Motorcycle oil tank

A technology for motorcycles and fuel tanks, applied in gasoline drums, vehicle parts, bicycle accessories, etc., can solve the problems of low fuel tank assembly efficiency, increase the risk of oil leakage from the fuel tank body, tedious and time-consuming assembly, and reduce false alarms. , Reduce the risk of oil leakage, the effect of simple and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In the following, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, so as to understand the technical ideas claimed in the present invention more clearly.

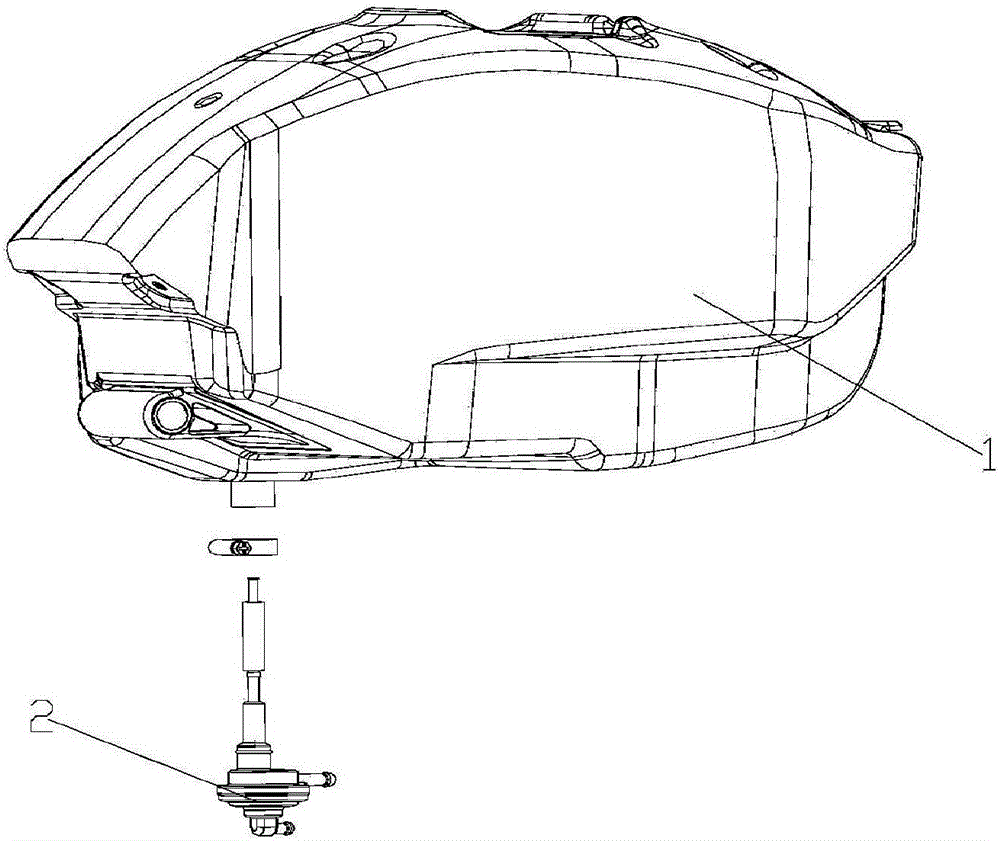

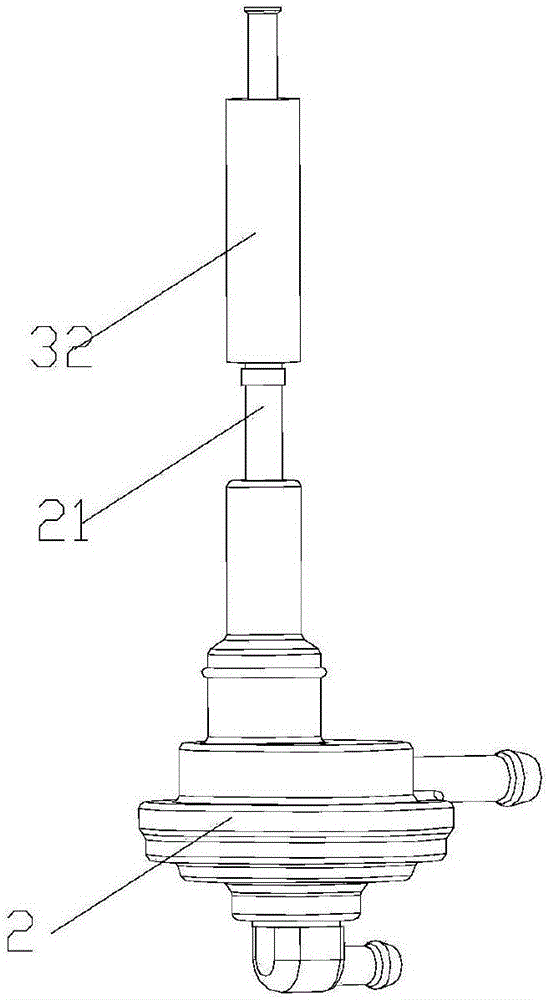

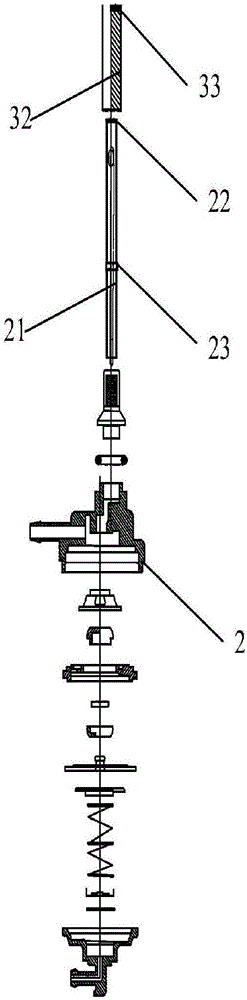

[0016] Such as figure 1 , 2 , shown in 3, is a kind of motorcycle fuel tank of the present invention, comprises fuel tank body 1, is installed in the negative pressure diaphragm type oil switch 2 at the installation hole place of fuel tank body 1 lower end, oil level sensing device, alarm circuit; The top of the negative pressure diaphragm oil switch 2 is also provided with a top pipe 21 located in the fuel tank body 1; the oil level sensing device includes a reed switch and a float 32; the reed switch is constituted as a switch on the alarm circuit, Used to control the on-off of the alarm circuit; the reed switch is installed in the top pipe 21, and the float 32 is movably fitted on the top pipe 21 and can rise and fall with the liquid level of the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap