Intelligent pulping machine and control process method thereof

A pulping machine and intelligent technology, applied in dairy products, beverage preparation devices, milk substitutes, etc., can solve the problems of undercooked soybean milk, small capacity range, insufficient quantity, etc., achieve simple and convenient control methods, and improve the level of intelligence , the effect of intelligent control method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

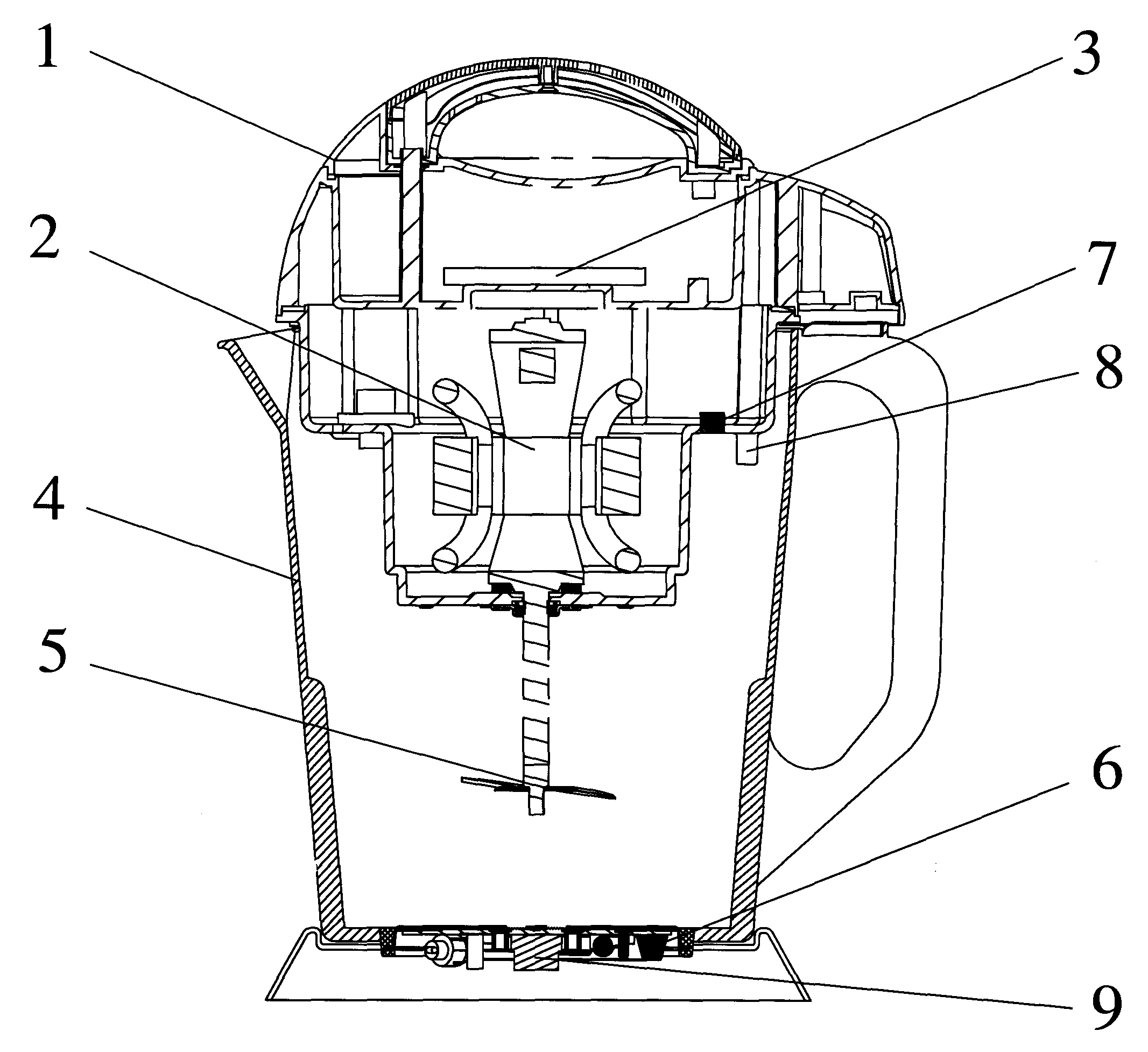

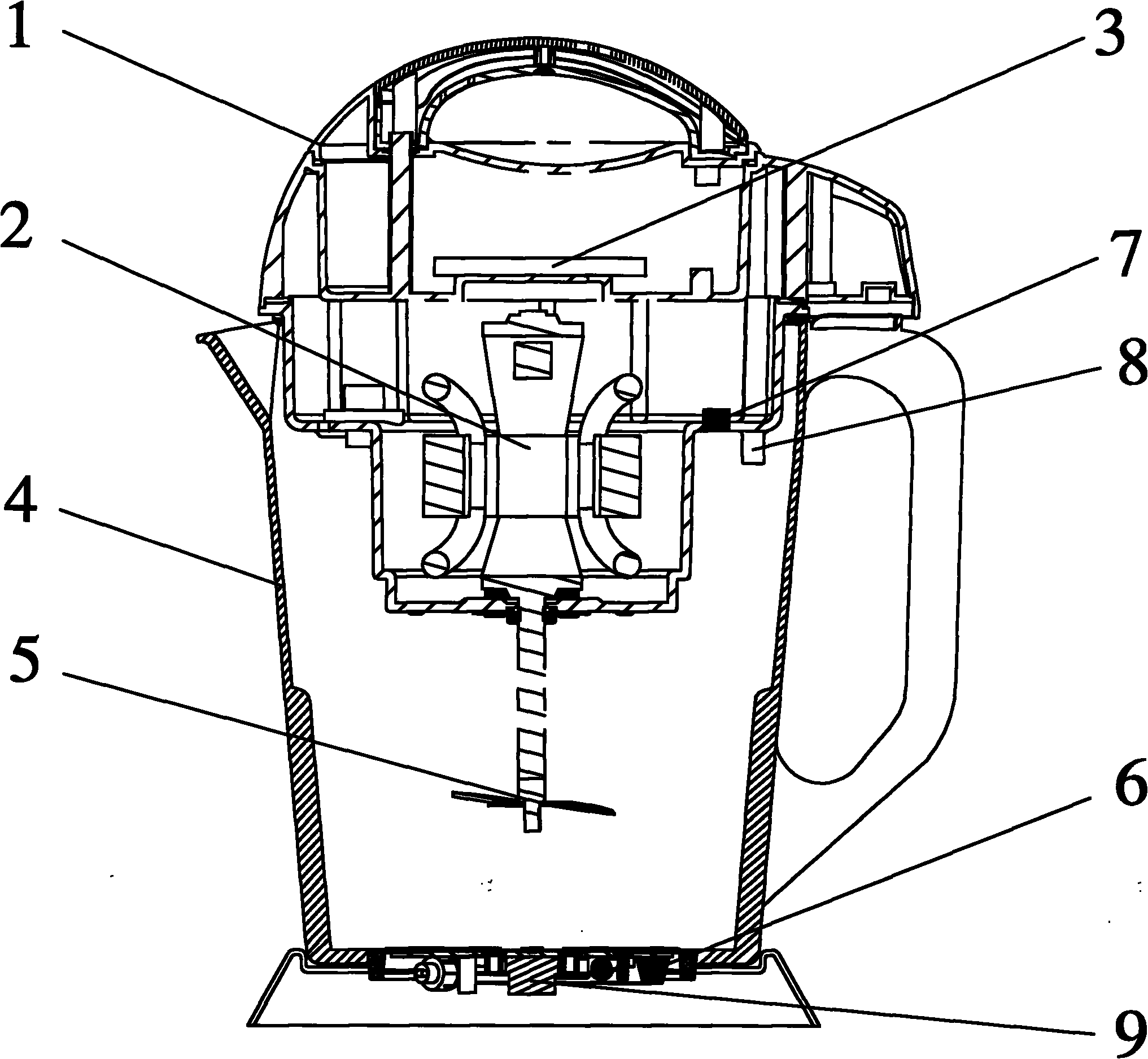

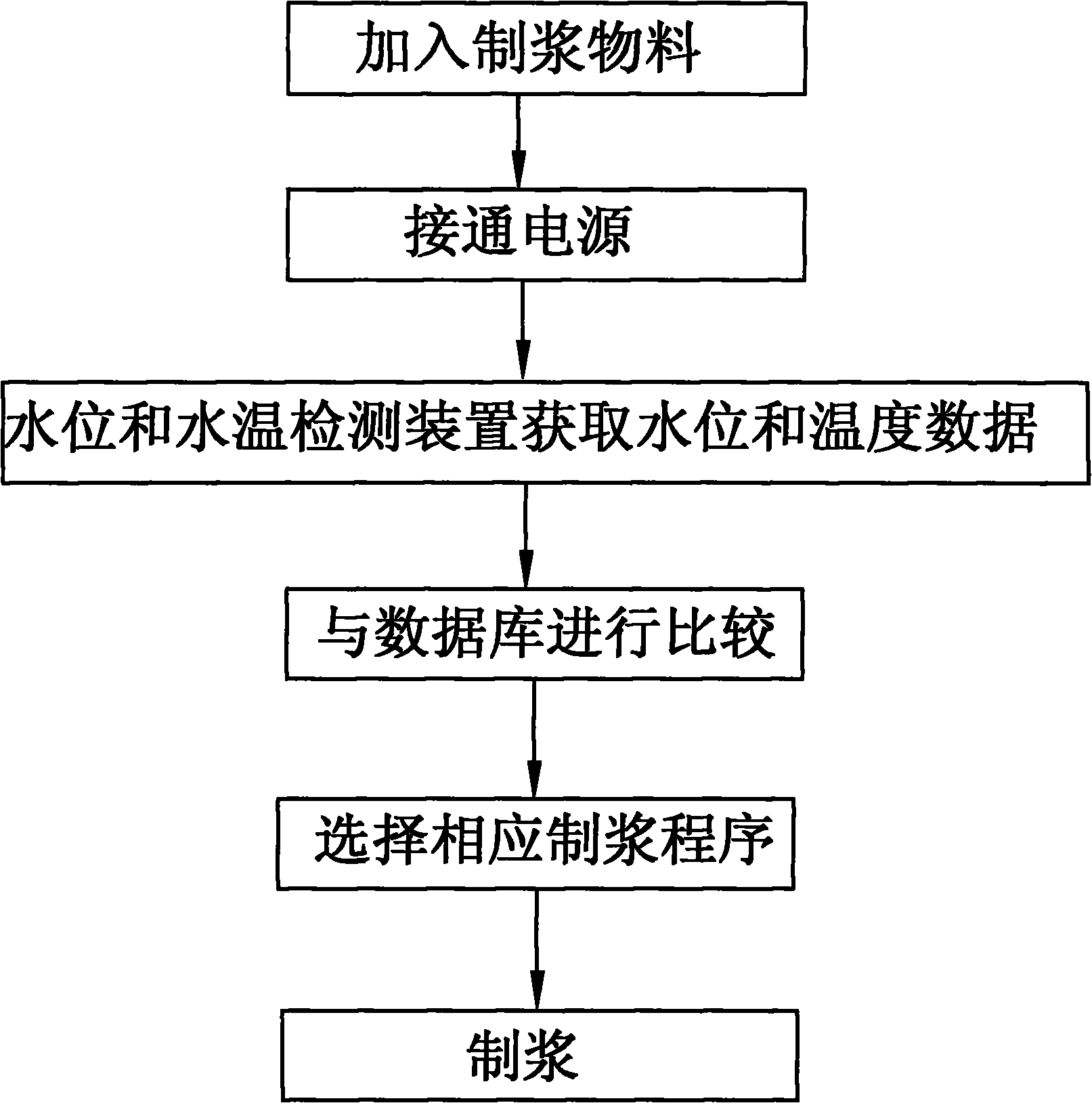

[0019] As shown in Figure 1, the intelligent pulping machine of the present invention includes a machine head 1, a motor 2 installed in the machine head 1, a control device 3 installed in the machine head 1, and a container placed at the lower end of the machine head 1. The pulp container 4 and the pulverizing device 5 and the heating device 6 installed in the pulp container 4. In addition, the present invention also includes a water level detection device 7 and a temperature detection device 8 , the signal output ends of the water level detection device 7 and the temperature detection device 8 are electrically connected to the signal input end of the control device 3 . The water level detection device 7 and the temperature detection device 8 are used to detect the water level and water temperature respectively, and feed back the detection structure to the control device 3, so that the control device 3 can select different pulping process programs according to the detected water l

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap