Efficient filter-bag dust separation device

A technology of purification equipment and filter bag dust removal, which is applied in the direction of dispersed particle filtration, chemical instruments and methods, and separation of dispersed particles. good vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

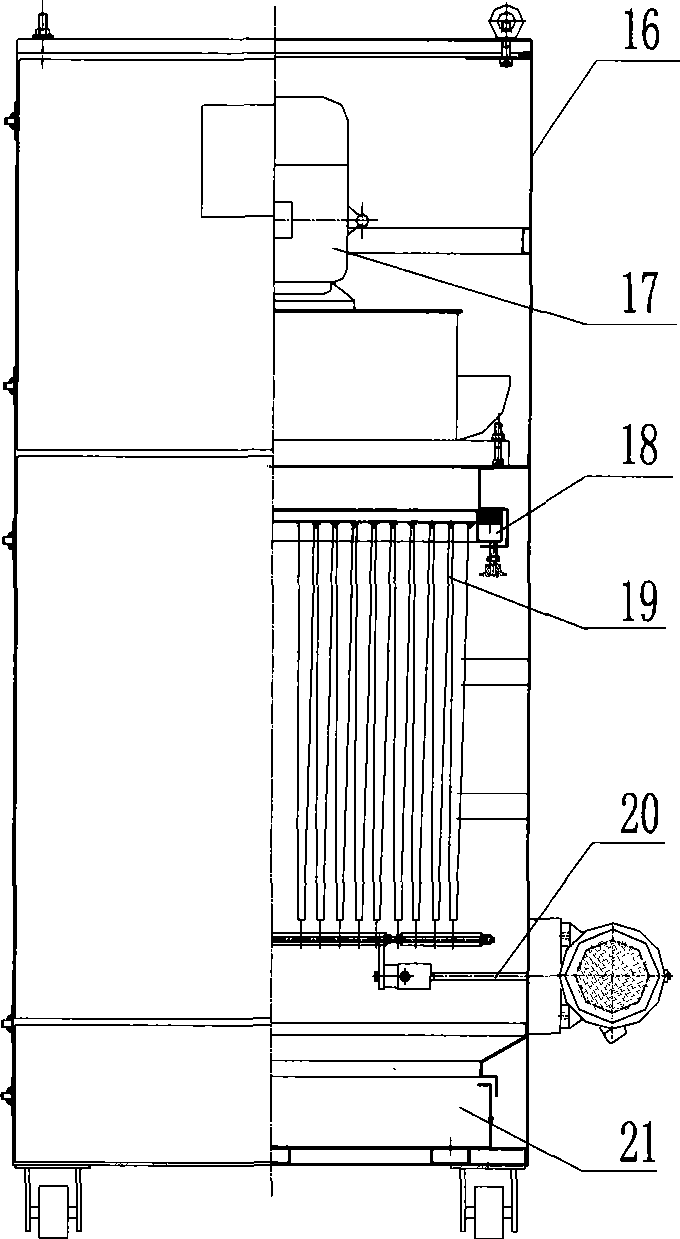

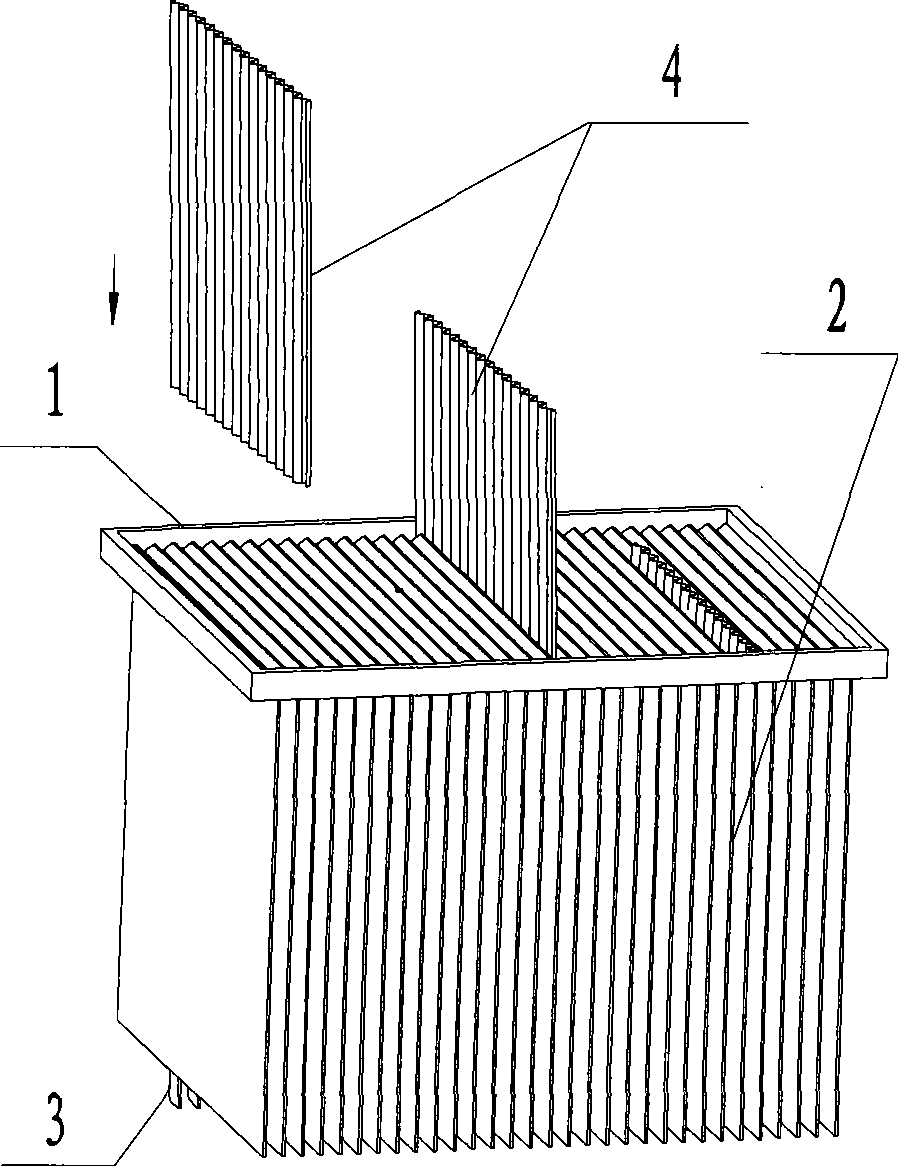

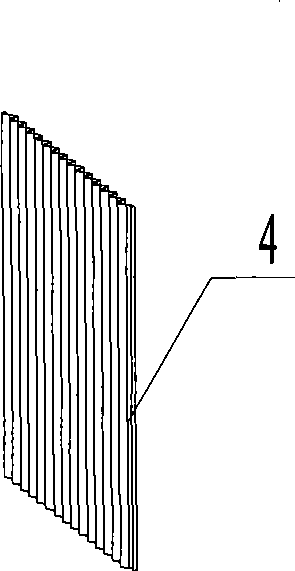

[0014] Embodiment 1: with reference to attached Figure 1~3 . High-efficiency filter bag dust removal and purification equipment, which includes a box body 16, a fan 17, a filter bag frame 18, a flat bag filter device 19, ash cleaning mechanism 20, and ash collection drawer 21, see the attached figure 1 , the making of casing, dust removal device, ash collection drawer is prior art, do not narrate at this. The mouths of a plurality of flat cloth bags 2 are connected to the frame 1, and the lower ends are equipped with matching ears 3. The matching ears 3 are connected to the threaded rods in the dust cleaning machine and driven by the dust cleaning mechanism to vibrate and clear the dust (on the cloth bag). , a plurality of flat cloth bags 2 constitute a flat cloth bag set, and its manufacturing process is the prior art, so it will not be described here. A plurality of flat cloth bags 2 are respectively provided with a flat cloth bag partition plate 4 with a concave-convex stru

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap