Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46 results about "Hot pressing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hot pressing is a high-pressure, low-strain-rate powder metallurgy process for forming of a powder or powder compact at a temperature high enough to induce sintering and creep processes. This is achieved by the simultaneous application of heat and pressure.

Epoxy resin-enhanced laminated insulating profile and preparation method thereof

The invention discloses an epoxy resin-enhanced laminated insulating profile. The epoxy resin-enhanced laminated insulating profile comprises modification polymers and a reinforcing material, wherein the modification polymers include epoxy resin, a curing agent, a promoting agent, a flame retardant, a wetting dispersant and a solvent; the reinforcing material is a fiber material; the components of the modification polymers are mixed to form a modification polymer solution, the reinforcing material is soaked into the modification polymer solution and is finally subjected to hot press molding to form the epoxy resin-enhanced laminated insulating profile. The epoxy resin-enhanced laminated insulating profile is integrated with lightness, flame retardance, corrosion resistance and insulativity, has extremely high mechanical property, excellent electrical insulation property and halogen-free flame retardance, is environmentally friendly, is high in use safety and can be applied to industries and fields including State Grid Corporation of China, new energy resources, energy conservation, consumption reduction and track traffic which have high requirements to material performance and special working conditions and environments.

Owner:SICHUAN D&F ELECTRICAL TECH

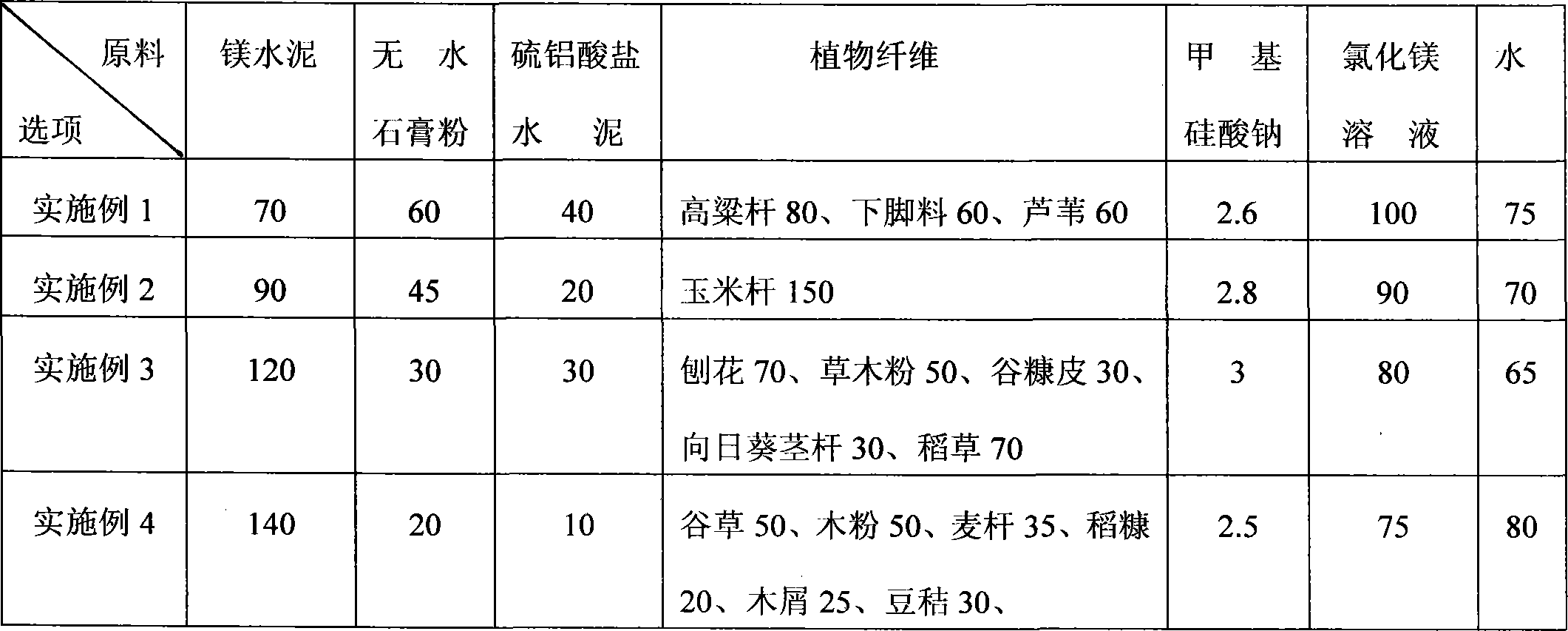

Magnesium-calcium pyrophyte pressed-fibre board and method of manufacturing the same

InactiveCN101172825AObvious beneficial effectGood effectSolid waste managementWeather resistancePlant fibre

Owner:谢涛

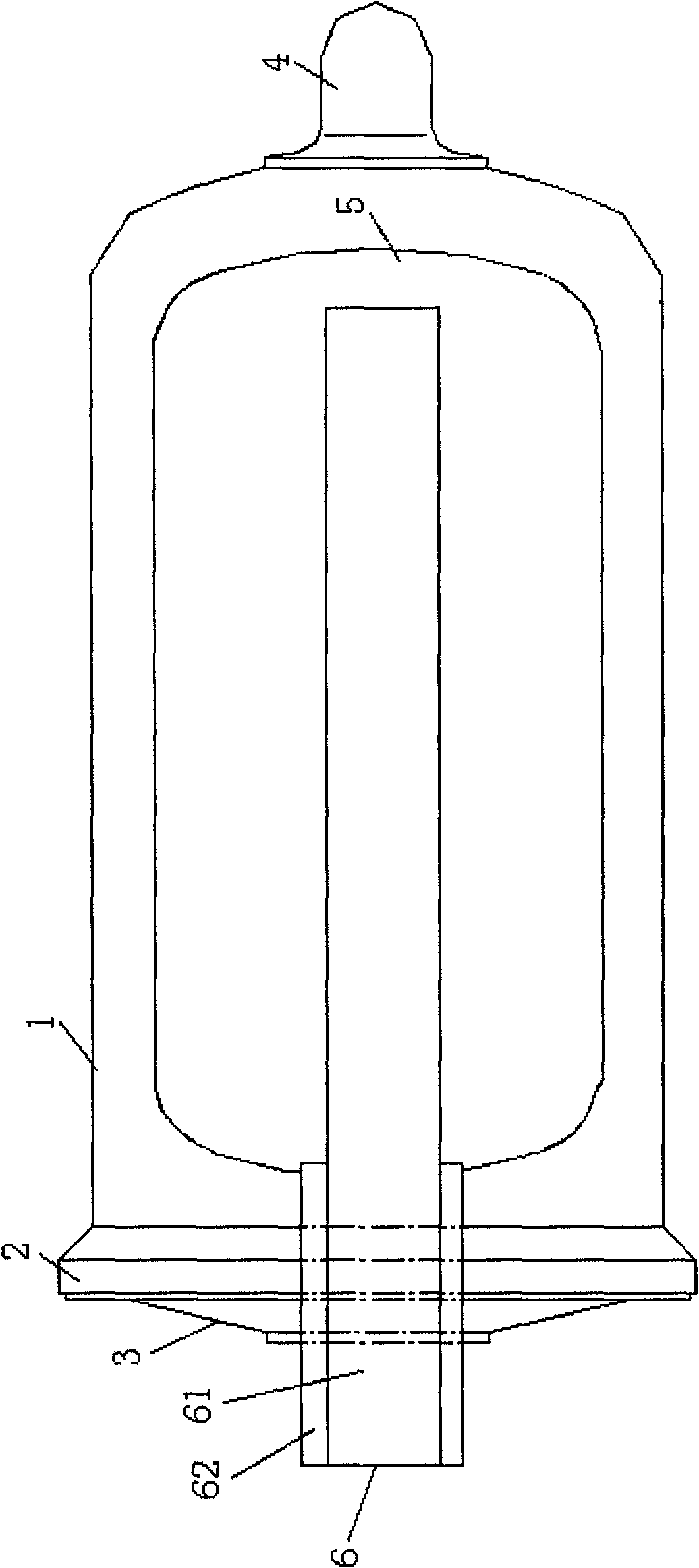

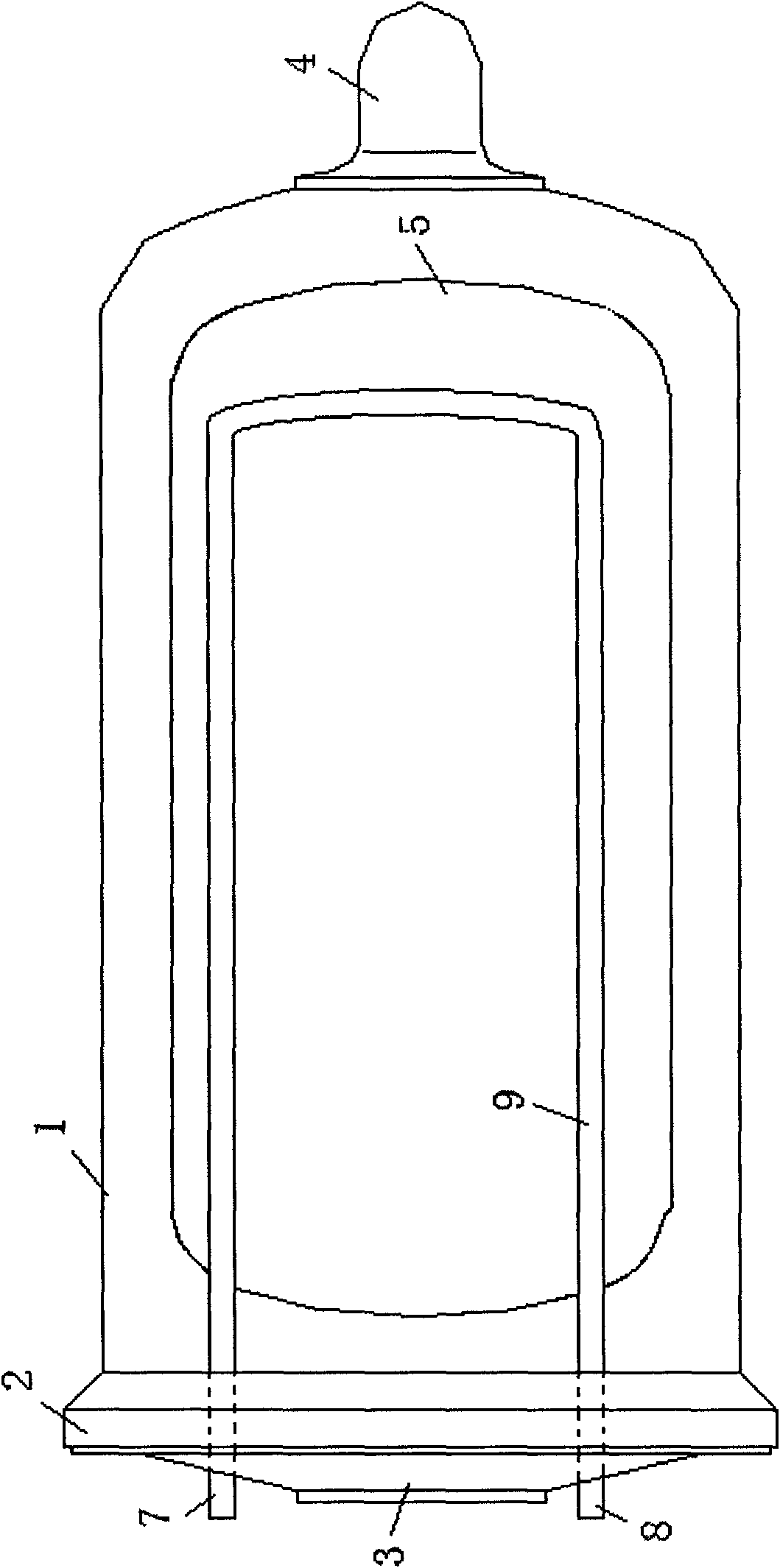

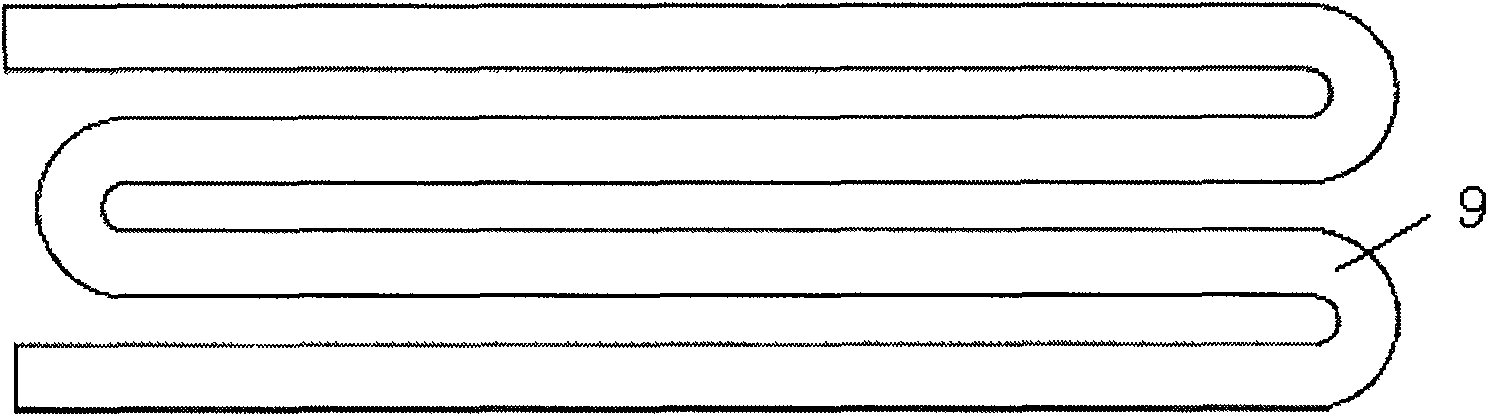

Thermal storage type vacuum tube

InactiveCN101639296AExtended service lifeIncrease the heat exchange areaHeat storage plantsSolar heat devicesSolar waterMetallic materials

Owner:北京桑达太阳能技术有限公司

High-temperature resistant heat insulating material using vermiculite as main raw material and method for manufacturing same

InactiveCN101560087ASolve the strength problemSolve temperature problemsSolid waste managementMixing operation control apparatusPhosphateVolumetric Mass Density

Owner:佛山市冠富贸易有限公司 +1

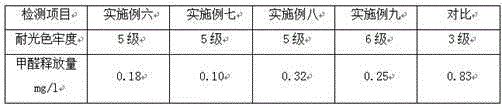

Preparation method of environment-friendly ecological board

ActiveCN105291540AImprove light resistanceReduce irradianceLaminationLamination apparatusHindered amine light stabilizersAdhesive

Owner:DEHUA TB NEW DECORATION MATERIAL CO LTD

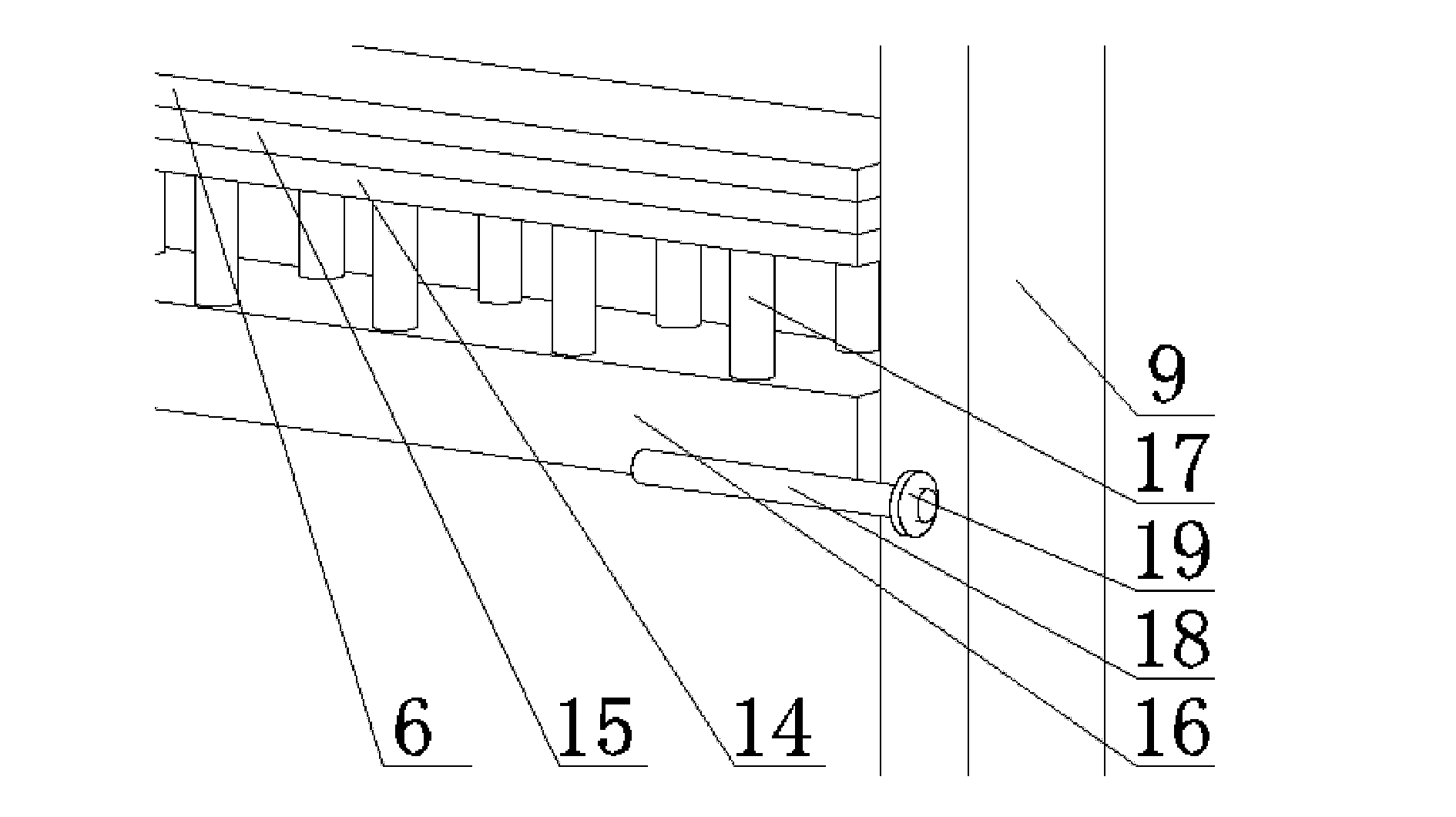

Flanging hot-die apparatus for automobile plafond

The invention relates to a vehicle ceiling flanged edge hot die device which is applied to the hot pressing technique for front edges and back edges of a ceiling and flanged edges around a sky light of a vehicle. According to the technical proposal provided by the invention, the device comprises a lifting cylinder which is fixedly arranged on a stand; a piston rod of the lifting cylinder is extended upward; the top end part of the piston rod of the lifting cylinder is fixedly provided with a shift cylinder, a piston rod of the shift cylinder is transversely extended; the end parts of the piston rod of the shift cylinder is fixedly connected with a connecting plate vertically extended upward; the top end part of the connecting part is fixedly connected with a pressing die head, and a working face of the pressing die head which is arranged downward is the same as the shape of the ceiling surface. The device has the advantages of simple, compact and reasonable structure, suitability for various products, high flexibility, high automaticity, guarantee of smooth flanged edges around the vehicle ceiling, accurate positioning of a work piece, quick process rhythm, high production efficiency, reduction of the labor intensity of a worker and manufacturing cost of the product and high product quality.

Owner:WUXI GISSING AUTO PARTS CO LTD

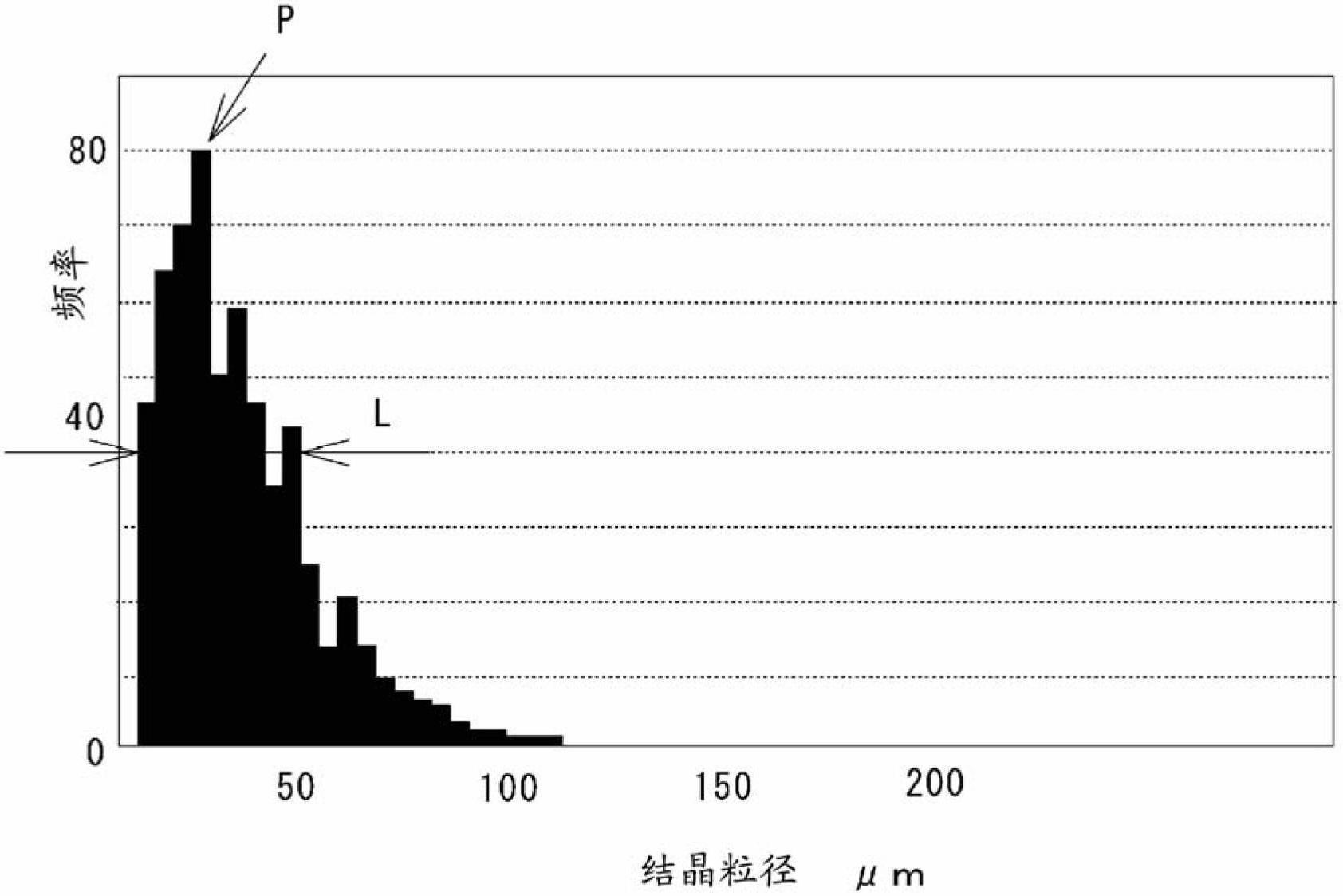

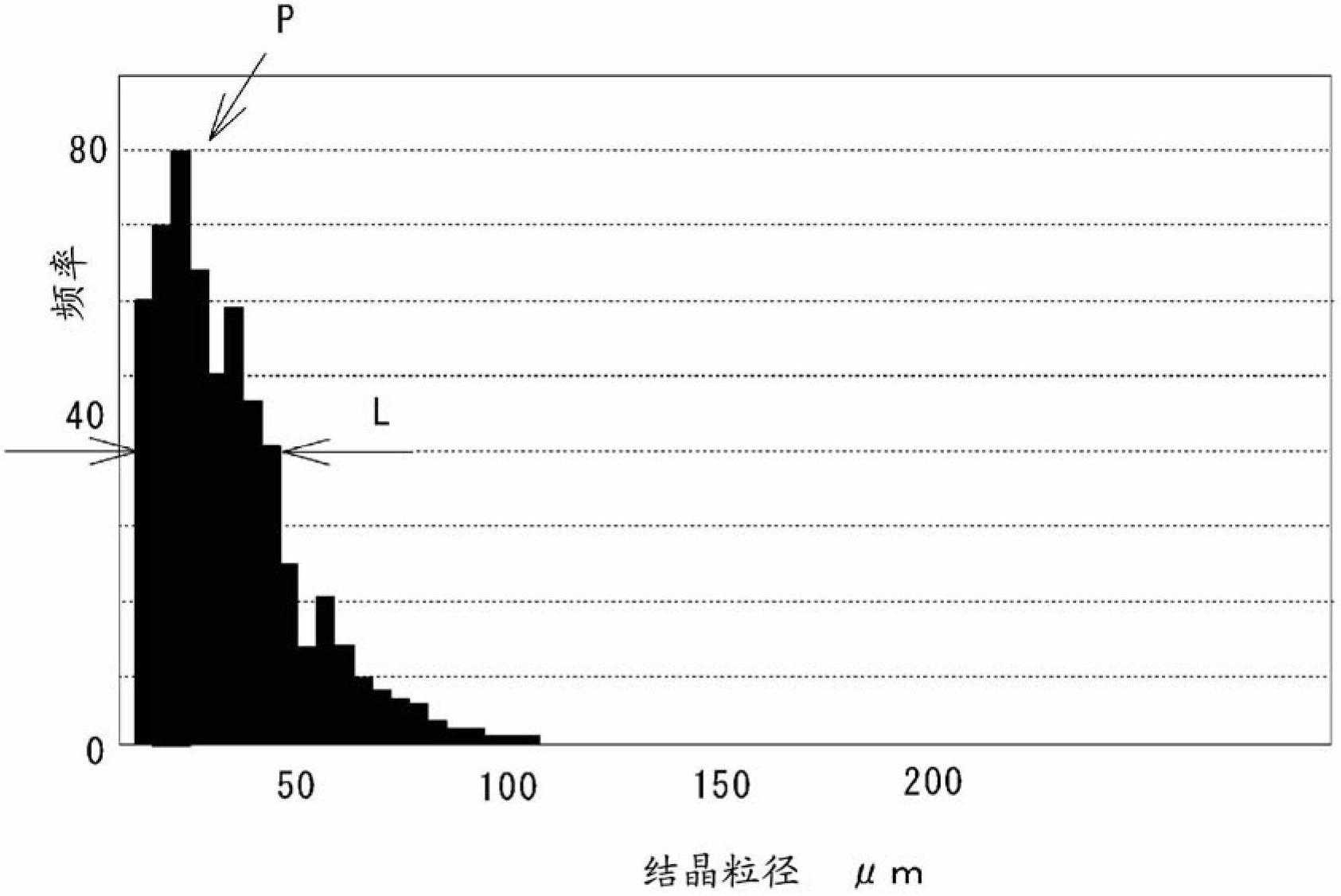

Manufacturing method of pure copper plates, and pure copper plate

ActiveCN102652182AFine uniform grainsEasy to processVacuum evaporation coatingSputtering coatingIngotCopper

Owner:MITSUBISHI SHINDOH CO LTD +1

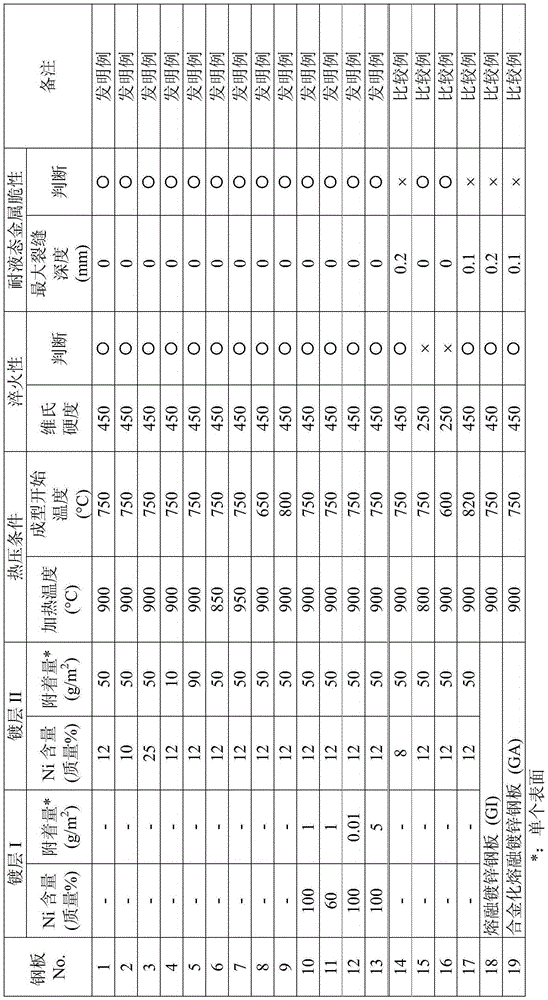

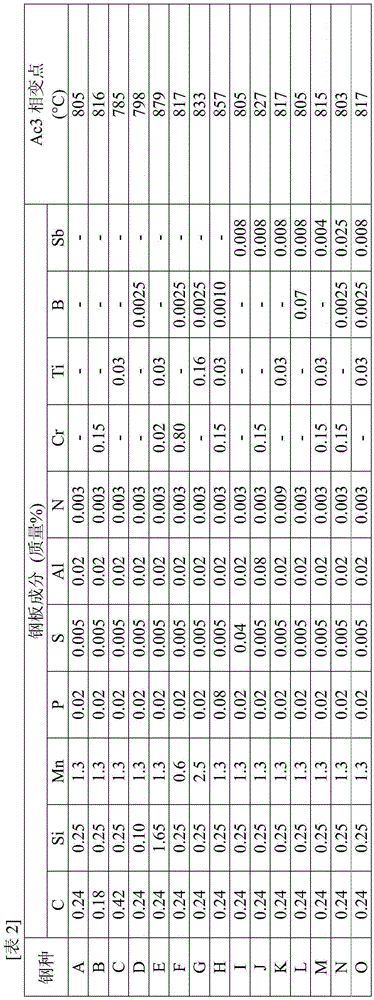

Method of manufacturing hot press member

InactiveCN105339106AImprove brittlenessImprove corrosion resistanceFurnace typesHeat treatment furnacesLiquid metalZinc

Owner:JFE STEEL CORP

Servo-motor-driven dual-hot-pressing plant fiber molding method and machine

The invention relates to a method and device to manufacture plant fiber products containing pulp by means of molding and is intended to provide a full-automatic manufacture method and device of plantfiber molded products, which have good operation stability and higher yield. According to the technical scheme, a servo-motor-driven dual-hot-pressing plant fiber molding method comprises the steps of1) allowing a suction filter forming device to manufacture a wet blank with slurry and transfer the wet blank to a left hot-pressing lower mold 3c or right hot-pressing lower mold 4c of a wet blank transfer station 7.1; 2) allowing the wet blank transfer station 7.1 to receive the wet blank to the left hot-pressing lower mold, and carrying the wet blank to horizontally move along a hot-pressing lower mold horizontal rail 8 to a left hot-pressing station 3.1; allowing a left hot-pressing upper mold 3a to move down and to be closed, and performing hot-pressing and drying on the wet blank to shape; 3) allowing the left hot-pressing upper mold 3a to move up and separate from the left hot-pressing lower mold, and taking out a dried product; allowing a right hot-pressing upper mold 4a to move up and separate from the right hot-pressing lower mold, and taking out the dried product.

Owner:郑天波

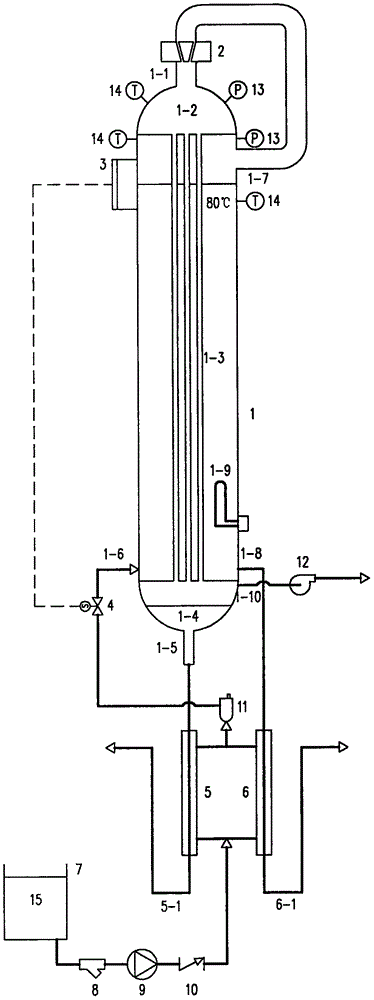

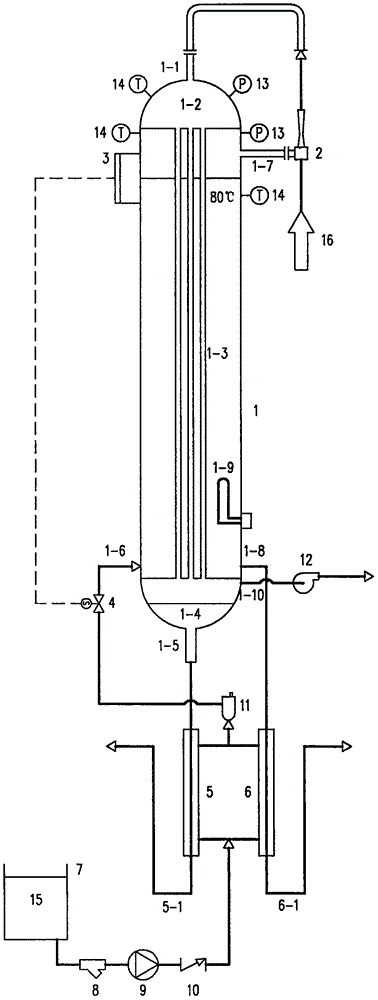

Siphon circulation, contraflow heat regeneration and vapor compression distillation device

InactiveCN105920863ASave investmentSave power consumptionEvaporation with vapour compressionSeawater treatmentSiphonWater vapor

Owner:侴乔力 +1

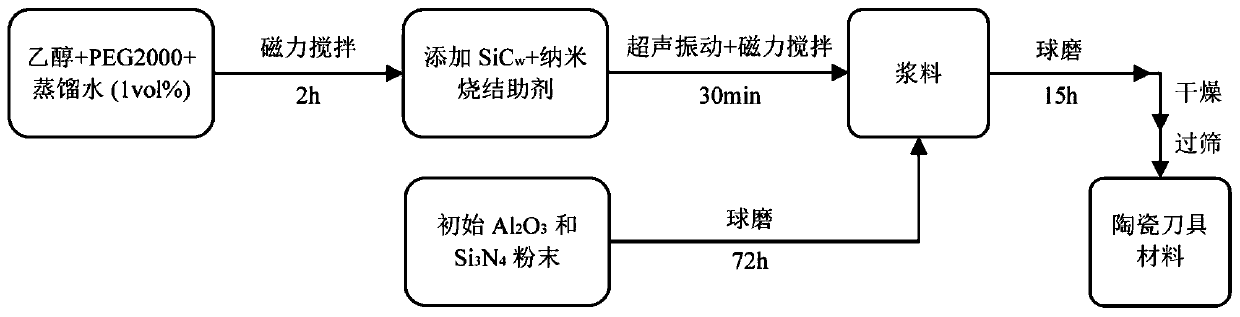

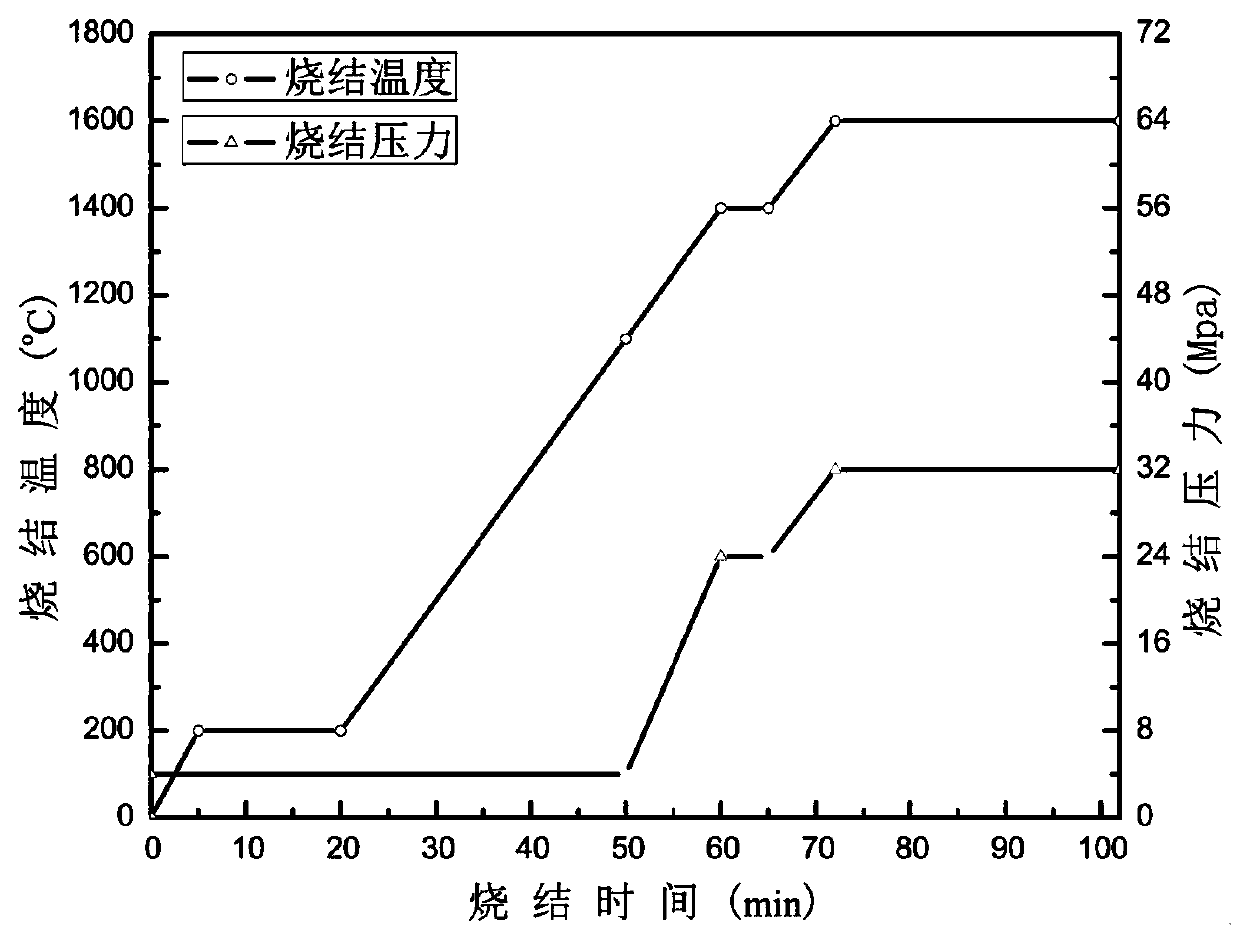

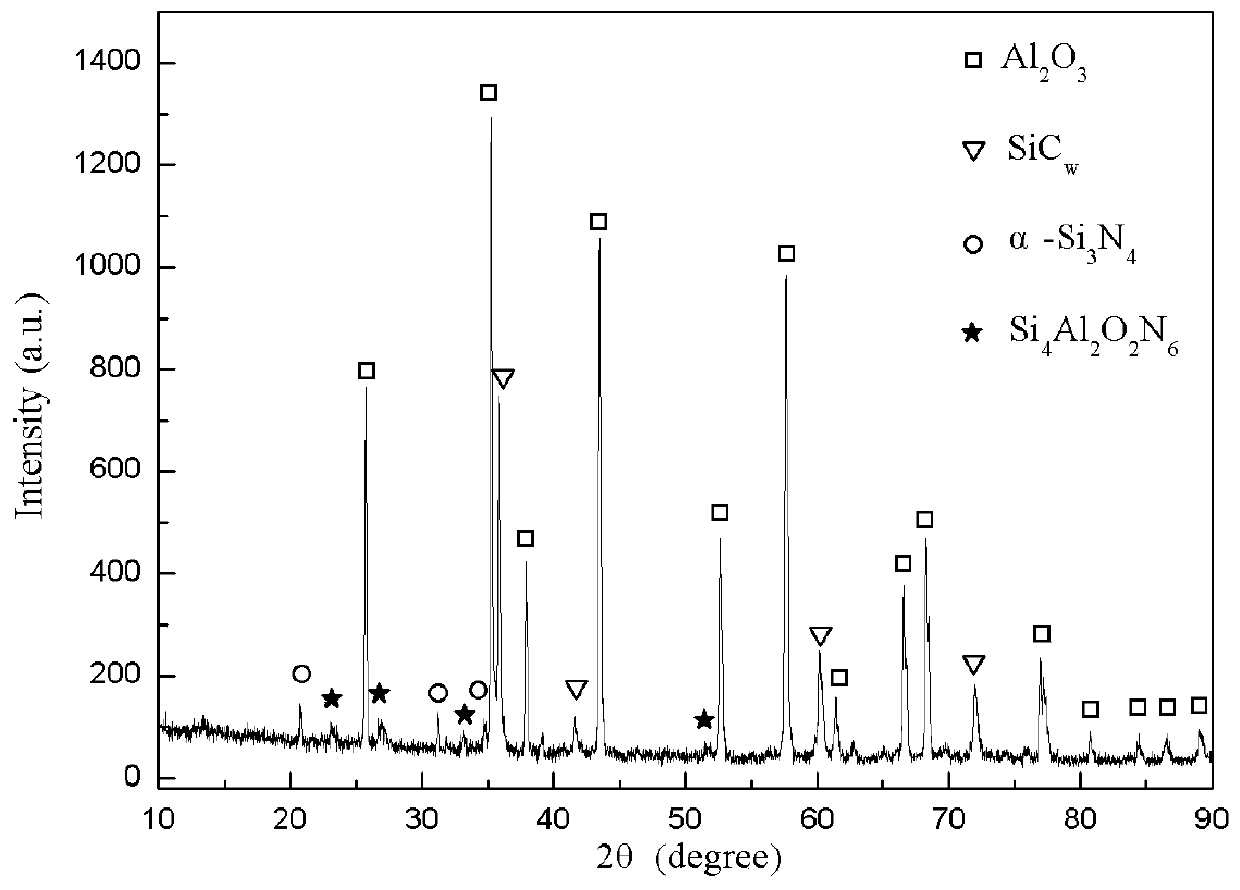

SiC whisker synergistic silicon nitride particle toughened alumina-based ceramic cutter material and preparation process thereof

ActiveCN110818395AImprove corrosion resistanceHigh processing compatibilityComposite ceramicCeramic knife

Owner:SHANDONG UNIV

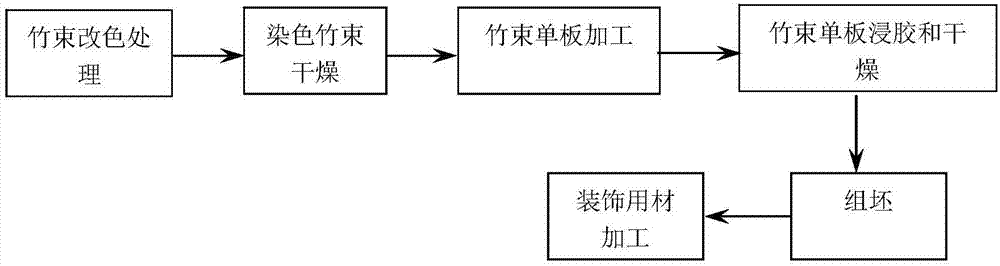

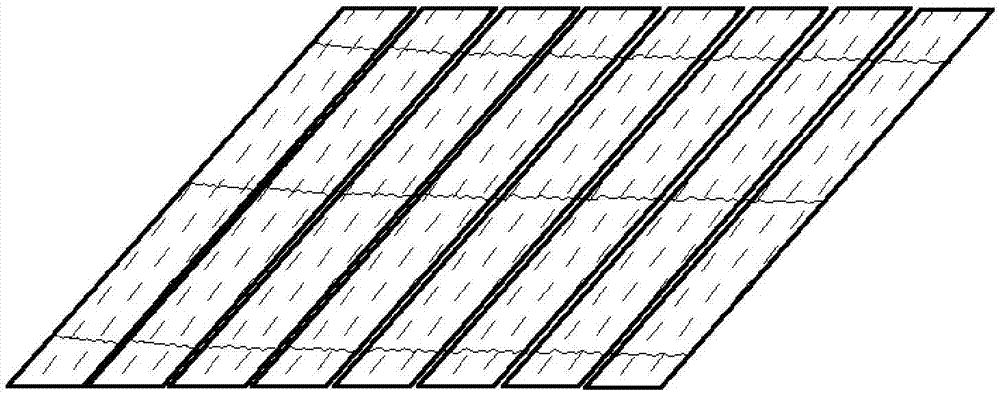

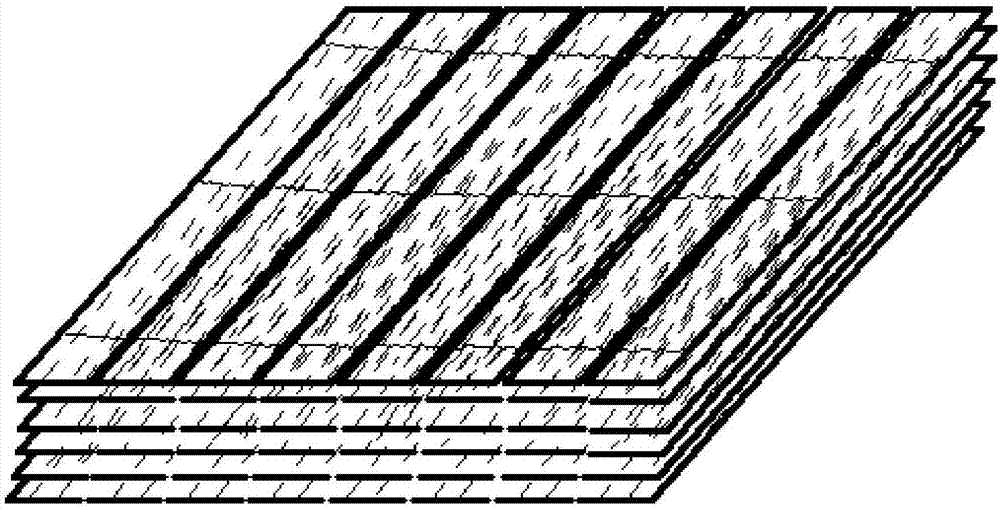

Manufacturing method of bamboo-based heterochromous laminated decorative plate

ActiveCN106926330AVariety of colorsFacilitate continuous productionOther plywood/veneer working apparatusWood treatment detailsChange colorSingle plate

Owner:国家林业局竹子研究开发中心

Manufacturing method of rare earth metal PrNd rotary target

InactiveCN108251802AImprove magnetic propertiesReduce manufacturing costVacuum evaporation coatingSputtering coatingRare-earth elementGraphite

Owner:BAOTOU RES INST OF RARE EARTHS +1

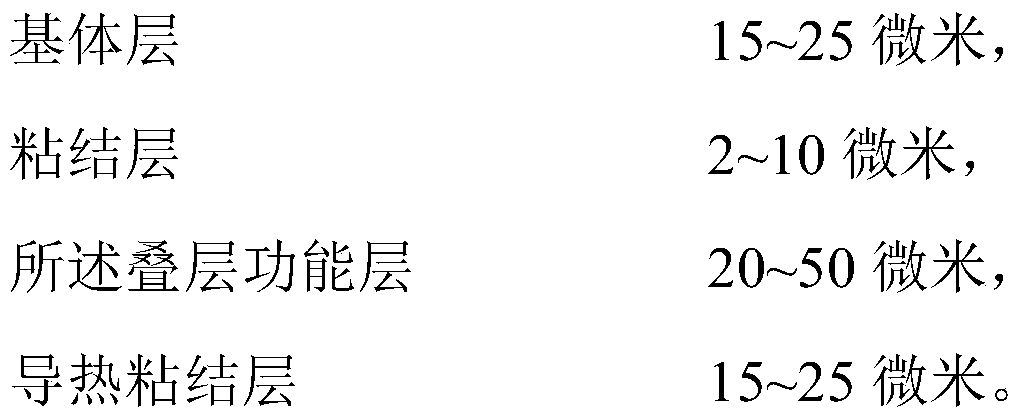

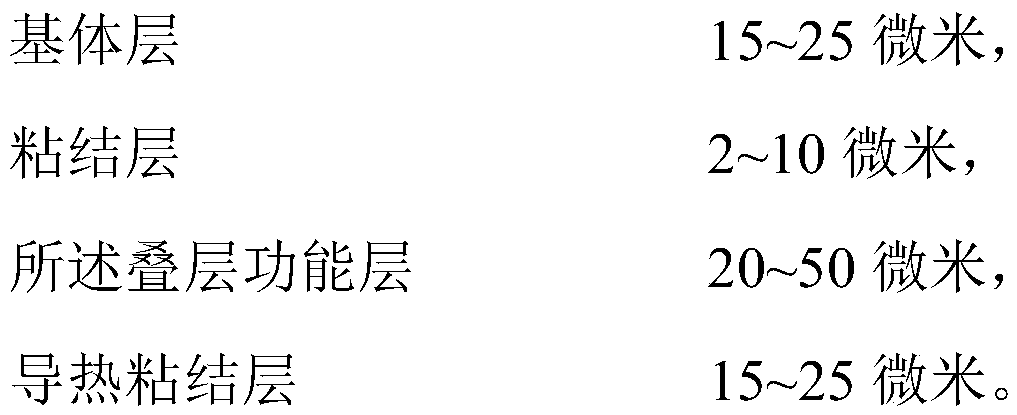

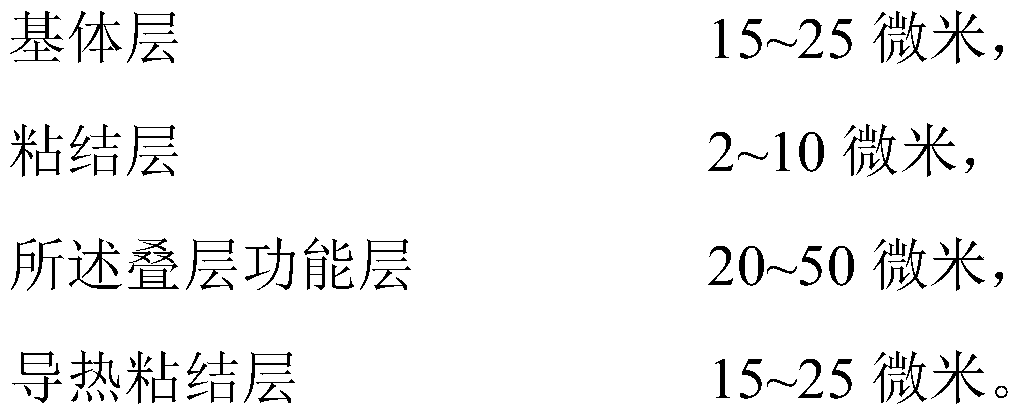

Electromagnetic shielding heat dissipation film and preparation method and application thereof

InactiveCN110602934AHigh thermal conductivityImprove conductivityMagnetic/electric field screeningSynthetic resin layered productsAdhesiveCarbon nanotube

Owner:SHENZHEN XIWAN TECH CO LTD

Novel neodymium-doped near-infrared fluorescent material and preparation method thereof

InactiveCN104130775AGood physical and chemical stabilityGood dispersionLuminescent compositionsPhysical chemistryLight excitation

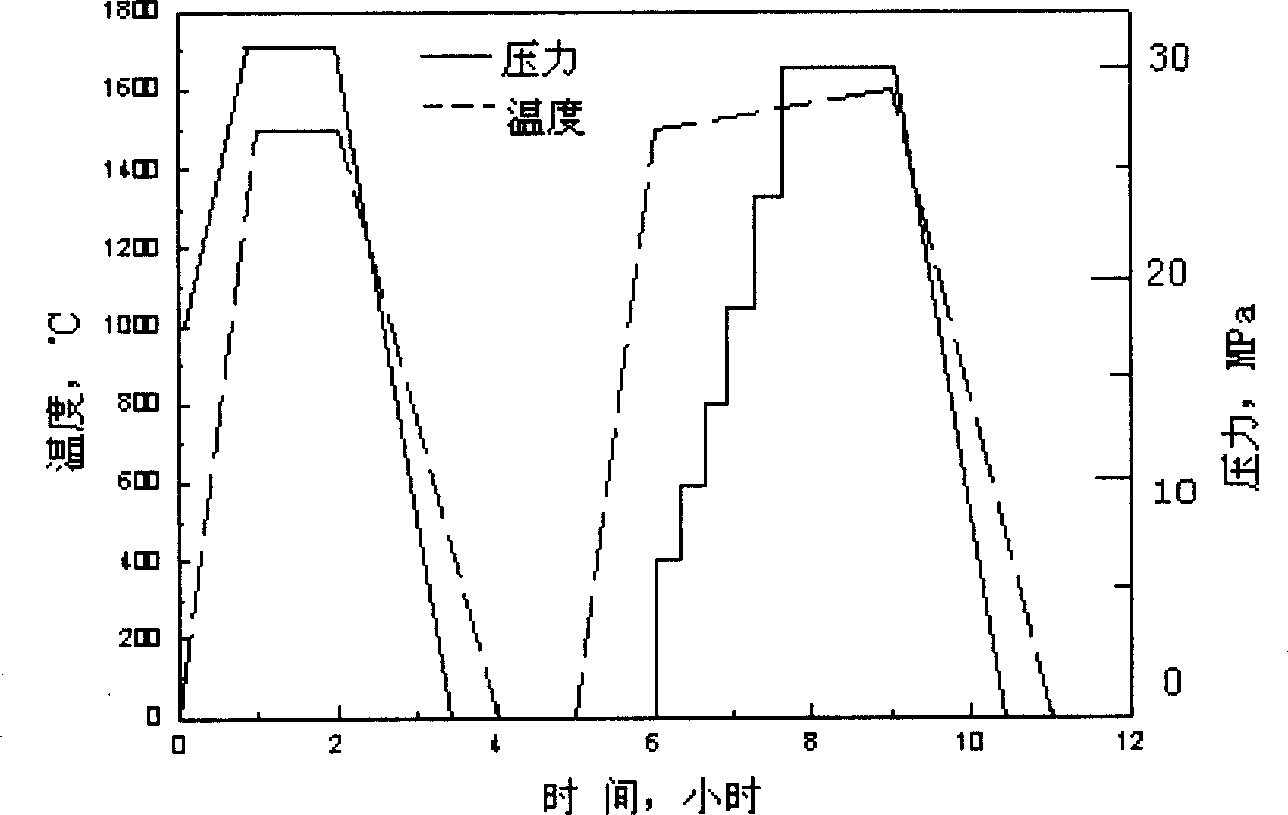

The invention discloses a novel neodymium-doped near-infrared fluorescent material and a preparation method thereof. The material is mainly characterized in that the composition is X1SiO2-2Al2O3-3Na2O-4Nd2O3 (X1=20-30%, X2=5-10%, X3=2-5%, and X4=1-10%); and the preparation method of the material comprises: (1) uniformly mixing zeolite and neodymium nitrate, heating to 500-600 DEG C, and keeping warm for 2-5 h, so as to obtain a neodymium-doped zeolite precursor; (2) performing hot-pressing forming on the neodymium-doped zeolite precursor, controlling the pressure intensity to be 10 MPa-3 GPa and the heating temperature to be 700 DEG C-1200 DEG C, and keeping the high temperature for 1 hour or more; and (3) naturally cooling in the furnace. The rare-earth fluorescent material with stable physical and chemical properties, which is obtained by using the method, is characterized in that fluorescence is generated at 1064 nm when 582 nm yellow light is employed for exciting the glass, the transmission scope is 300-400 mu s, and the material is widely applicable to fields such as substance analysis, infrared detection, optical communication and the like.

Owner:CHONGQING LEADING NEW MATERIAL CO LTD

Hot pressing edge banding machine and edging banding method thereof

InactiveCN102350851AImprove securityImprove work efficiencyLaminationLamination apparatusEngineeringWorkbench

Owner:北京三木易和科技有限公司

Self-lubricating hard alloy wire drawing die and preparation method thereof

InactiveCN109226301AImprove drawing process qualityAchieve self-lubricating effectDrawing diesManufacturing technologyHigh energy

Owner:SOUTHEAST UNIV

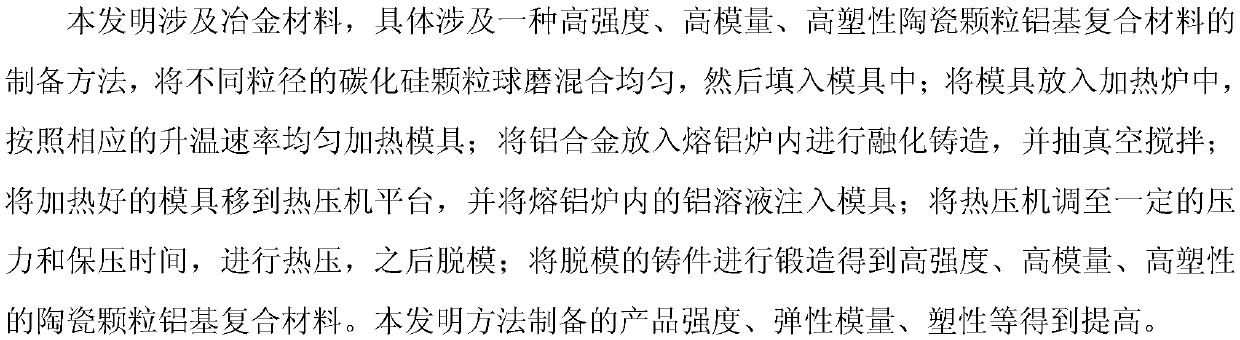

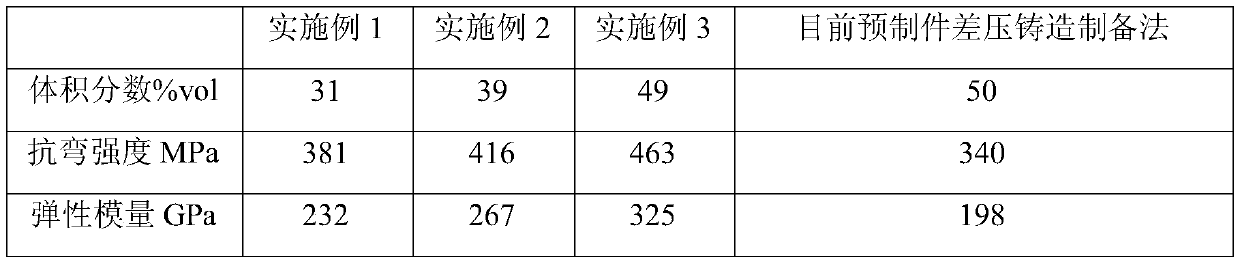

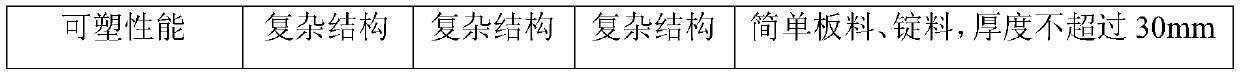

Preparation method of high strength, high modulus and high plasticity ceramic particle aluminum-based composite material

ActiveCN110066937AMeet the technical requirements of aerospaceSimple processHeating furnaceUltimate tensile strength

Owner:西安创正新材料有限公司

Shaping method of nanometer bioceramic artificial joint

Owner:HARBIN MEDICAL UNIVERSITY

An adhesive used for moisture-proof fiberboards

InactiveCN106554737AShort curing timeImprove waterproof and water resistanceNon-macromolecular adhesive additivesStarch adhesivesAdhesiveMoisture

Owner:SHIFANG MIDEE WOOD IND

Manufacturing method of titanium-steel composite board and titanium-steel inner container cup

PendingCN112705570AReduce usageCorrosion resistanceFurnace typesMetal rolling arrangementsExplosive claddingComposite slab

Owner:沈州

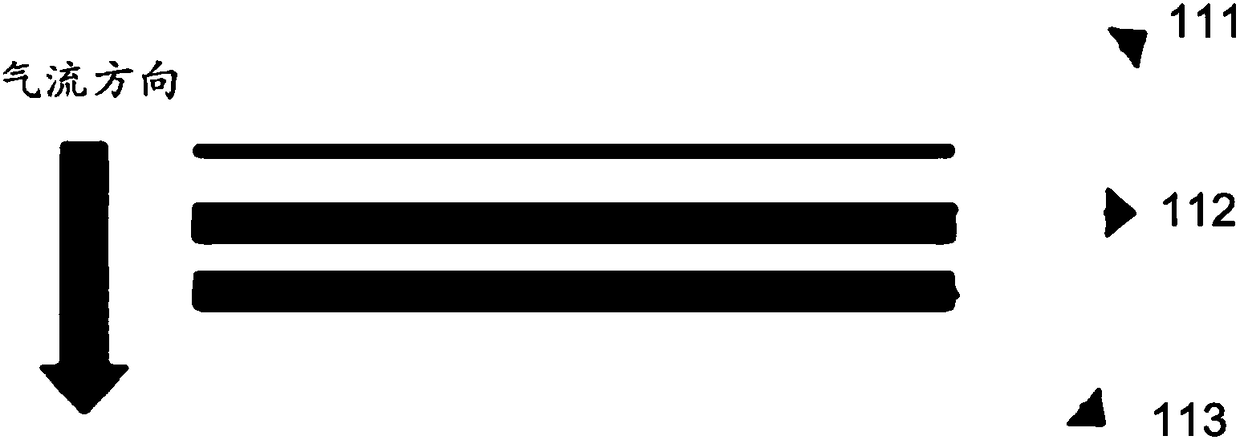

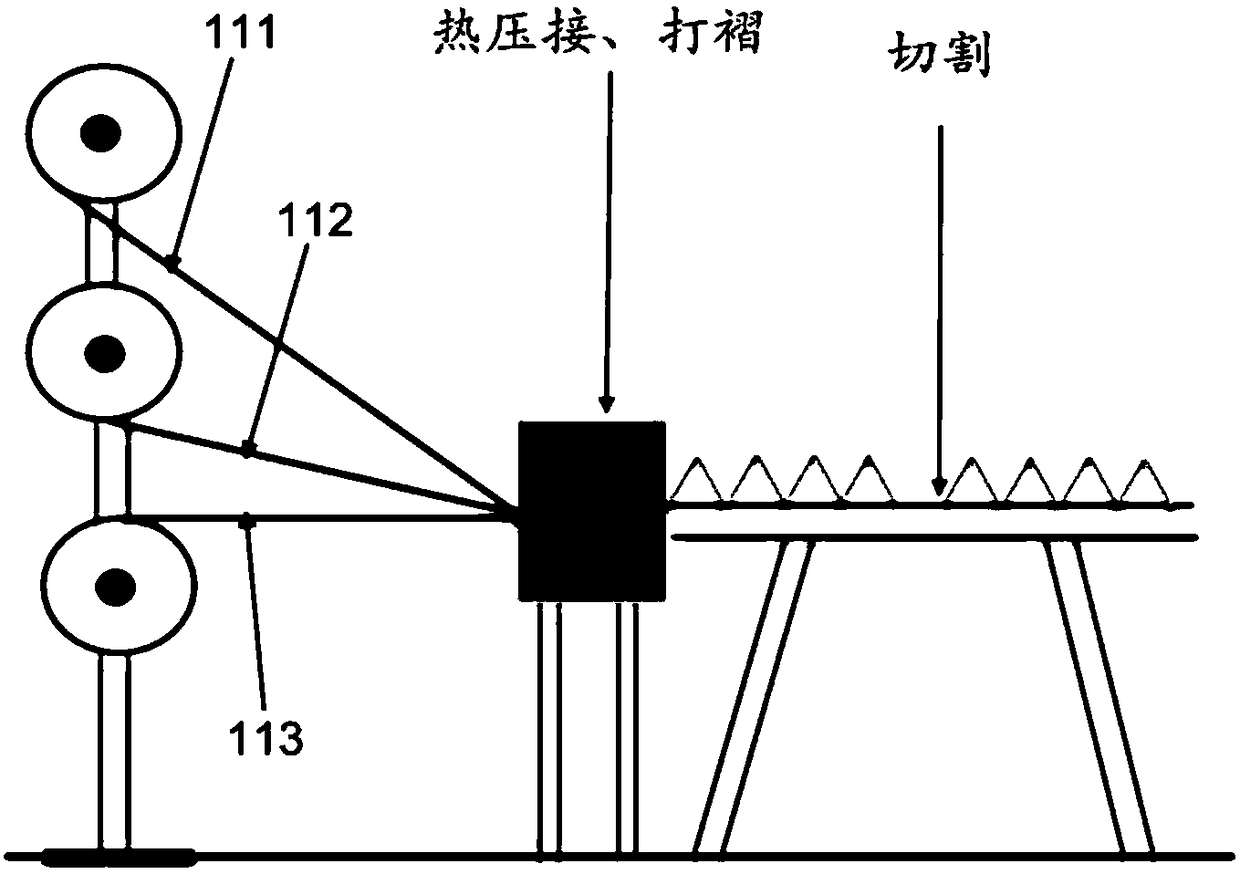

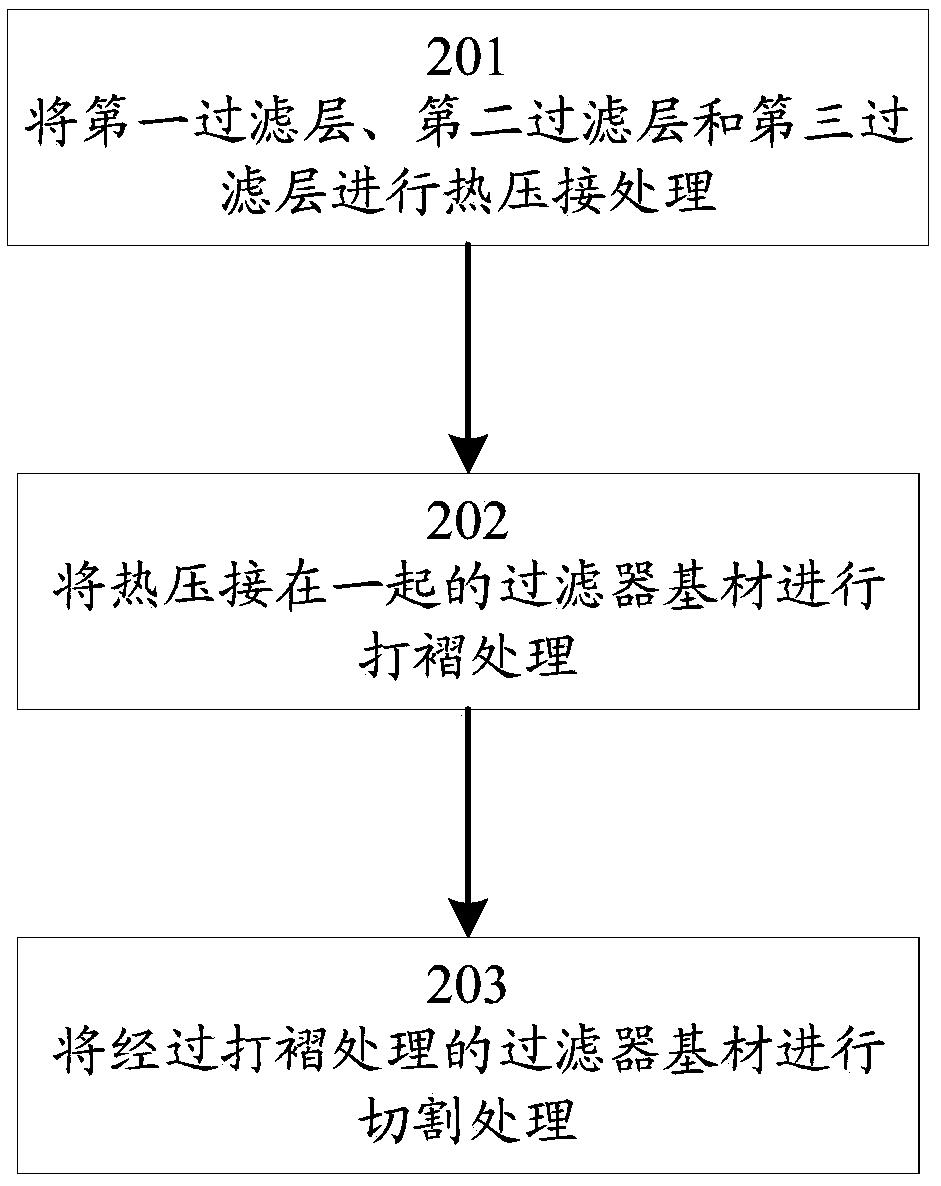

Automobile air conditioner filter

InactiveCN108211554AWide range of specific surface areaSmall filter resistanceGas treatmentDispersed particle filtrationFiberCarbon fibers

Owner:VALEO AUTOMOTIVE AIR CONDITIONING HUBEI CO LTD

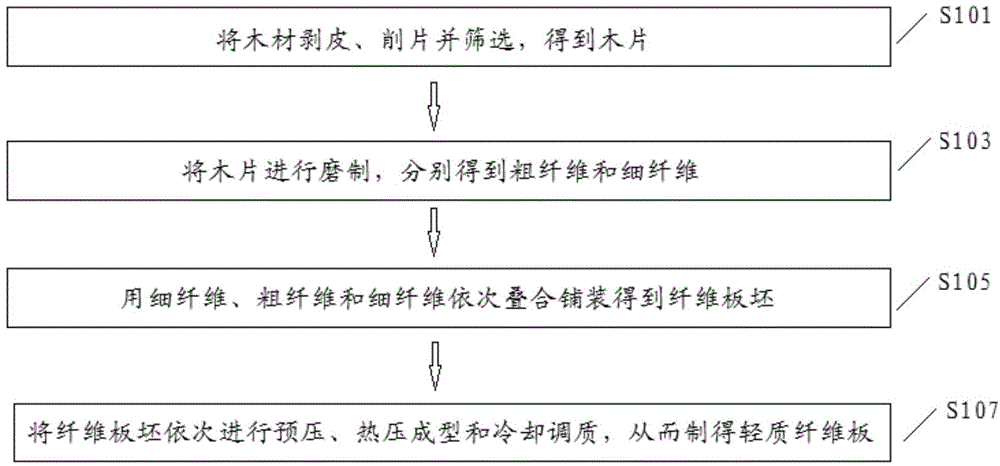

Method for manufacturing light-weight fiberboard

InactiveCN104669394AImprove mechanical propertiesLow densityWood working apparatusFlat articlesFiberSurface layer

Owner:CHINA FOMA GROUP

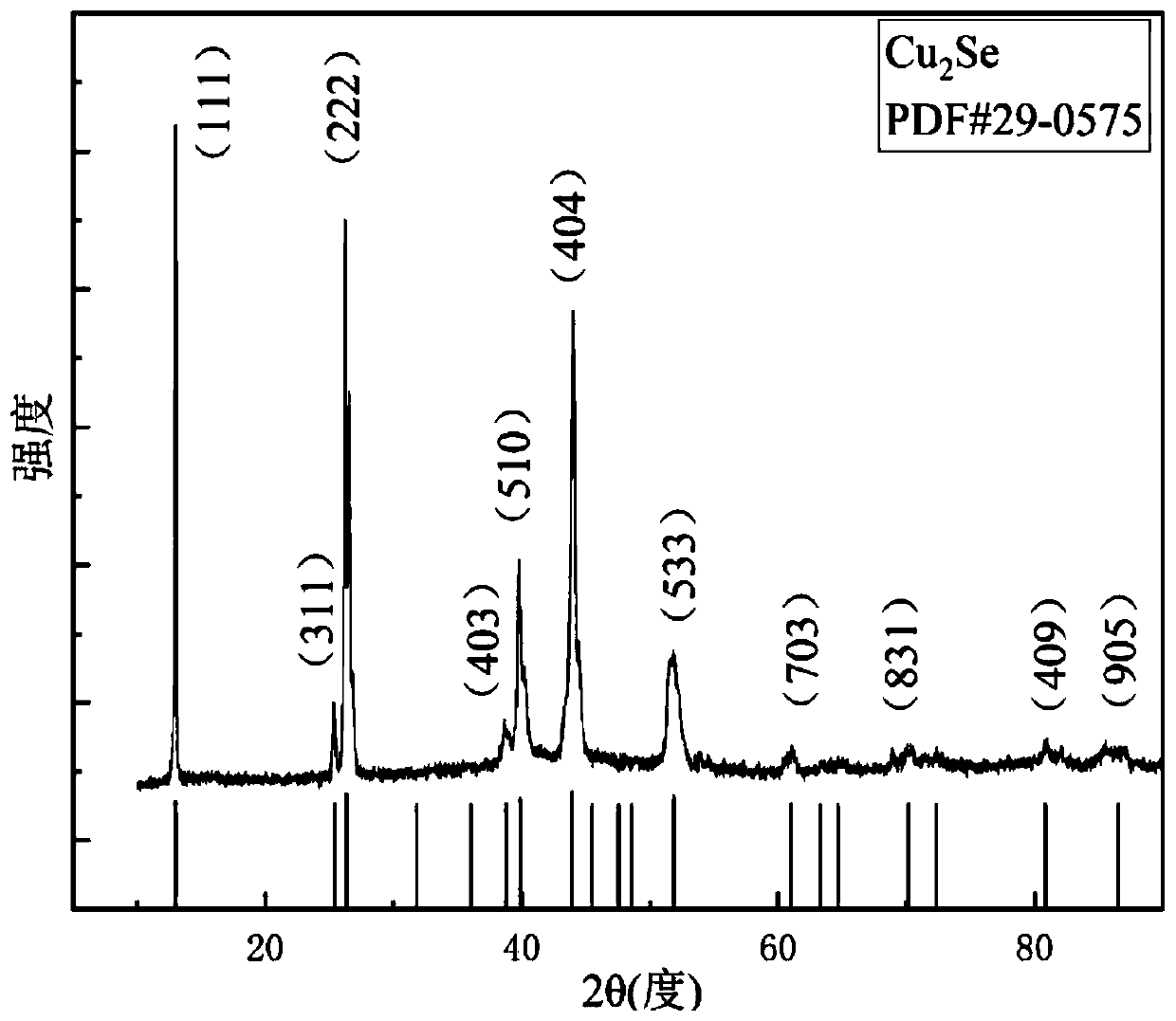

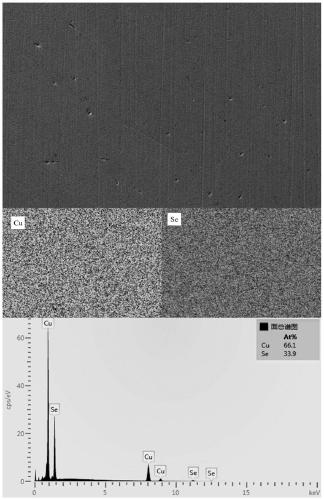

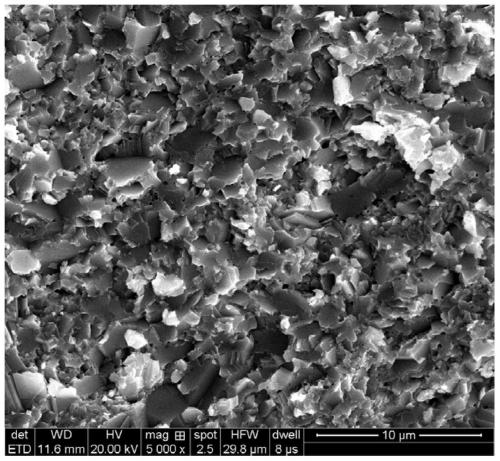

Method for preparing Cu2Se thermoelectric material

PendingCN111446357AThermoelectric device manufacture/treatmentMetal selenides/telluridesEnergy consumptionHot pressing

Owner:UNIV OF JINAN

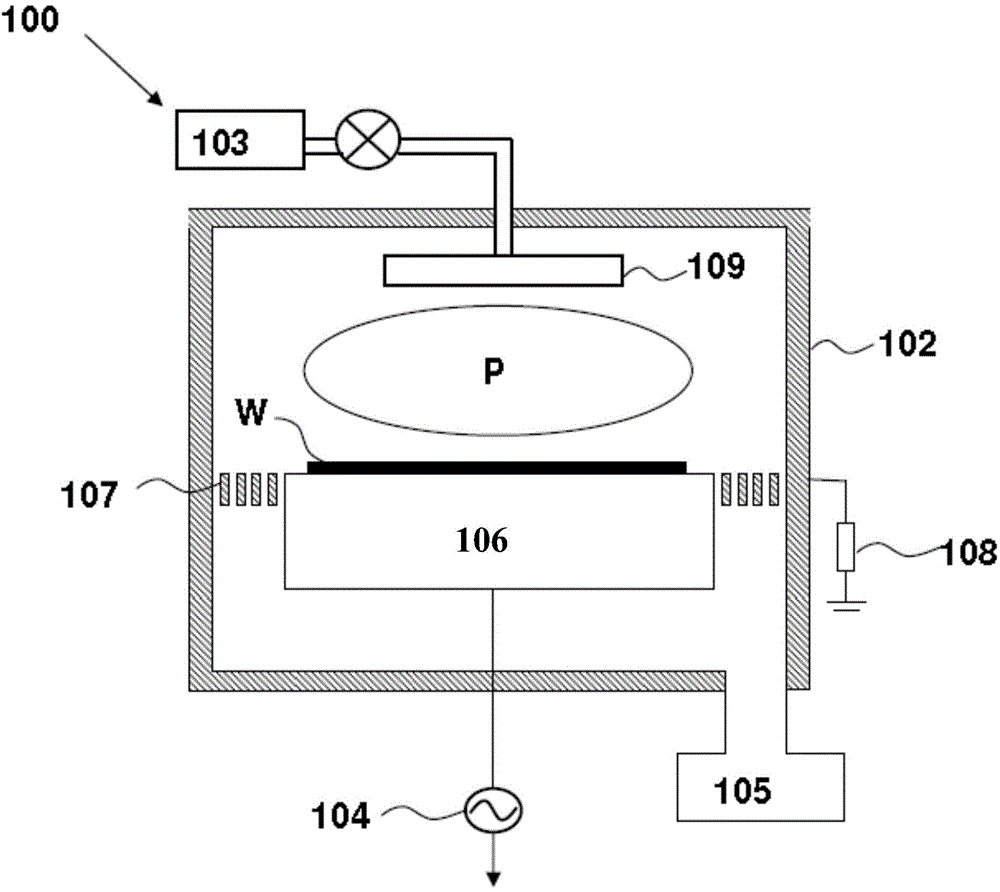

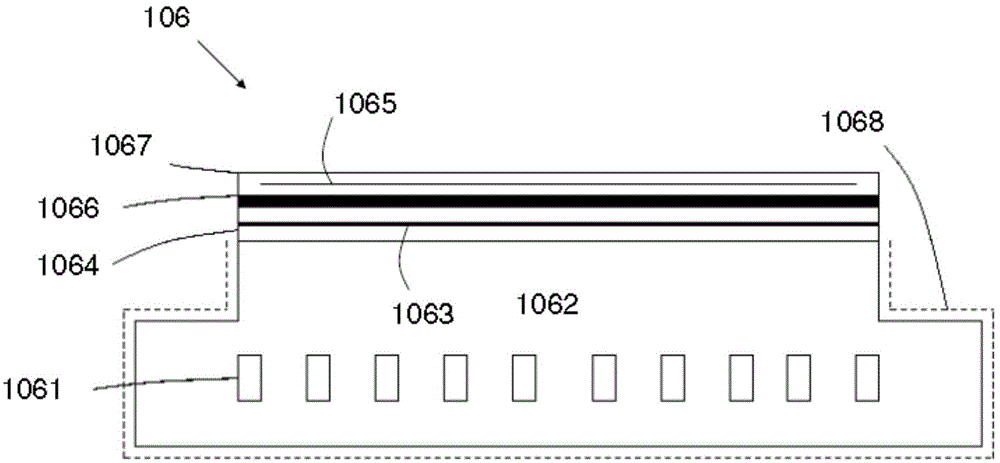

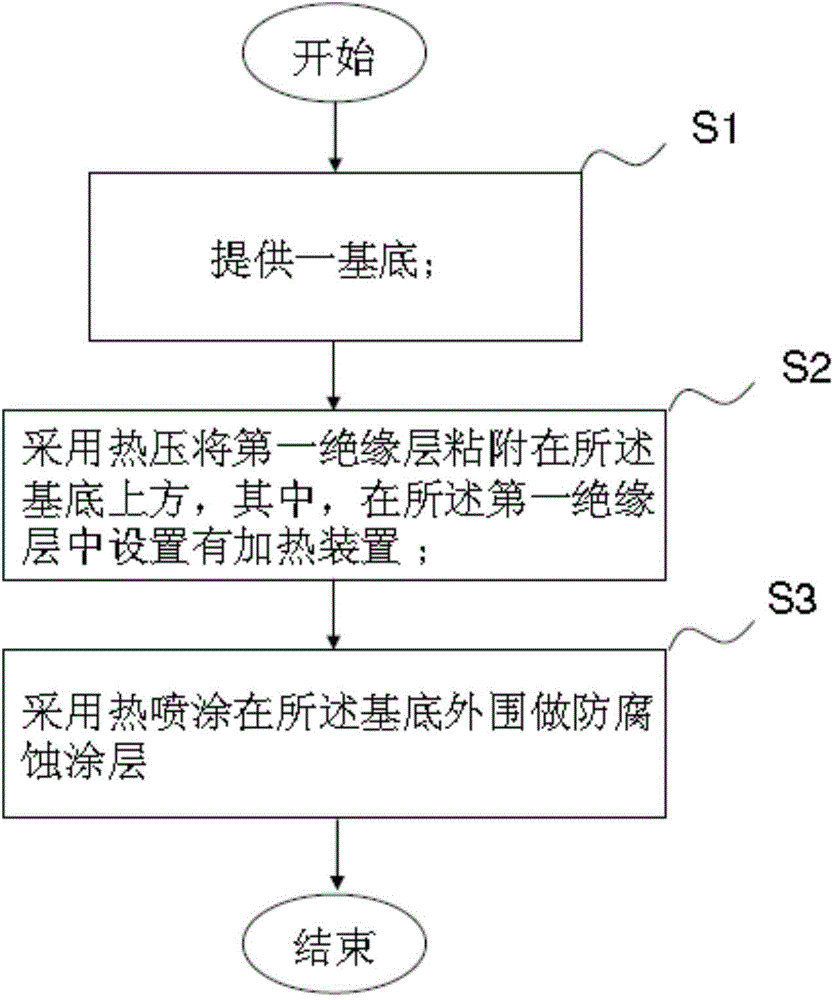

Plasma processing chamber and base manufacturing method therefor

ActiveCN104934279AAvoid pollutionVessels or leading-in conductors manufactureThermal sprayingTemperature difference

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

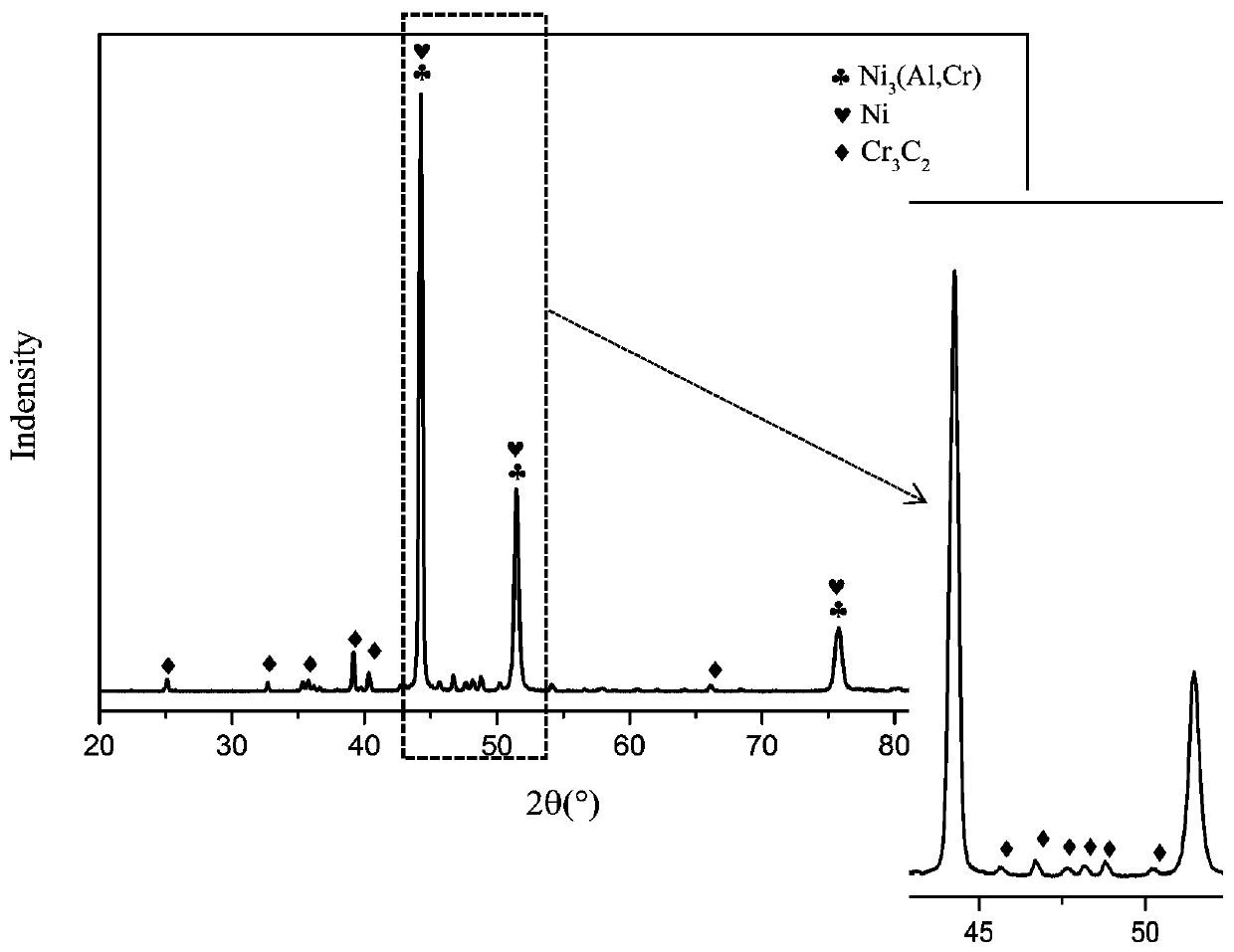

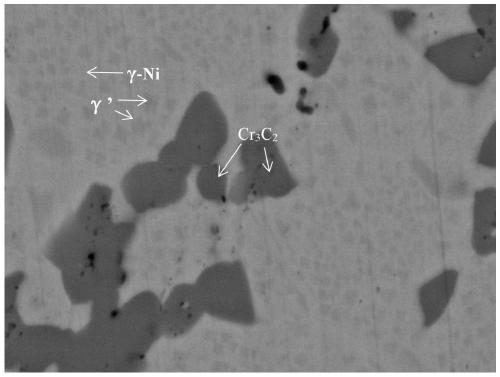

In-situ synthesized Cr3C2 reinforced Ni-based composite material and hot-press preparation method thereof

Owner:BEIJING JIAOTONG UNIV

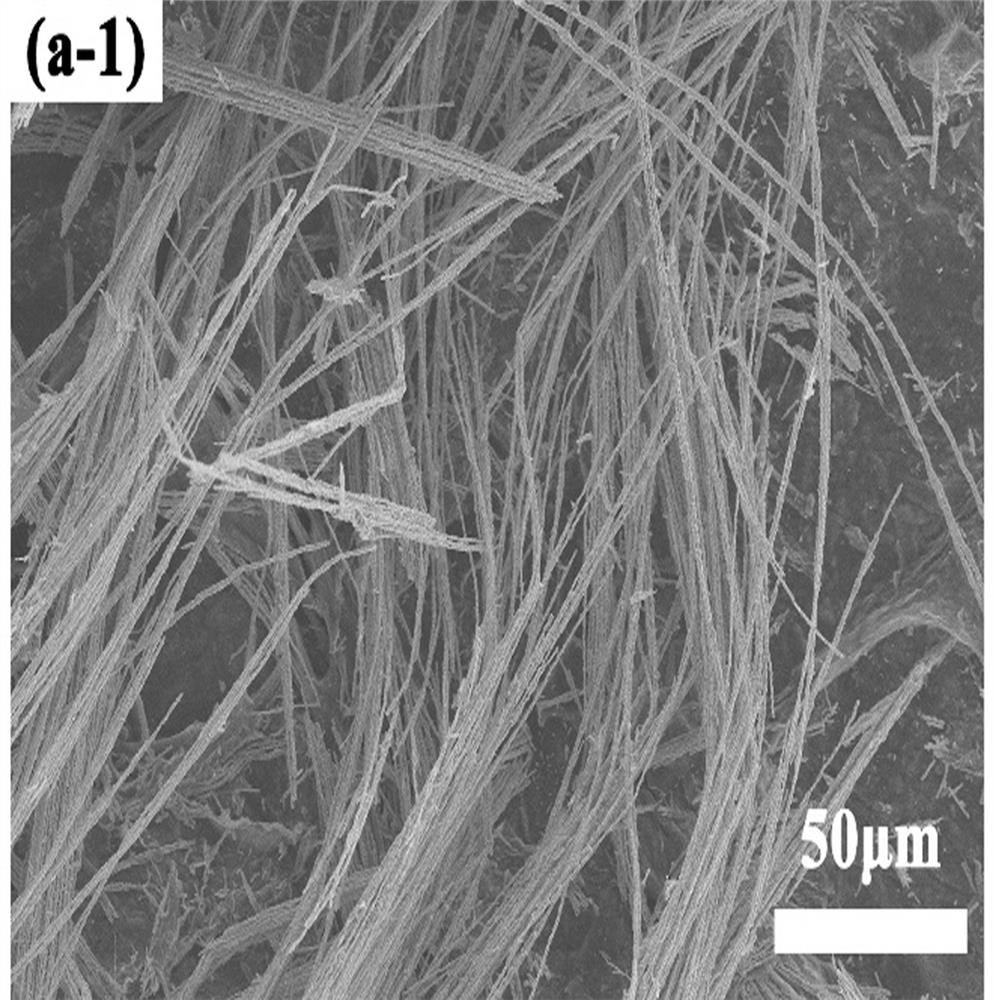

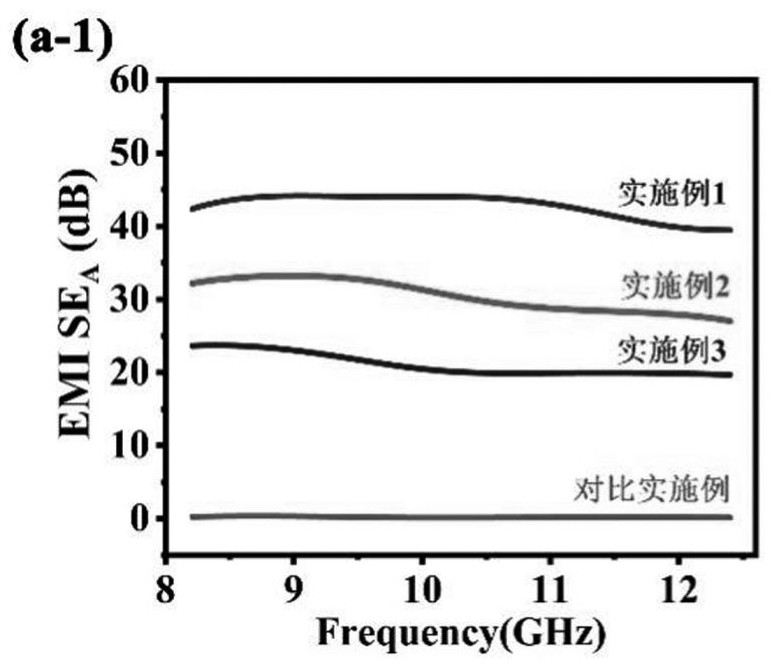

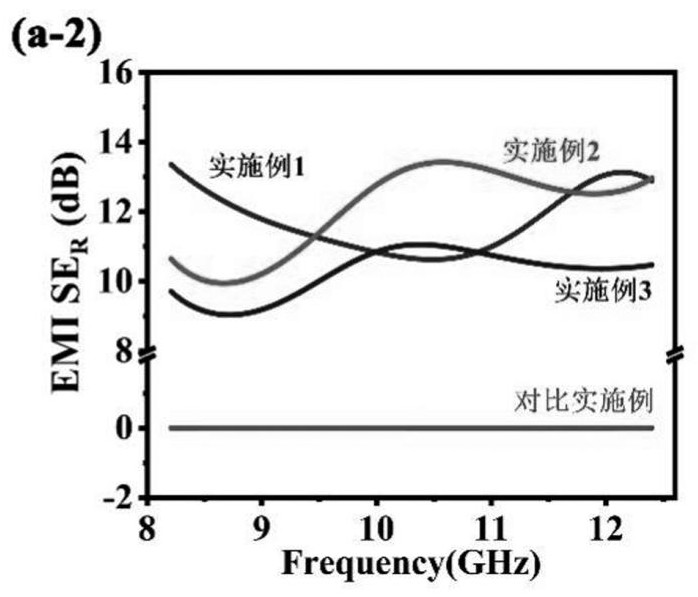

Chitin@MXene@Ni chain thin film material and preparation method and application thereof

PendingCN113817195AEasy to prepareImprove shielding effectMagnetic/electric field screeningThin membraneFilm material

Owner:浙江优可丽新材料有限公司

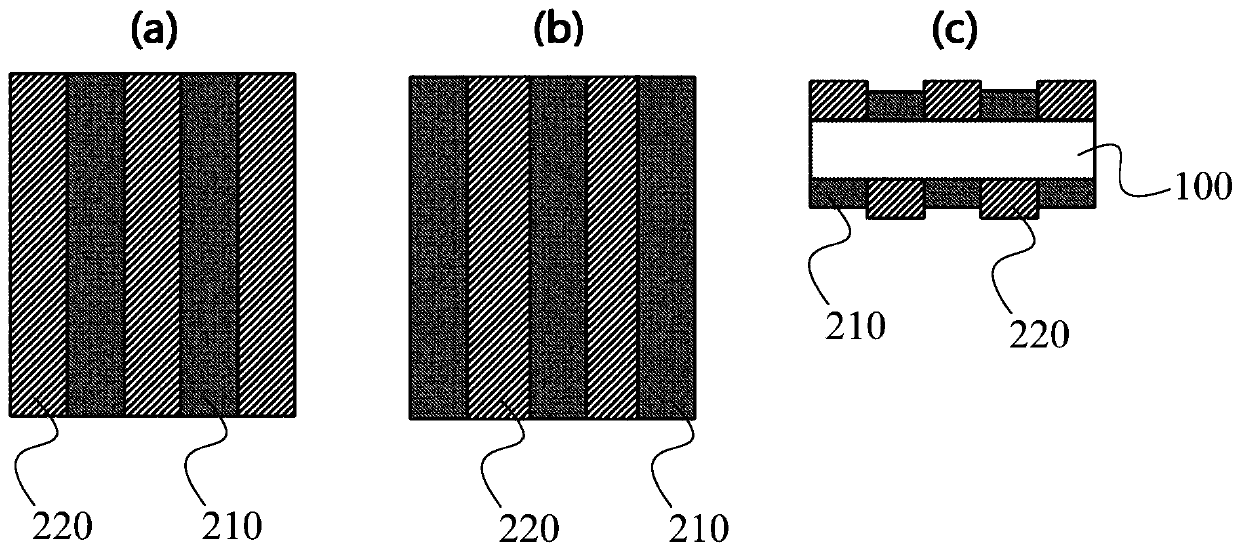

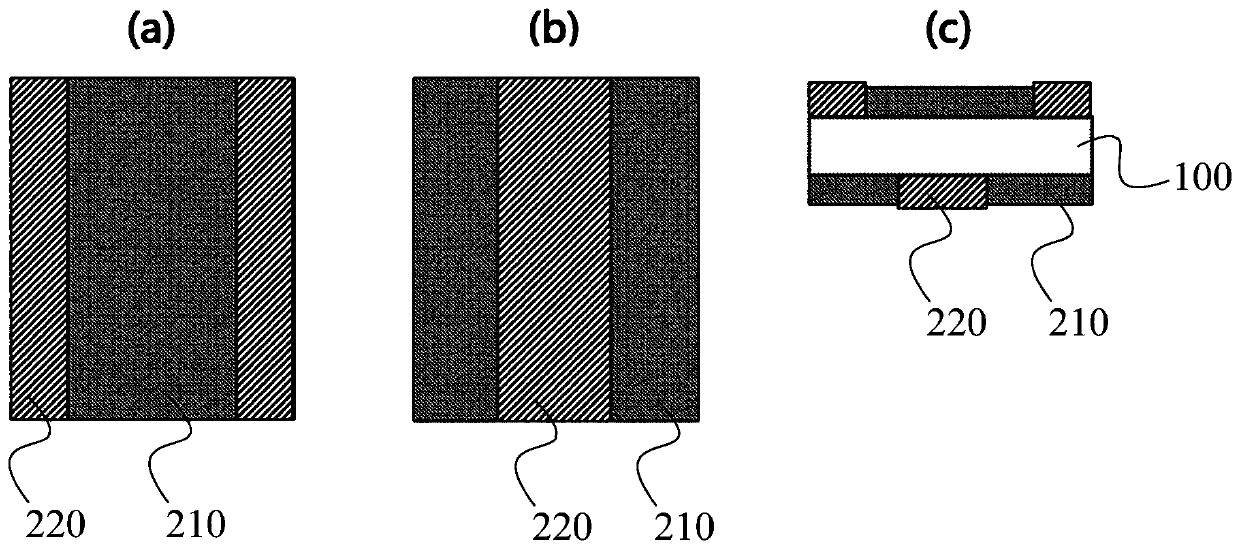

Electrochemical device and diaphragm thereof

PendingCN110854347AImprove thermal stabilityLow heat shrinkageSecondary cellsCell component detailsCeramic coatingBond coating

Owner:乐凯胶片股份有限公司

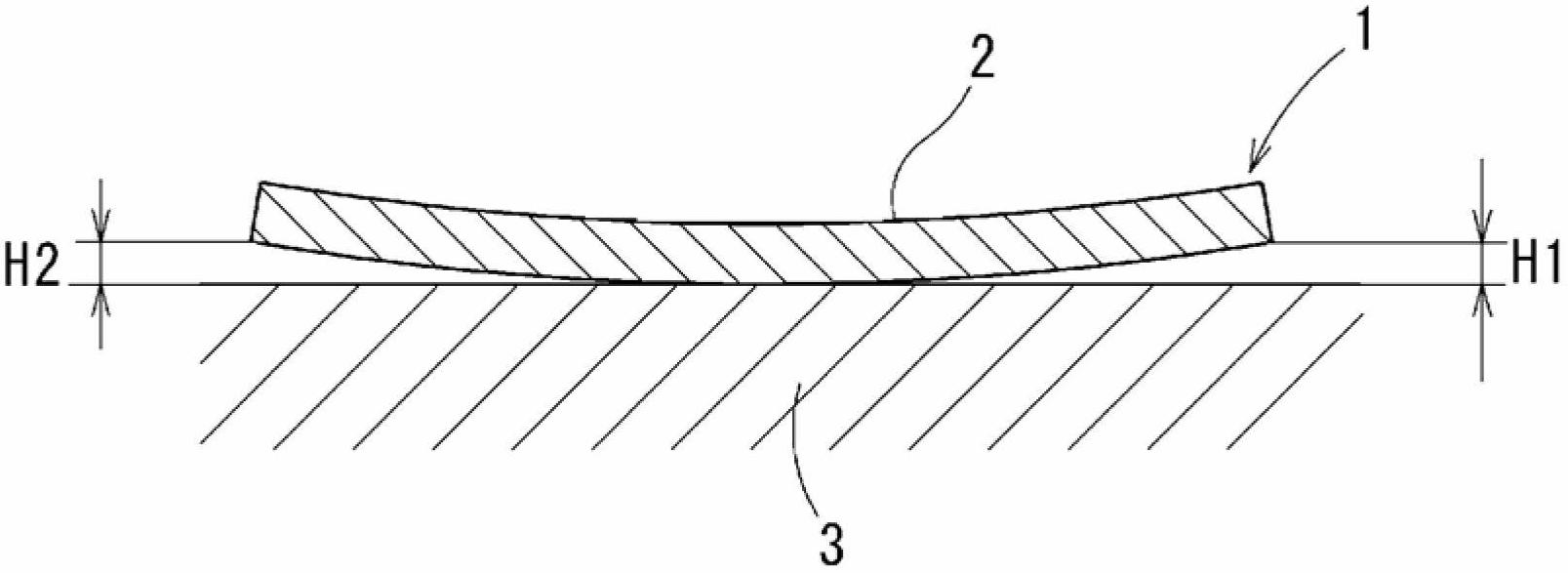

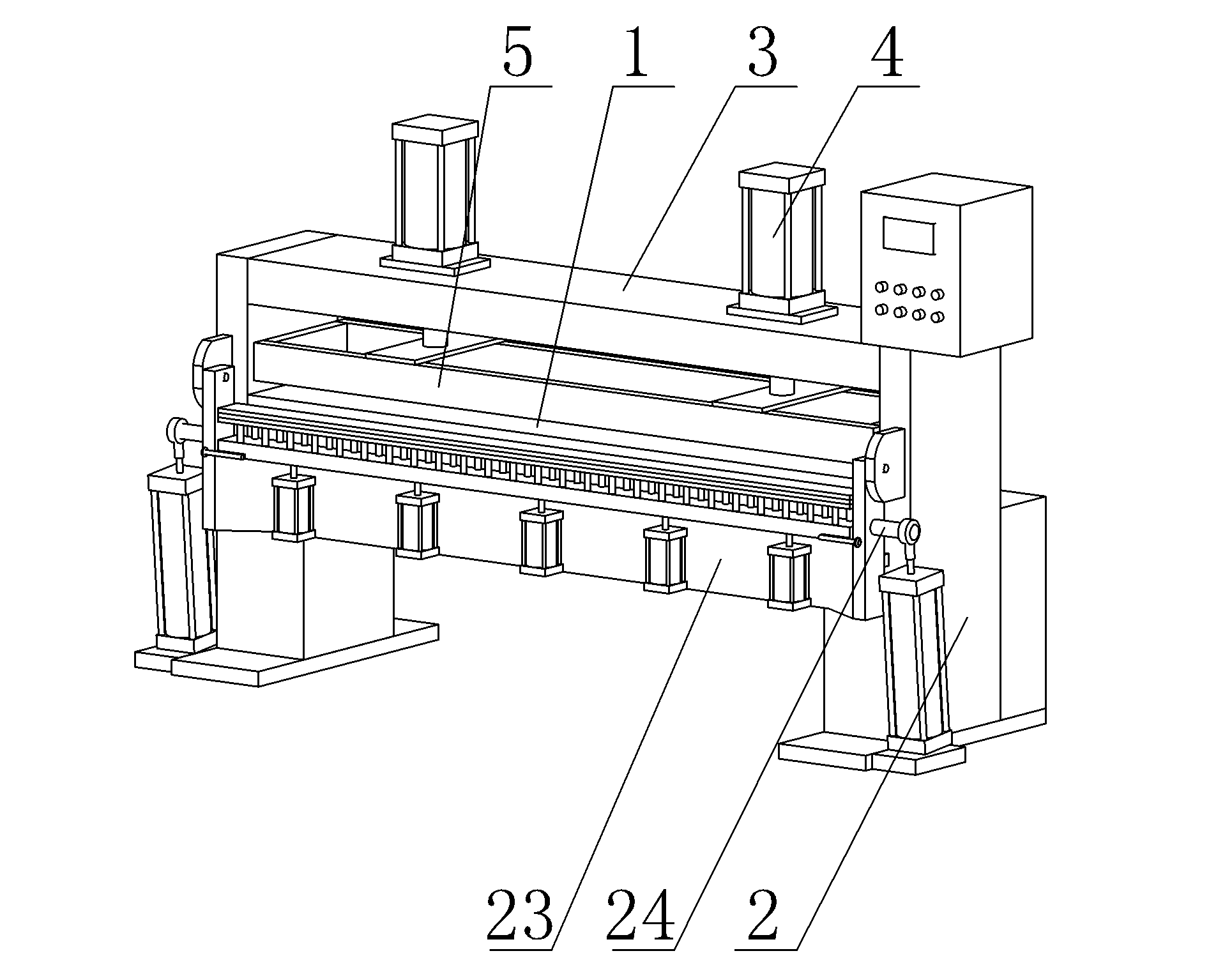

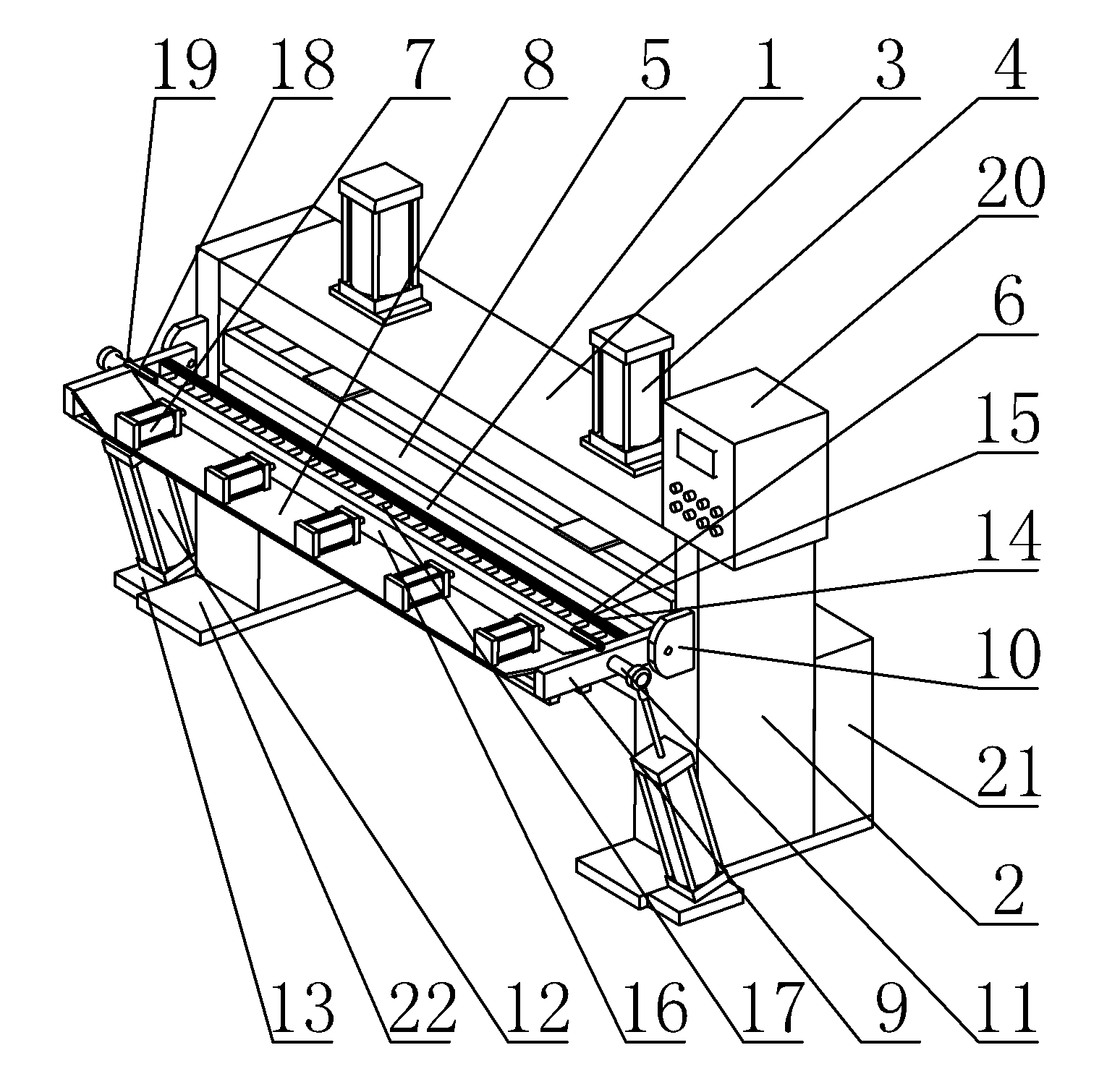

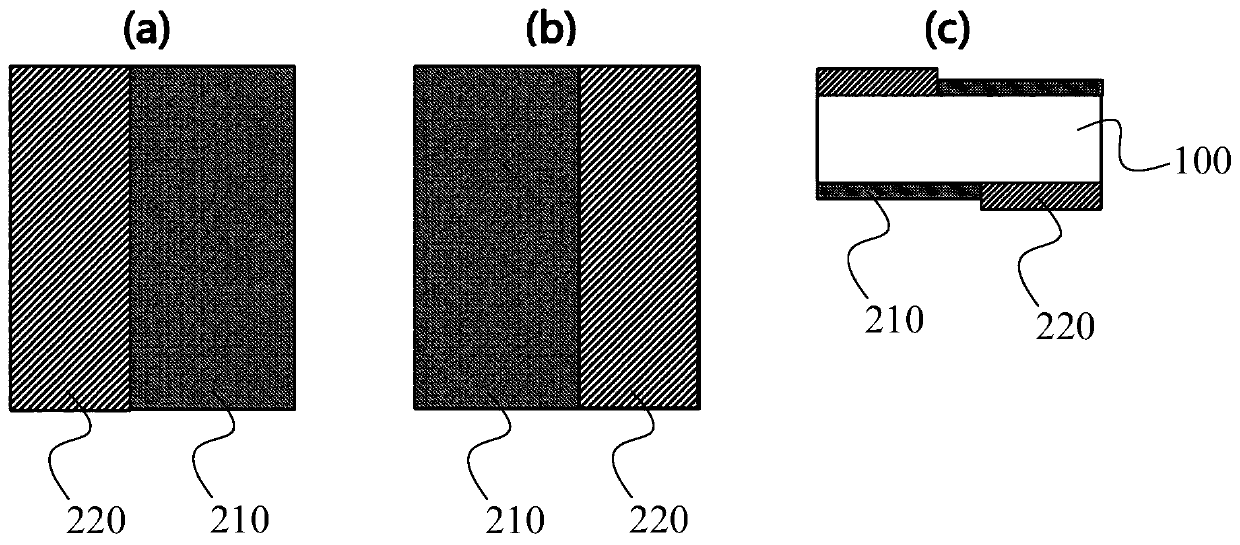

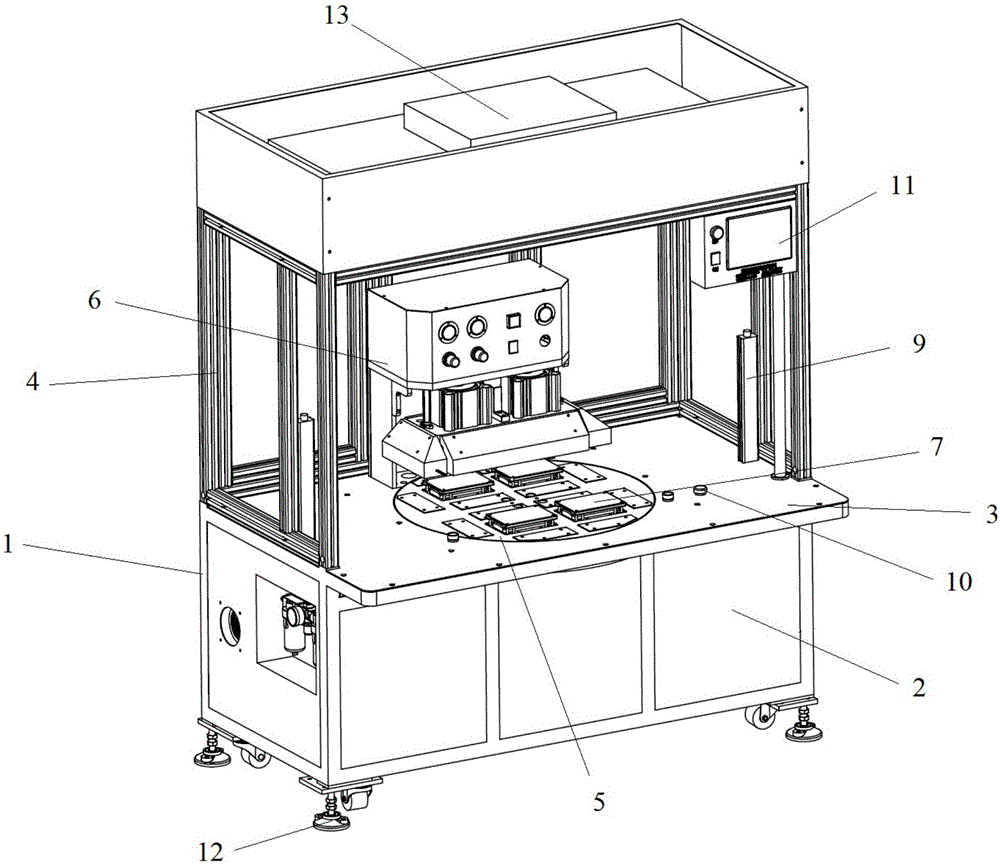

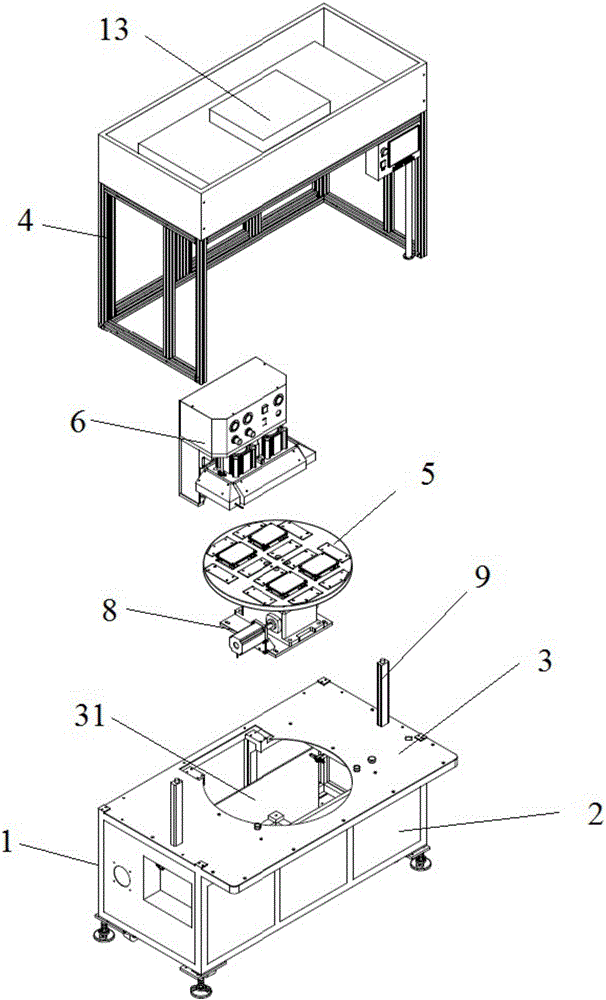

Hot-pressing fixing equipment and hot-pressing method

PendingCN111276557AStimulate adhesion propertiesAchieve the desired effectPhotovoltaic energy generationSemiconductor devicesStructural engineeringWorkbench

The invention provides hot-pressing fixing equipment and a hot-pressing method, the hot-pressing fixing equipment is used for pressing a panel and a to-be-pressed substrate, and the hot-pressing fixing equipment comprises a workbench which is provided with a bearing platform for bearing the to-be-pressed substrate; ahot-pressing device which comprises a hot-pressing assembly, wherein the hot-pressing assembly is located on the side, used for bearing the to-be-pressed substrate, of the bearing platform, can move towards or away from the bearing platform and is used for heating and extruding anadhesive clamped between the panel and the to-be-pressed substrate; and apressing device which is located on the side, used for bearing the to-be-pressed substrate, of the bearing platform, wherein the face, facing the bearing platform, of the pressing device is matched with the shape of the to-be-pressed substrate, and the pressing device can move towards or away from the bearing platform. The hot-pressing fixing equipment provided by the embodiment of the invention is high in production efficiency.

Owner:DONGJUN NEW ENERGY CO LTD

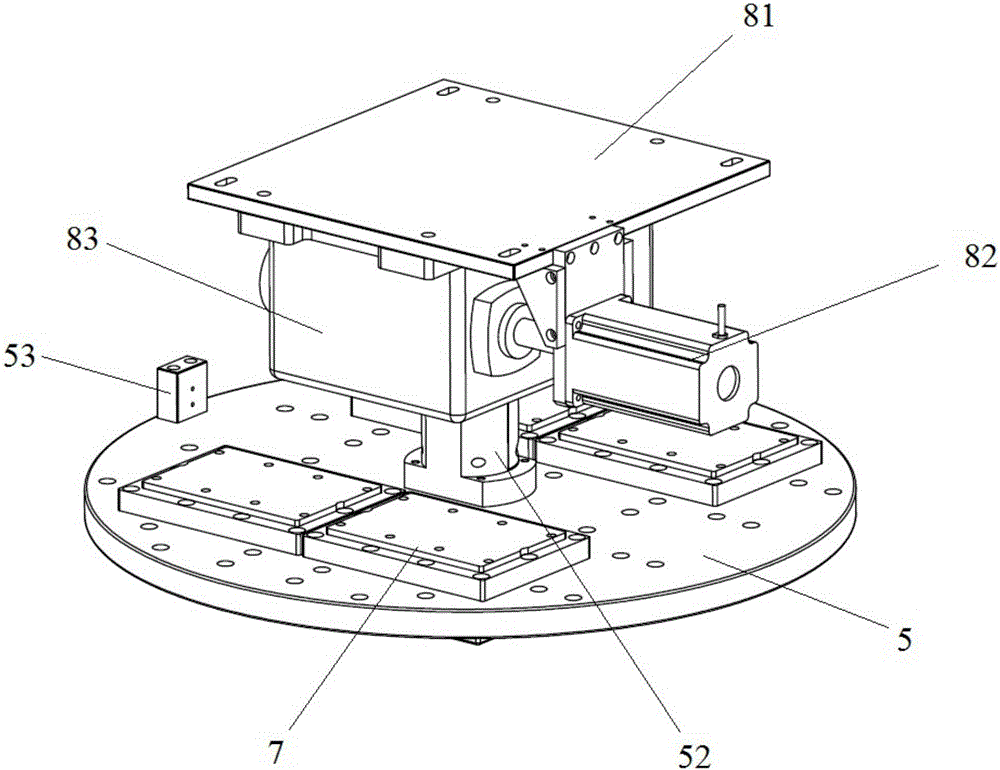

Curved surface fitting equipment and fitting method of curved surface fitting equipment

ActiveCN106827765AImprove fitting accuracyAvoid fitLaminationLamination apparatusAutomatic controlElectrical control

Owner:SHENZHEN CHENG XI ELECTROMECHANICAL EQUIP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap