Device for storing compressed fluids

A technology for compressing fluids and technical devices, which is applied in the field of devices storing compressed fluids, can solve the problems of not considering the use of large-scale vehicle bodies, and not meeting size requirements, and achieve the effects of small heating, non-flammable costs, and high thermal conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

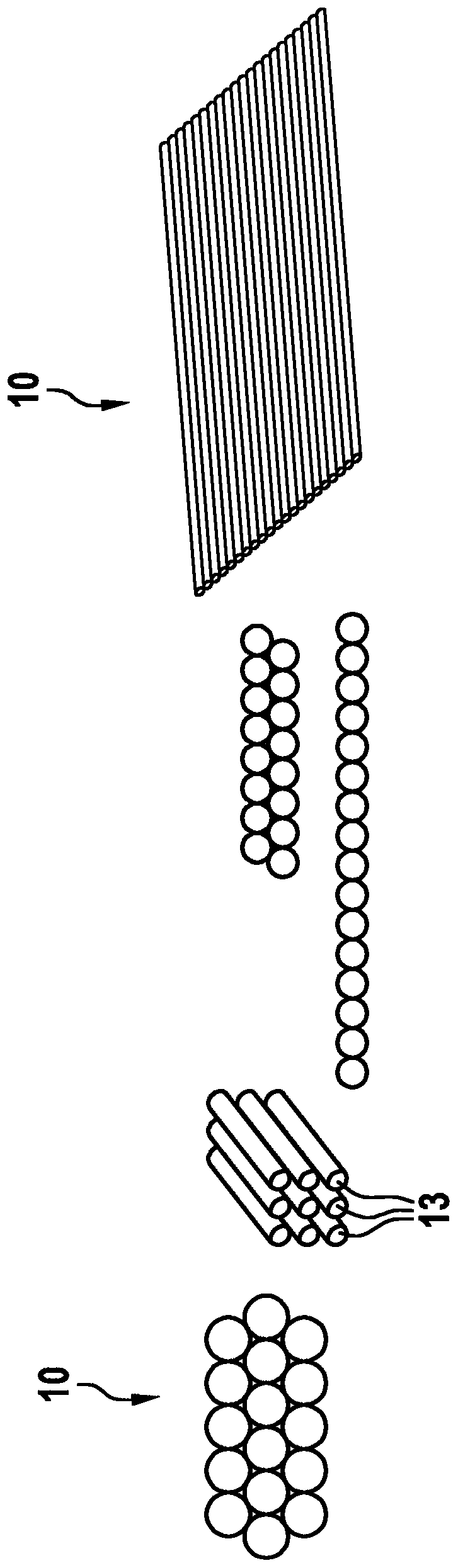

[0030] exist figure 1 A schematic diagram of the modular construction of the device 10 for storing compressed fluid consisting of tank modules is shown in . The device 10 consists of a series of tank modules 13 made of metal. The individual tank modules 13 can be produced from tubular semi-finished products. The tank modules 13 can be arranged as a stack on top of each other or next to each other and can be produced in any desired length. The tank module 13 is connected via at least one high-pressure fuel distributor 14 to at least one integrated control and safety technology device 15 .

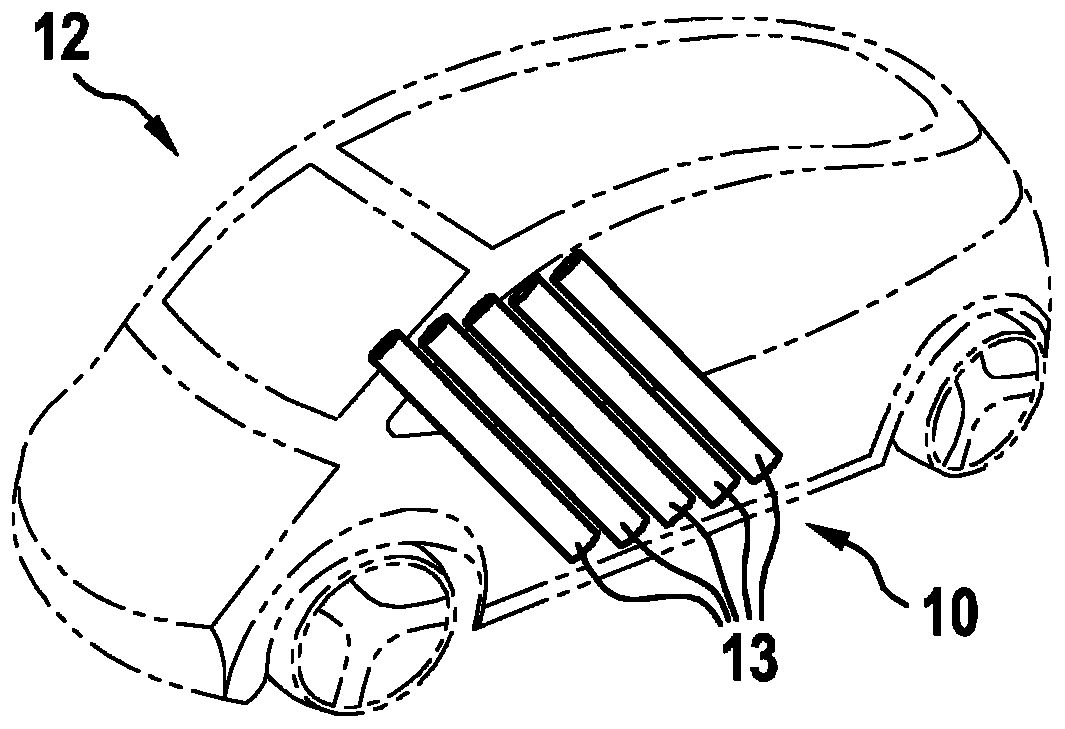

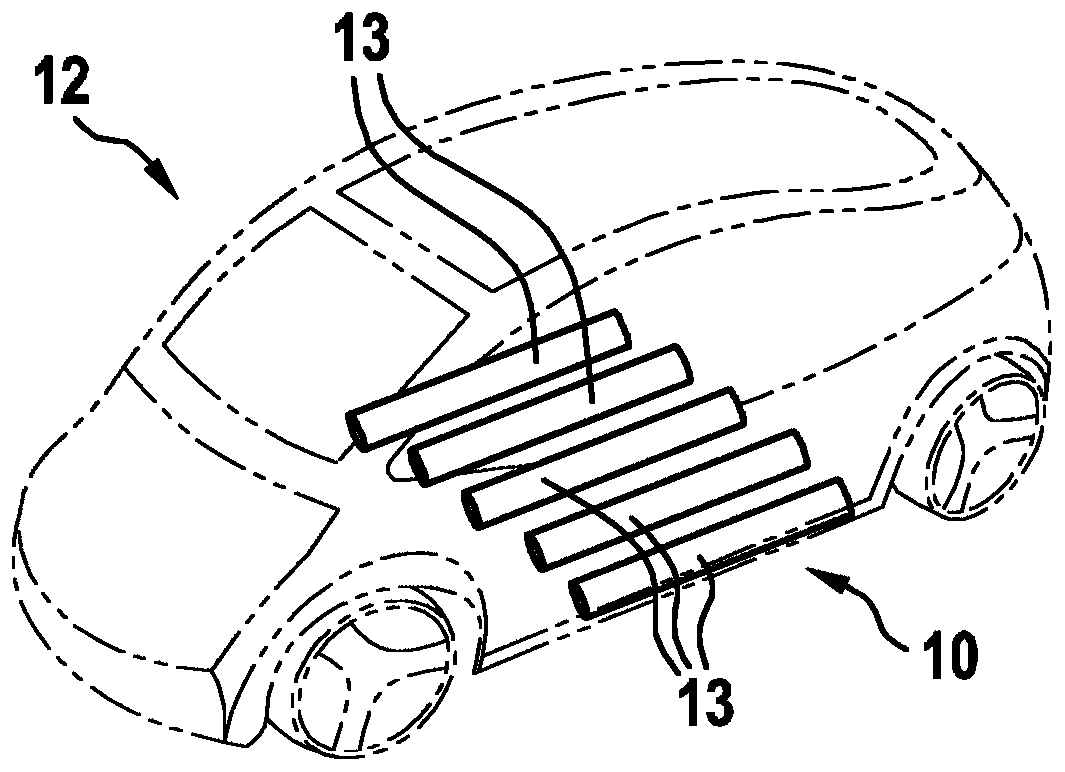

[0031] figure 2 A schematic view of a vehicle 12 is shown with a device 10 for storing compressed fluid, which is made up of tank modules 13 and is installed transversely in the vehicle floor. In this vehicle 12 , the tank module 13 is arranged transversely to the direction of travel of the vehicle 12 . The arrangement of the tank module 13 below the passenger compartment of the vehicle 1

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap