Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

90 results about "Piston rod" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In a piston engine, a piston rod joins a piston to the crosshead and thus to the connecting rod that drives the crankshaft or (for steam locomotives) the driving wheels. Internal combustion engines, and in particular all current automobile engines, do not generally have piston rods. Instead they use trunk pistons, where the piston and crosshead are combined and so do not need a rod between them. The term piston rod has been used as a synonym for 'connecting rod' in the context of these engines.

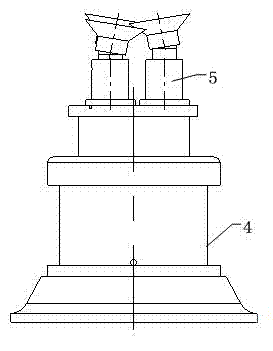

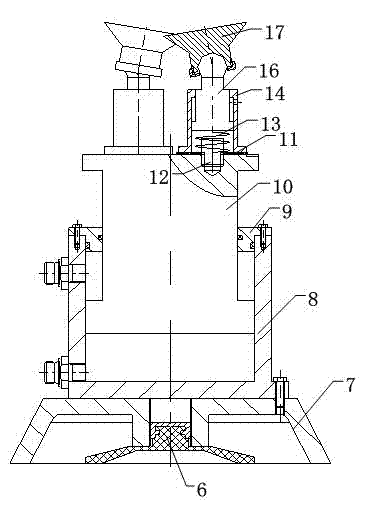

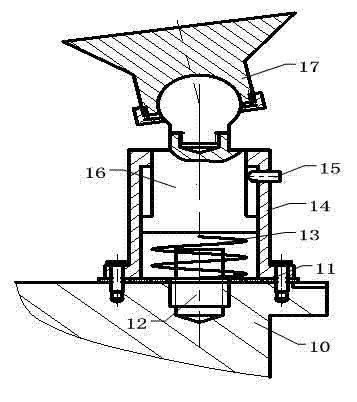

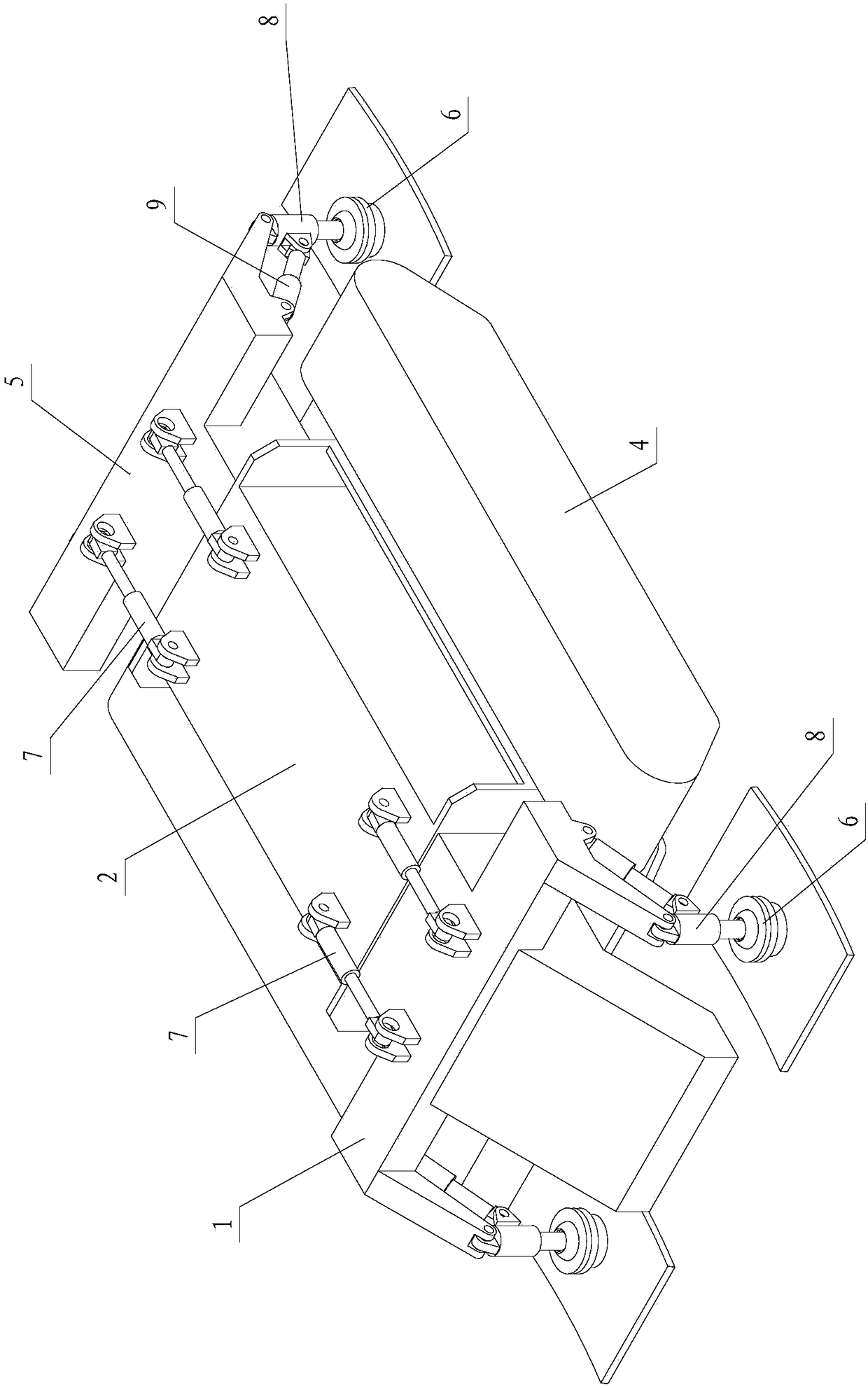

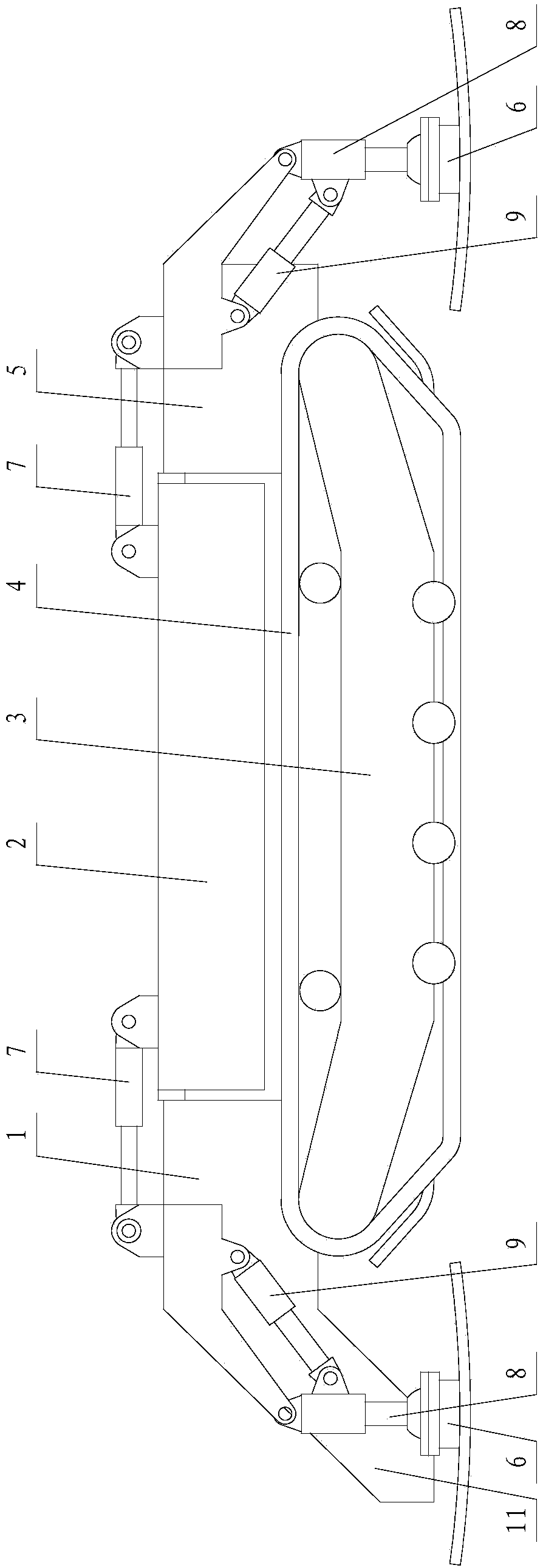

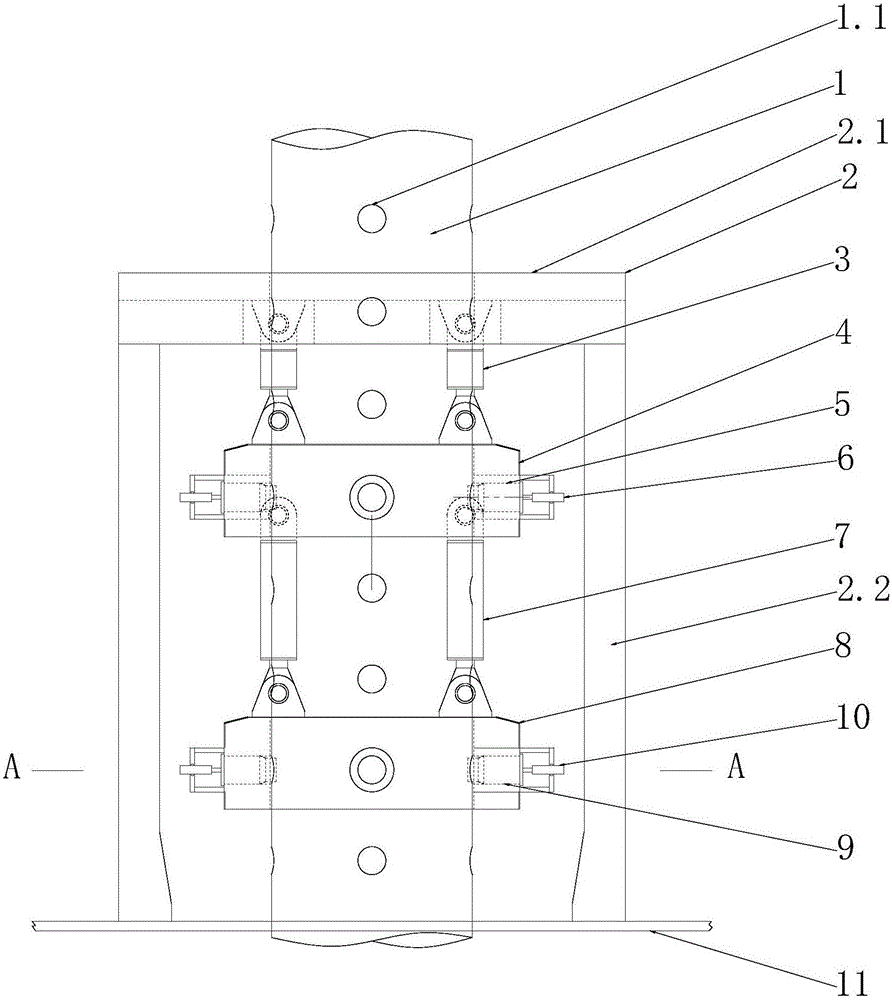

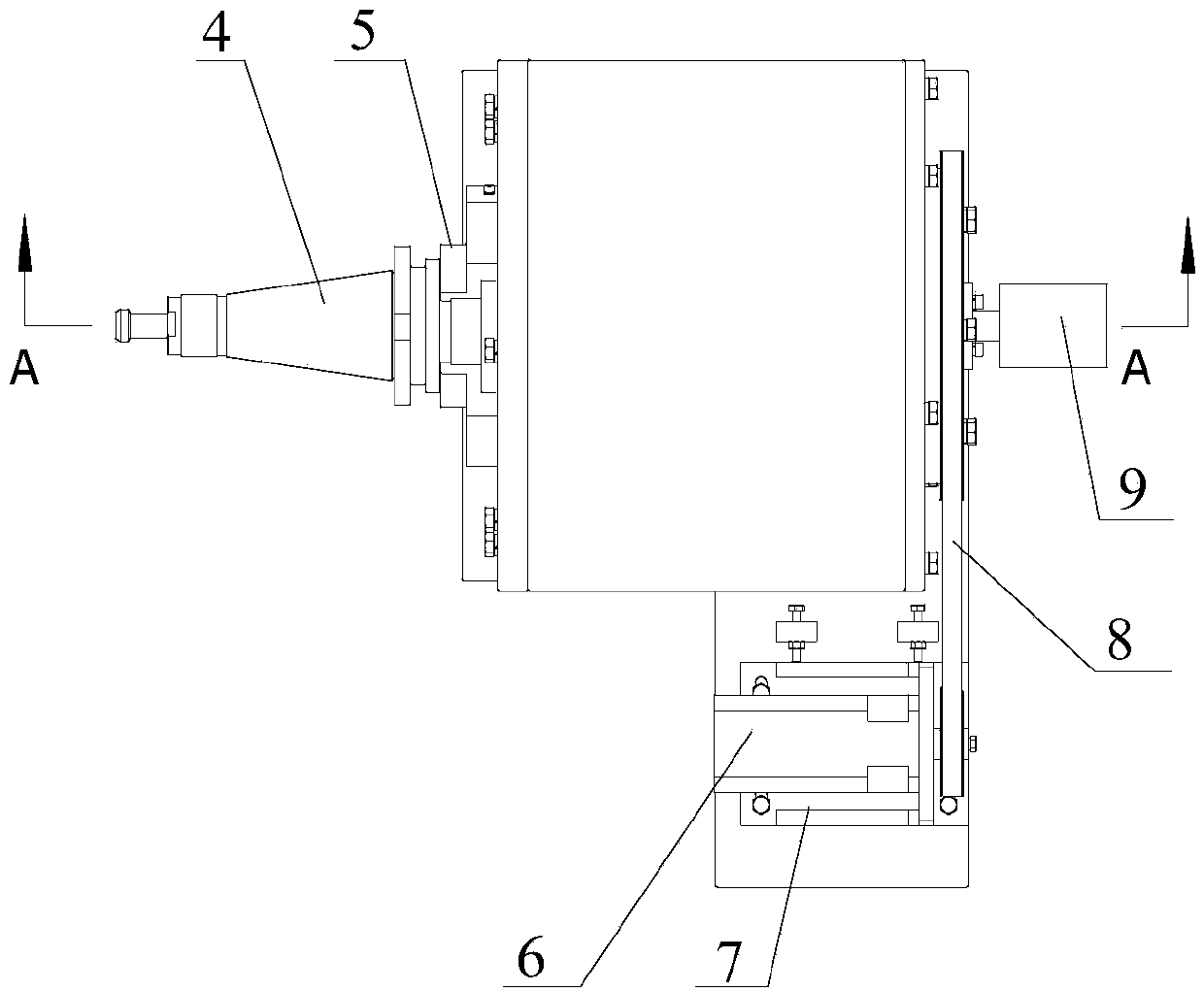

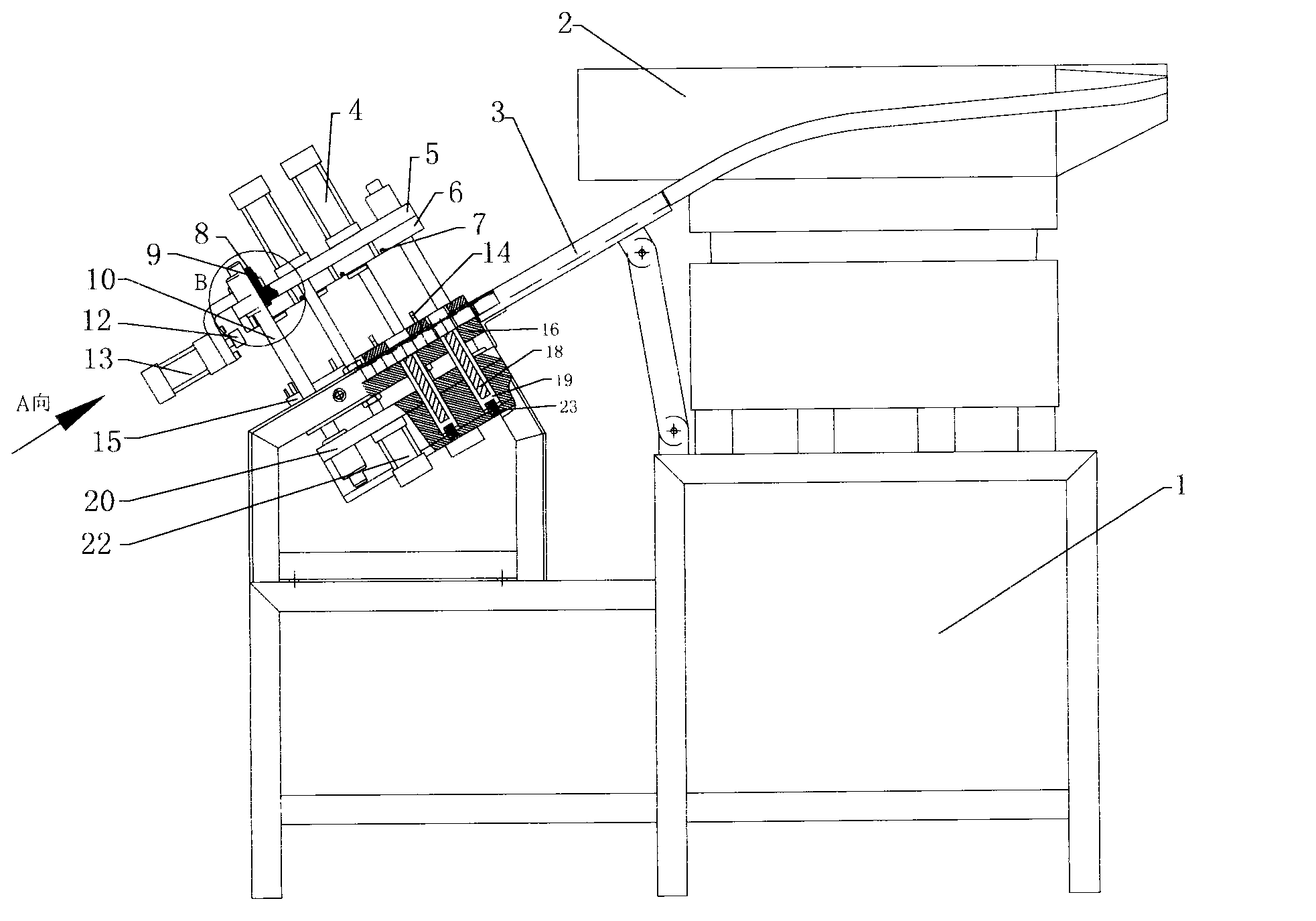

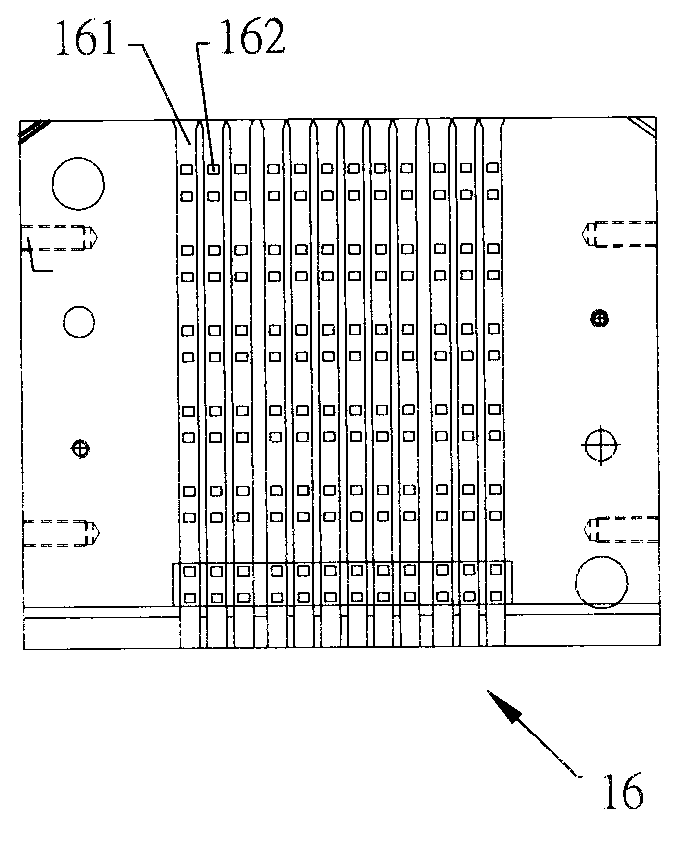

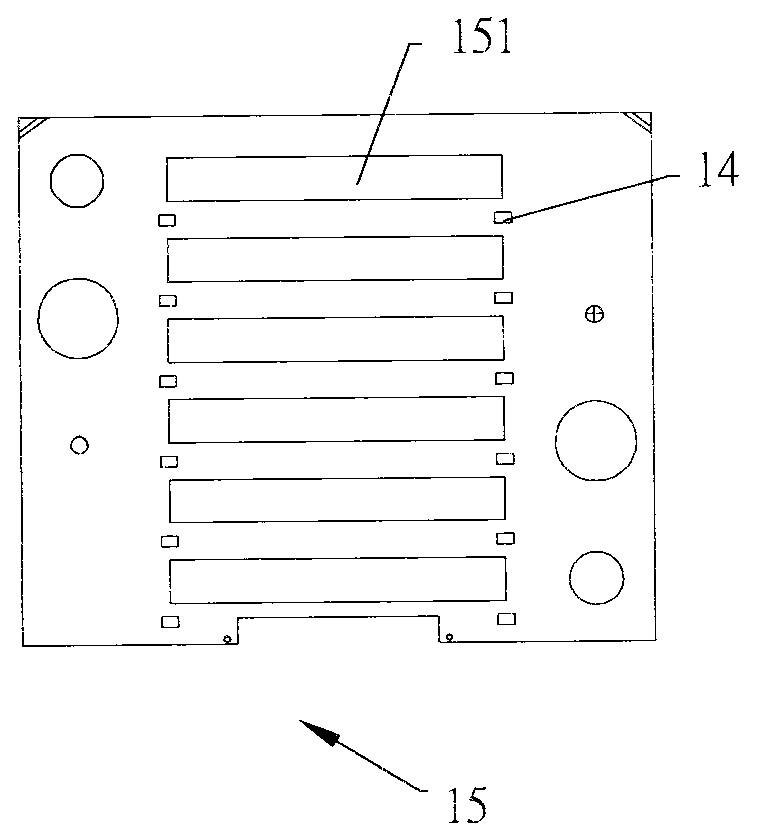

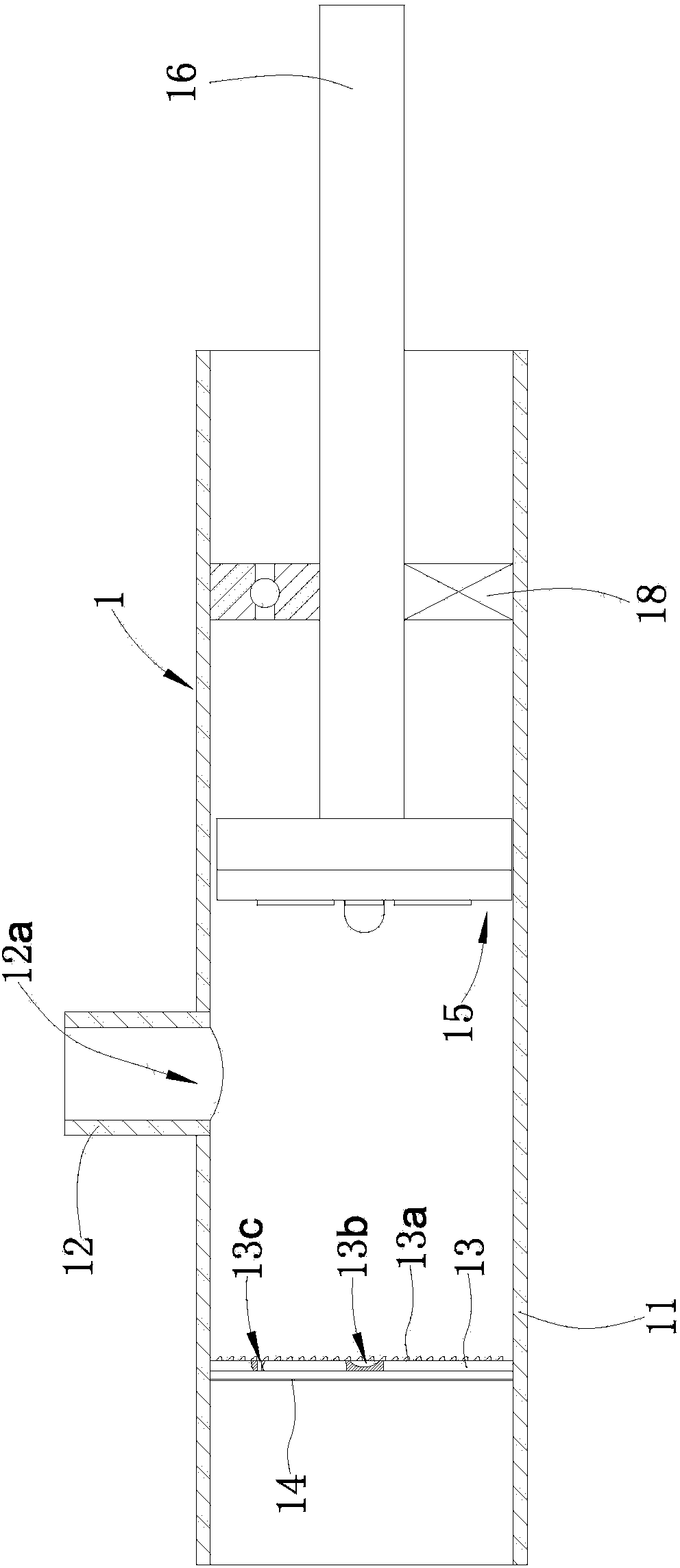

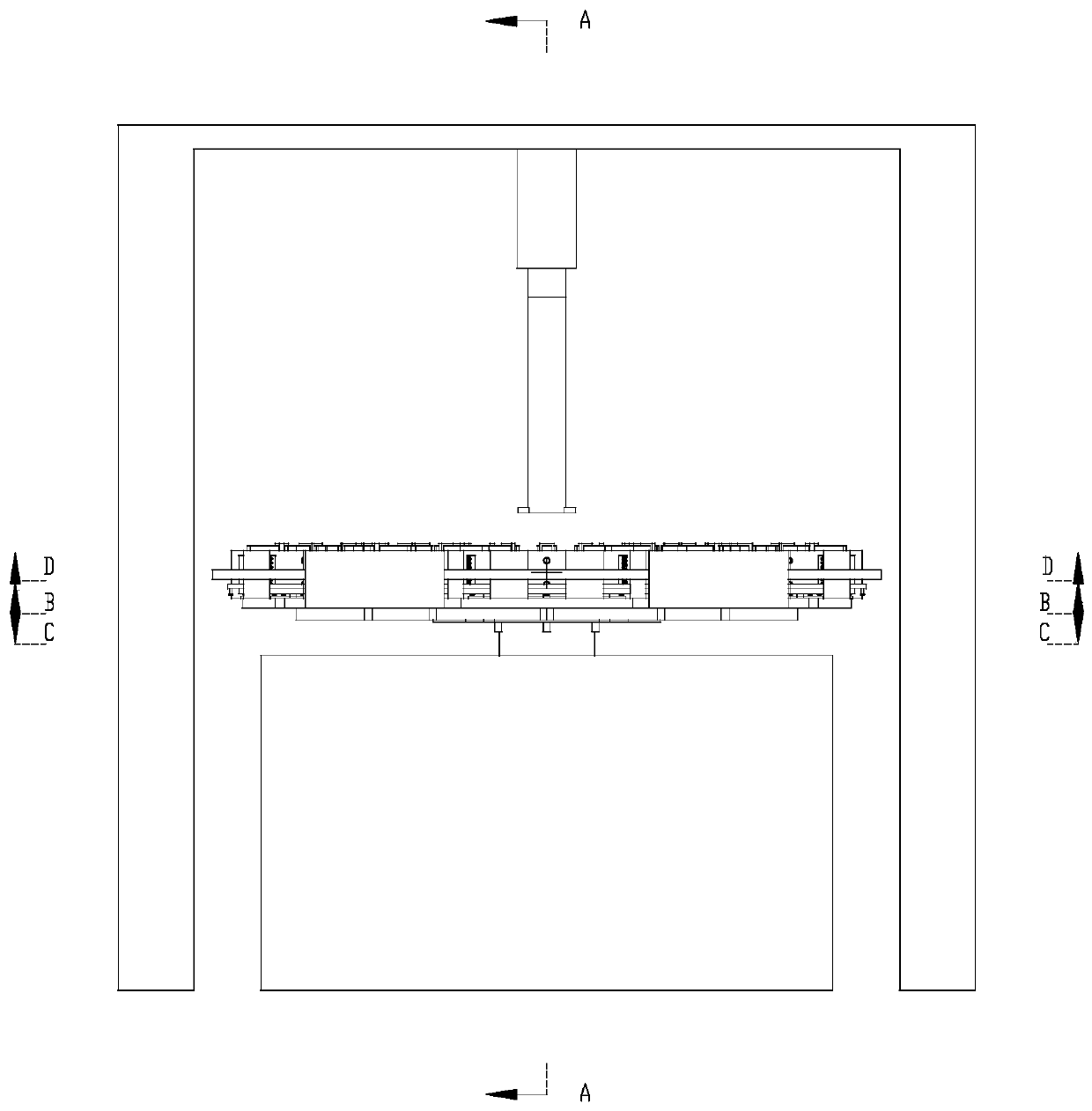

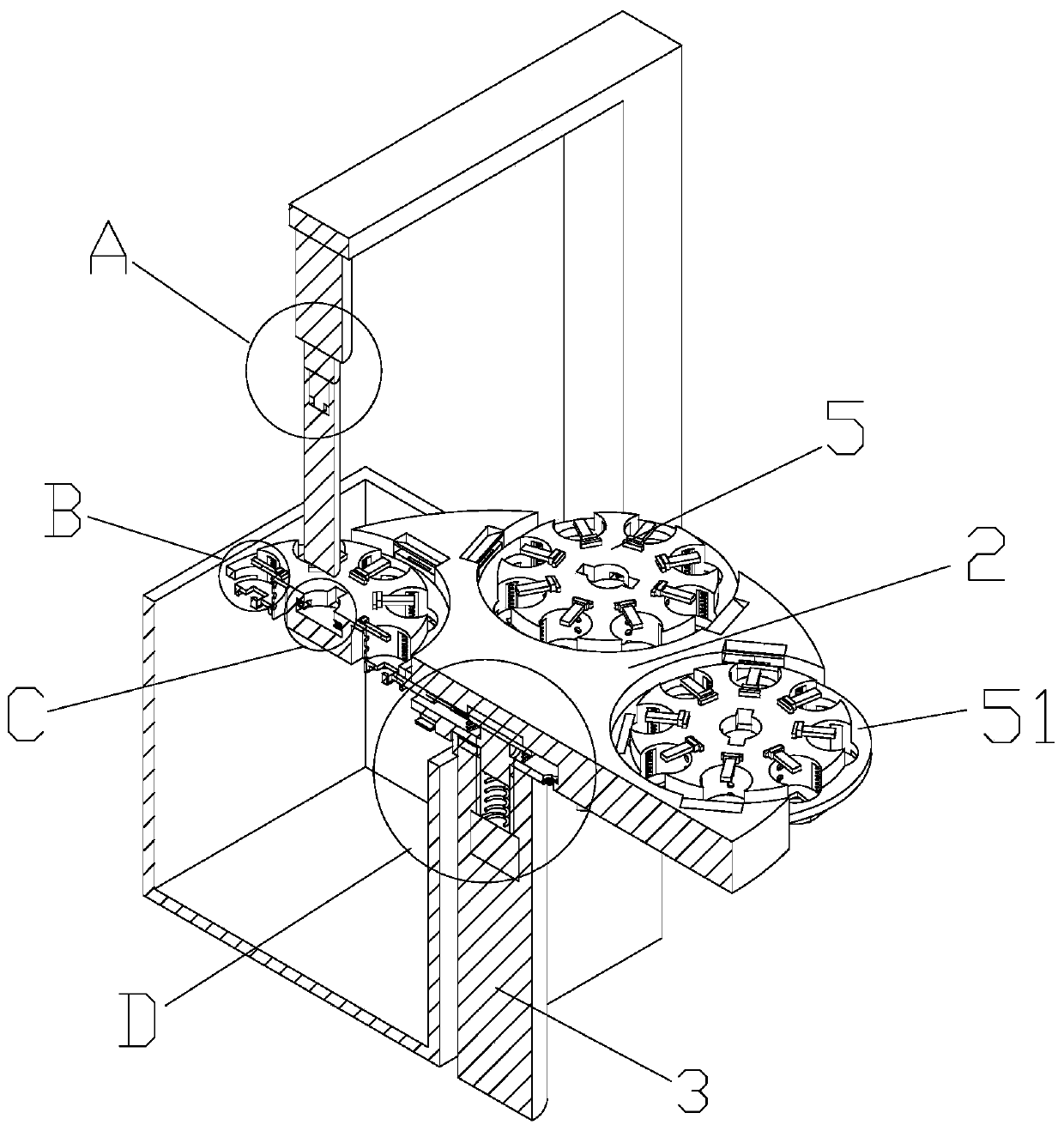

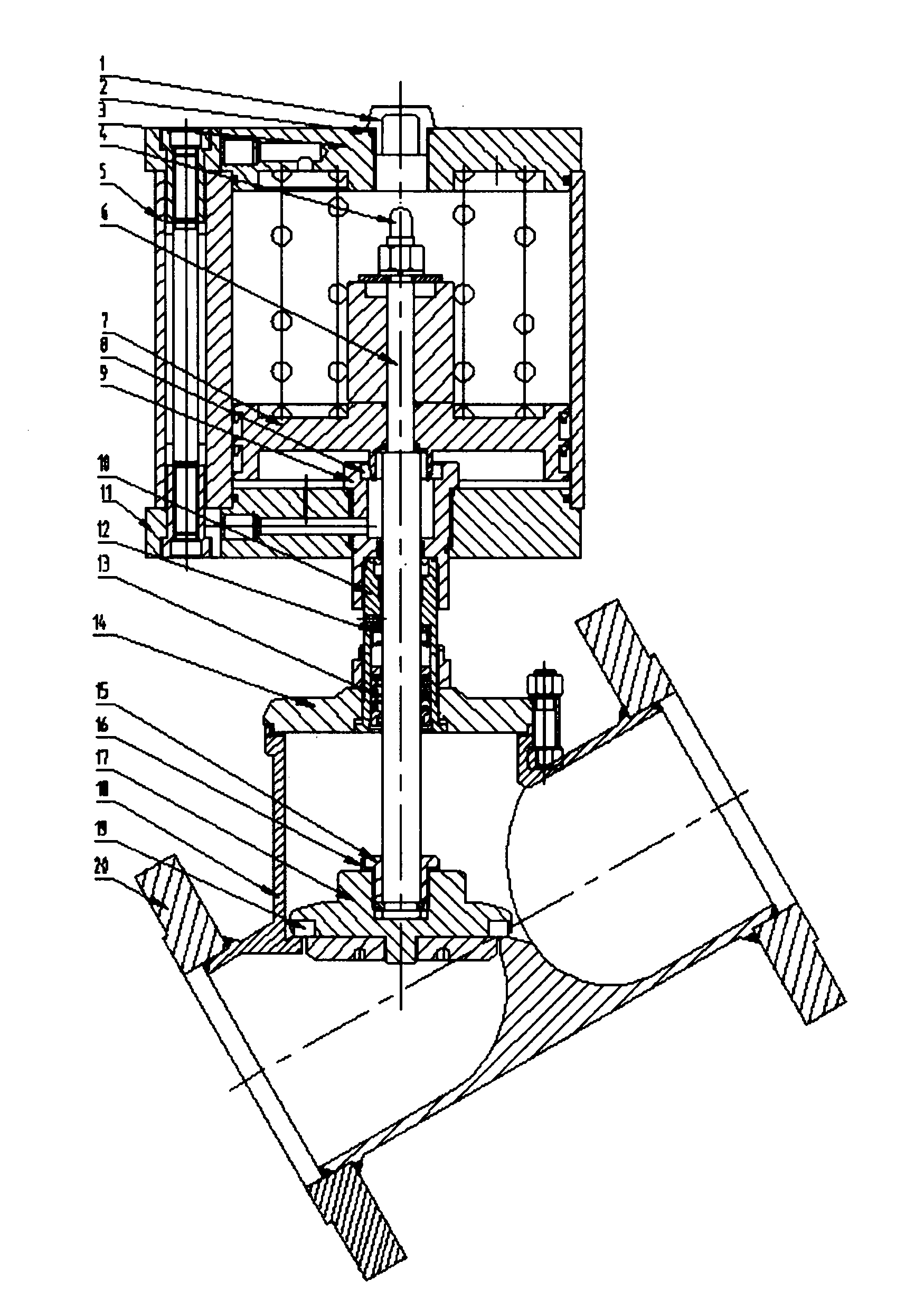

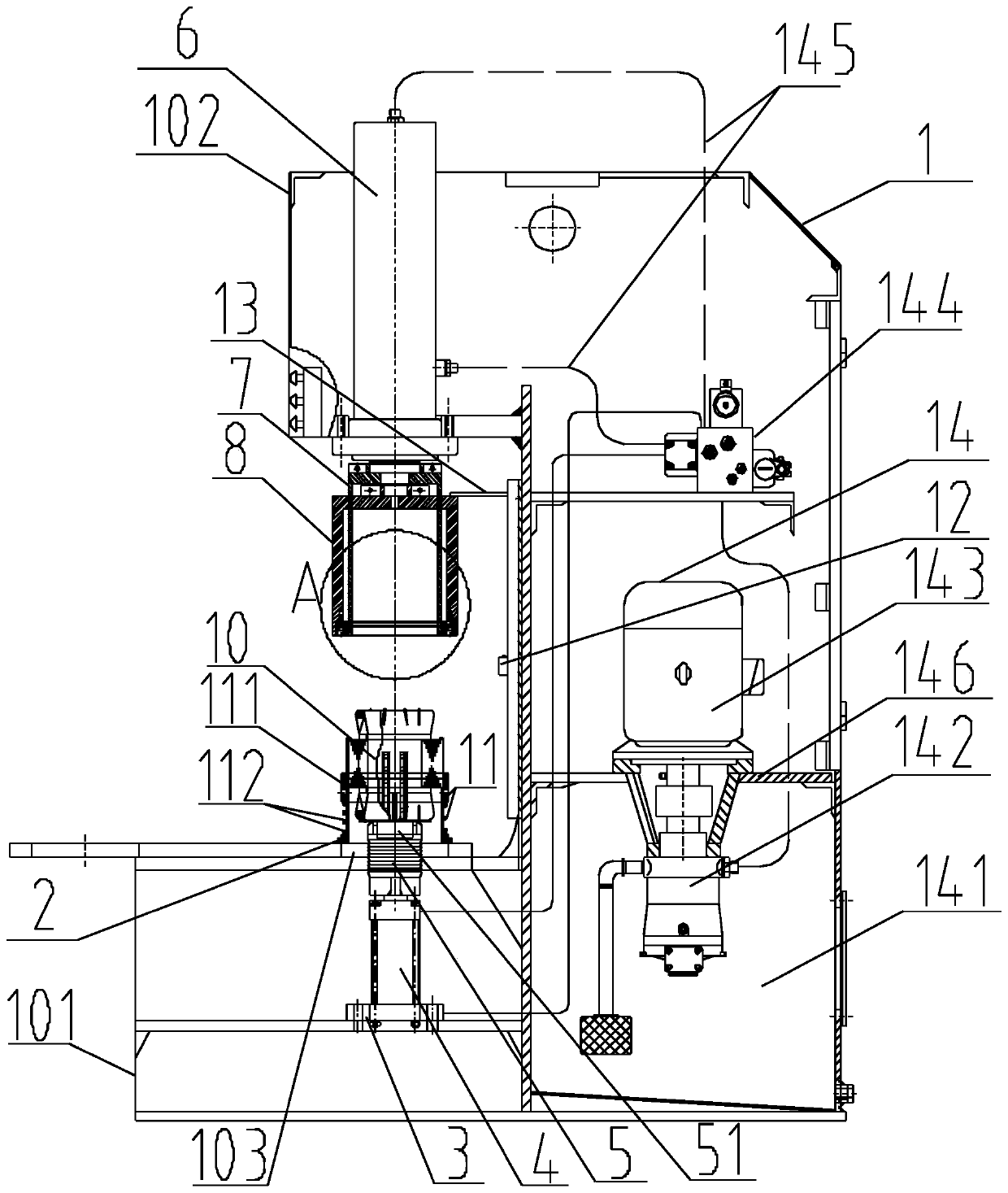

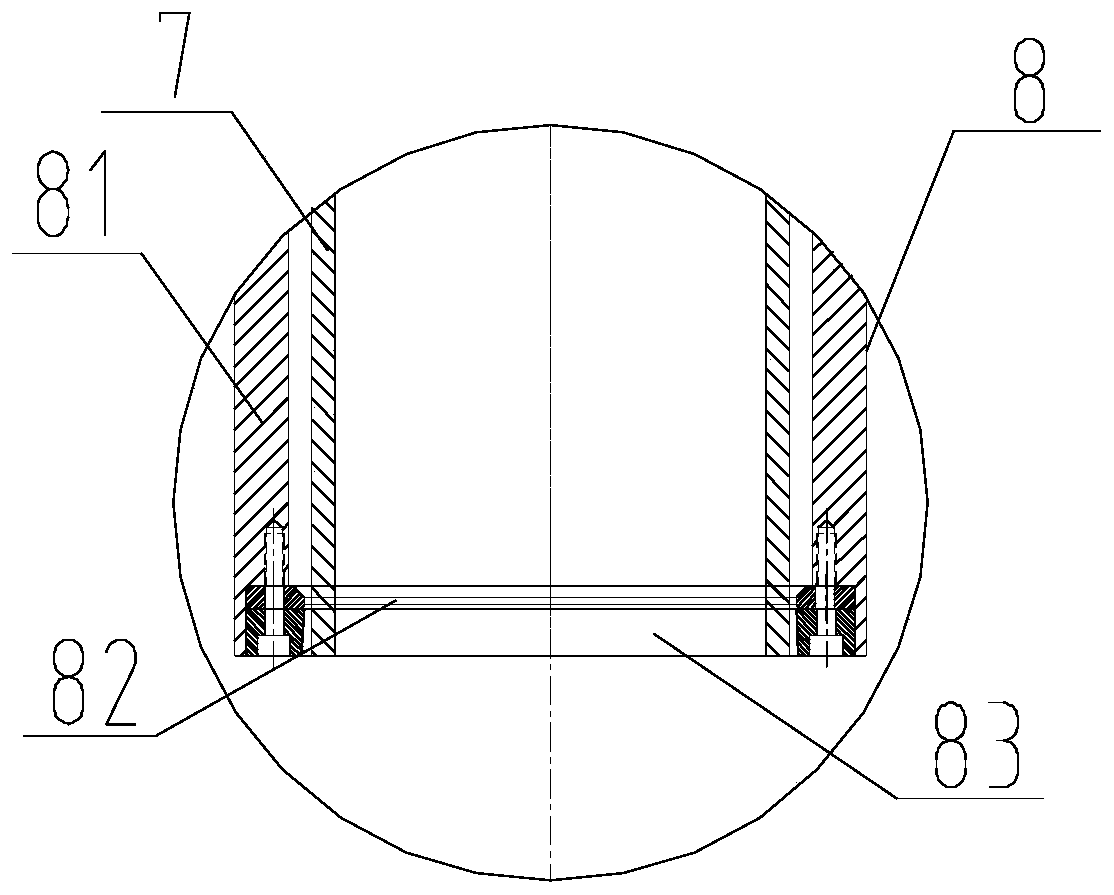

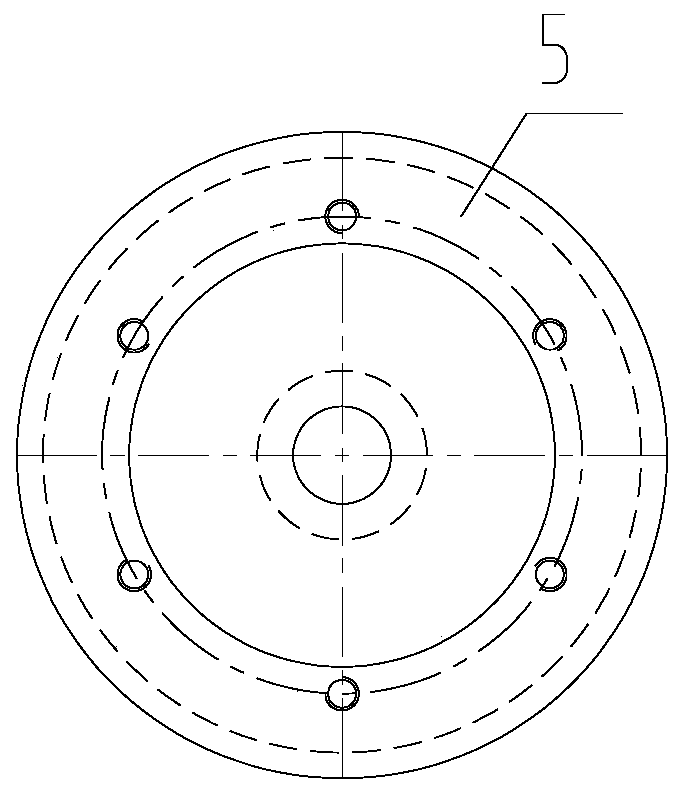

Supporting device and supporting method for machining propeller blade

InactiveCN102886699AIncrease stiffnessStable supportPositioning apparatusMetal-working holdersHydraulic cylinderPropeller

Owner:JIANGSU UNIV OF SCI & TECH

Device for performing surface treatment on pole piece of lithium battery

InactiveCN102151665AQuality improvementReduce the probability of short circuitCell electrodesCleaning using toolsPole pieceEngineering

The invention discloses a device for performing surface treatment on a pole piece of a lithium battery. In one piece-brushing process, the front side and the reverse side of the pole piece can be treated simultaneously, so that the treatment efficiency can be improved and the treatment quality can be guaranteed. The device comprises a machine frame, a workbench, an upper sponge, a lower sponge, a negative pressure device and an upper sponge driving cylinder; the lower sponge is fixed on the workbench; the upper sponge driving cylinder is arranged on the machine frame; a piston rod of the upper sponge driving cylinder faces downward; the bottom of the piston rod is fixedly connected with the upper sponge; the upper sponge is positioned above the lower sponge; the negative pressure device comprises an air compressor and a suction pipe; the suction pipe is inserted upward from the bottom of the workbench; and the pipe orifice of the suction pipe is positioned in the lower sponge. The process for brushing the piece is improved, a technology for automatically brushing the two sides of the piece simultaneously is adopted, two sponge plates which are correspondingly arranged up and down are used and when dust adsorbed to the sponge plates is more, the sponge plates can be replaced at any time. The device is high in quality for cleaning the pole piece, and high in yield, and can timely remove the dust and debris and obviously improve the quality of the pole piece, and the battery manufactured by the pole piece is low in short circuit rate.

Owner:JIANGSU YINGTAI ELECTRONICS

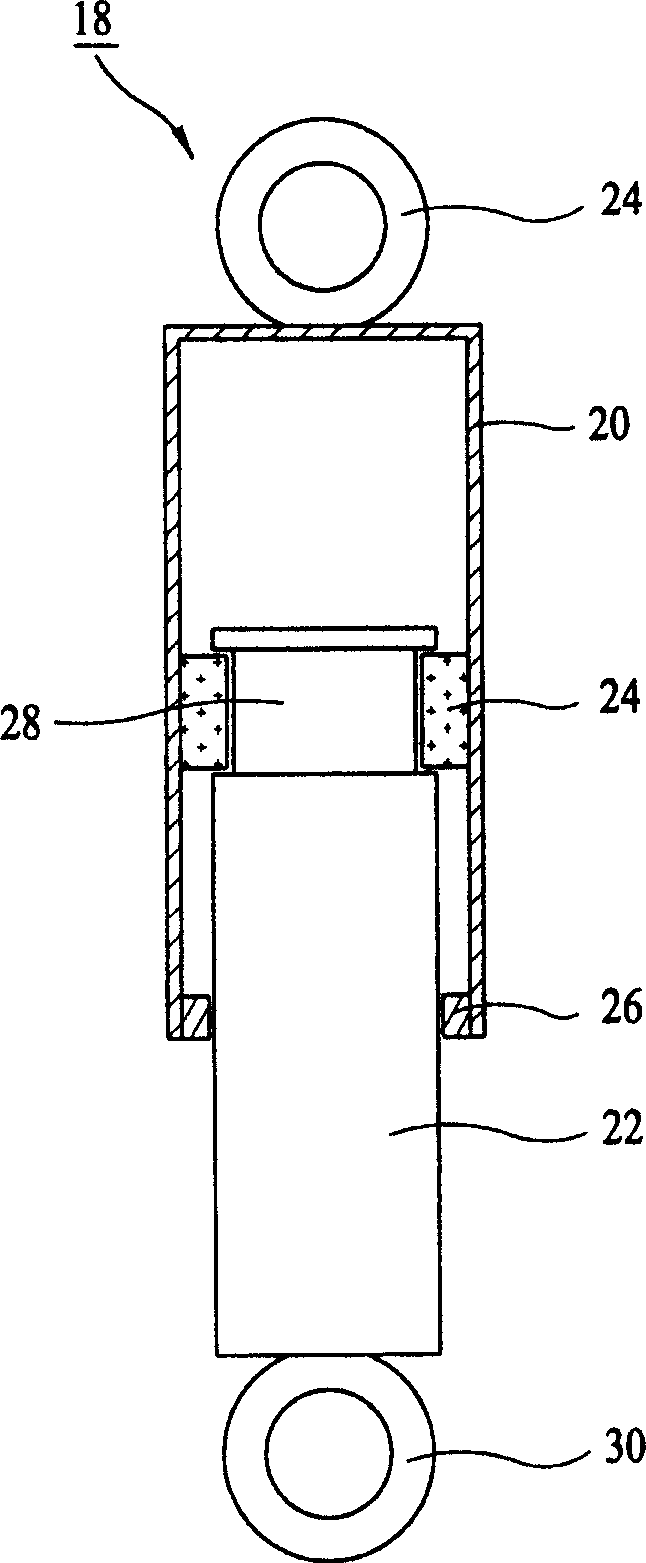

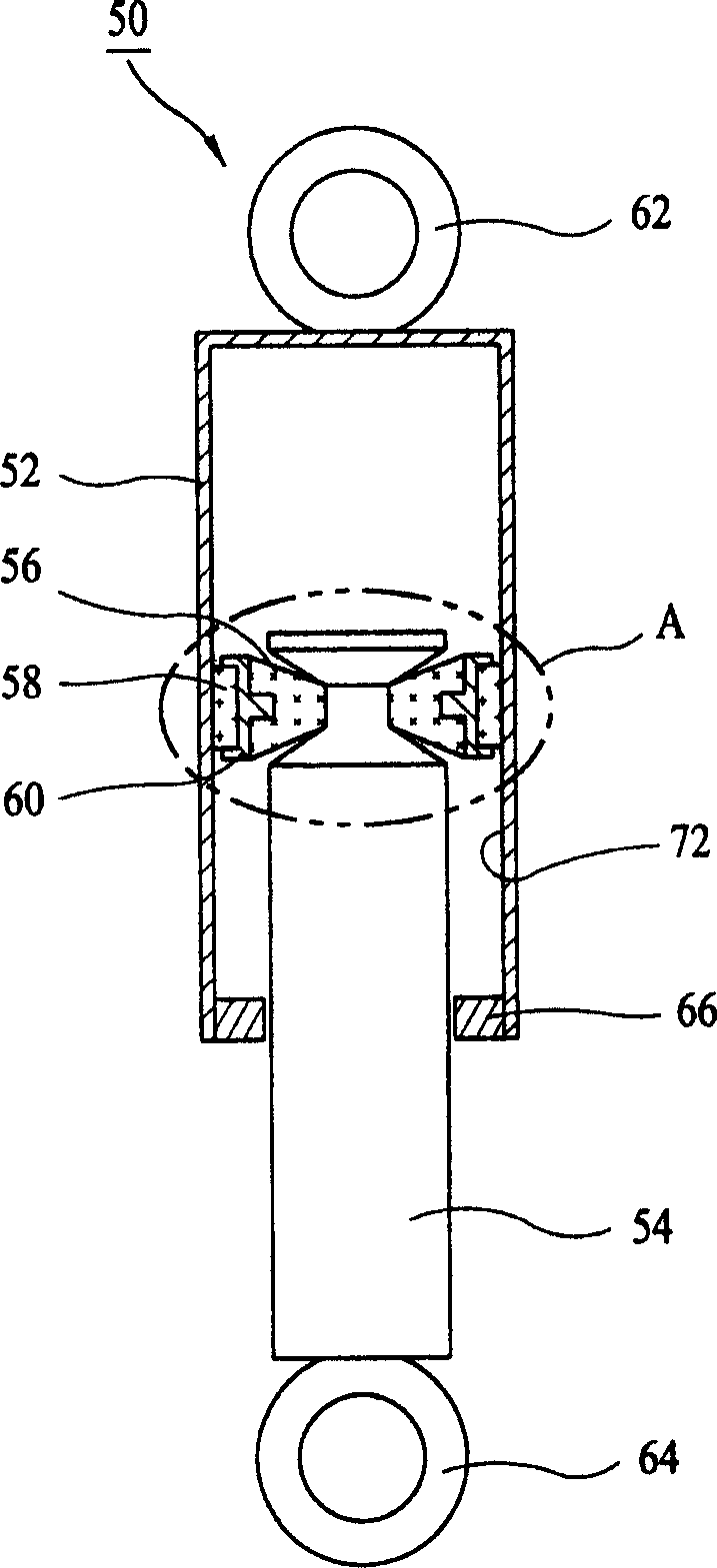

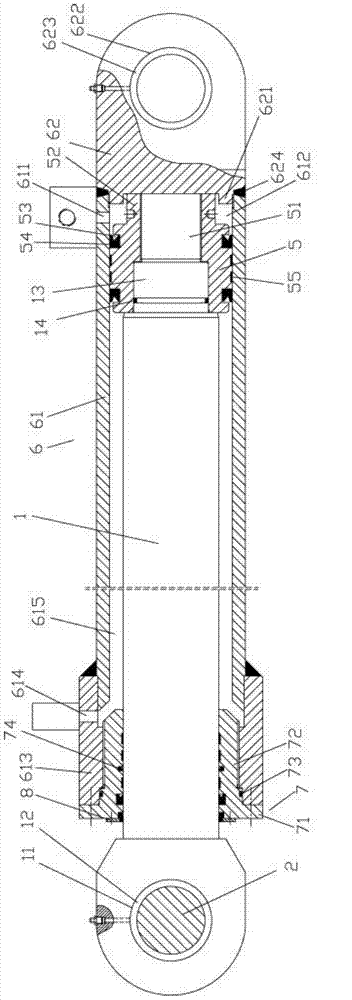

Electric gas spring

InactiveCN103410906AEasy to useCompact structureSpringsGas based dampersElectric machineReciprocating motion

The invention relates to a gas spring, in particular to an electric gas spring electrically driven. External force needs to be applied by hands to allow the prior gas spring to reciprocate or to be located, and the manual mode causes great inconveniences to users. The electric gas spring is characterized in that a drive motor, a decelerator and a coupling are mounted in a motor connecting sleeve of an electric drive device; a spiral reciprocating mechanism, a guide sleeve and a piston rod component are disposed in a gas spring cylinder barrel; the gas spring cylinder barrel is filled with nitrogen. The electric gas spring has the advantages that applying external force by hands is avoided, more convenient, safer and high-comfort humanized services are provided for users, and the application range of the gas spring is widened; the electric gas spring is compact in structure, simple to mount, convenient to use, stable in performance, safe and reliable, and widely applicable.

Owner:王振民 +1

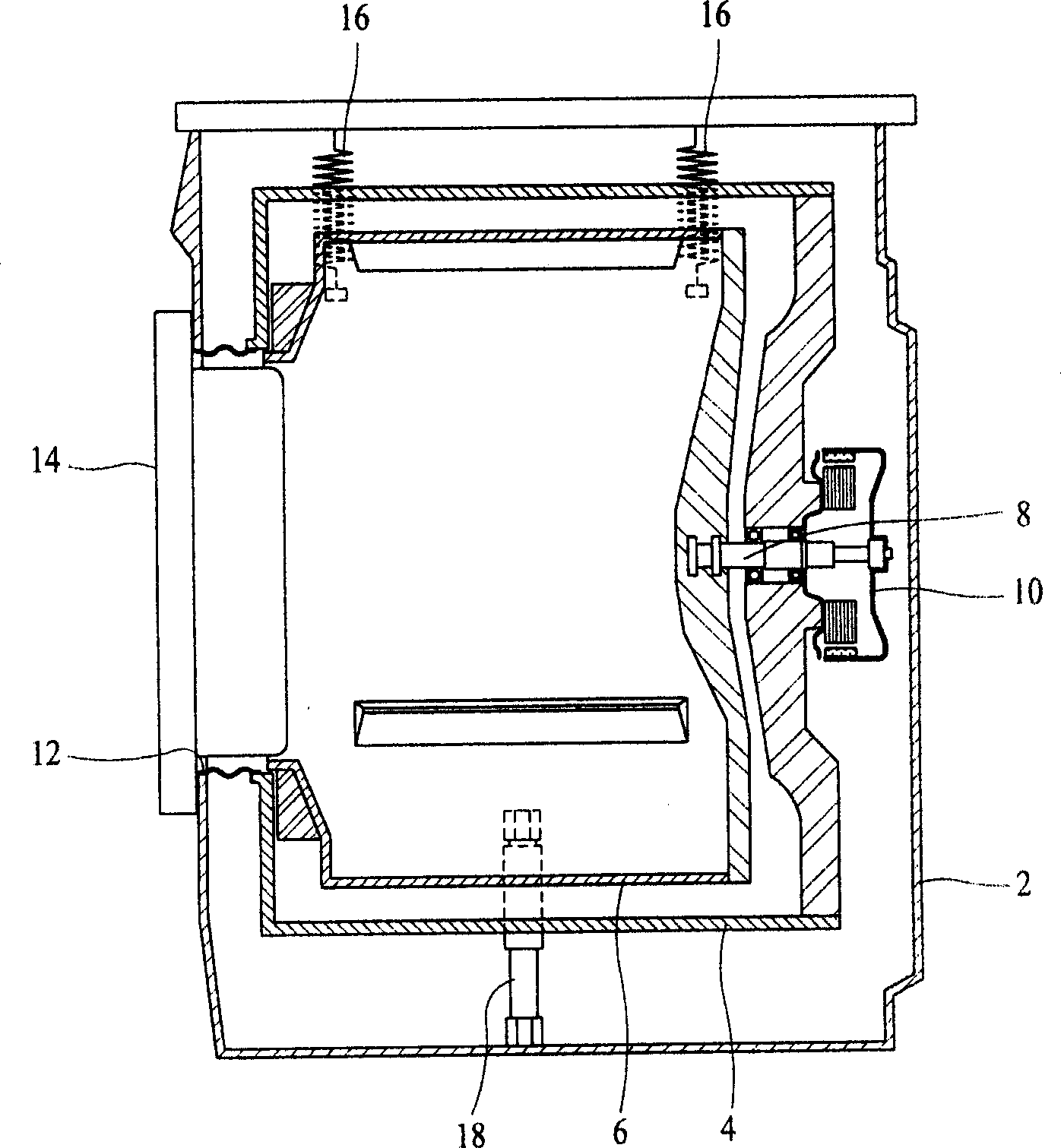

Shock absorber of washing machine

Owner:LG ELECTRONICS INC

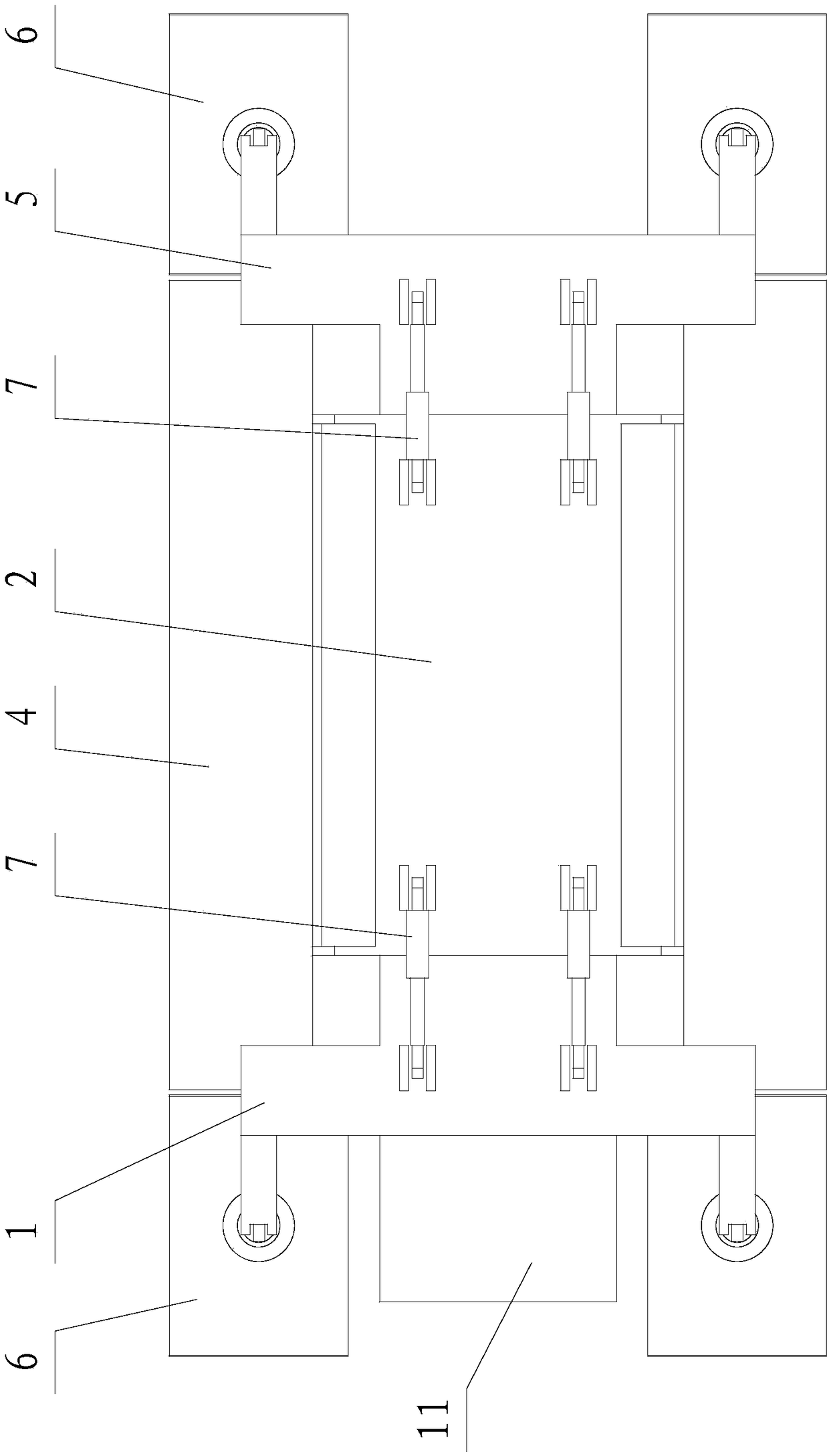

Submarine mining vehicle walking chassis and self-rescue method thereof

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

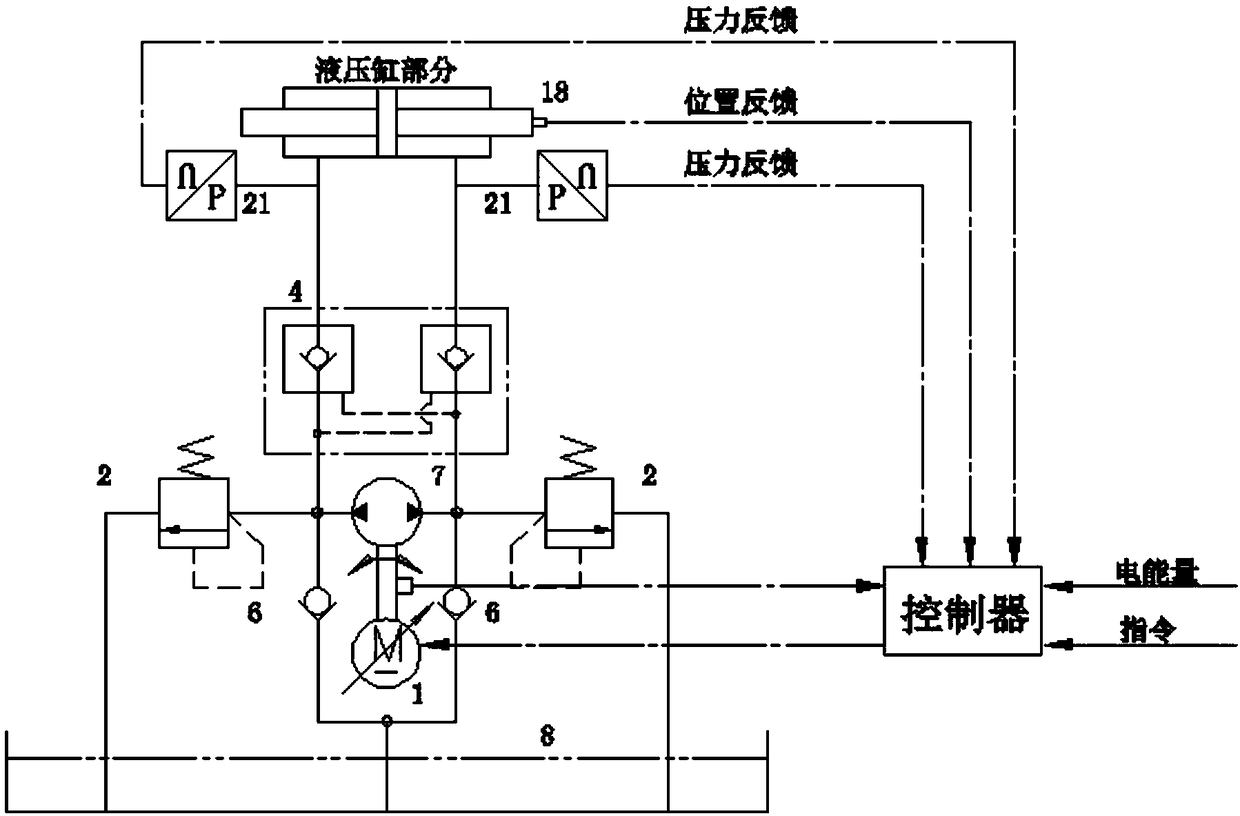

Electric static liquid actuator for deep sea

ActiveCN109340220AHigh level of integrationReduce volumeFluid-pressure actuator componentsHydraulic cylinderElectric machine

Owner:BEIJING UNIV OF TECH

Matching drying equipment for dyeing clothing cloth

InactiveCN109654856AConvenient and fast windingFully heatedDrying gas arrangementsDrying machines with progressive movementsEngineeringCopper

The invention provides matching drying equipment for dyeing clothing cloth. The matching drying equipment comprises lower guide rollers, upper guide rollers, guide roller mounting plates, a cloth passing frame, a positioning plate and a top plate. A drying box is integrally arranged in a rectangular shape. The bottom of the drying box is provided with a water receiving tank. A group of pressing rollers driven by a motor are supported and welded to openings in the front end of the drying box. The middle of the bottom of the outer wall at the front end of the water receiving tank is provided with a drain copper ball valve in a threaded locking mode. Two electric heating fans are symmetrically locked and installed on the top plate of a hot air box. The three groups of lower guide rollers arearranged and supported at bottom positions of the left and right side walls of the drying box at equal intervals. Four electric push rods are symmetrically and vertically supported on the left side and right side of the water receiving tank. Piston rods of the four electric push rods are connected with screws of the two guide roller mounting plates in a screw locking mode. Due to the arrangement of the four positioning rods, the left-and-right swinging of the three upper guide rollers can be limited by the four positioning rods, and the piston rods of the four electric push rods are preventedfrom being broken by conveying and drawing force of cloth.

Owner:FO SHAN SHI TAO LIAN RAN ZHENG DING XING YOU XIAN GONG SI

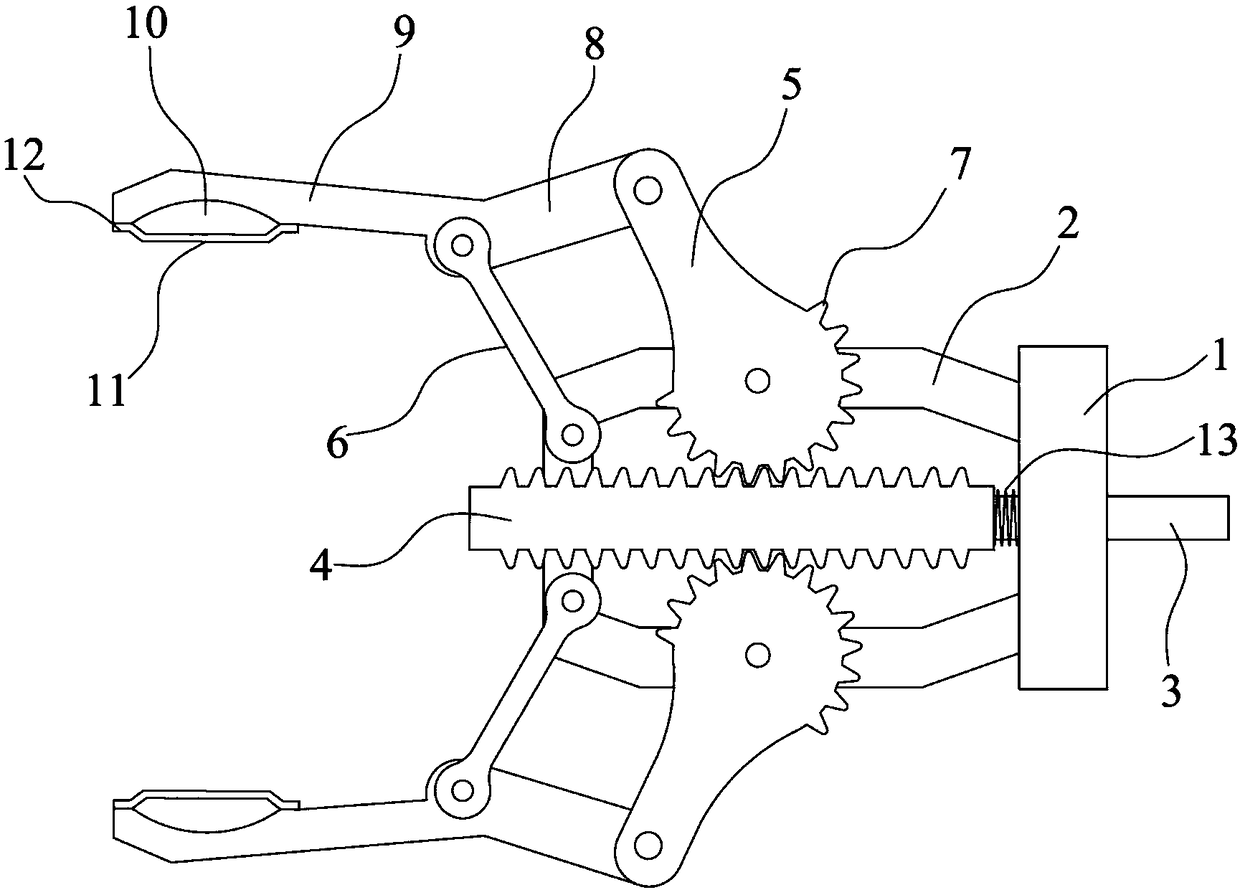

Large-opening-and-closing-angle manipulator

InactiveCN108544522ALarge opening and closing angleAvoid being scratchedGripping headsEngineeringManipulator

Owner:东阳市天齐科技有限公司

Gas spring with guide

ActiveUS20090072453A1Prevent gas leakageConvenient lengthLiquid springsLiquid based dampersReciprocating motionGas spring

In at least one embodiment, a gas spring includes a casing having an inner surface defining in part a gas chamber, a piston rod and a seal. The piston rod is received at least partially in the casing for reciprocation along an axis between extended and retracted positions. The piston rod has an internal cavity defining a hollow space, a stop and a rod guide disposed adjacent to the inner surface of the casing to guide the reciprocation of the piston rod at least in part. The seal generally is provided between the piston rod and the casing to prevent gas leakage from the gas chamber.

Owner:DADCO INC

Bolt type hydraulic lifting system

ActiveCN106192965AEven by forceExtended service lifeArtificial islandsUnderwater structuresFixed framePiston rod

Owner:WUHAN MARINE MACHINERY PLANT

Conveyer belt production line centering mechanism capable of realizing convenient adjustment

ActiveCN106626152AAffect qualityImprove alignment efficiencyBeltsDomestic articlesProduction lineLocking mechanism

The invention discloses a conveyer belt production line centering mechanism capable of realizing convenient adjustment. The conveyer belt production line centering mechanism comprises an upper guide rail, a lower guide rail and a clamping device, wherein the lower guide rail is provided with a first slide block and a second slide block; the lower side of the clamping device is in slip connection with the first slide block; the upper side of the clamping device is in slip connection with the upper guide rail; an electrically controlled locking mechanism is arranged between the clamping device and the first slide block; the first and second slide blocks are respectively provided with first and second synchronization cylinders; piston rods of the first and second synchronization cylinders are respectively provided with first and second references; the working cavity of the first synchronization cylinder communicates with the working cavity of the second synchronization cylinder; an intermediate point between the first reference and the second reference is positioned on the centered flat plane of a vulcanizer; and a synchronization moving mechanism is connected between the first slide block and the second slide block, so that the first slide block and the second slide block synchronously move. The conveyer belt production line centering mechanism can obviously improve the centering efficiency, ensure the centering precision and prevent the quality of a conveyer belt from being influenced due to a centering error.

Owner:ZHEJIANG SANWEI RUBBER ITEM CO LTD

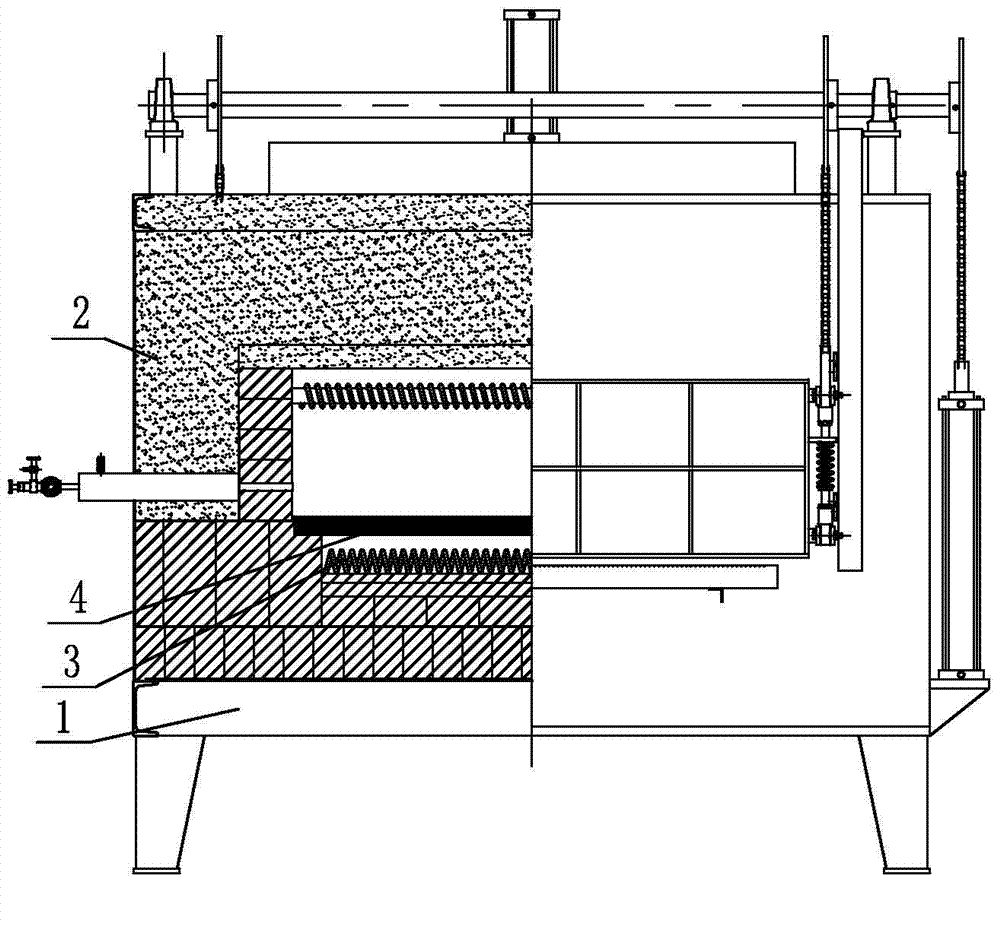

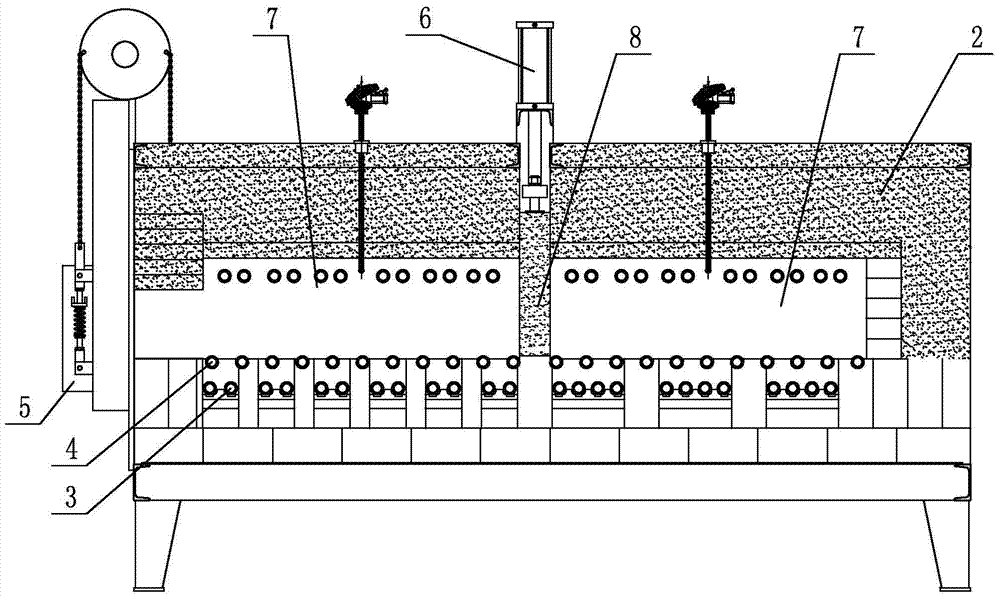

Mobile roller-type van-type heating furnace and hot-forming subsection strengthening technique

ActiveCN104729278AReduce volumeLess investmentFurnace typesHeat treatment furnacesPunchingRoom temperature

Owner:YANCHENG KEAO MECHAICAL

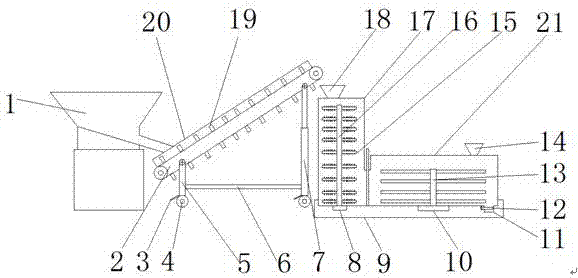

Stalk chopping and mixing feed preparation device

InactiveCN107183766APrevent slippingImprove stabilityFeeding-stuffCuttersHydraulic cylinderSteering wheel

Owner:王文奎

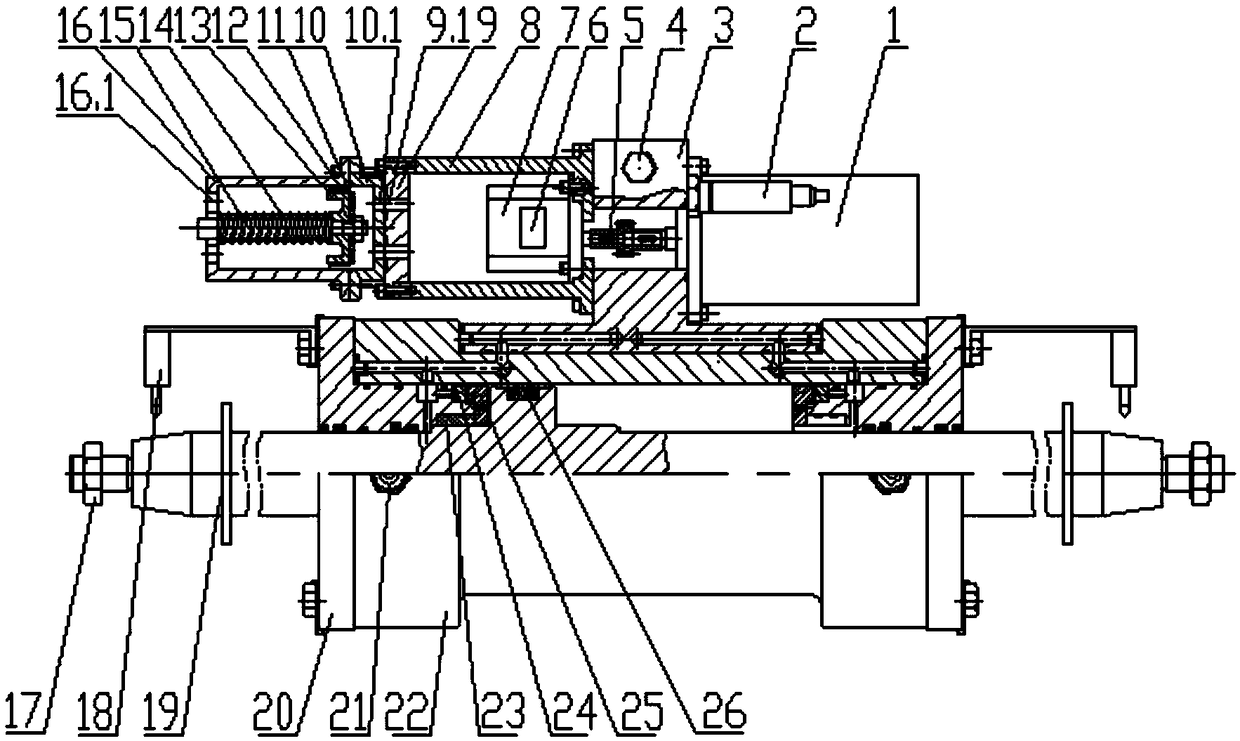

Machine tool cutting force simulation loading device

ActiveCN103737431AHigh simulationSimple structureProgramme controlMeasurement/indication equipmentsNumerical controlHydraulic cylinder

Owner:通用技术齐齐哈尔二机床有限责任公司

Disposable negative-pressure loop ligation appliance for hemorrhoids of patients

InactiveCN103110445AEliminate the hidden danger of insufficient negative pressureLarge negative pressure adjustment rangeSurgeryInlet valveEngineering

The invention relates to a disposable negative-pressure loop ligation appliance for hemorrhoids of patients. The disposable negative-pressure loop ligation appliance is characterized by comprising a gun shell, a fixing seat is mounted at the upper end of the gun shell, a cannula is fixed to the front end of the fixing seat, a push tube is sleeved on an outer layer of the cannula, a suction port is arranged at the front end of the cannula, an expansion tube is inserted in the suction port, two outlets are arranged at the rear end of the cannula, one outlet is connected with a check valve, the other outlet is connected with an air inlet valve, a negative-pressure cylinder is further arranged in the middle of the inside of the gun shell, an air inlet of the negative-pressure cylinder is communicated with another port of the check valve, the front end of a piston rod in the negative-pressure cylinder is connected with a negative-pressure trigger, and a loop ligation trigger is arranged on the lower side of the fixing seat and is hinged with the rear end of the push tube. The disposable negative-pressure loop ligation appliance for the hemorrhoids of the patients has the advantages that the disposable negative-pressure loop ligation appliance is convenient and speedy and is simple in operation when used in loop ligation treatment for hemorrhoids of a patient, cross infection is prevented, suffering of the patient is relieved, and the disposable negative-pressure loop ligation appliance is applicable to hospitals in various environments and is obvious in loop ligation effect.

Owner:JIANGSU HUAYANG BIOTECH

Flanging hot-die apparatus for automobile plafond

The invention relates to a vehicle ceiling flanged edge hot die device which is applied to the hot pressing technique for front edges and back edges of a ceiling and flanged edges around a sky light of a vehicle. According to the technical proposal provided by the invention, the device comprises a lifting cylinder which is fixedly arranged on a stand; a piston rod of the lifting cylinder is extended upward; the top end part of the piston rod of the lifting cylinder is fixedly provided with a shift cylinder, a piston rod of the shift cylinder is transversely extended; the end parts of the piston rod of the shift cylinder is fixedly connected with a connecting plate vertically extended upward; the top end part of the connecting part is fixedly connected with a pressing die head, and a working face of the pressing die head which is arranged downward is the same as the shape of the ceiling surface. The device has the advantages of simple, compact and reasonable structure, suitability for various products, high flexibility, high automaticity, guarantee of smooth flanged edges around the vehicle ceiling, accurate positioning of a work piece, quick process rhythm, high production efficiency, reduction of the labor intensity of a worker and manufacturing cost of the product and high product quality.

Owner:WUXI GISSING AUTO PARTS CO LTD

Sprue plugging device for casting sand mold at low pressure and method for casting sand mold at low pressure

Owner:JINAN CASTING FORGING MACHINERY INST

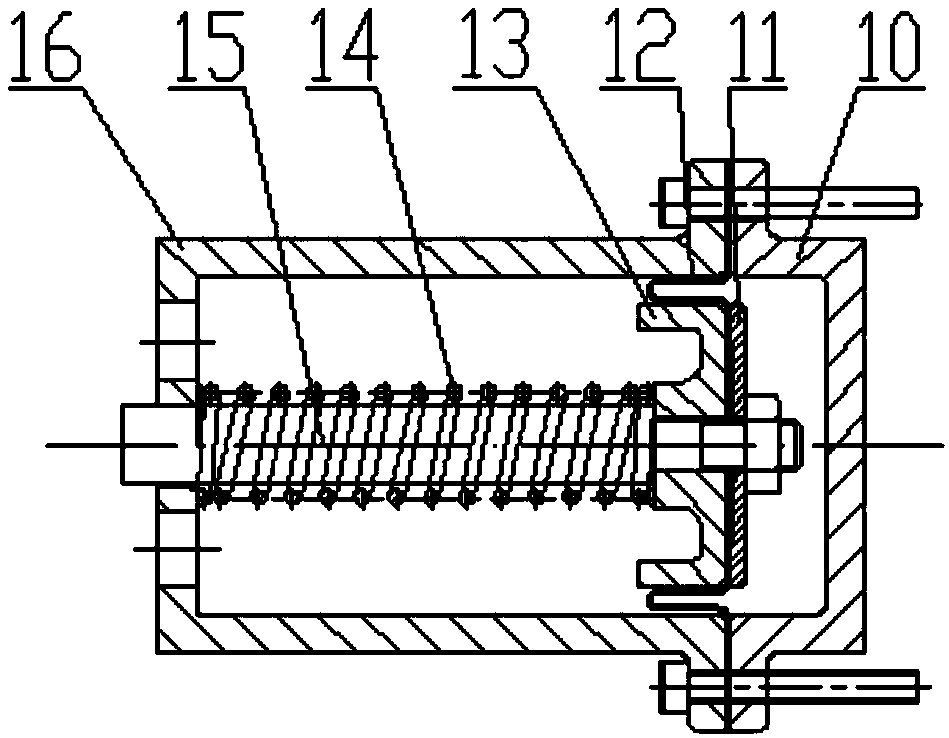

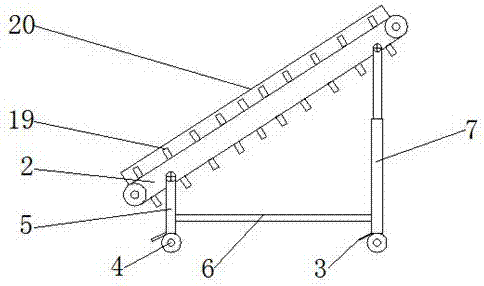

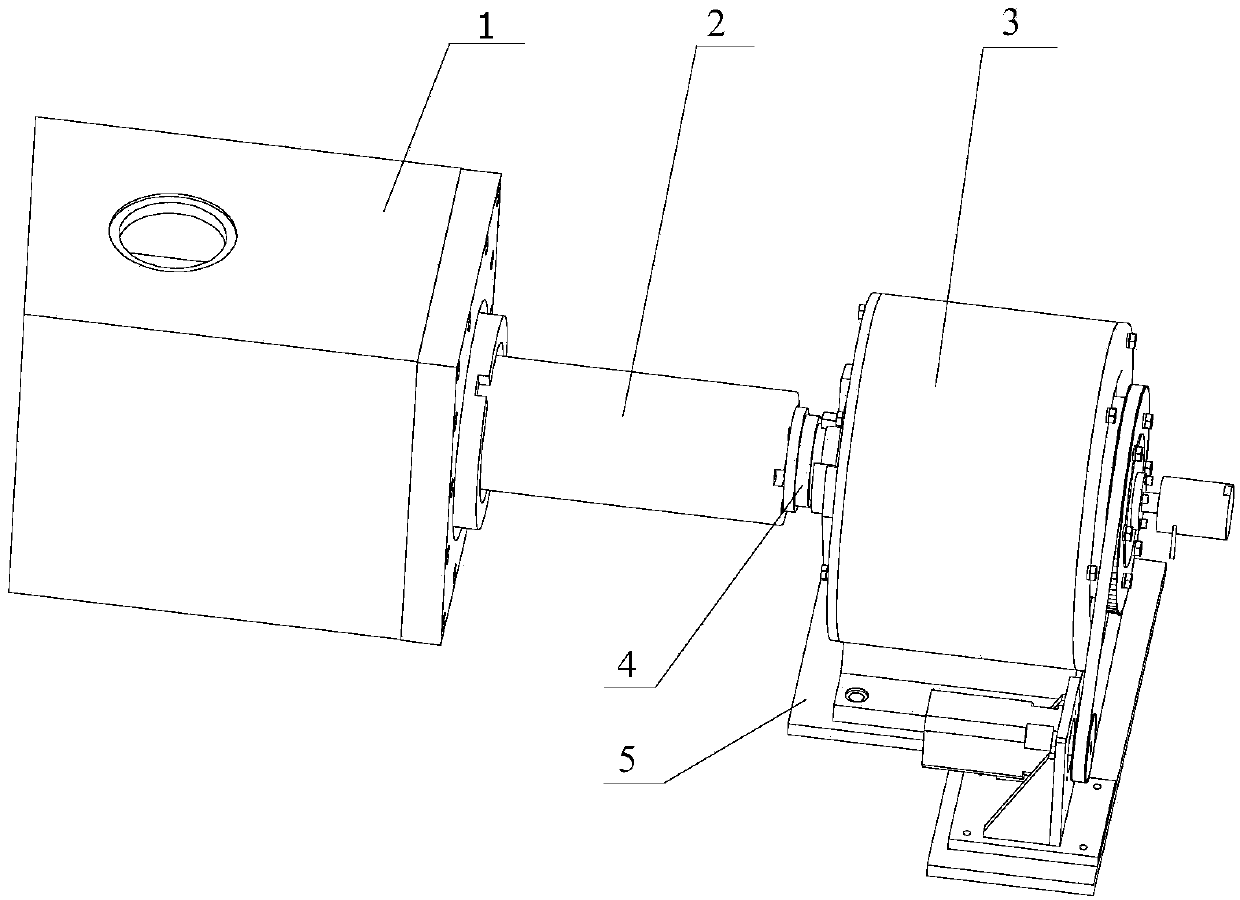

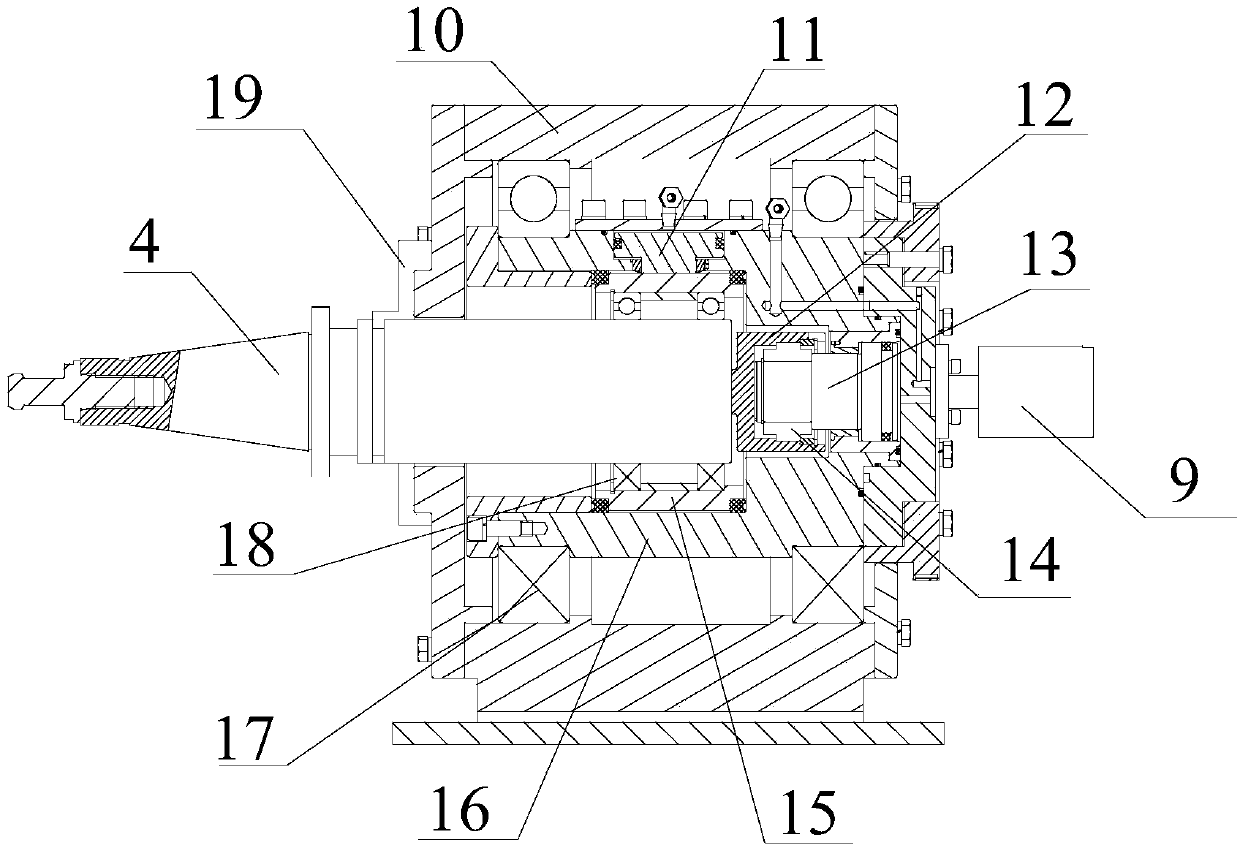

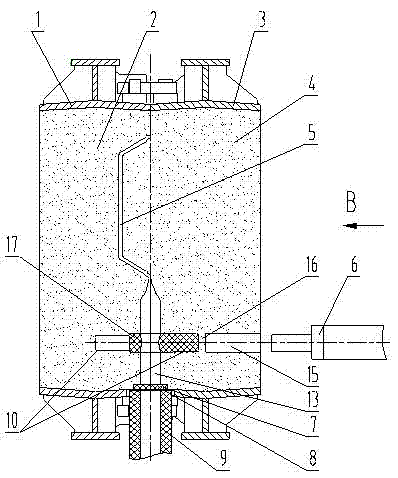

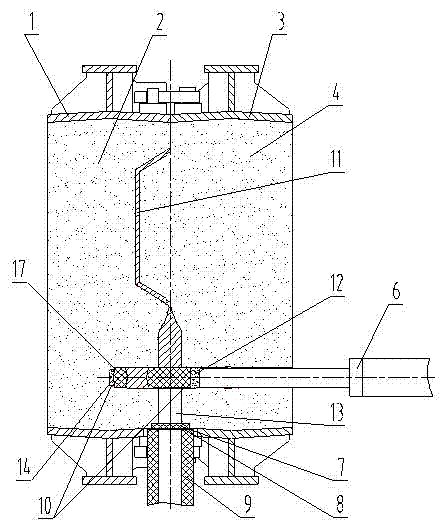

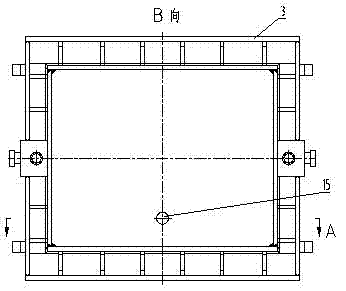

Composite connection type hydraulic knife handle

ActiveCN108907776AHigh strengthPrevent extravasationPositioning apparatusMetal-working holdersConnection typeInterference fit

The invention relates to a composite connection type hydraulic knife handle. The composite connection type hydraulic knife handle comprises a main knife handle body and an elastic thin-wall inner ringarranged in the main knife handle body, wherein a hydraulic oil cavity is arranged between the main knife handle body and the elastic thin-wall inner ring; the elastic thin-wall inner ring is arranged as a barrel thin-wall structure with two thick ends and a thin middle part; and the side outer rings of the two ends of the elastic thin-wall inner ring make contact with the support surfaces of inner holes of the main knife handle body. The main knife handle body and the elastic thin-wall inner ring are fixed in a manner of combining brazed connection and interference fit connection, the effectof stress on the connection performance of the main knife handle body and the elastic thin-wall inner ring is reduced, the joint of the main knife handle body and the elastic thin-wall inner ring isprevented from tear under the high pressure state, and therefore the service life of the hydraulic knife handle is prolonged. Meanwhile, by improving the structure of a piston rod and the structure ofa piston sleeve, the piston sleeve is quickly maintained, the overall sealing performance of a hydraulic access is improved, and the overall strength of the hydraulic knife handle is improved.

Owner:CHENGDU CHENGLIN CNC TOOL CO LTD

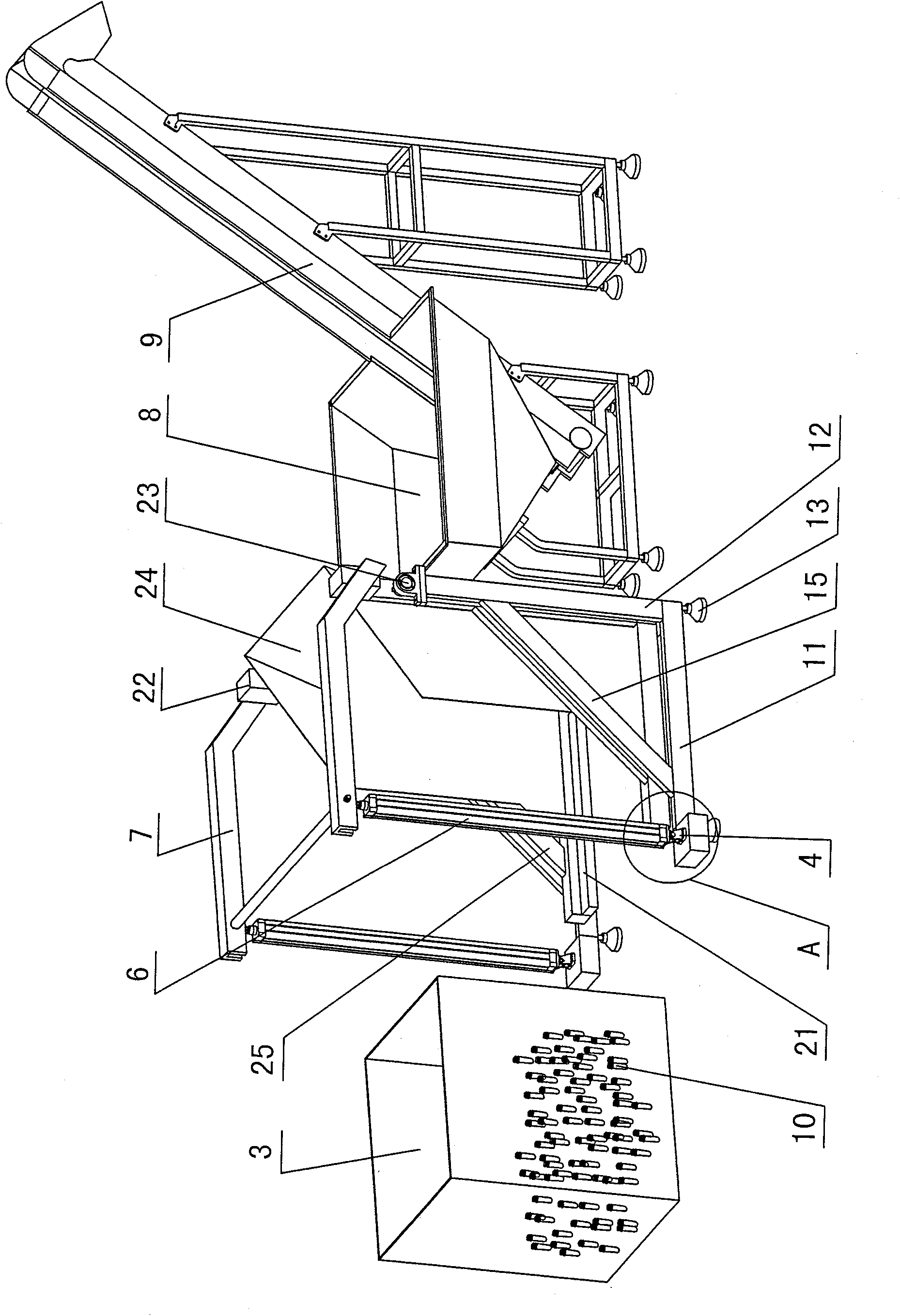

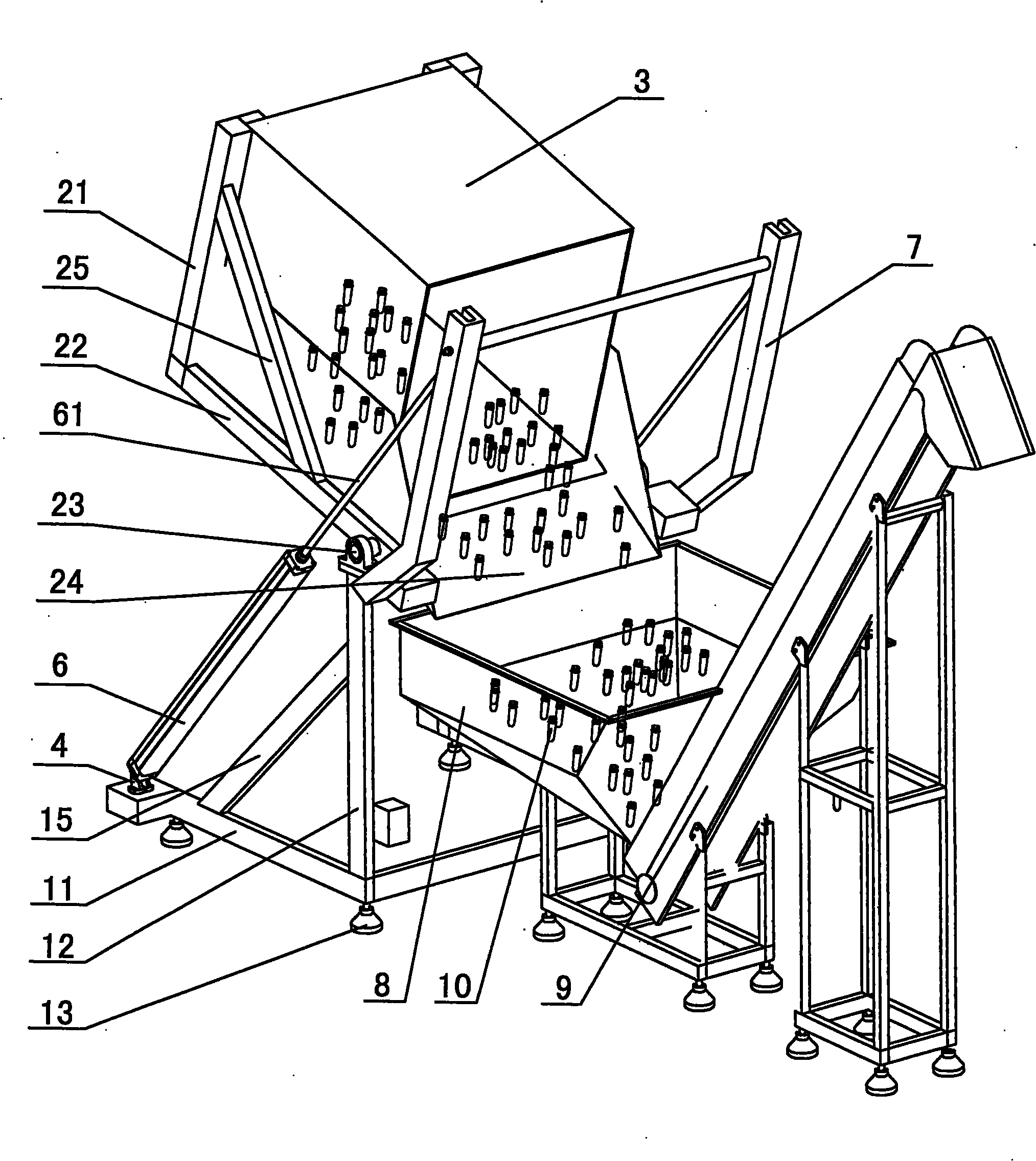

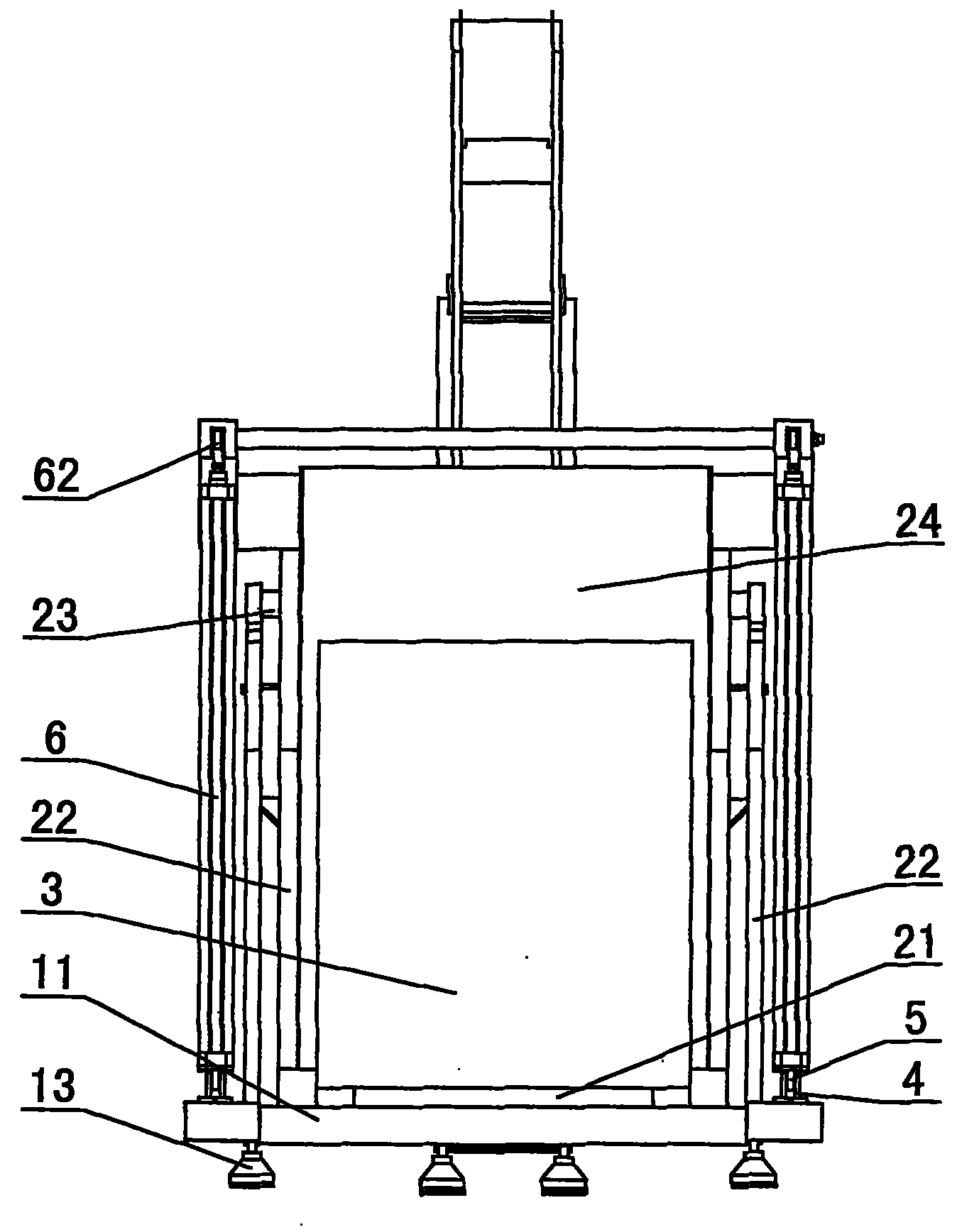

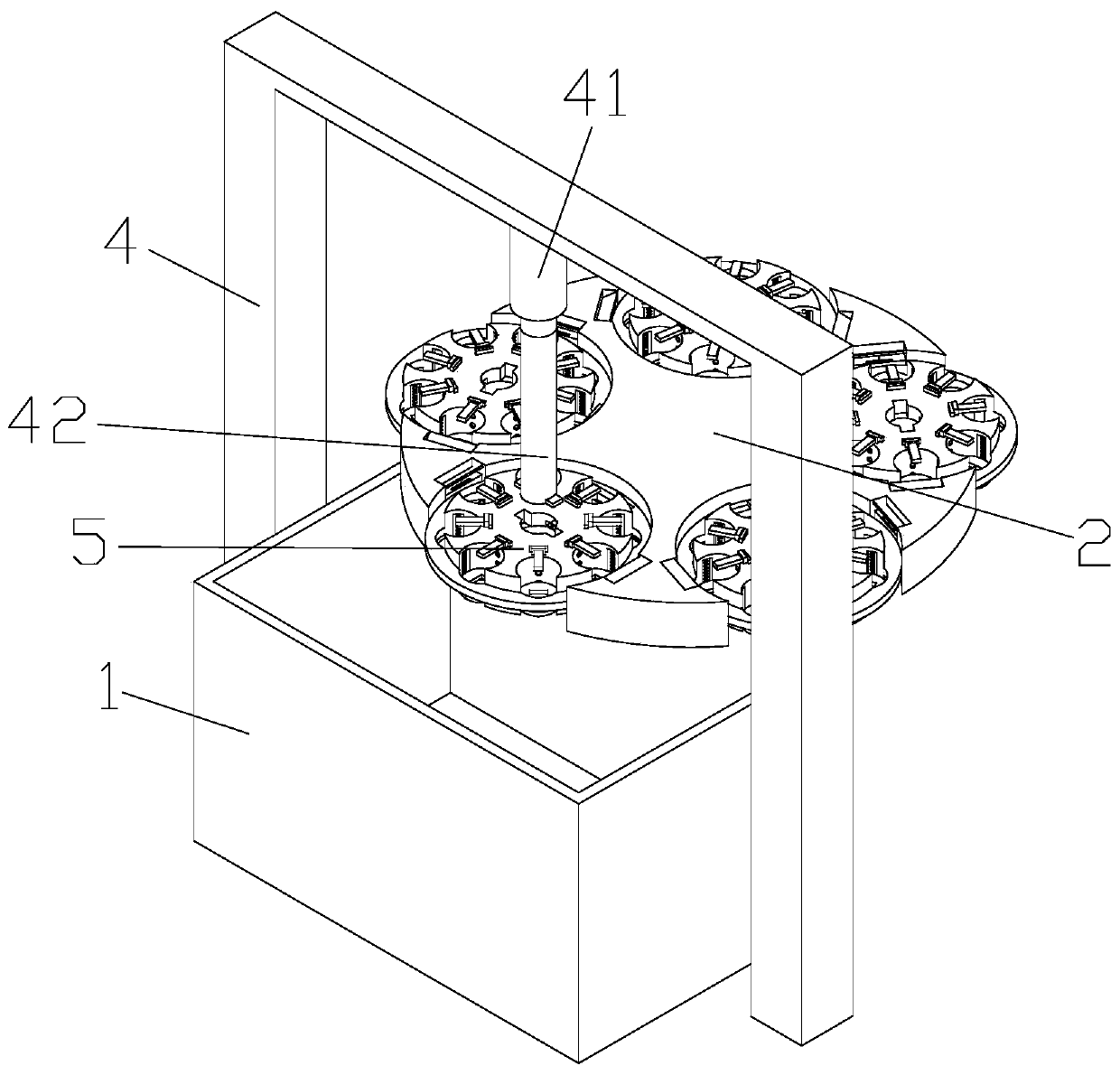

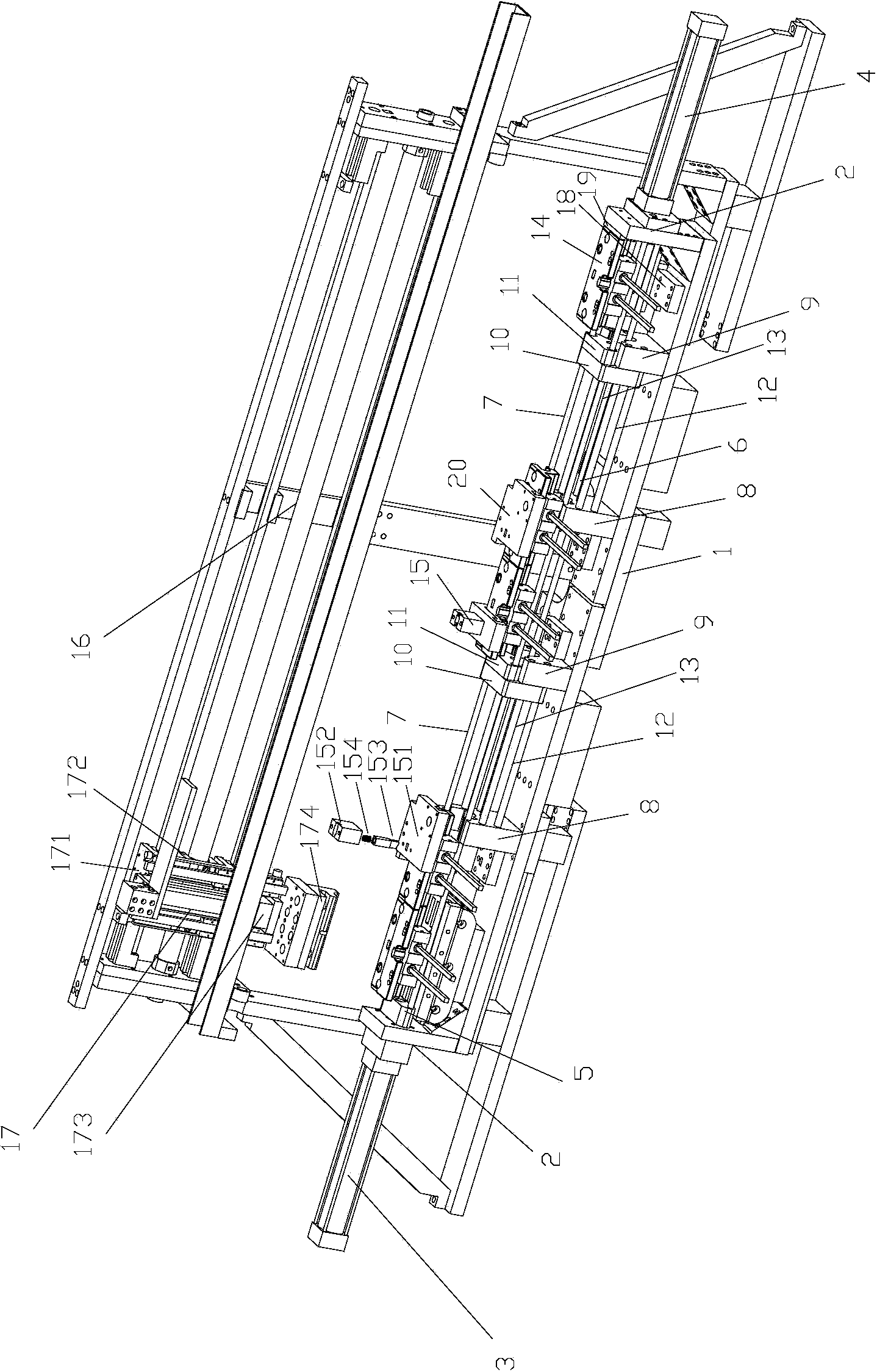

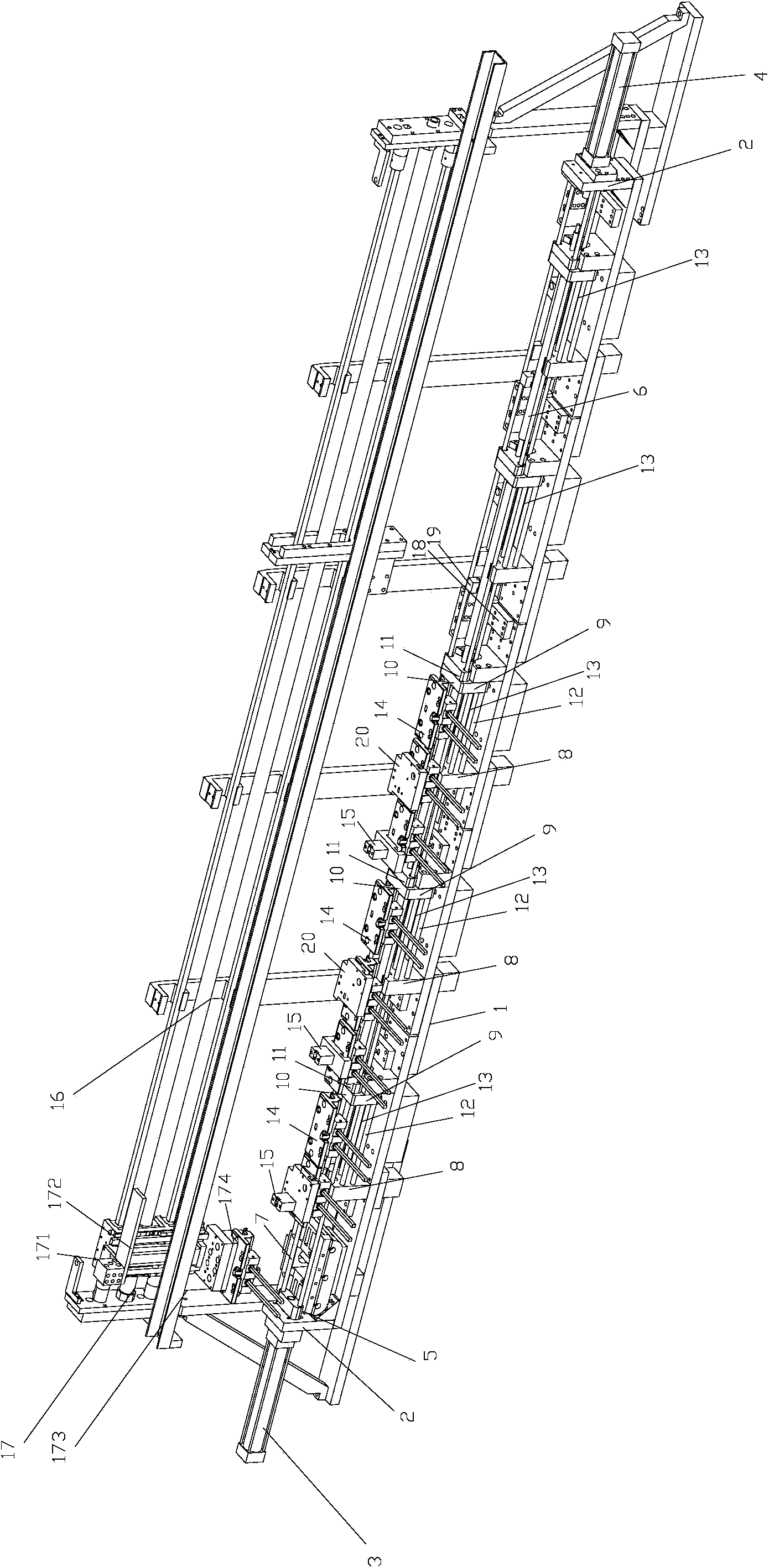

Automatic passing and clamping machine for long tail clamp

ActiveCN102794624ASpeed up clampingIncrease productivityMetal working apparatusEngineeringPiston rod

Owner:QIJING MACHINERY

Grinding filter component and bone slurry machine

Owner:润桐(苏州)技术服务有限公司

Automatic roller forming device for ceramic manufacturing

InactiveCN107225654AEasy to trimLow costPress rollersAuxillary shaping apparatusRoll formingEngineering

The invention discloses an automatic rolling forming device for ceramic production, which comprises an operation platform, the lower end of the operation platform is provided with supporting legs, and the upper end of the operation platform is sequentially provided with a first transmission mechanism and a second transmission mechanism along the horizontal direction. mechanism, both sides of the first transmission mechanism are provided with support plates, the upper ends of the two support plates are provided with fixed plates, and the lower ends of the fixed plates are fixed with two first cylinders parallel to each other, and the first cylinders A pressure block is provided at the end of the piston rod, and a first protection box is provided at both ends of one side of the first transmission mechanism, and a second driving device is provided in the first protection box. The present invention realizes the automatic conveying and flattening of the mud through the combination of the transmission mechanism, the first cylinder and the pressing block, and realizes the automatic clamping and rolling through the combination of the electric slide rail, the clamping block, the rolling head and the turntable, etc. pressure, reduces cost, improves work efficiency, enhances output, and is suitable for promotion.

Owner:CHONGQING YAYU CERAMICS CO LTD

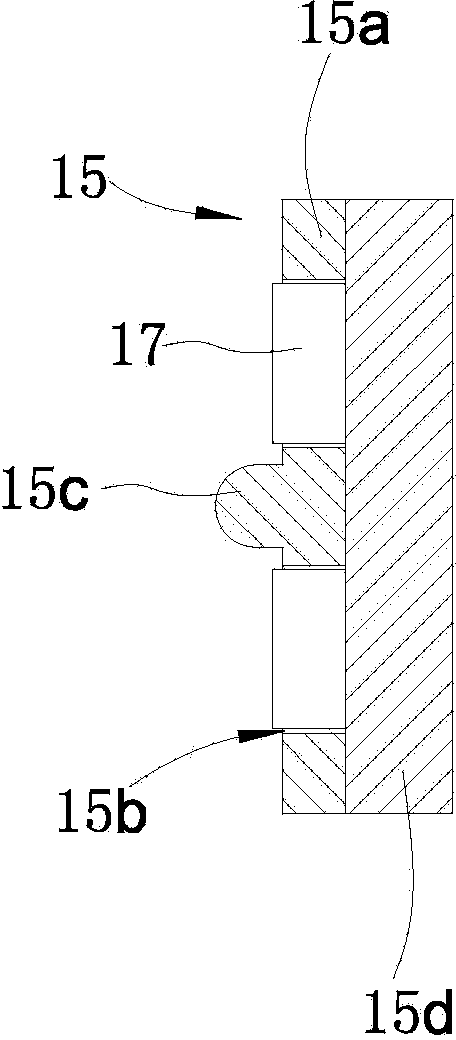

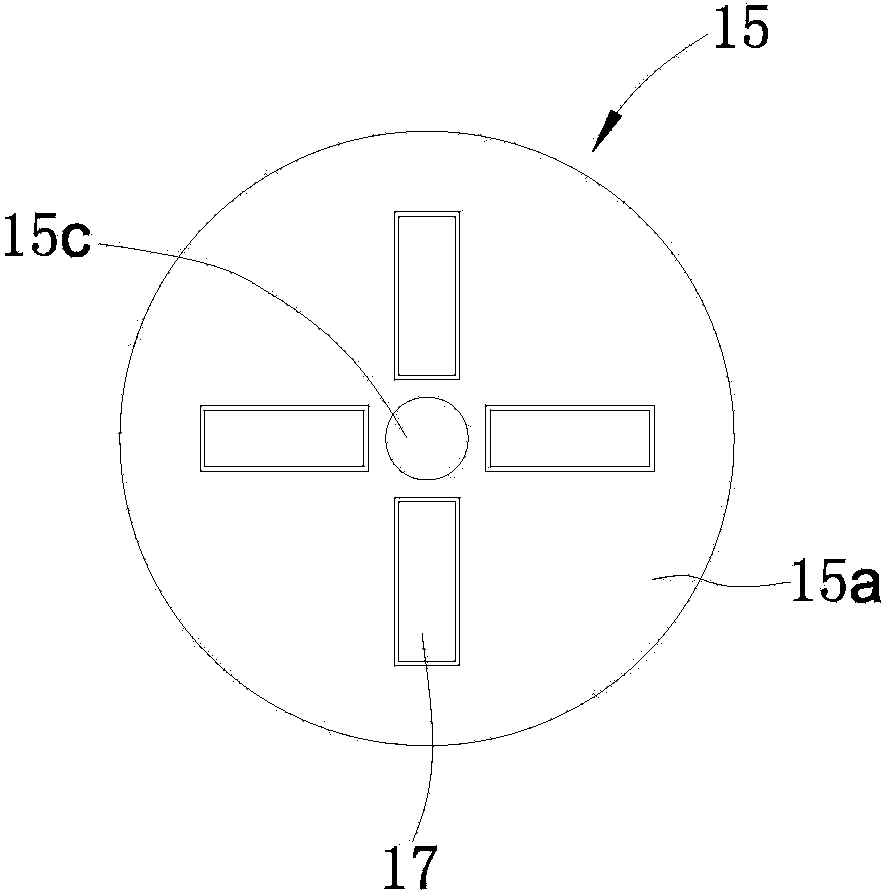

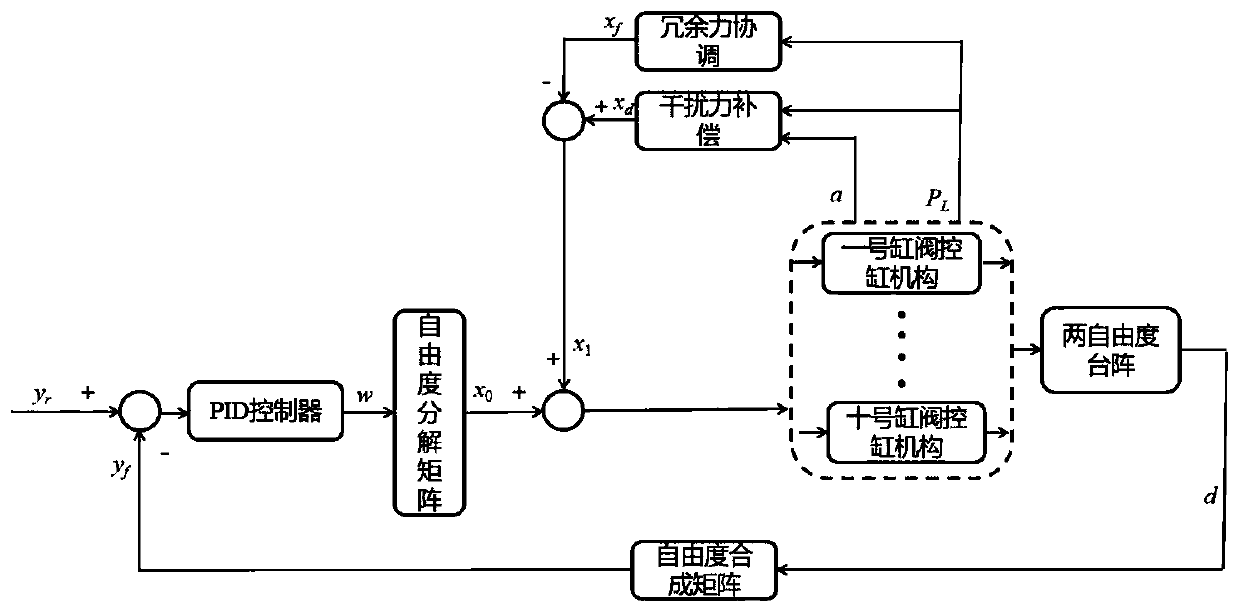

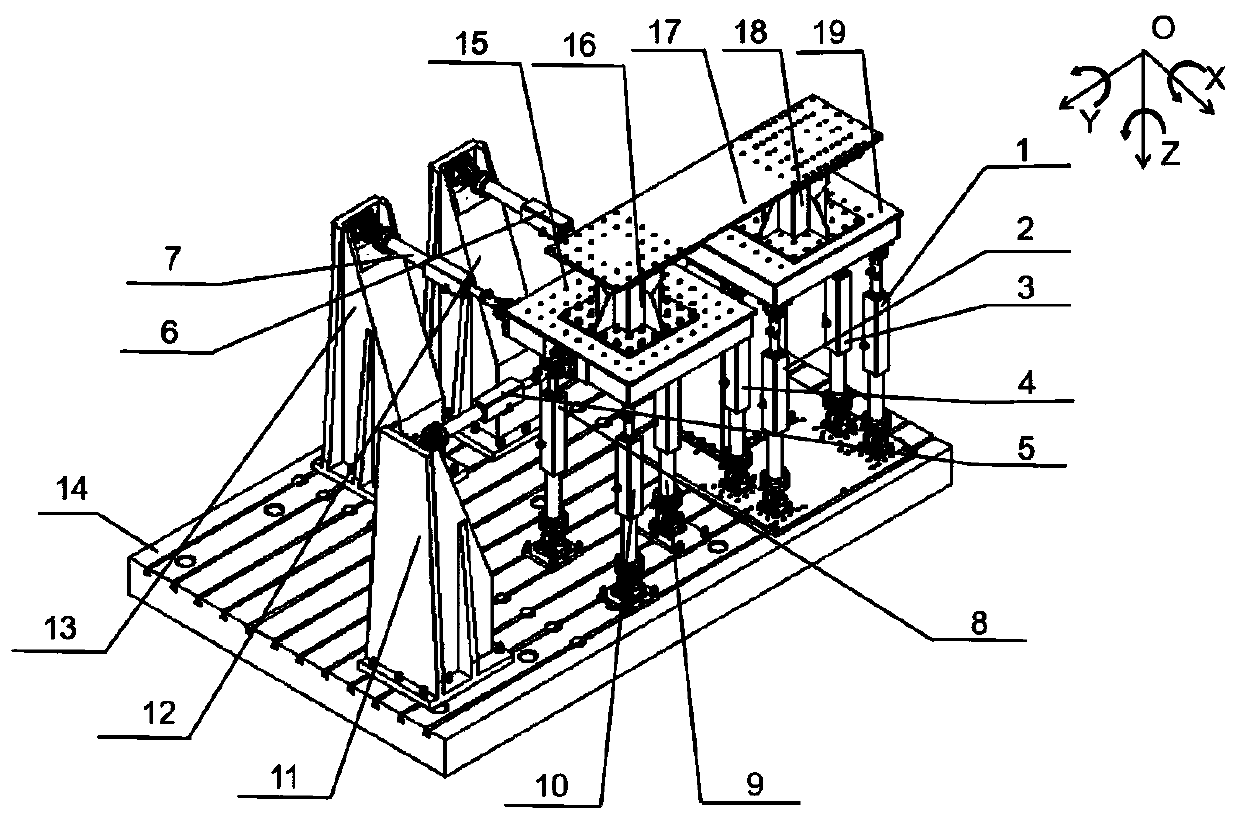

Disturbing force compensation method of two-degree-of-freedom double electro-hydraulic vibrostand array simulation system

ActiveCN110044568AHigh control precisionMeet the experimental requirementsVibration testingDifferential pressureEngineering

Owner:DALIAN MARITIME UNIVERSITY

Mangosteen squeezing device

A mangosteen squeezing device comprises a base, wherein a main supporting frame is installed on the base, an arc-shaped fixed plate is installed in the middle of the main supporting frame, the convex surface of the arc-shaped fixed plate is connected with the main supporting frame, a vertically-opened guide cylinder is formed at the upper portion of the main supporting frame, the guide cylinder is located at the upper portion of the arc-shaped fixed plate, an L-shaped side supporting frame is arranged at the side portion of the guide cylinder, an electric extruding push rod is arranged on the side supporting frame, an arc-shaped movable plate is installed on a piston rod of the electric extruding push rod, and the concave surface of the arc-shaped movable plate faces the arc-shaped fixed plate. A turnover plate is hinged to the lower portion of the main supporting frame and is located at the lower portion of the arc-shaped fixed plate, and an electric turnover push rod is arranged between the lower portion of the turnover plate and the main supporting frame. The mangosteen squeezing device can squeeze mangosteens in a batched mode, reduces the labor intensity and meanwhile can prevent the hands from being stained with mangosteen juice.

Owner:NANTONG WEALTH MASCH TECH CO LTD

Automatic feeding hopper turnover mechanism of plastic container forming machine

Owner:ZHEJIANG DEMARK MACHINERY

Double-cylinder kiln car pusher

Owner:应县优尊陶瓷有限责任公司

Machining device for producing external balance thermal expansion valves of QPW5 automobile air conditioner

Owner:SHANGYU DESHI PRECISION MACHINERY CO LTD

Multi-station automatic conveying mechanism for work-pieces

Owner:ZHANGJIAGANG XINXIN MOLDING

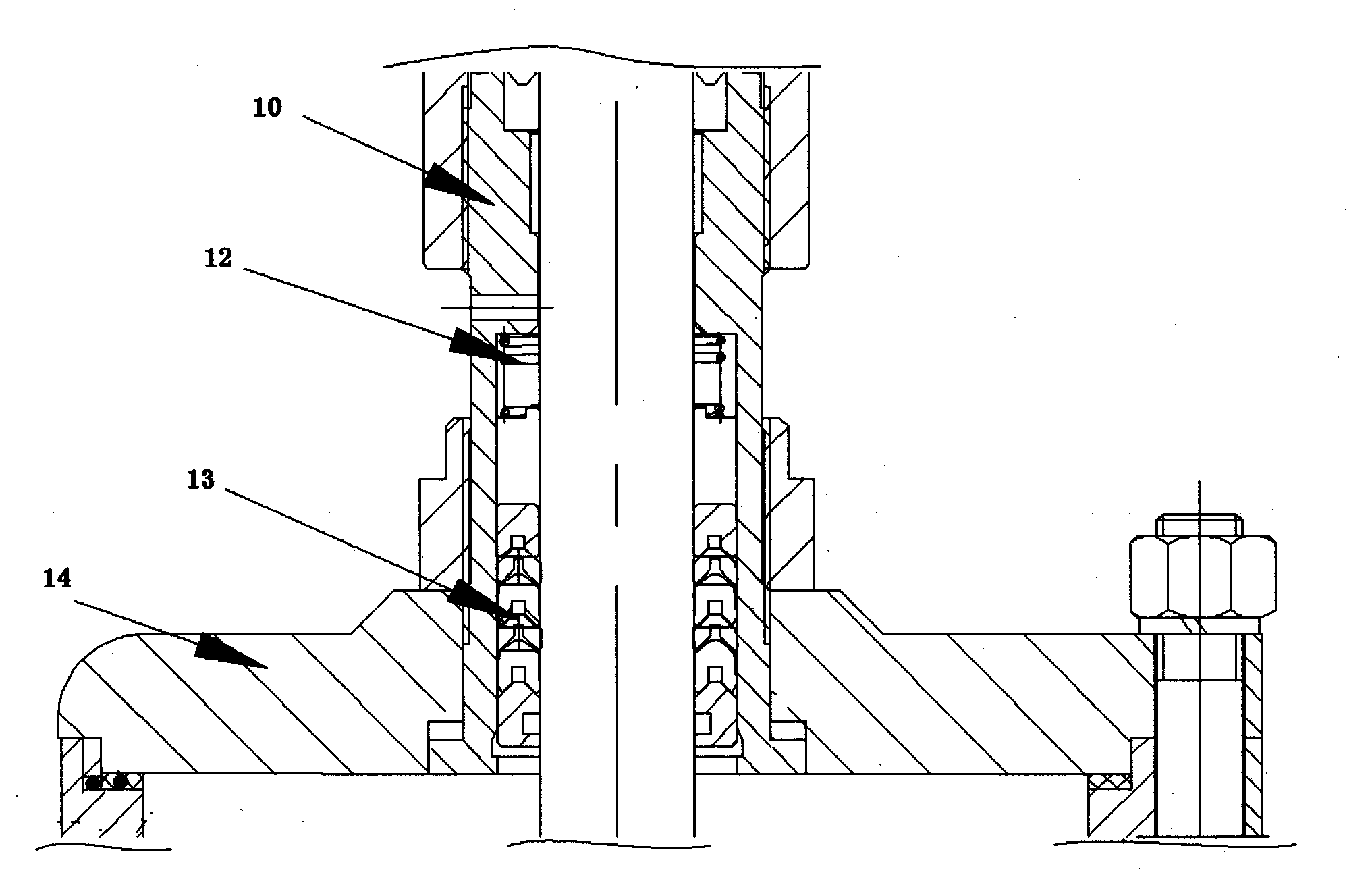

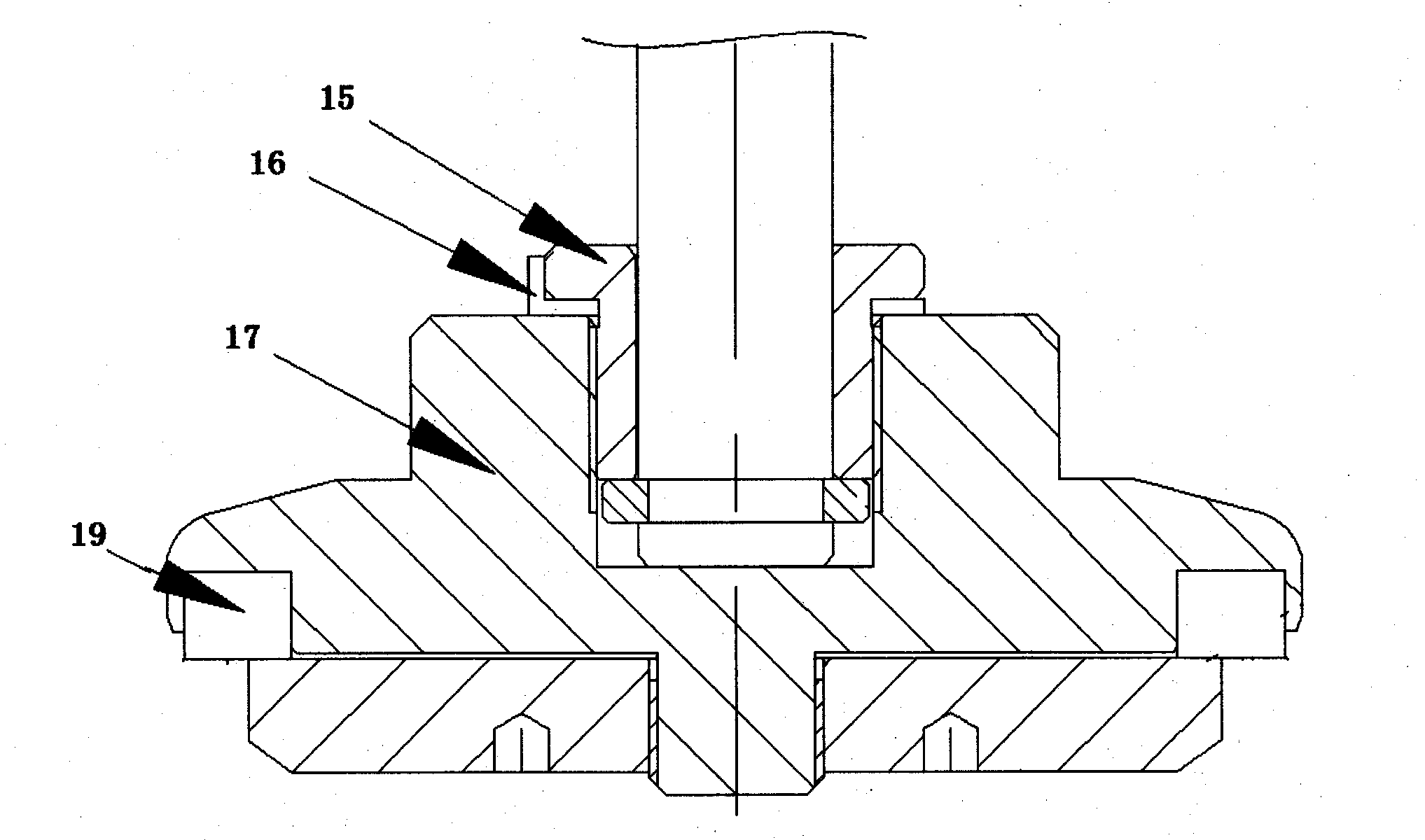

Two-position two-way piston type flanged buffer multi-medium angle seat valve

ActiveCN102588642AGuaranteed Conditions of UseEliminate shockOperating means/releasing devices for valvesValve housingsCylinder blockHigh pressure

Owner:上海宏芃流体科技有限公司

Extruder oil cylinder piston rod and novel oil cylinder structure

Owner:WUXI WEITE MACHINERY

Motor winding stator iron core inner and outer surface special automatic cleaning machine and application method thereof

PendingCN109877076AHigh degree of automationPrevent movementCleaning using toolsForeign matterMachine tool

Owner:ZHEJIANG JIANGCHAO MOTOR IND CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap