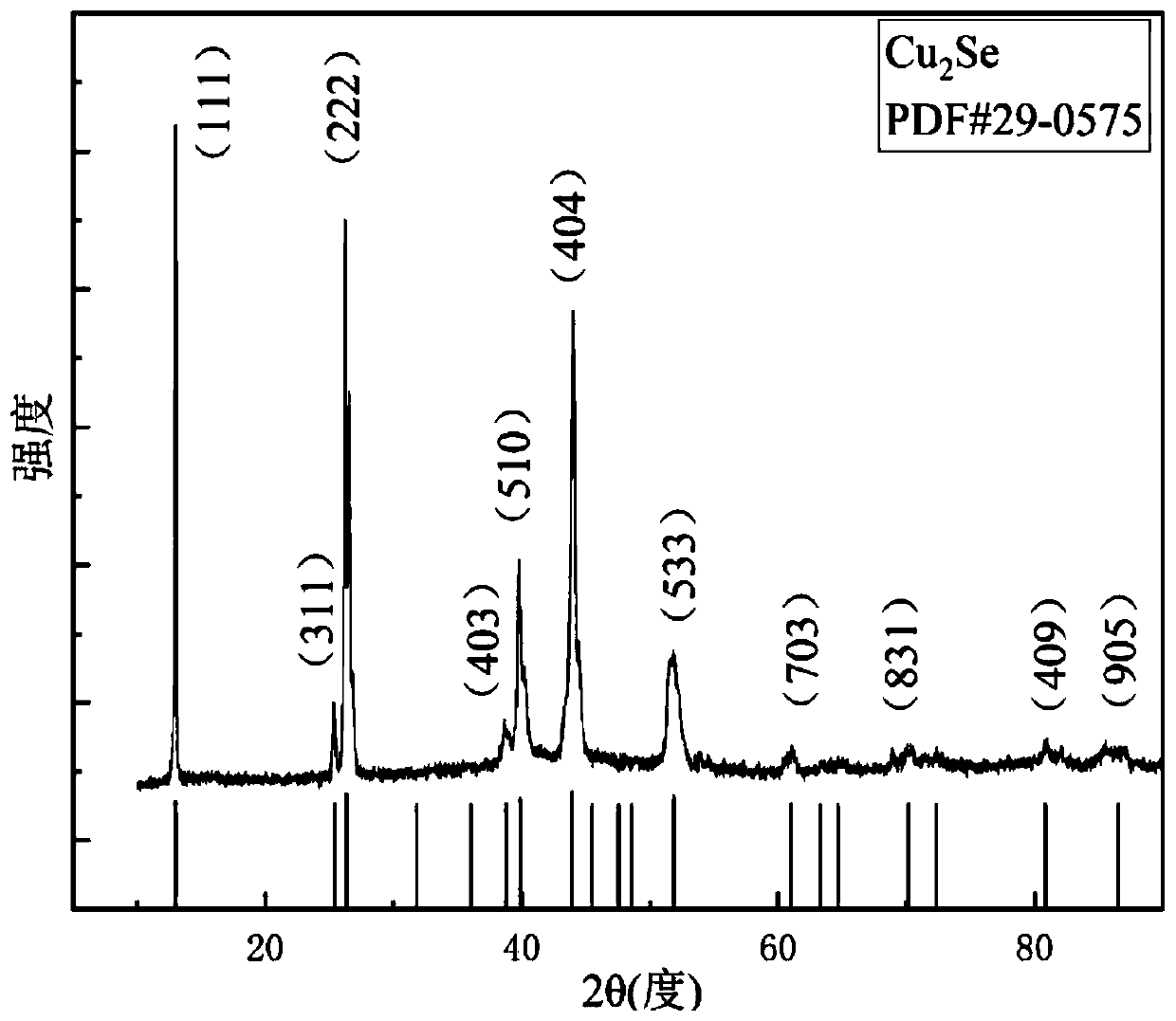

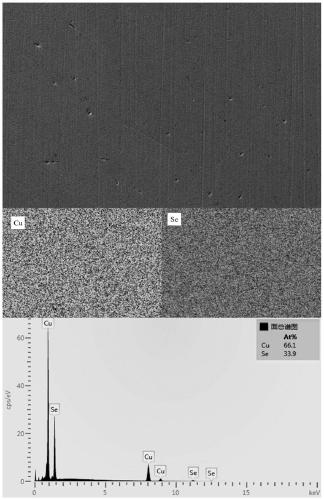

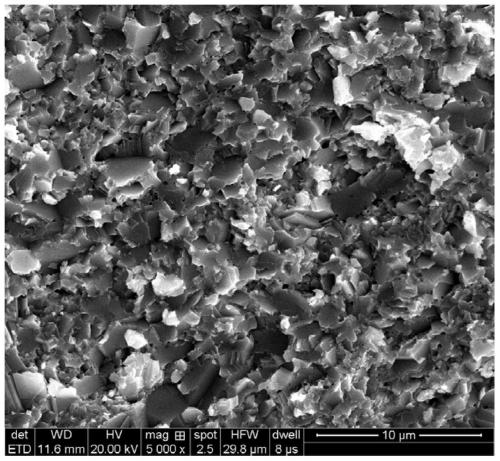

Method for preparing Cu2Se thermoelectric material

A technology of thermoelectric materials and wet ball milling, which is applied in the direction of thermoelectric device junction lead-out materials, thermoelectric device manufacturing/processing, chemical instruments and methods, etc., can solve the problems of long production cycle and high production cost, and achieve short production cycle , produce a low, mixed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] 1. Weigh copper powder and selenium powder with a purity of 99.99%. Among them, copper powder weighs 2.467g, selenium powder weighs 1.533g, and the total mass is 4g. Put the copper powder and selenium powder into a ball mill jar, add absolute ethanol, set the ball-material ratio to 50:1, the rotating speed to 300r / min, and the ball milling time to 20-30 minutes. Dry after ball milling, put the powder into a φ12mm cold-press mold, and cold-press at room temperature and 40MPa for 5 minutes to obtain a block.

[0041] 2. Place the obtained briquette in a quartz tube coated with carbon on the inner wall, and seal it after vacuuming, keeping the vacuum degree below 0.01Pa. Spread a layer of refractory cotton evenly around and at the bottom of the inner wall of the corundum crucible, and then add 10g of graphite powder with a purity of 99.9% and a particle size of 100 mesh and 3g of quartz sand with a particle size of 20 mesh to 40 mesh as wave-absorbing materials. The tube

Embodiment 2

[0048] 1. Weigh copper powder and selenium powder with a purity of 99.99%. Among them, copper powder weighs 2.467g, selenium powder weighs 1.533g, and the total mass is 4g. Put copper powder and selenium powder into a ball mill jar, add absolute ethanol, set the ball-to-material ratio to 40:1, the rotational speed to 200r / min, and the mixing time to 20-30 minutes. Dry after ball milling, put the powder into a φ12mm cold press mold, and cold press at room temperature and 50MPa for 5 minutes to obtain a block.

[0049] 2. Place the obtained briquette in a quartz tube coated with carbon on the inner wall, and seal it after vacuuming, keeping the vacuum degree below 0.01Pa. Spread a layer of refractory cotton evenly around the inner wall and bottom of the corundum crucible, and then add 10g of graphite powder with a purity of 99.9% and a particle size of 200 mesh and 3g of quartz sand with a particle size of 20-40 mesh as wave-absorbing materials. Embed the sealed vacuum quartz t

Embodiment 3

[0053] 1. Weigh copper powder and selenium powder with a purity of 99.99%. Among them, copper powder weighs 2.467g, selenium powder weighs 1.533g, and the total mass is 4g. Put copper powder and selenium powder into a ball mill jar, add absolute ethanol, set the ball-to-material ratio to 60:1, the rotational speed to 100 r / min, and the mixing time to 20-30 minutes. Dry after ball milling, put the powder into a φ12mm cold press mold, and cold press at room temperature and 50MPa for 5 minutes to obtain a block.

[0054] 2. Place the obtained briquette in a quartz tube coated with carbon on the inner wall, and seal it after vacuuming, keeping the vacuum degree below 0.01Pa. Spread a layer of refractory cotton evenly around the inner wall and bottom of the corundum crucible, and then add 10g of graphite powder with a purity of 99.9% and a particle size of 200 mesh and 3g of quartz sand with a particle size of 20-40 mesh as wave-absorbing materials. Embed the sealed vacuum quartz

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap