Sprue plugging device for casting sand mold at low pressure and method for casting sand mold at low pressure

A low-pressure casting and sand mold technology, applied in the field of aluminum alloy green sand mold low-pressure casting, can solve the problems of long solidification time, poor thermal conductivity, and low productivity of castings, and achieve the effects of reducing casting defects, filling molds smoothly, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

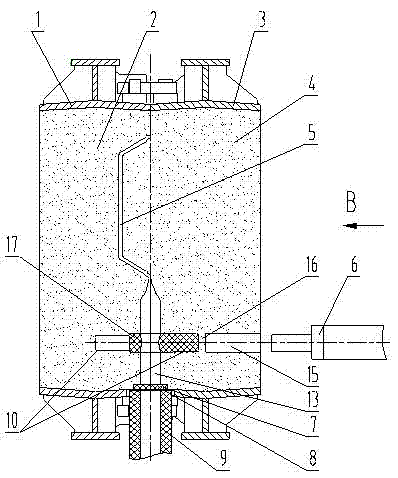

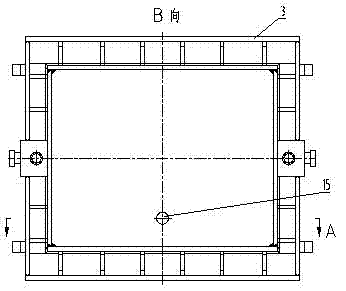

[0021] like Figure 1-5 Shown, a kind of sand mold low-pressure casting plugging gate device, it comprises upper sand mold 2 and lower sand mold 4, in the sprue position of described upper sand mold 2, lower sand mold 4, make the mold with casting draft angle Groove 10, in which the blocking member is placed, a guide hole 15 for the drive part of the blocking member drive mechanism to pass is provided on the back of the lower sand mold 4, and a guide hole 15 is provided outside the guide hole 15 Blocking drive mechanism. The driving mechanism of the blocking member includes an oil cylinder 6 , and the piston rod of the oil cylinder 6 faces the guide hole 15 of the lower sand mold 4 . Described plugging member comprises ceramic plugging block 17 and is arranged between guide hole 15 and sprue 13 and keeps guide hole 15 and sprue 13 apart retaining sand cluster 16, and the setting of retaining sand cluster 16 makes guide hole 15 and the sprue 13 cannot pass through; the groove 10

Embodiment 2

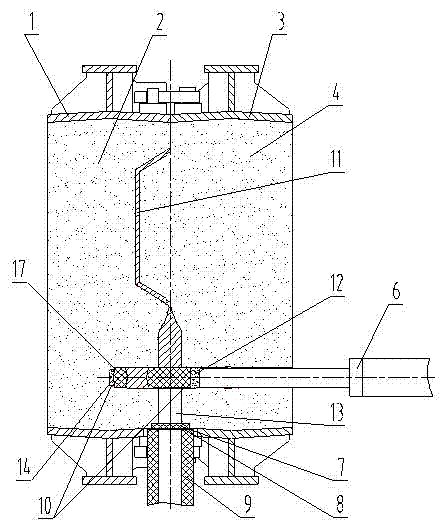

[0027] like Figure 6 ~ Figure 10 As shown, the similarities between this embodiment and the first embodiment will not be repeated. The difference is that the sealing member includes a resin sand block 19 fixed in the groove 10 and a sealing steel plate 20 slidingly fitted therewith. The resin sand block 19 is formed by bonding two halves of the sand block; a pouring hole is set on the resin sand block 19, and a guide groove 21 is arranged in the middle of the resin sand block 19 perpendicular to the axis of the pouring hole, and the guide grooves 21 are respectively arranged on the two halves of the sand block and combined to form a guide hole 18; the plugging steel plate 20 is set in the guide hole 18 on one side and is slipped with it to seal the pouring hole, and the other end of the plugging steel plate 20 extends into the guide hole 15. The guide holes 18 are distributed on both sides of the casting hole and are separated from the casting hole by 5-10mm of resin sand. The

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap