Central-through-sunken-part-reinforced front longitudinal beam

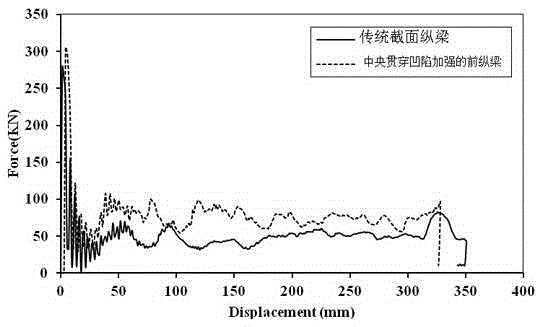

A front longitudinal beam and center technology, applied in the field of automobile body, can solve the problems of reducing design margin, insufficient energy absorption, increasing the difficulty of matching restraint system, etc. Energy absorption requirements, improving the effect of unstable deformation form

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

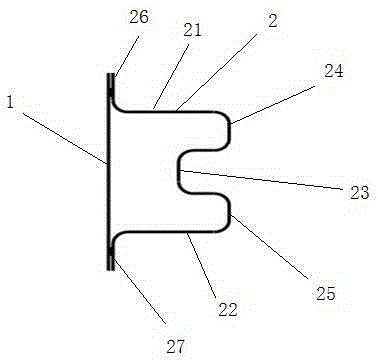

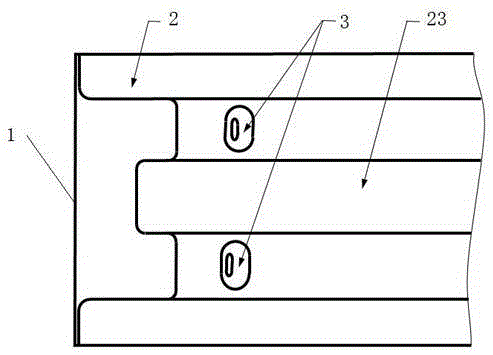

[0019] Figure 1 to Figure 2 The reference numerals in are: main side panel 1; concave side panel 2; first side panel 21; second side panel 22; central concave groove 23; first raised shoulder 24; second raised shoulder 25; The first flange 26; the second flange 27; the induction groove 3.

[0020] Such as Figure 1 to Figure 2 As shown in the figure, a front longitudinal beam reinforced by a central penetrating depression includes a main side panel 1 and a concave side panel 2, the main side panel 1 and the concave side panel 2 form a closed cavity, and the depression The side plate 2 is provided with a central concave groove 23 , and the concave direction of the central concave groove 23 faces the main side plate 1 .

[0021] Such as Figure 1 to Figure 2 As shown, the two ends of the central concave groove 23 are respectively extended an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap