHOU ZIJING QINGYUAN NEW ENERGY AUTOMOBILE TECH

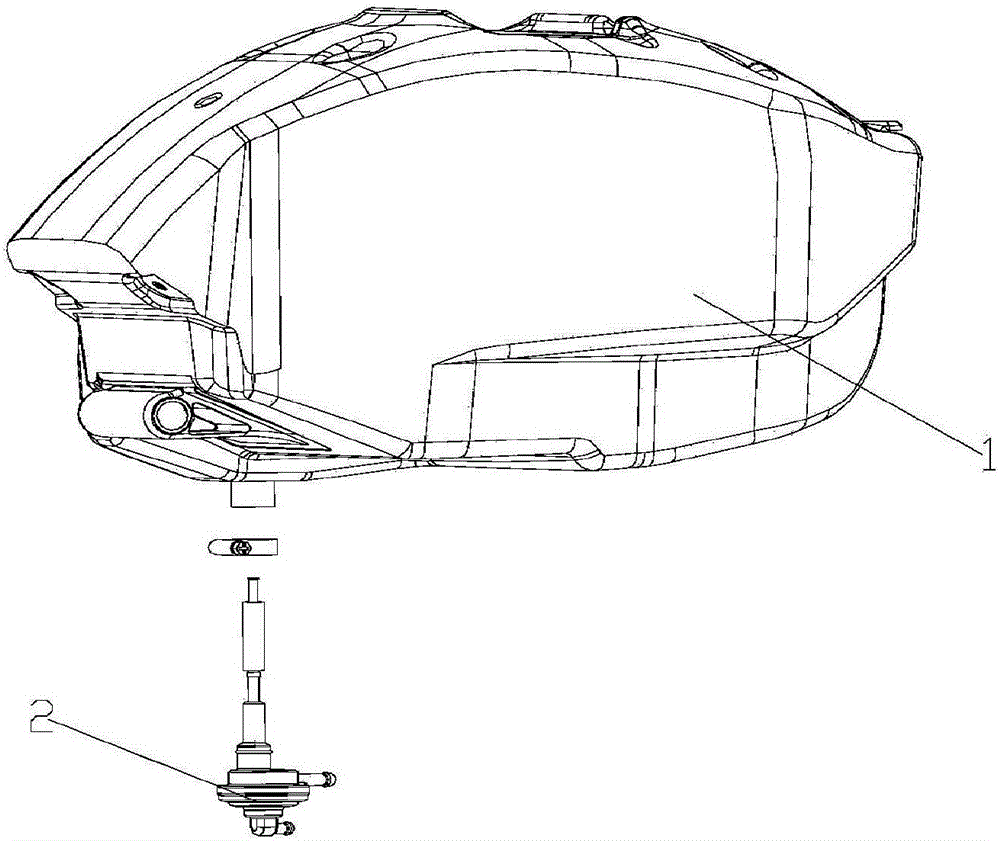

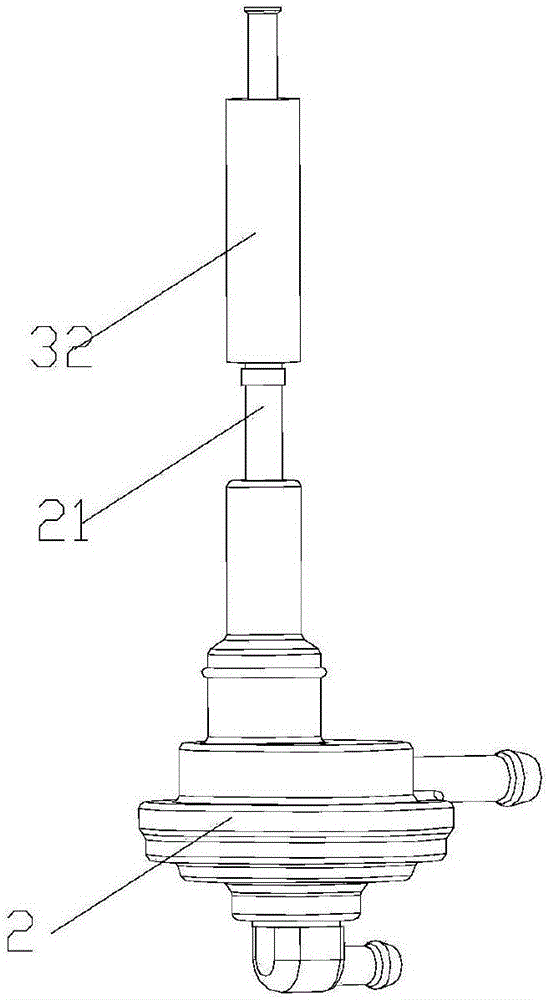

Motorcycle oil tank

Owner:重庆特巴斯科技有限公司

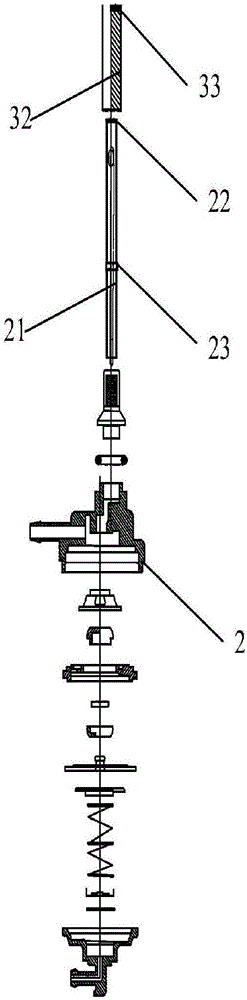

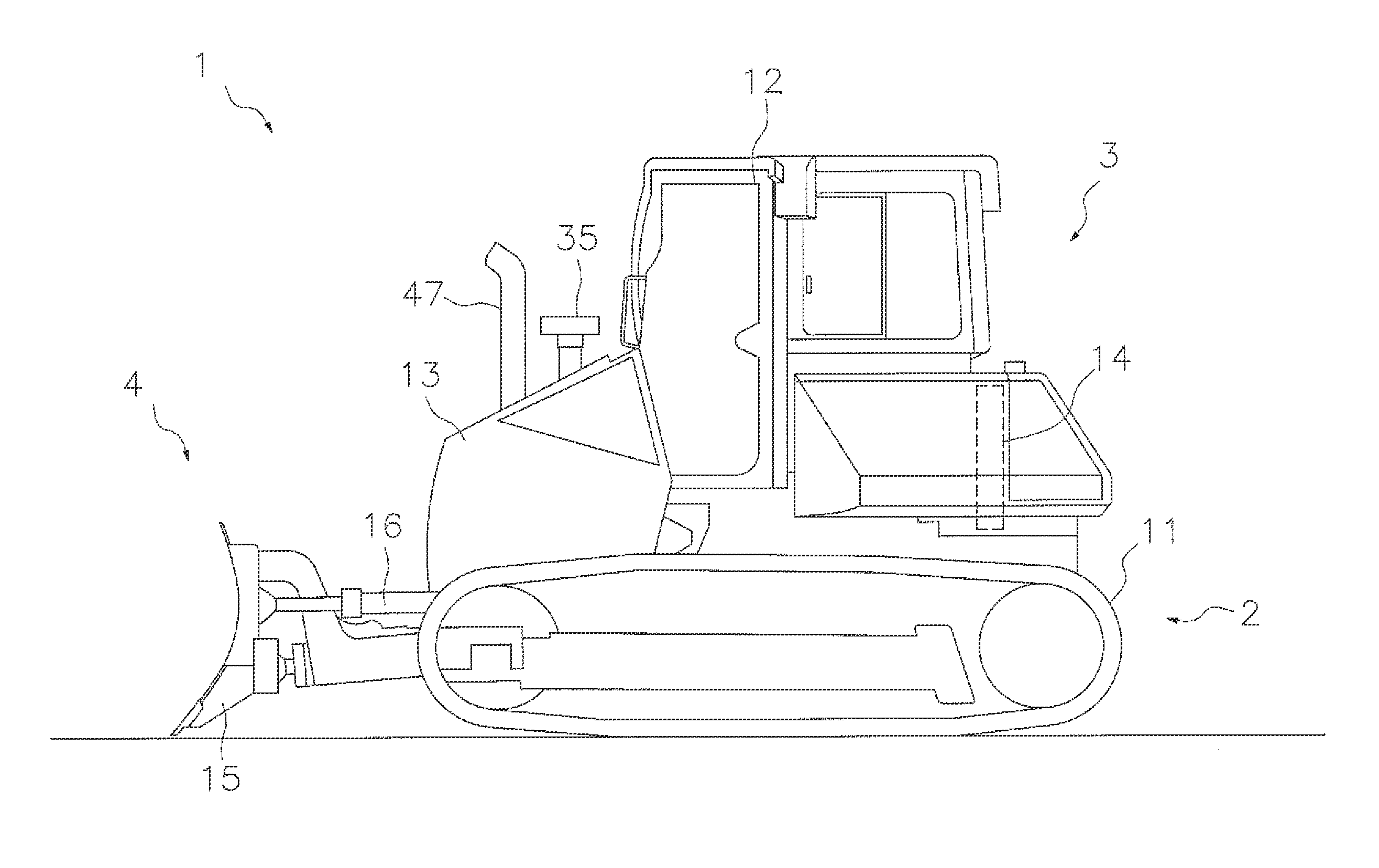

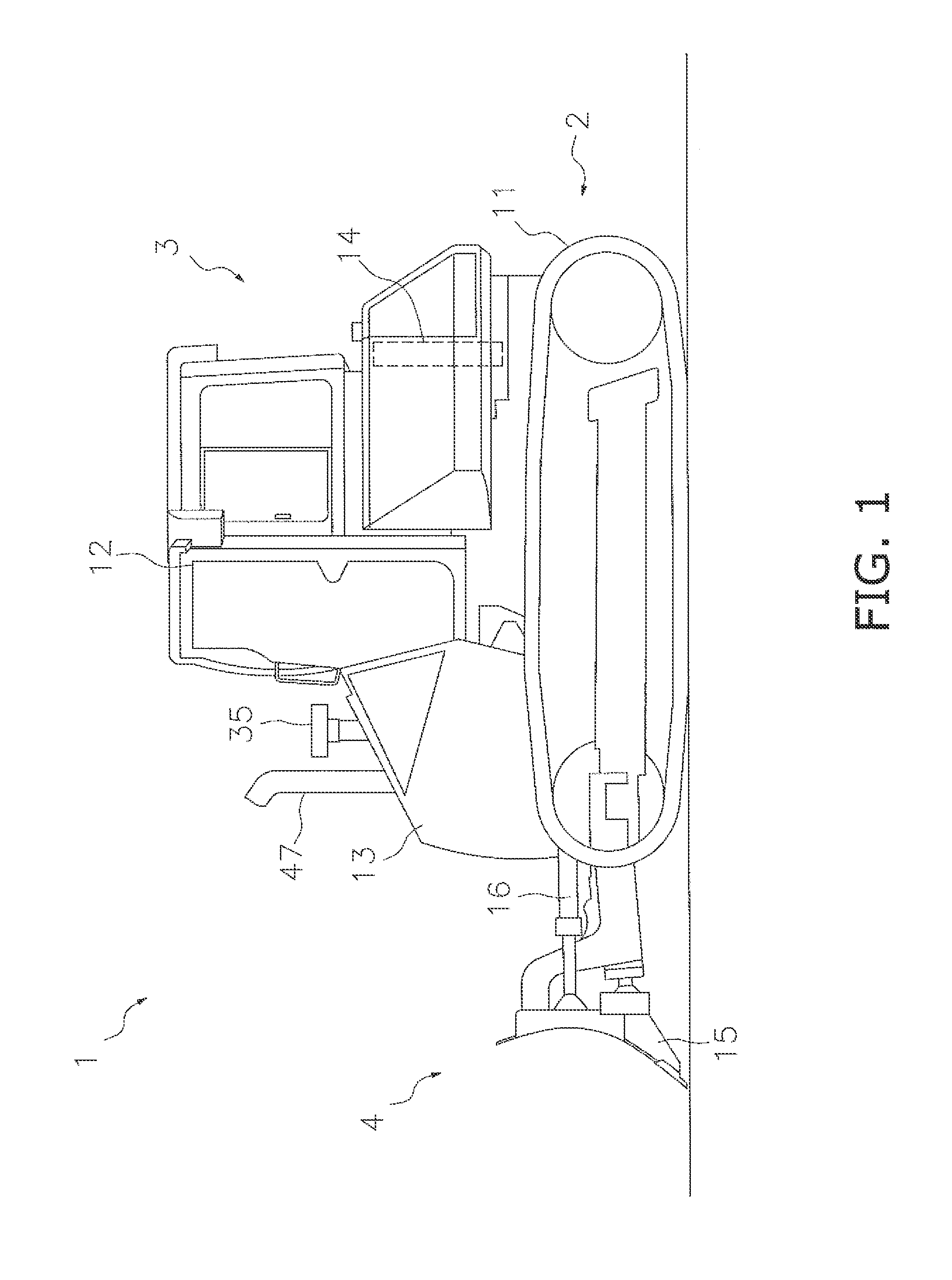

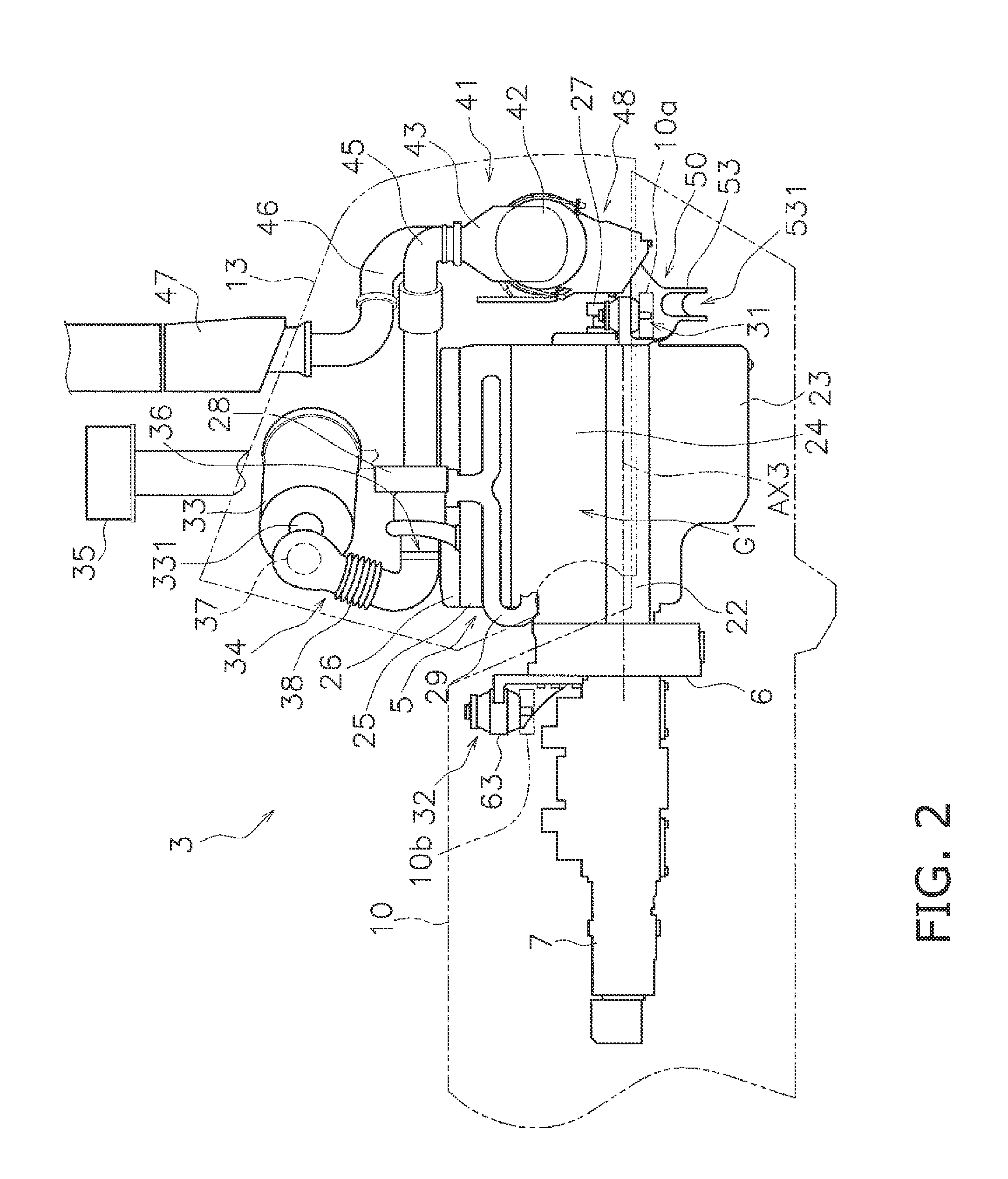

Bulldozer

ActiveUS20130277129A1Vertical distanceReduce loadMechanical machines/dredgersUnderstructuresAir cleanersVehicle frame

Owner:KOMATSU LTD

Shock absorbing apparatus for vehicle

ActiveUS20150175108A1Effective absorptionAvoid deformationPedestrian/occupant safety arrangementRailway wheel guards/bumpersPower flowControl unit

A shock absorbing apparatus for a vehicle may include a first coil provided in a bumper of the vehicle, a second coil provided on a vehicle body and facing the first coil, and a control unit applying voltage to generate a repulsive force between the first and second coils when a change in voltage may be detected by a movement of the first coil in an event of a vehicle collision, wherein an electric current flows between the control unit and the first and second coils.

Owner:HYUNDAI MOTOR CO LTD

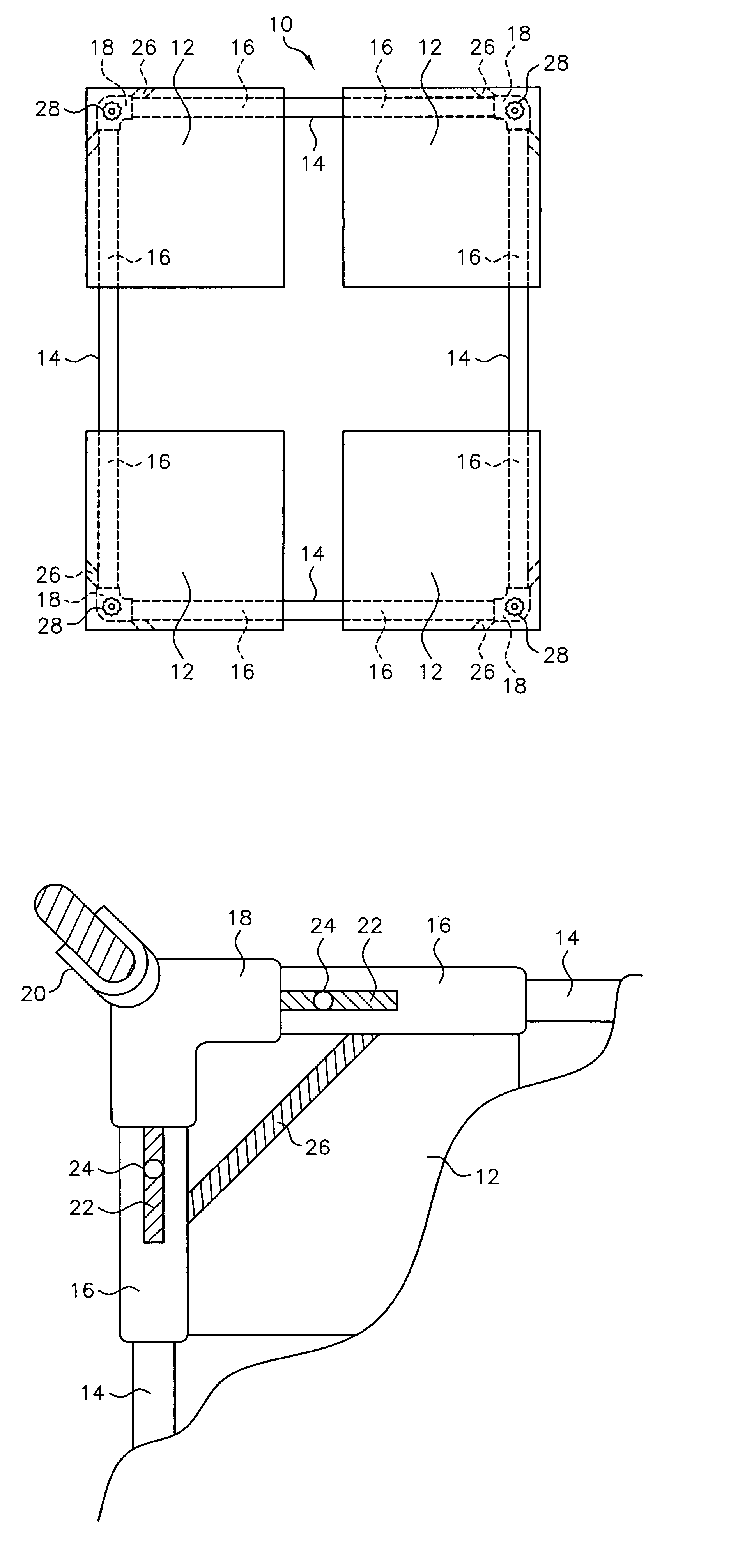

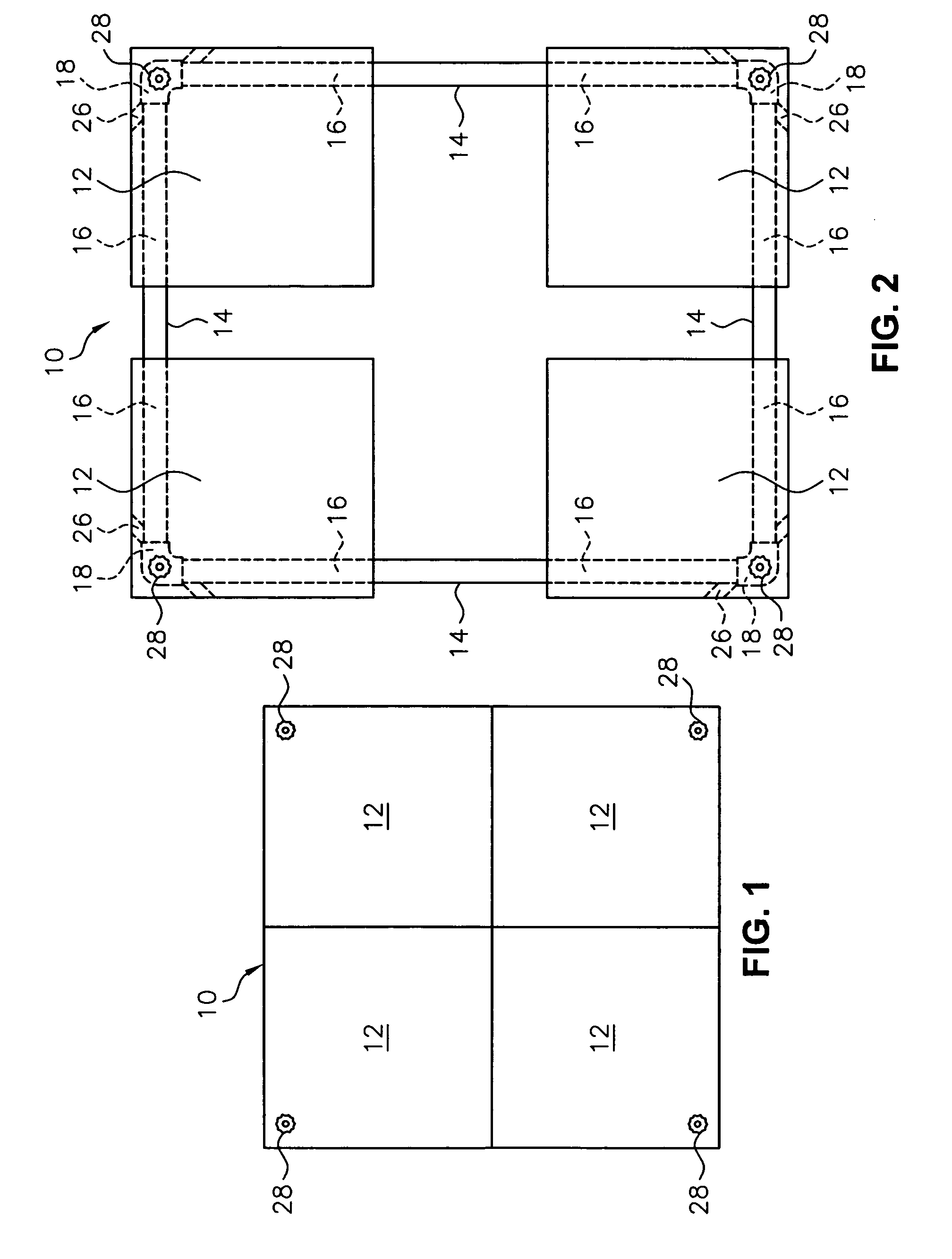

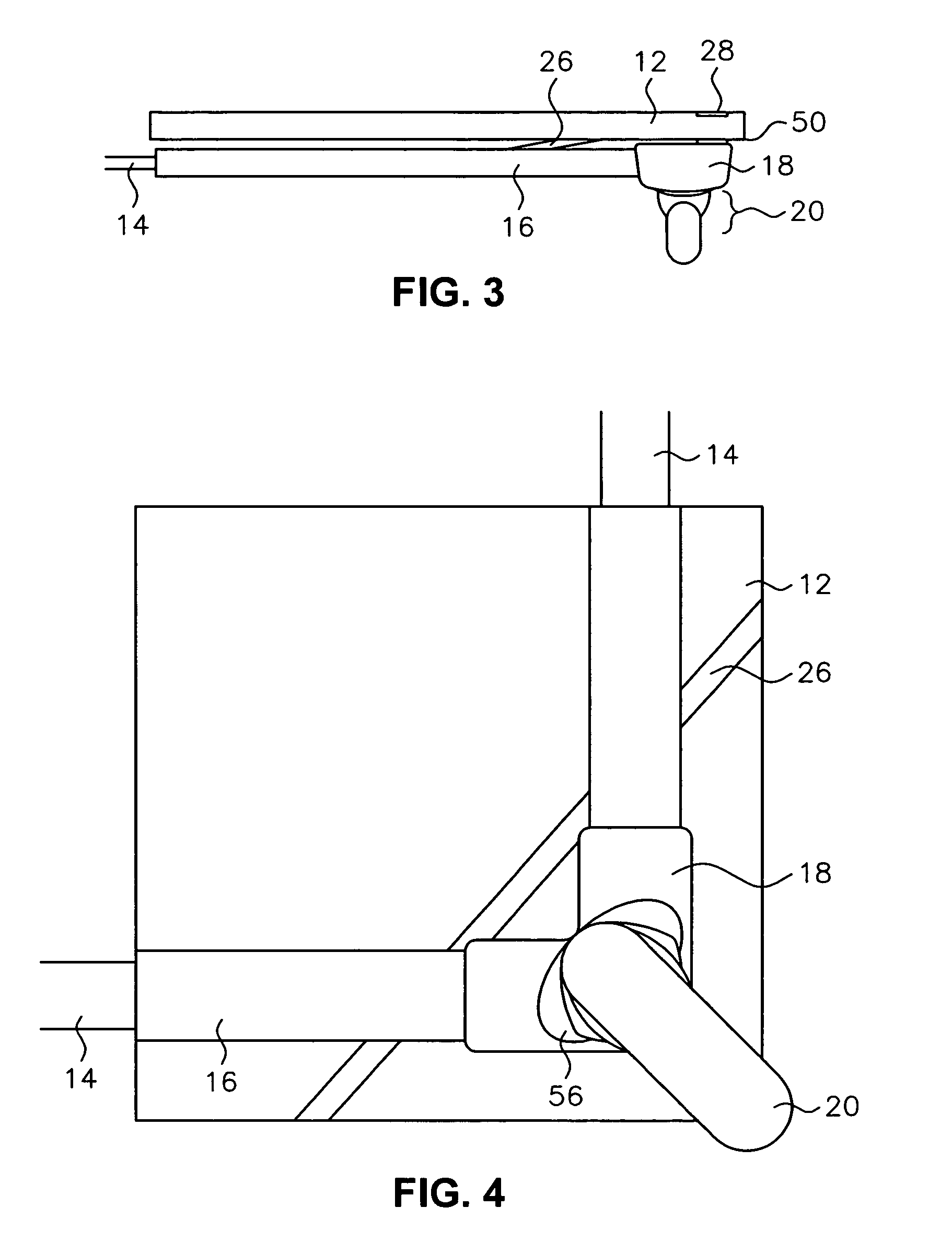

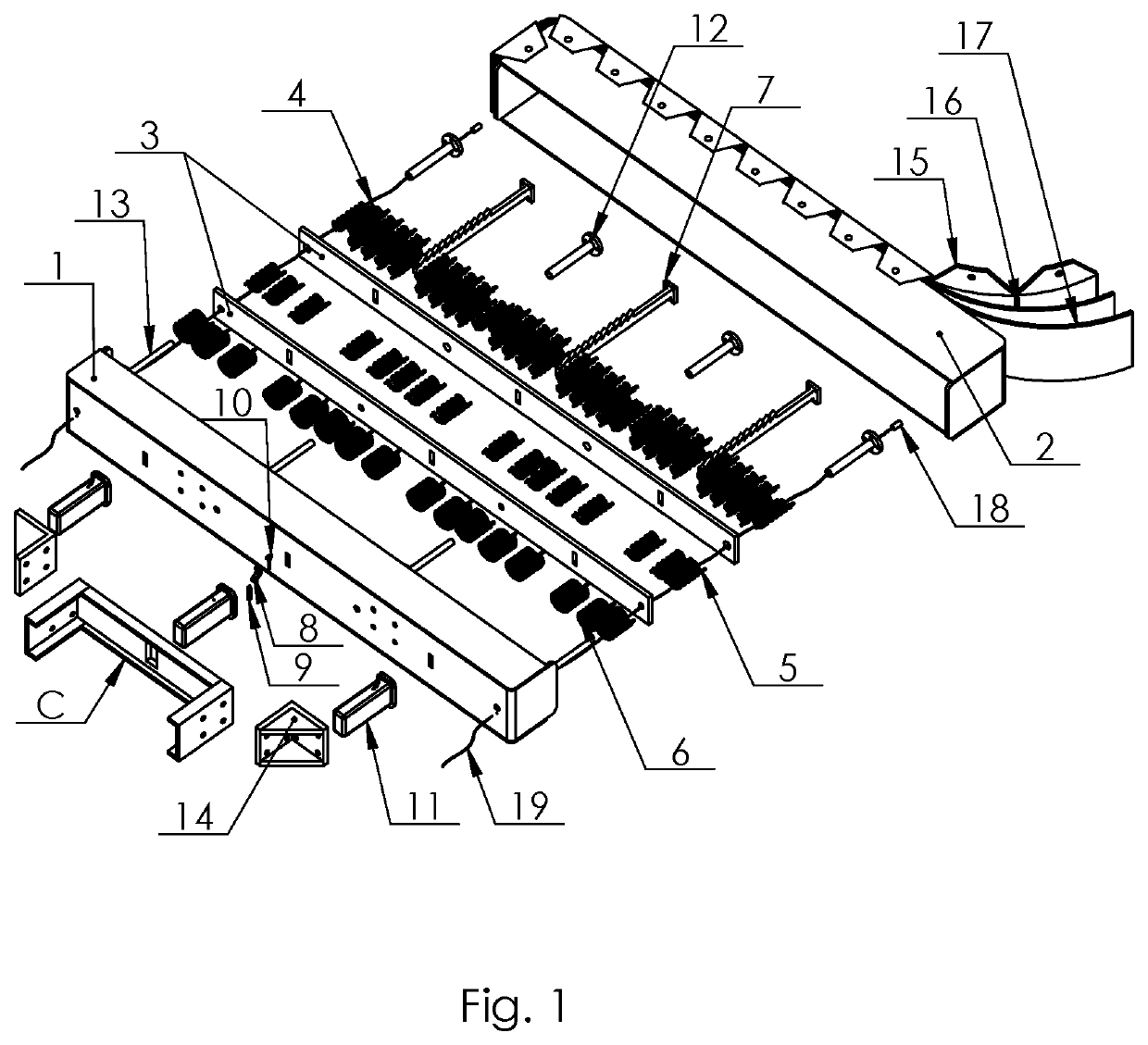

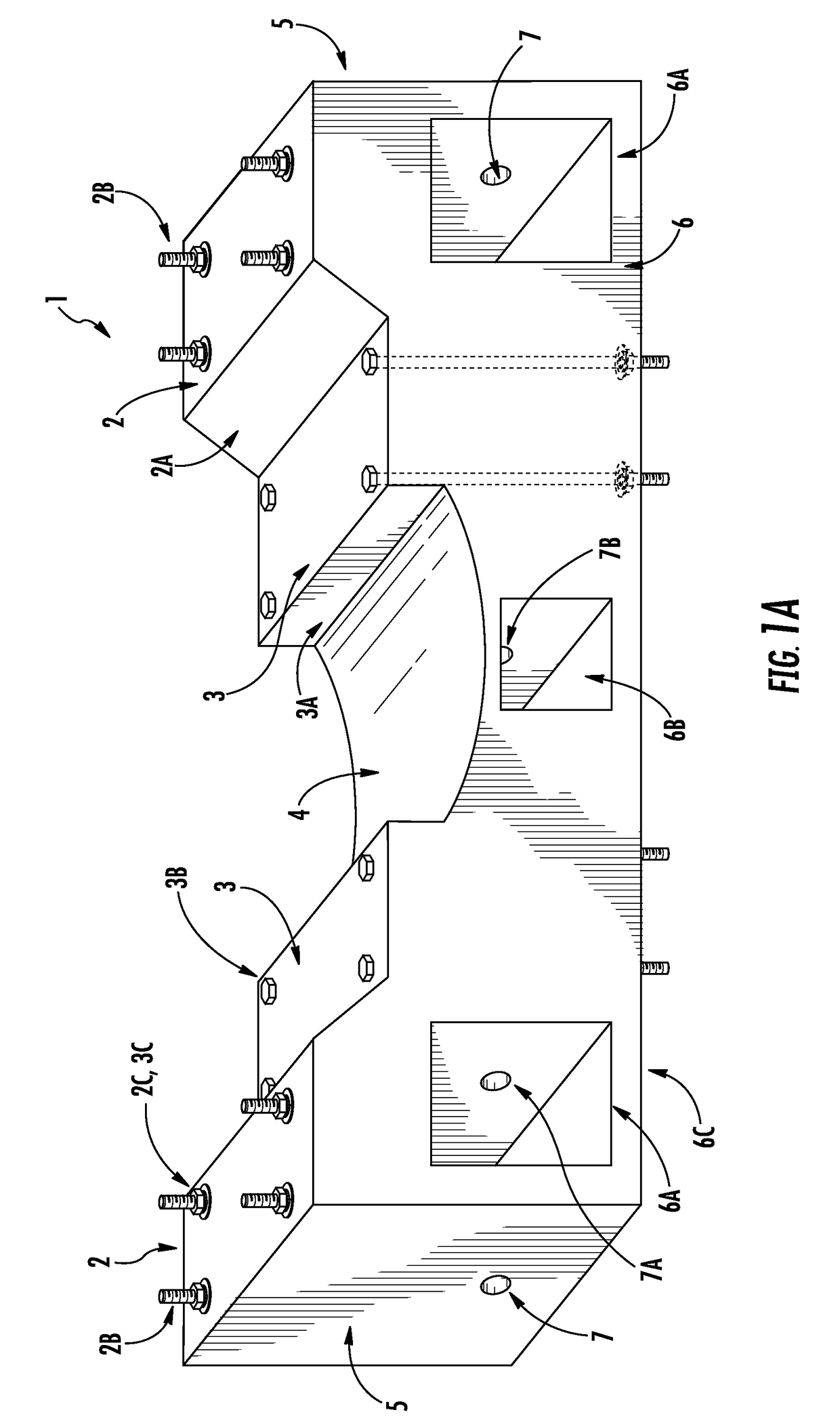

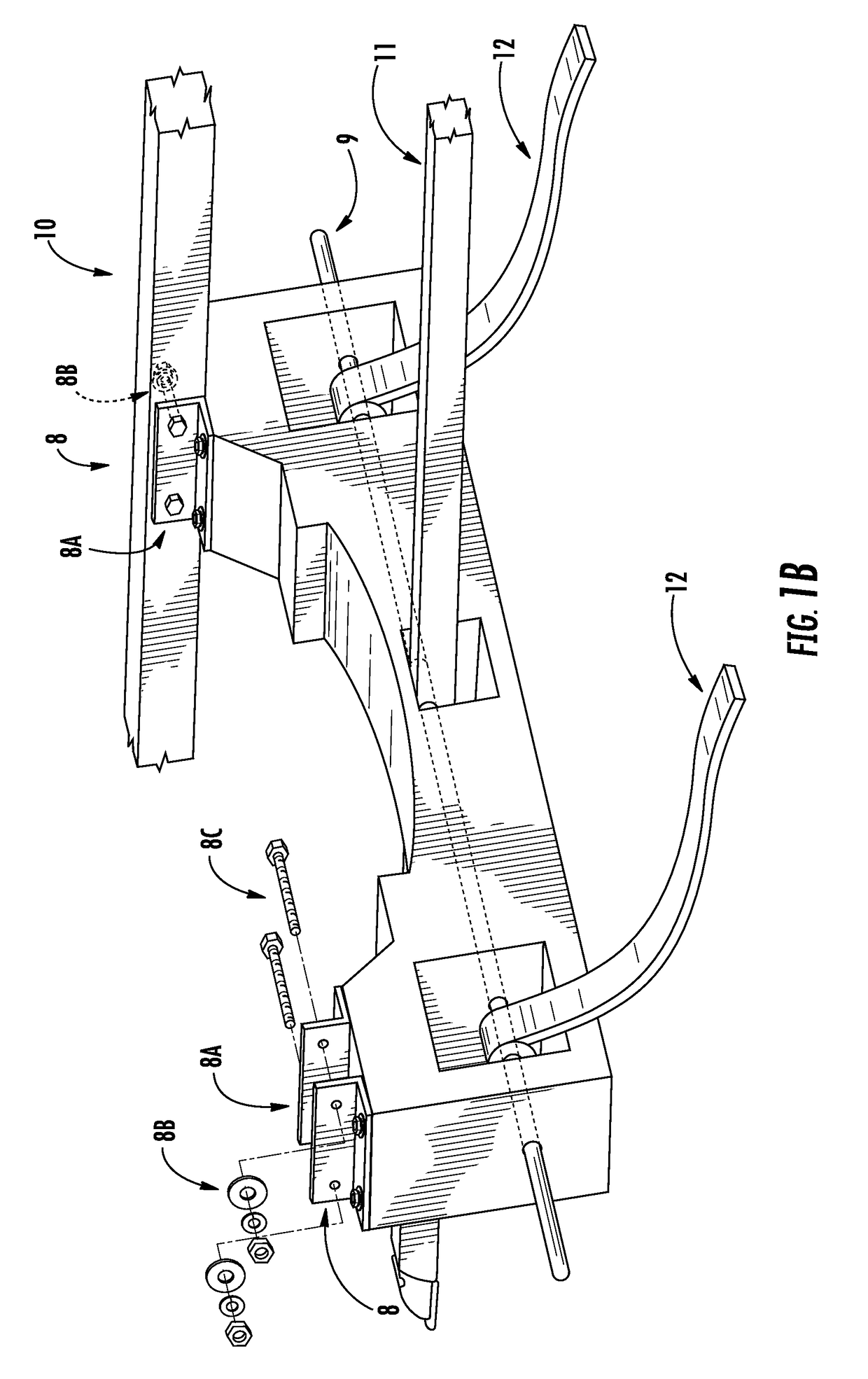

Structural cross frame connector and system

Owner:PINCHEON JEFFREY R

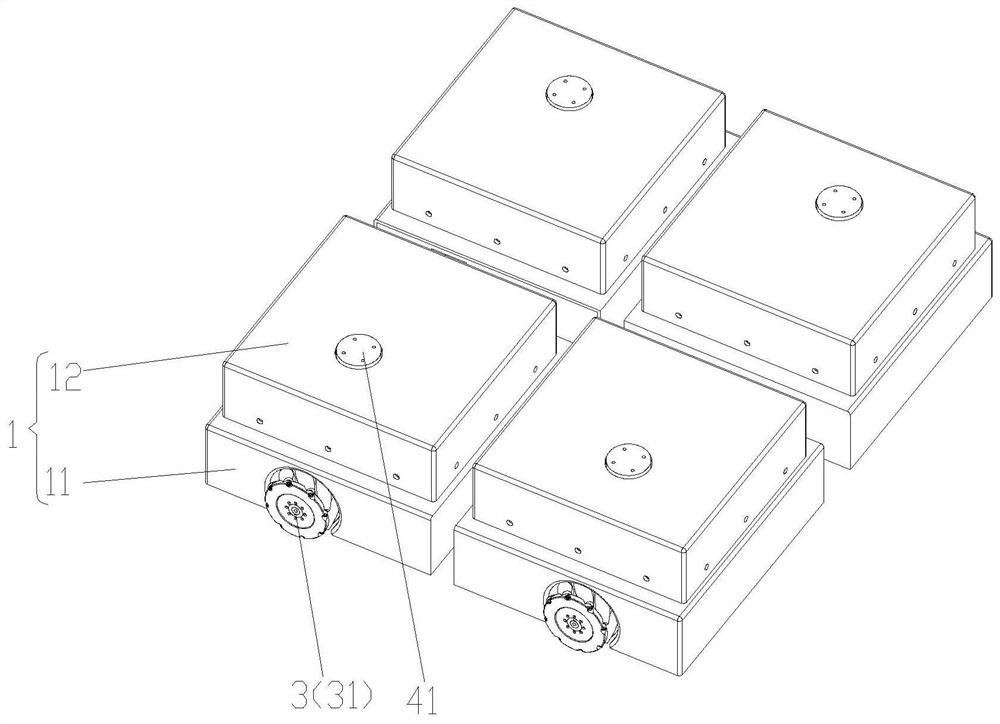

Appearance self-adaptive flexible transfer robot and material management application system

PendingCN112706679ARealize automated handling operationsOvercoming manual searchData processing applicationsTransmission systemsControl engineeringMonitoring system

Owner:苏州云骐智能科技有限公司

Determination method and device of deformation guide mechanism of front longitudinal beam of electric automobile

Owner:CH AUTO TECH CORP CO LTD

Vehicle

Owner:MAZDA MOTOR CORP

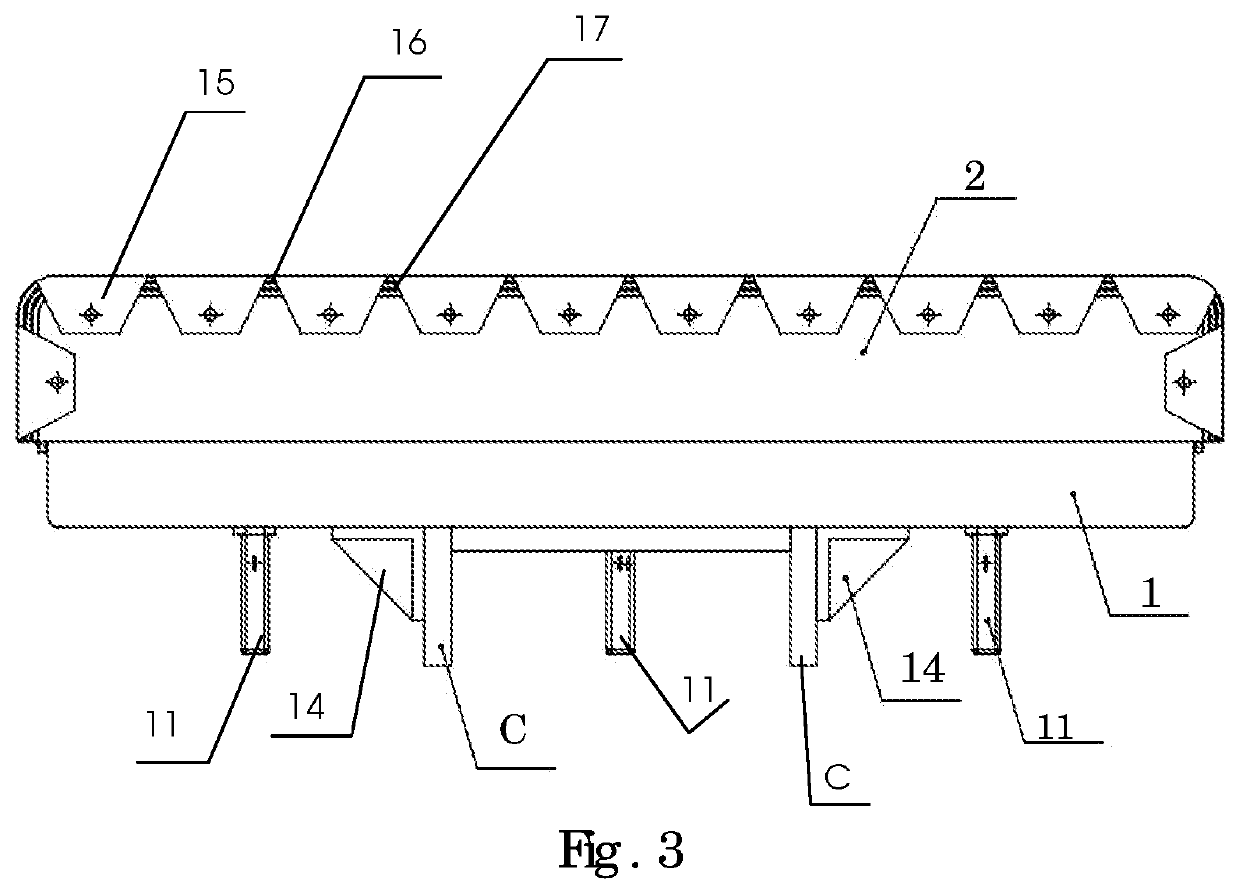

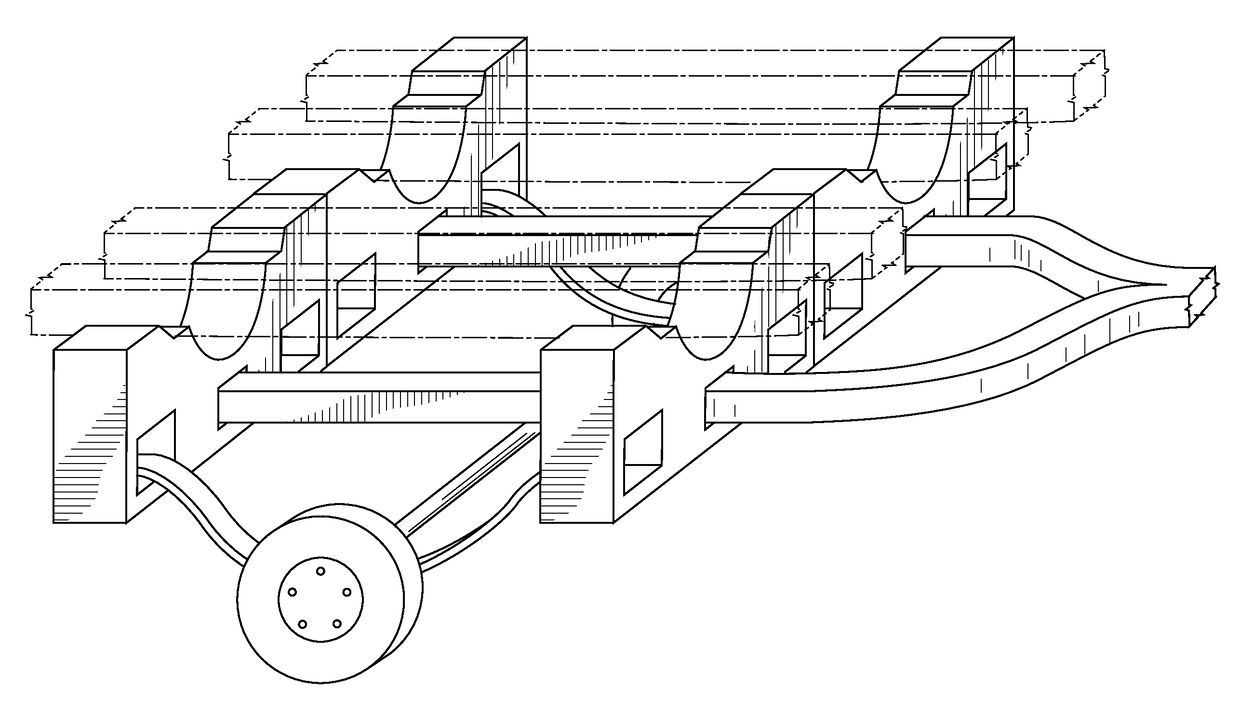

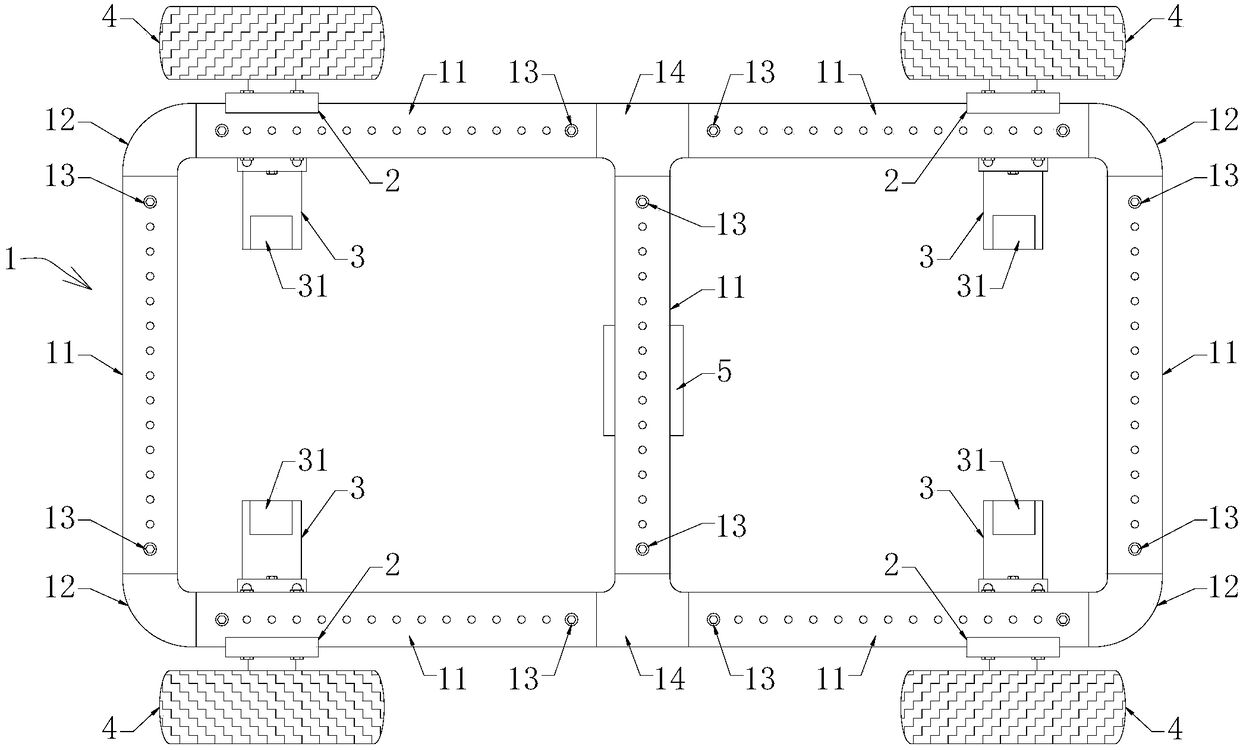

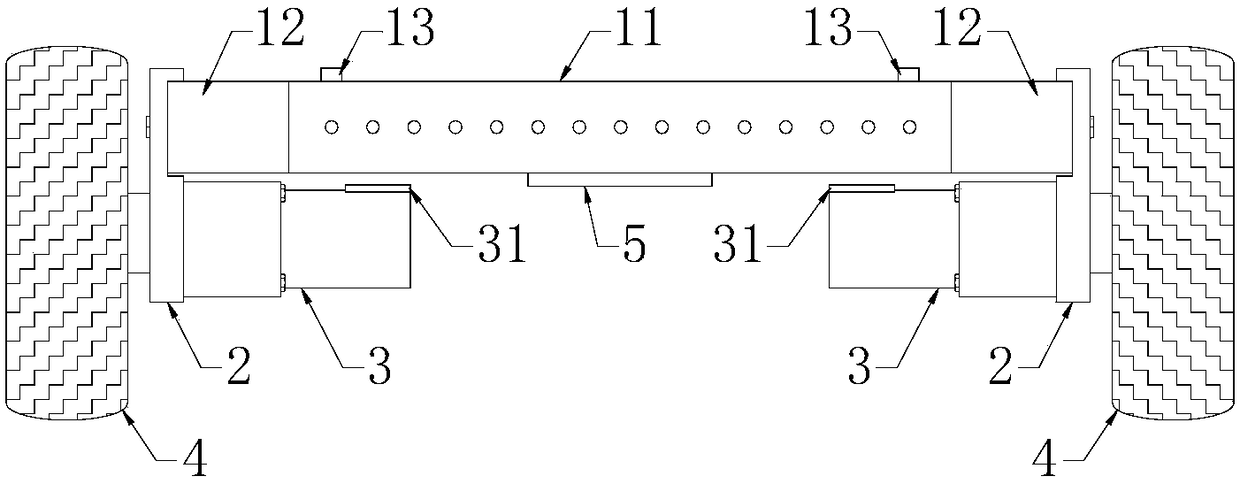

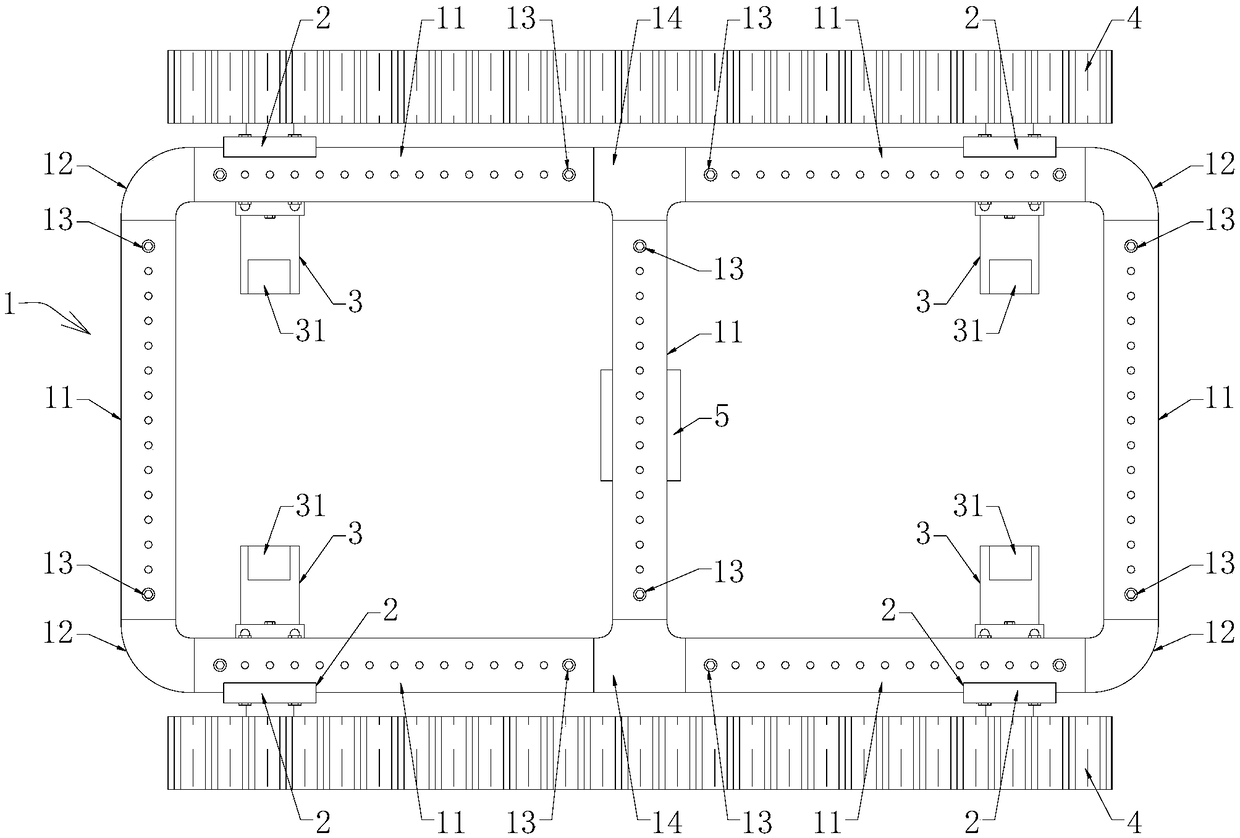

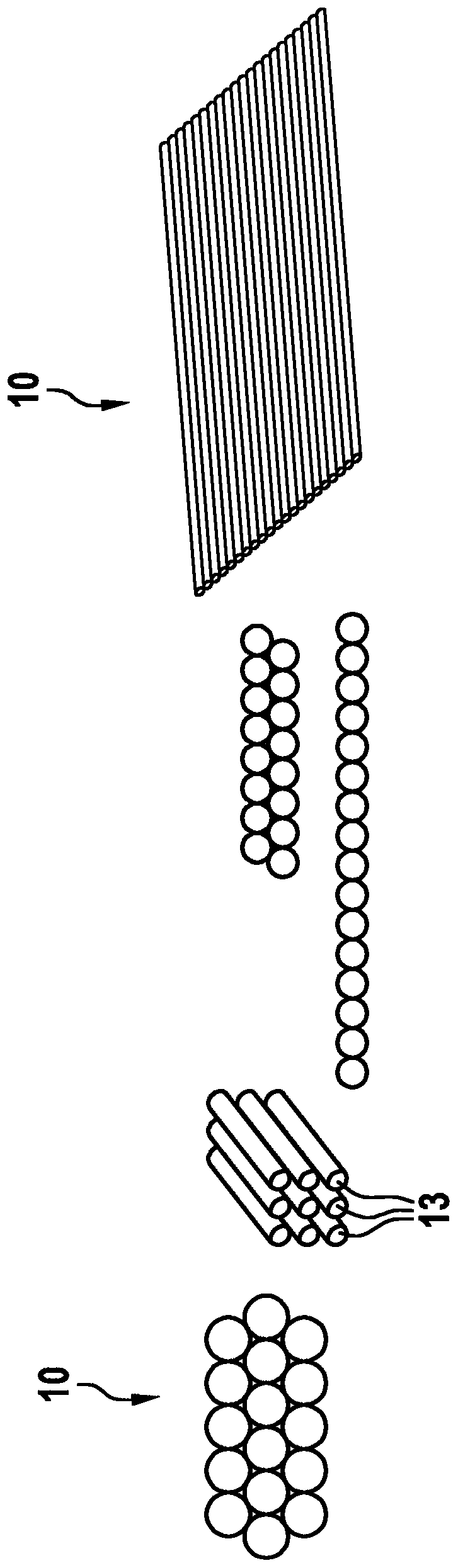

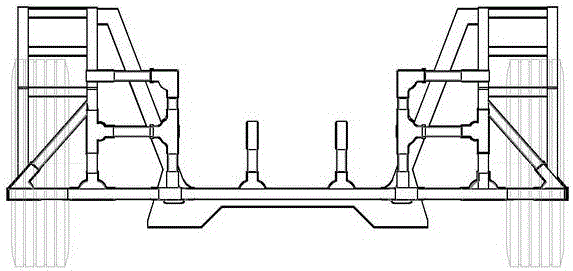

Combined type robot car chassis

PendingCN108216425AReasonable structureAssembly is quickly masteredUnderstructuresVehiclesFastenerEngineering

The invention discloses a combined type robot car chassis which comprises a chassis frame, multiple supports, motors and wheels. The chassis frame is of a frame structure formed by splicing of a plurality of aluminum square tubes, multiple double-head connectors and multiple of fasteners, the supports are mounted on the chassis frame, each support is provided with one motor, each motor output shaft is provided with one wheel, a motor driven board is arranged on each motor, and the motor driven boards are in communication connection with a main control chip. The robot car chassis is spliced through the frame structure and has the advantages of easy assembly, variable appearance and the like, the distinctive chassis is assembled freely, the chassis frame formed by splicing of the aluminum square tubes, the double-head connectors and the fasteners is solid and durable, repeated disassembly does not affect accuracy, different wheels or crawler belts can be assembled, different situations can be adapted, different functional needs are met, and needs of teaching, scientific research and competition of various mechanical and electronic majors are facilitated.

Owner:北京启创远景科技有限公司

Device for storing compressed fluids

PendingCN110958956AFlexible connectionImprove thermal conductivityUnderstructuresVehicle sub-unit featuresDistributorElectrical and Electronics engineering

Owner:ROBERT BOSCH GMBH

Construction component with a longitudinally changing cross-section shape

InactiveUS20050166538A1Easy to integrateImprove structural propertiesUnderstructuresBuilding constructionsArchitectural engineeringFlange

The invention concerns a construction component (1) profiled using roller profiling, with a profile cross-section changing in the longitudinal extent, wherein the profiled construction component includes a flange (4). The construction component having this shape is rigid and particularly easy to integrate into the vehicle body shell.

Owner:DAIMLER AG

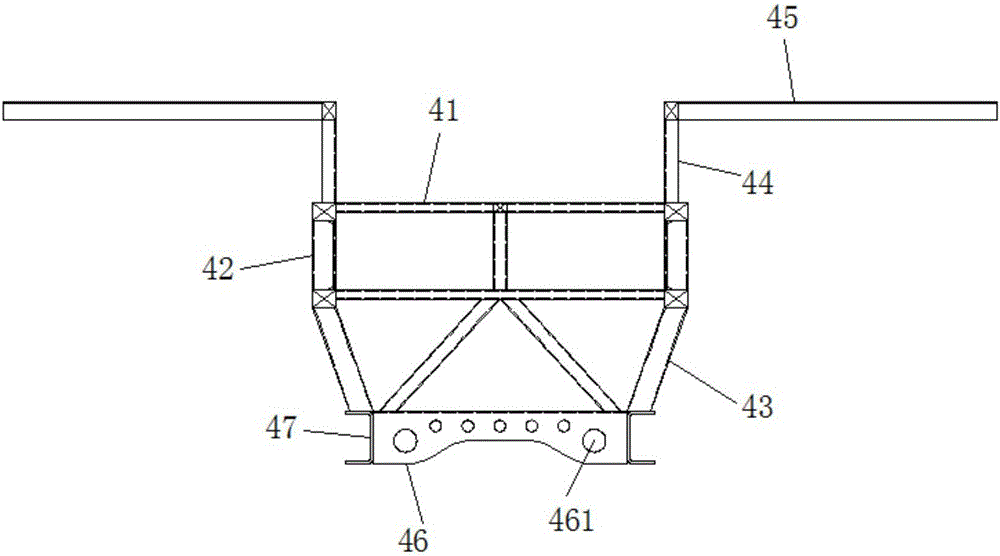

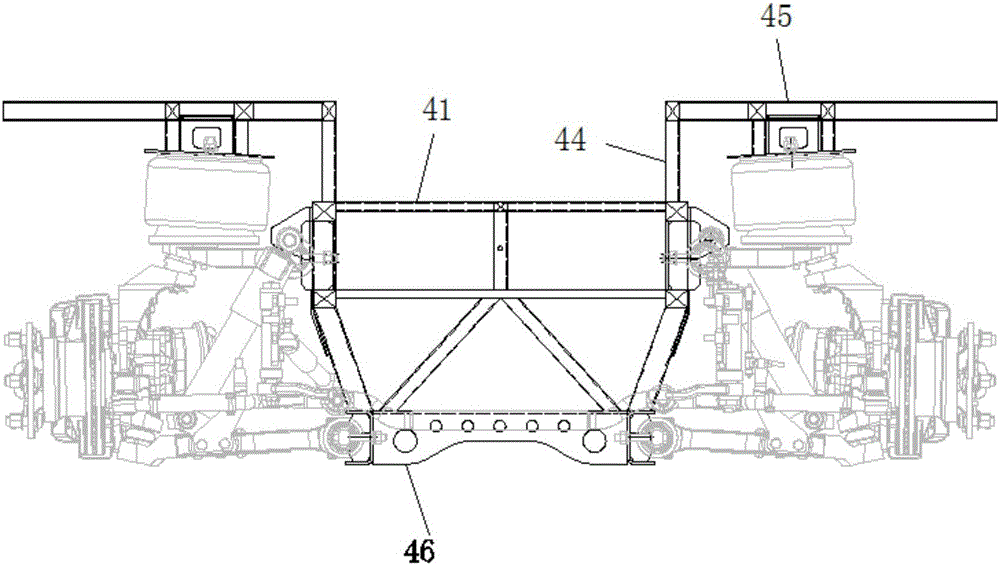

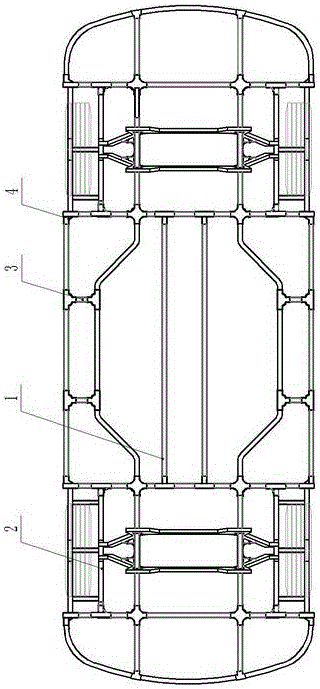

Axle frame in independent front suspension of electric bus

Owner:NANJING SKYSOURCE POWER TECH CO LTD

Wheel-beam combined type car frame

The invention discloses a wheel-beam type combined vehicle frame, which is composed of a longitudinal main beam, a wheel beam frame, a cross beam and a variety of connectors, and a unified standard connector insertion method is adopted between each part and each part They are interconnected and independent, can be assembled and adjusted at will, have sufficient strength and rigidity, and are completely independent and interchangeable. The invention adopts a modular combination mode, which is not only convenient for mass production, but also can be assembled in a standard manner, and the cost is low. The frame can be designed and assembled as a whole, or assembled in sections. The attachment structure is simple and the variability is controllable. It is convenient to reasonably arrange each assembly and parts, and each part adopts a standard overall unified plugging method; it can also be disassembled, integrated, and transformed into a variety of models. It can significantly reduce the height of the car floor, effectively and greatly improve the use of the space in the car, and enhance the comfort.

Owner:石宇 +1

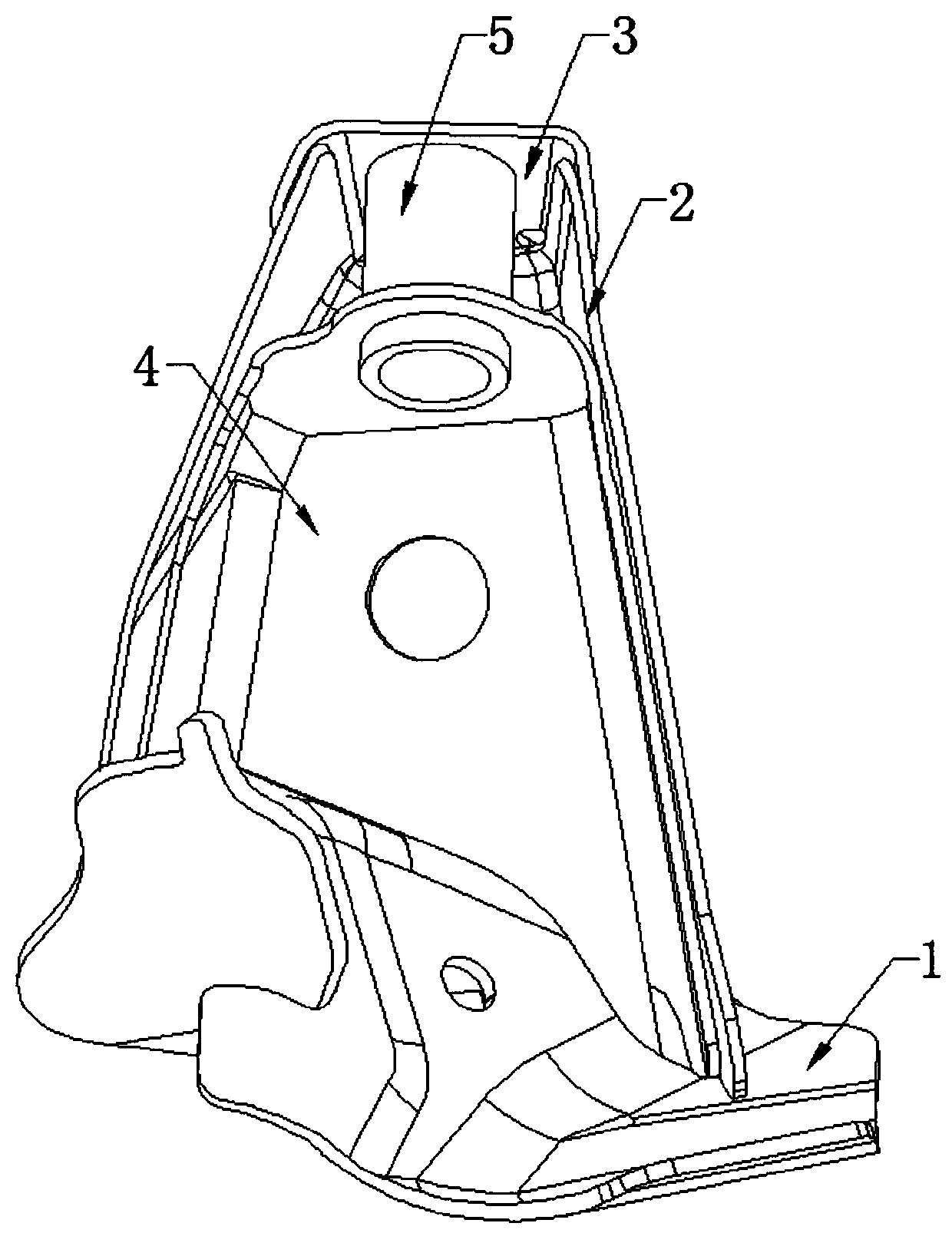

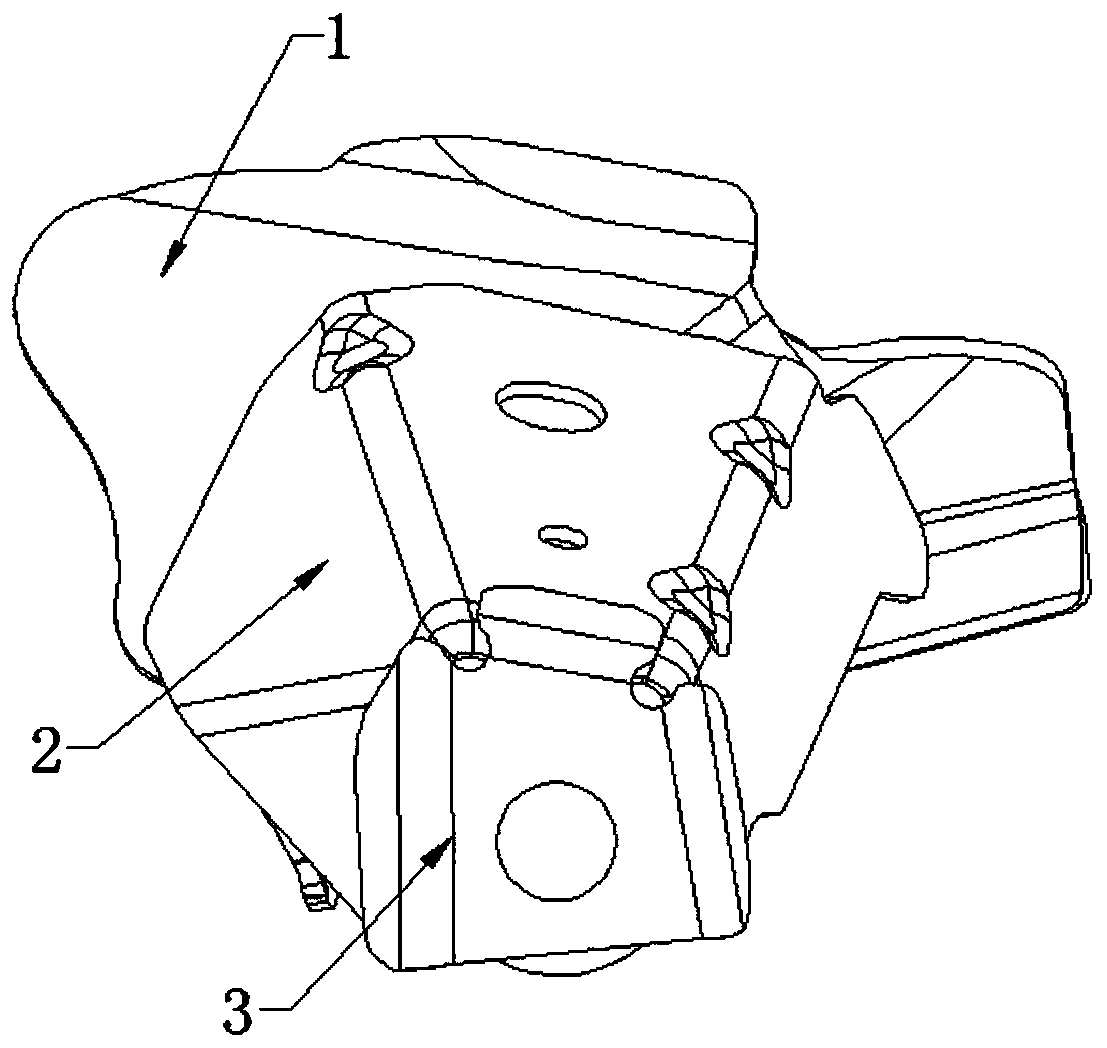

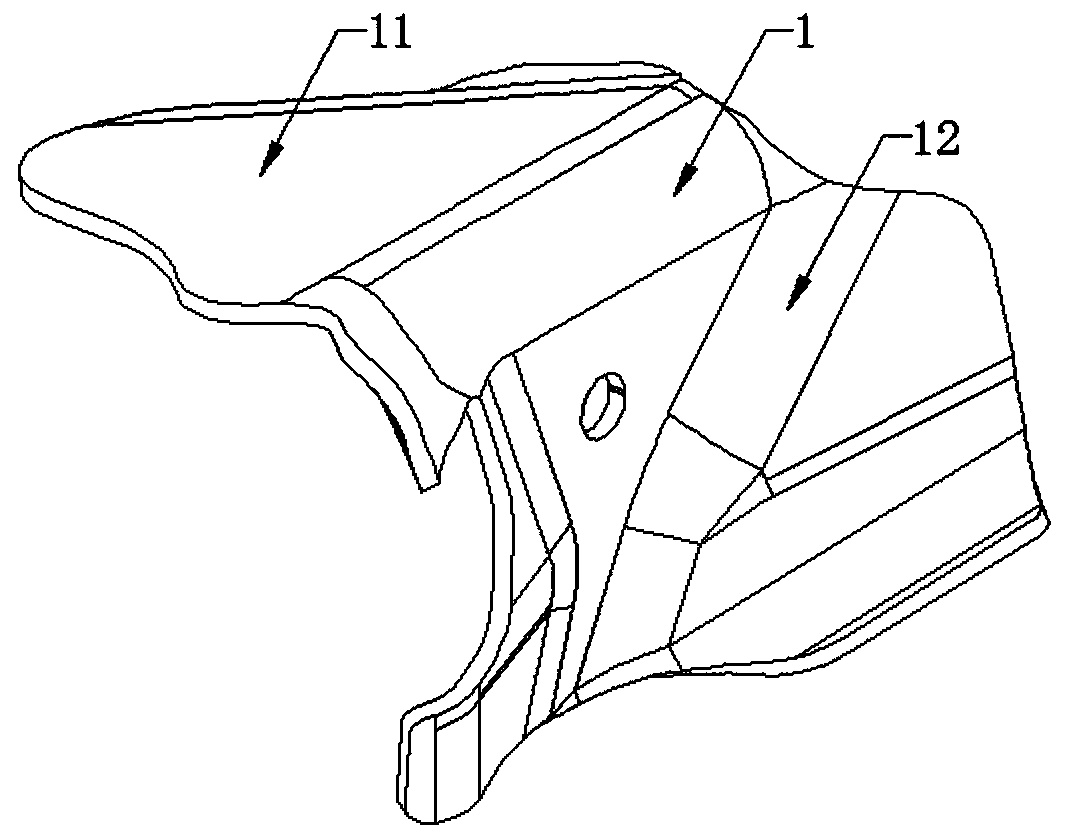

Auxiliary frame vehicle body mounting bracket

Owner:达奥(芜湖)汽车制品有限公司

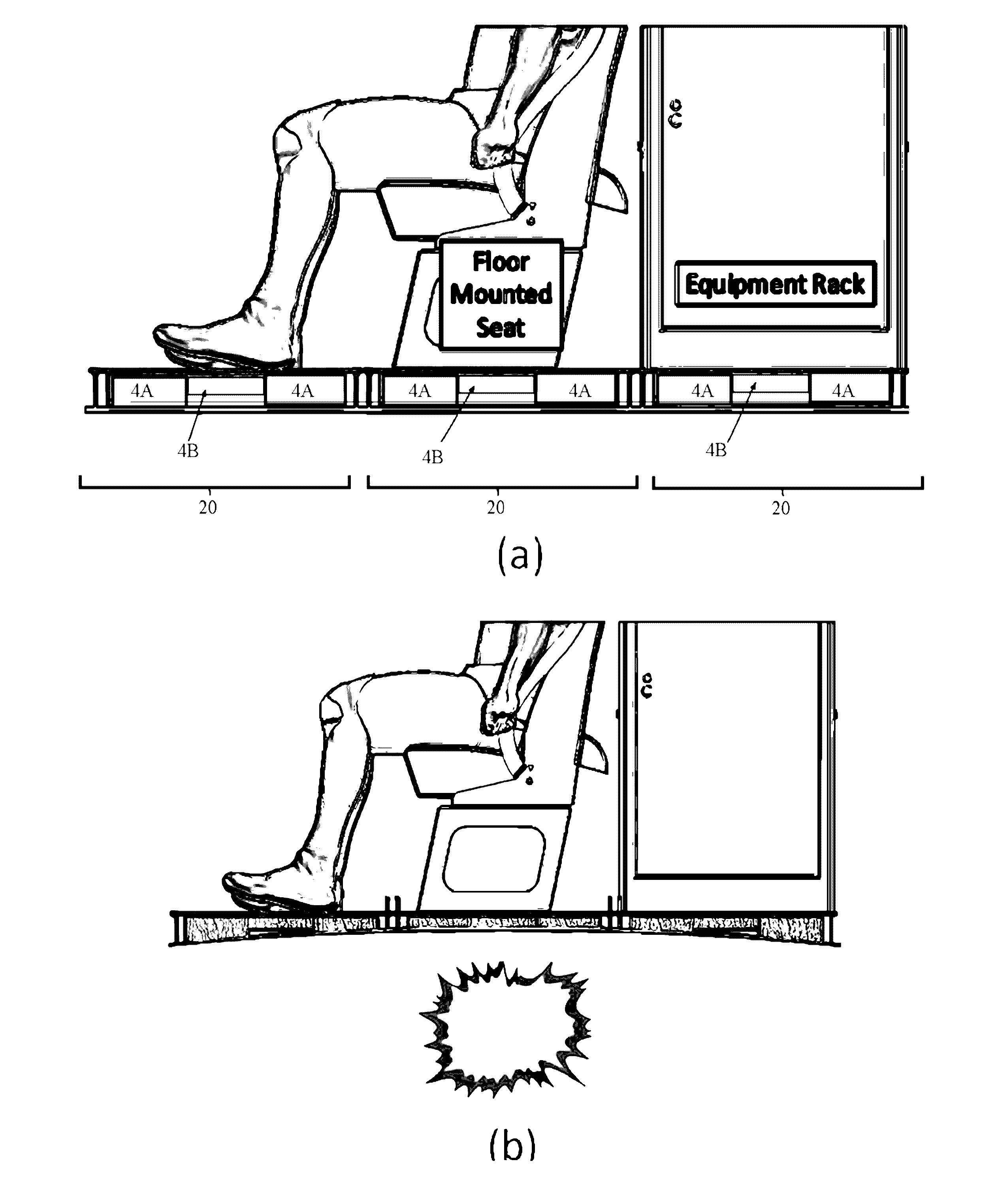

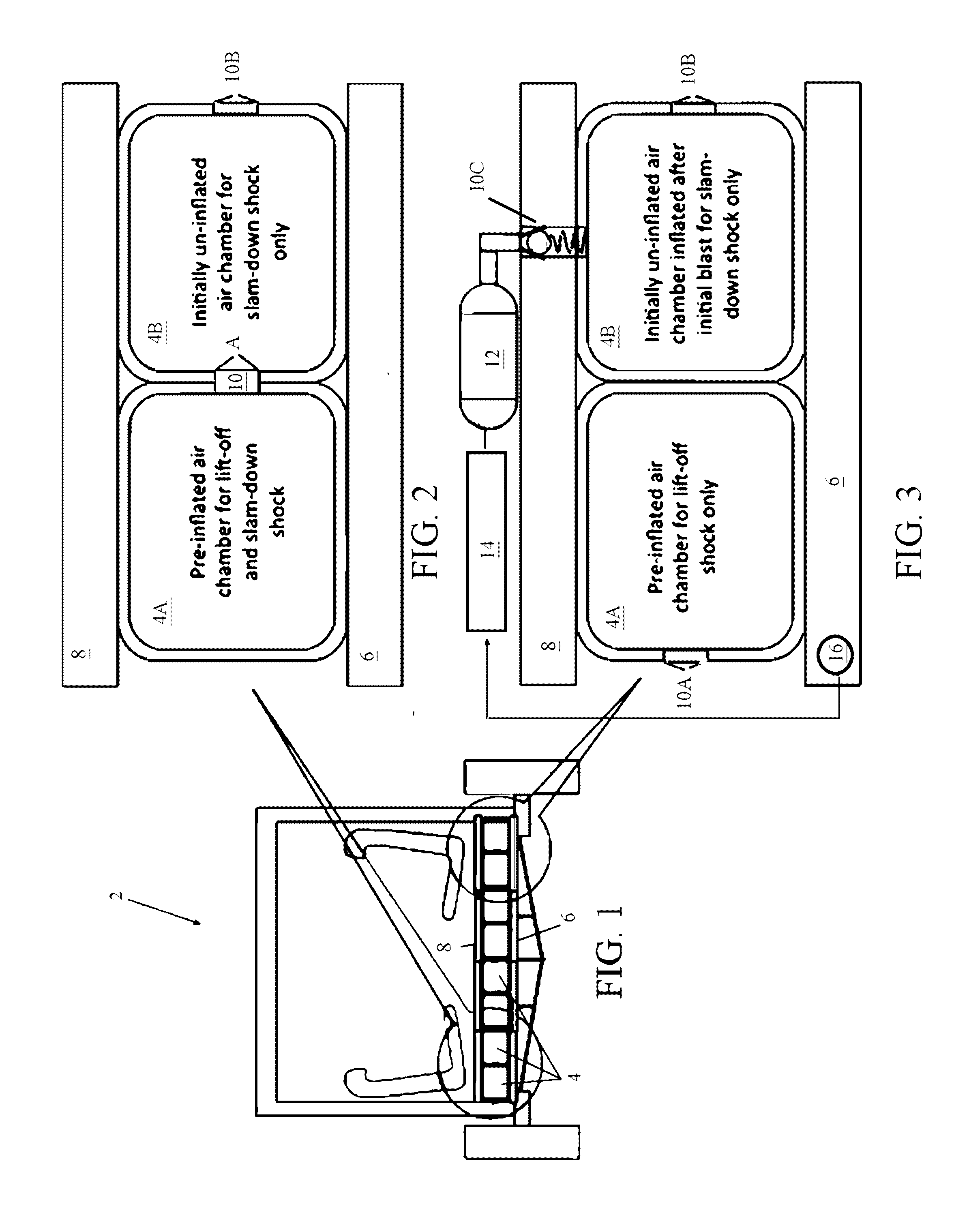

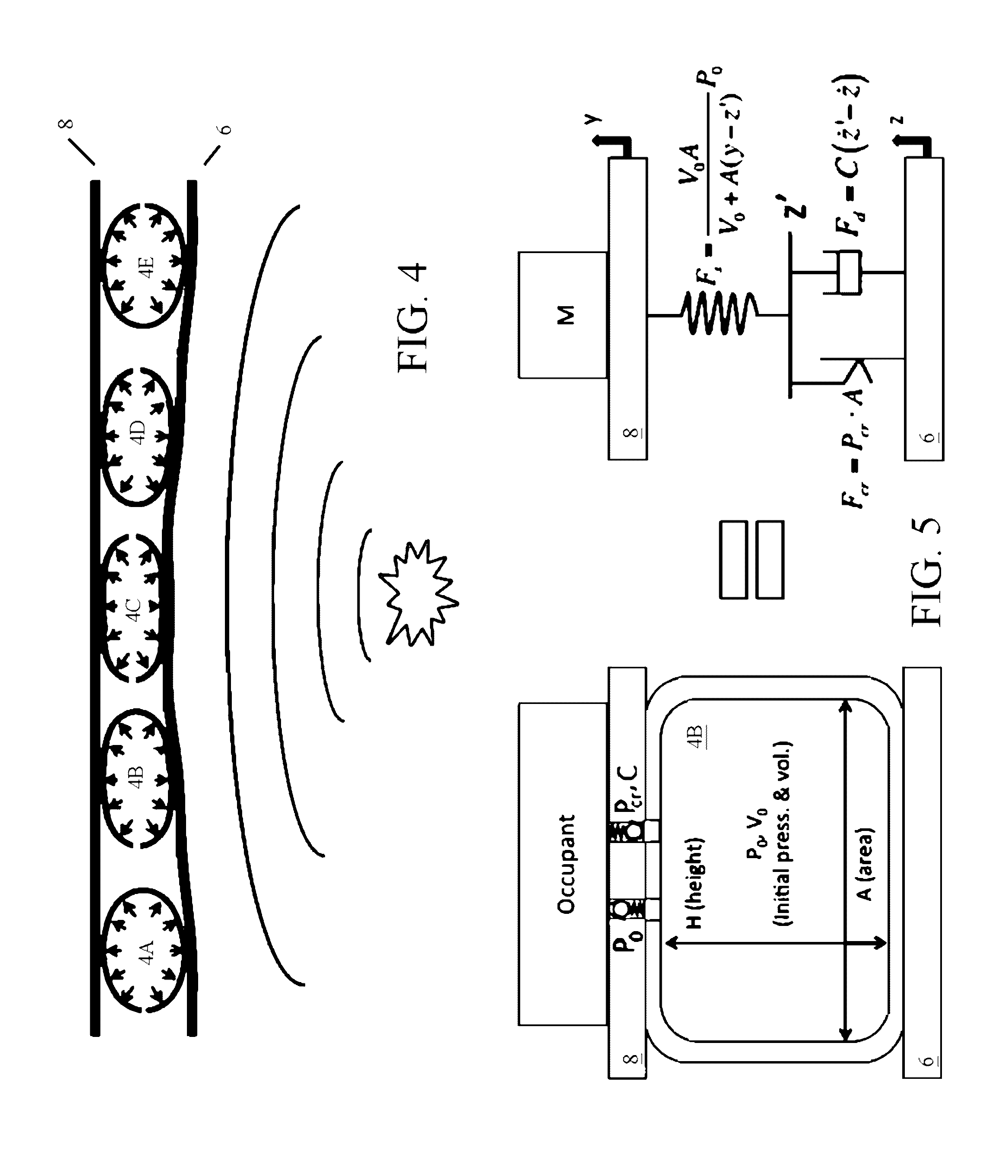

Fluid encapsulated flooring system

Owner:INNOVITAL LLC

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap