Solid-liquid separating mechanism for food residues

A technology for solid-liquid separation and catering waste, applied in filtration separation, separation methods, fixed filter element filters, etc., can solve the problems of difficulty in dredging, poor effluent quality, easy corrosion, etc., to reduce labor, simple operation and cost. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing:

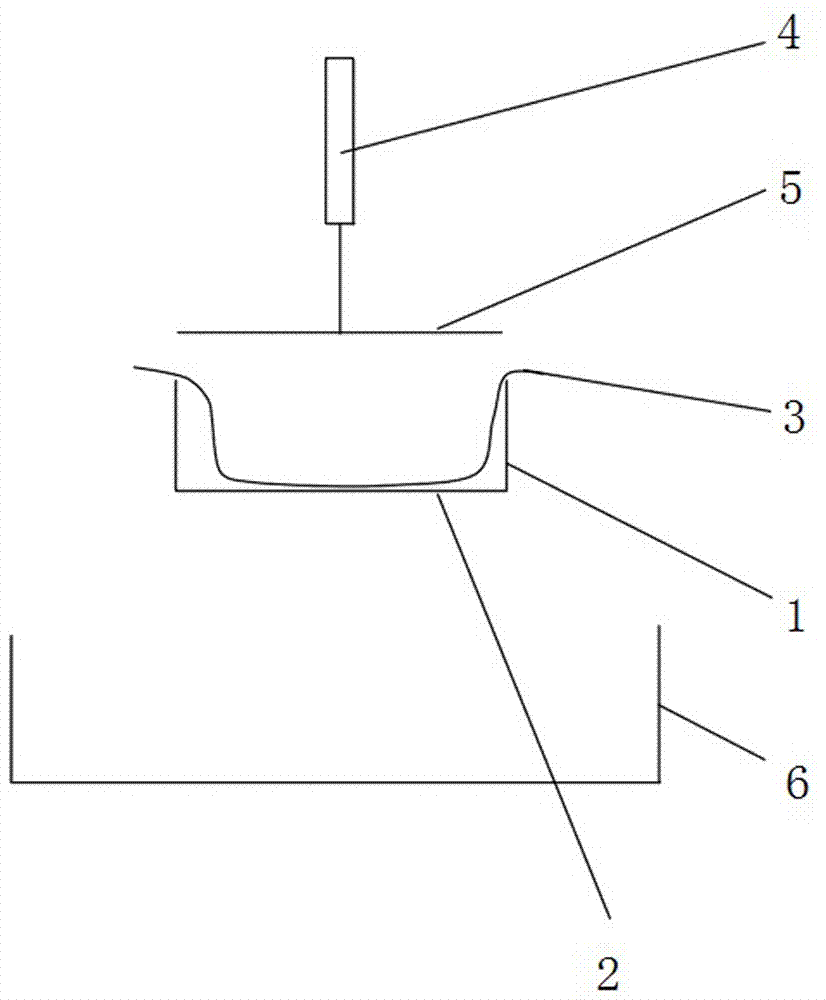

[0018] The food waste solid-liquid separation mechanism is characterized in that it includes a barrel-shaped separation box (1), the bottom of the separation box (1) is a filter plate (2), and a flat draw-line mesh bag is arranged above the filter plate (2) (3), a vertical cylinder (4) is set above the separation box (1), and a horizontal pressure plate (5) is set below the cylinder (4), and the pressure plate (5) is located above the separation box (1), The shape of the pressing plate coincides with the opening of the separation box, the pressing plate can be pressed into the separation box, and a material receiving barrel (6) is arranged below the separation box.

[0019] The aforementioned solid-liquid separation mechanism for food waste is characterized in that the thread-drawing net bag is made of fishing line.

[0020] The aforementioned solid-liquid separation mechanis

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap