Liquid surface detecting device

a detection device and liquid surface technology, applied in liquid/fluent solid measurement, instruments, machines/engines, etc., can solve the problems of lowering the accuracy of liquid surface detection and the risk of wearing a part of the electrode, so as to improve the degree of precision of detecting the liquid surface, reduce the abrasion of the contact parts, and reduce the friction resistance between the liquid and at least one of the arm and the float.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

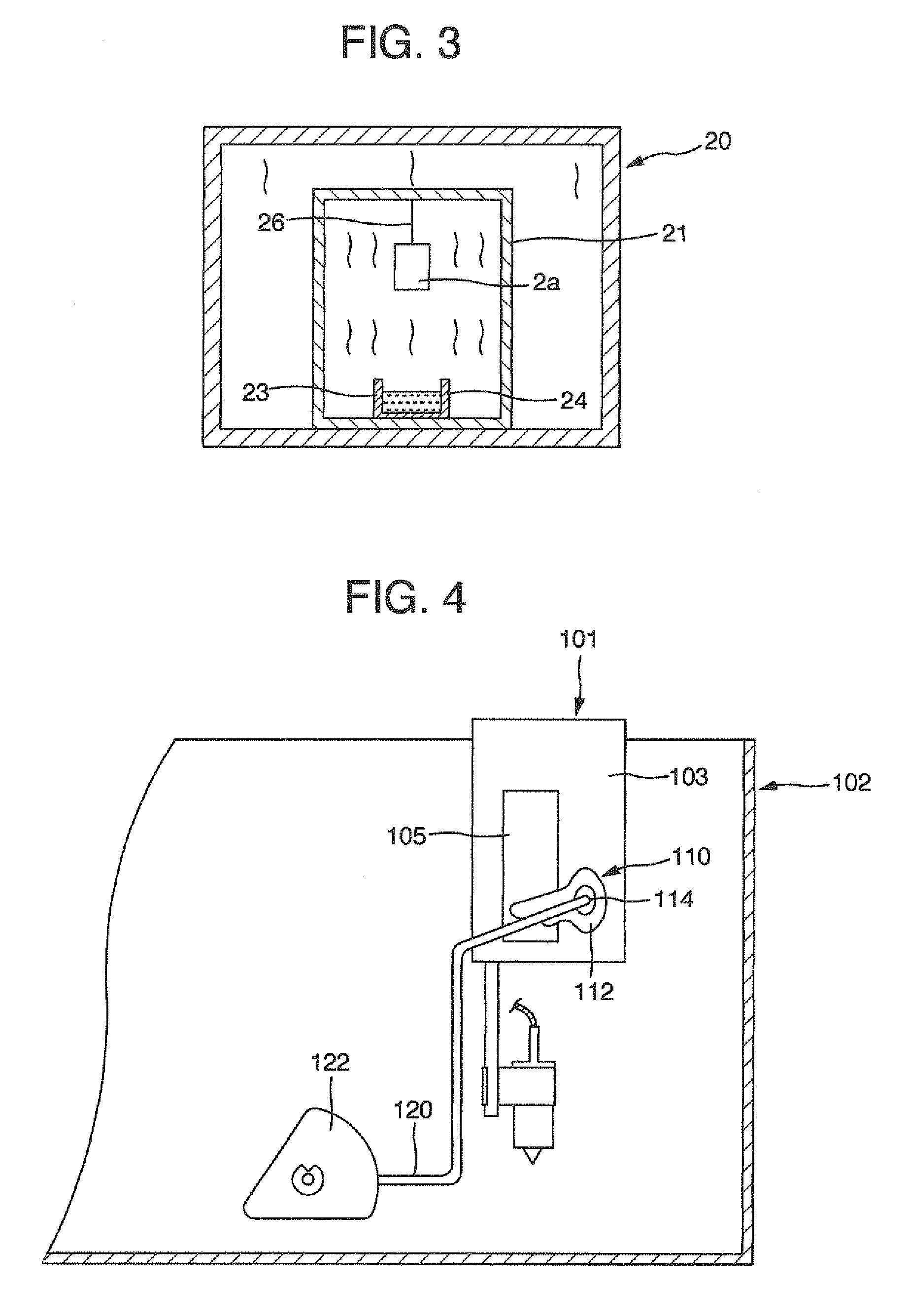

[0026]FIGS. 1 to 3 are views illustrating a first embodiment according to the invention.

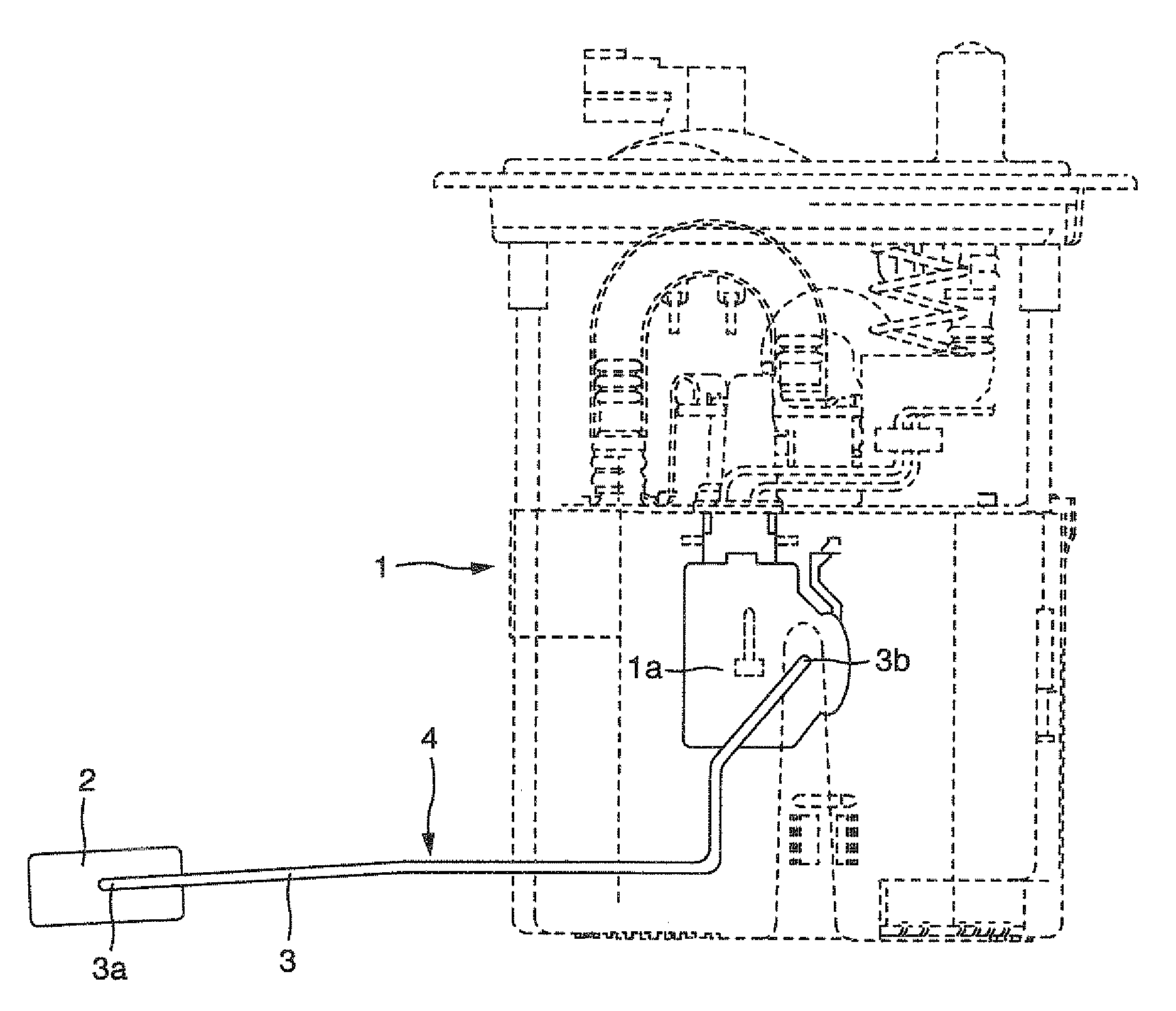

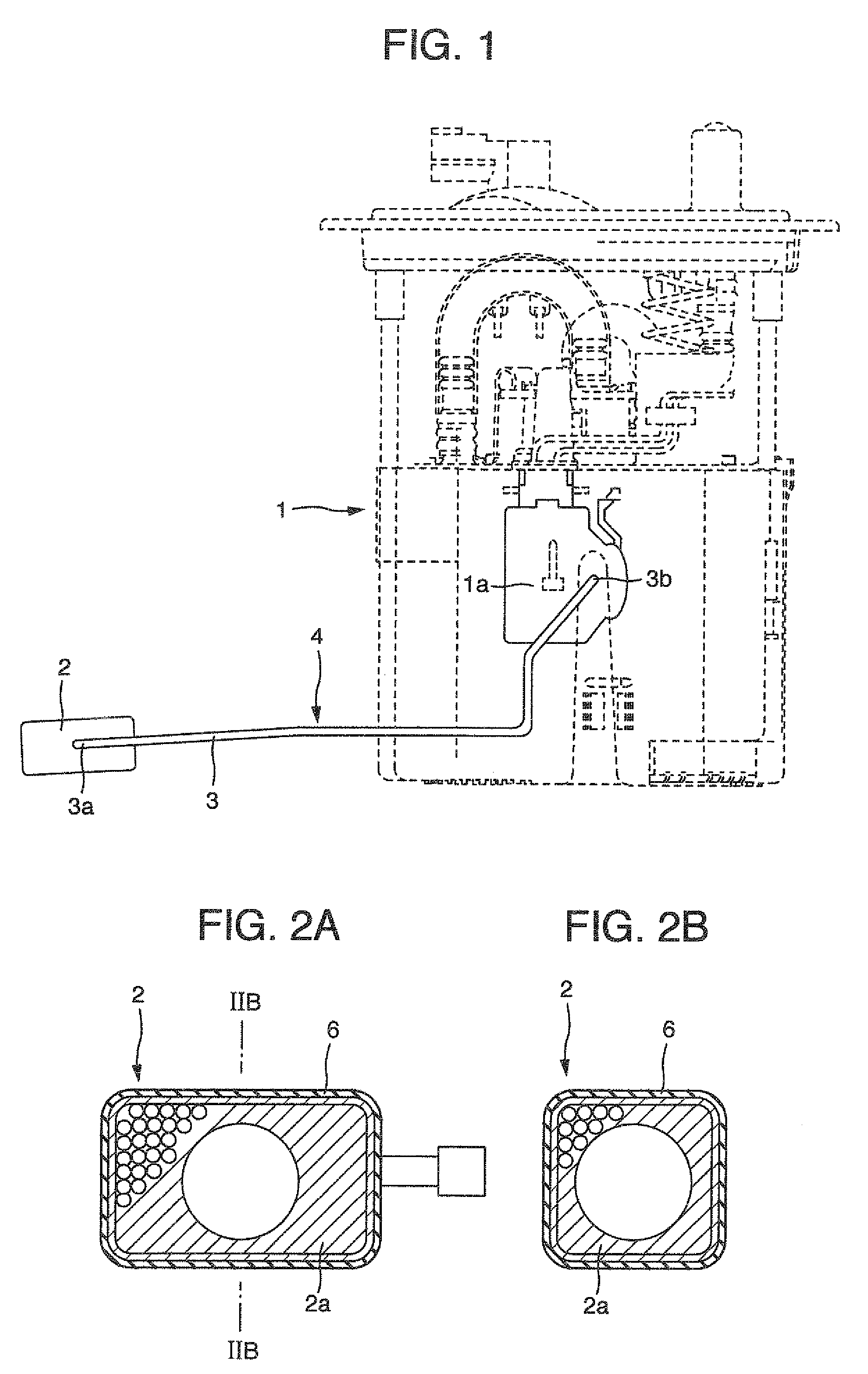

[0027]FIG. 1 is a side view illustrating a liquid surface detecting device 1. The liquid surface detecting device 1 is incorporated in a liquid fuel tank of the vehicle, and is adapted to detect the liquid surface of the fuel in the fuel tank.

[0028]The liquid surface detecting device 1 includes the same members substantially as those of the conventional liquid surface detecting device 101 including a substrate 105, a resistance layer 107, a plurality of electrodes 108, and a sliding ruler 110 composed of a contact plate 112 and a contact point 113 as shown in FIG. 5. These members are disposed in a case la in FIG. 1 so as to performs the same functions as that of the conventional liquid surface detecting device. Since these members are the same as those of the known liquid surface detecting device, these members are omitted in FIG. 1 in order to prevent the depiction thereof from being complicated.

[

embodiment 2

[0051]In the embodiment 1, although the liquid-repellent coating 6 is formed on the whole surface of the movable unit 4, the liquid-repellent coating 6 may be formed on at least one of the float 2 and the arm 3.

[0052]The other configuration is the same as that in the embodiment 1. Even in the second embodiment, the same advantage and effect as those of the embodiment 1 can be exhibited.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap