Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

21 results about "Heating temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heating systems are usually designed for a room temperature of 18-20 ºC, and that is for most cases sufficient. Elderly or sick persons may need a higher temperature to experience the same comfort as younger and healthy ones. The temperature difference vertically in a room should not be too great either.

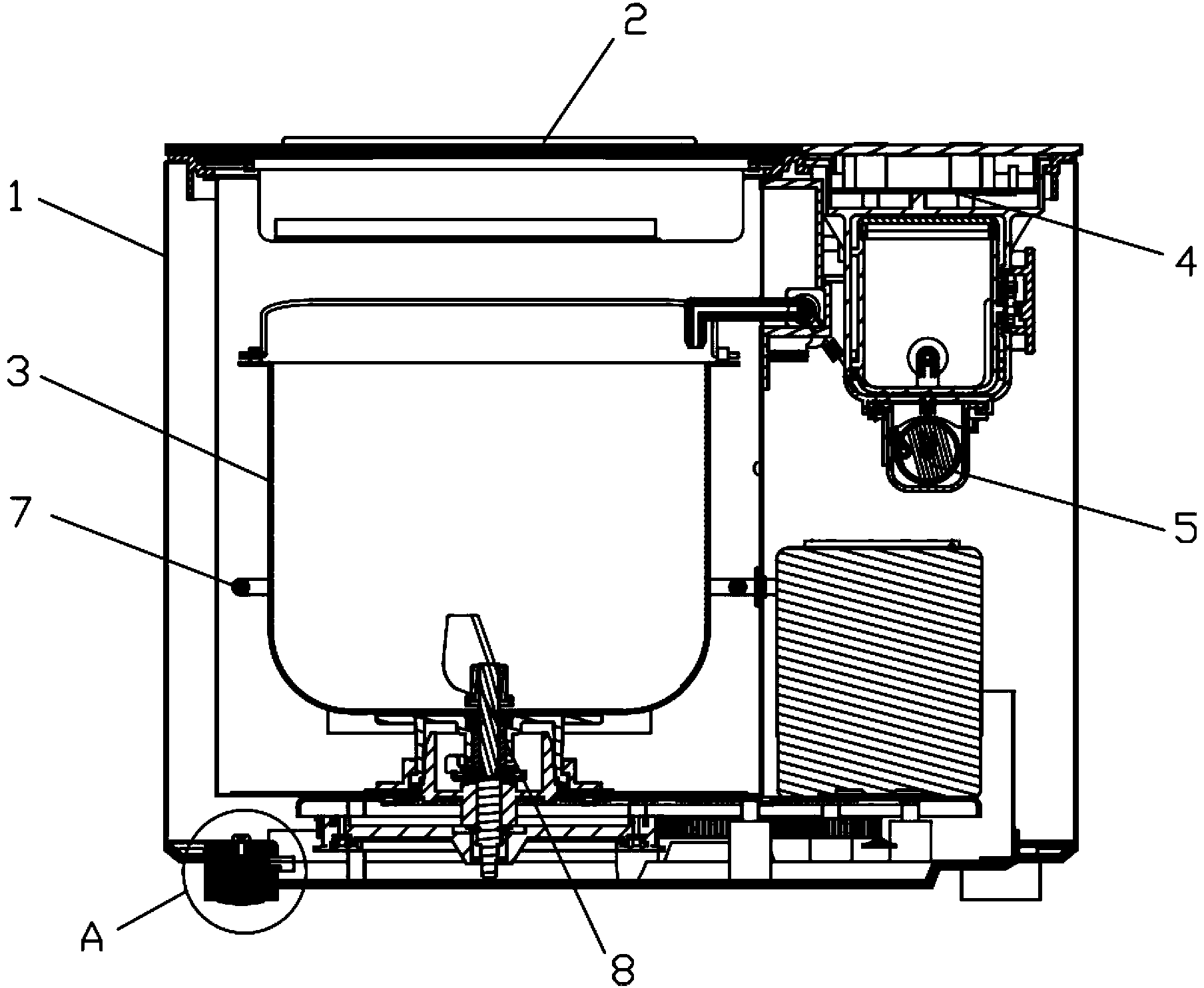

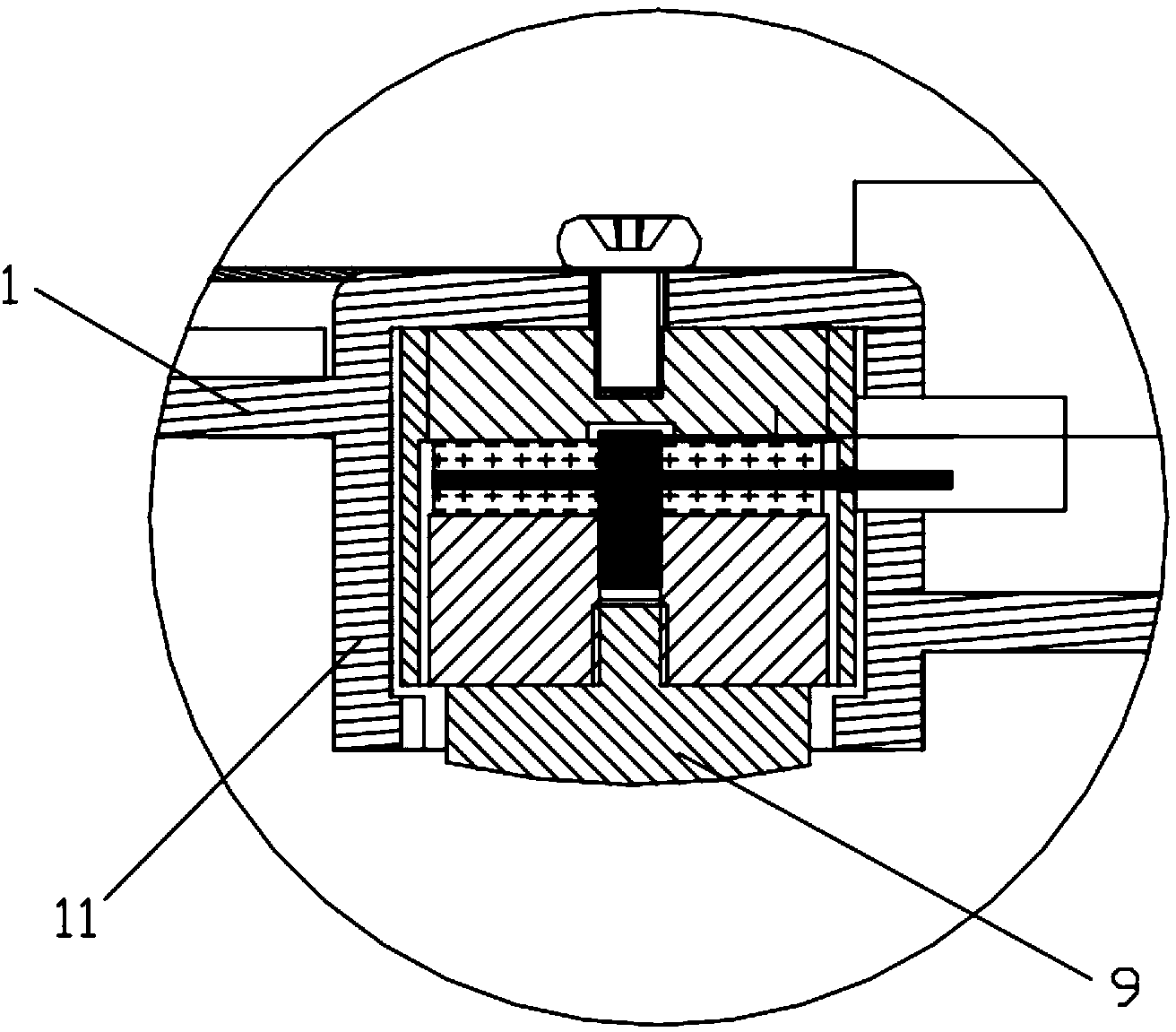

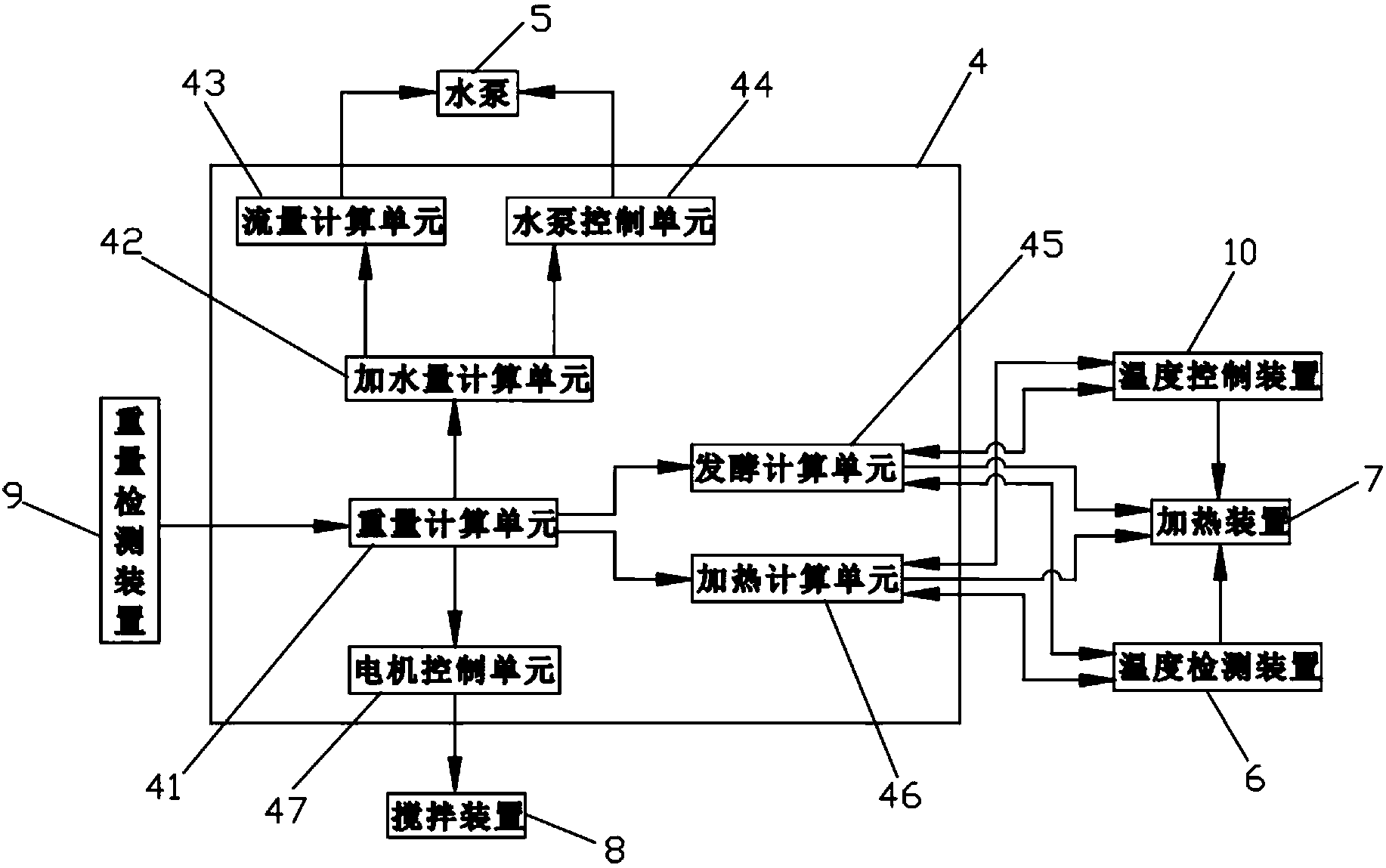

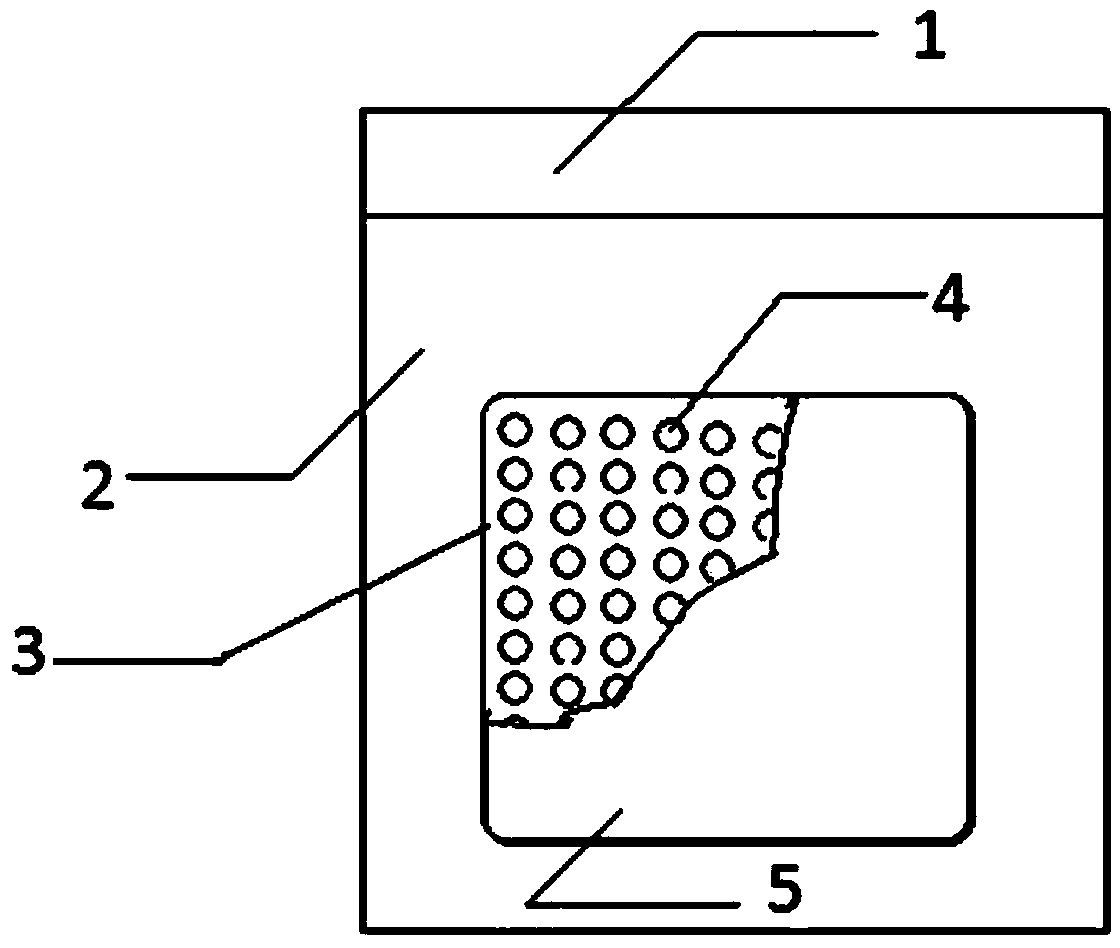

Intelligent bread machine and weighing control method thereof

ActiveCN103004917AManufacturing process intelligenceEasy to makeBakery productsSimultaneous control of multiple variablesElectricityHeating time

Owner:JOYOUNG CO LTD

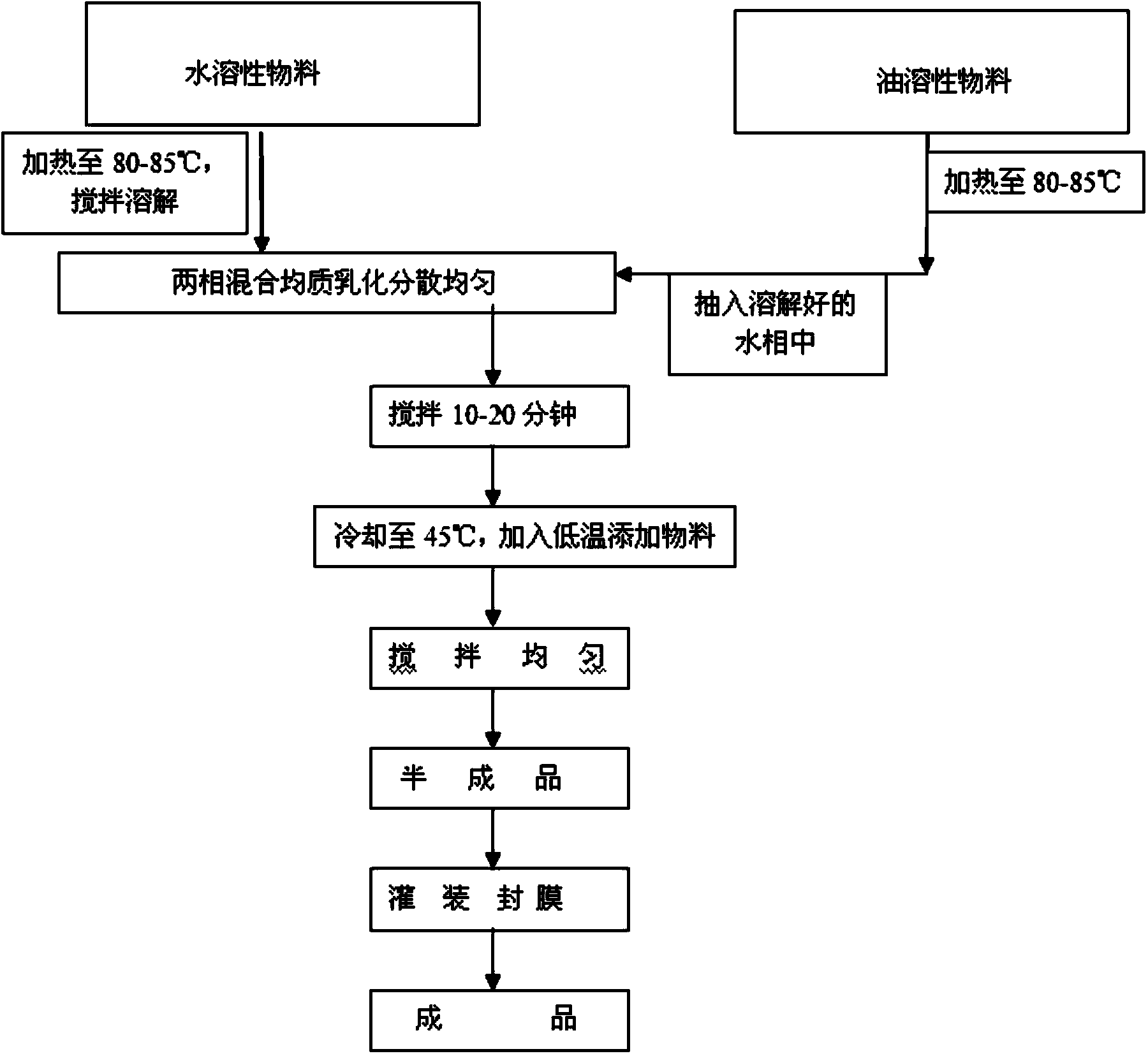

Facial mask and preparation method thereof

ActiveCN103908415AReduce water lossEasy to keepCosmetic preparationsToilet preparationsTemperature controlIrritation

Owner:康博士日化集团有限公司

Ultra-low carbon martensitic stainless steel seamless tube and manufacturing method thereof

InactiveCN108277438AHigh tensile strengthHigh yield strengthFurnace typesHeat treatment furnacesMartensitic stainless steelHigh pressure

The invention discloses an ultra-low carbon martensitic stainless steel seamless tube. The ultra-low carbon martensitic stainless steel seamless tube is prepared from ultra-low carbon martensitic stainless steel. The ultra-low carbon martensitic stainless steel is prepared from the following components in percentage by mass: less than or equal to 0.03% of C, 0.1-0.5% of Si, 0.2-0.5% of Mn, less than or equal to 0.015% of P, less than or equal to 0.002% of S, 12.2-13.2% of Cr, 5.2-5.7% of Ni, 1.9-2.1% of Mo, 0.1-1.6% of Cu and the balance of Fe and other impurities. The seamless tube can be suitable for oil and gas fields. The invention also provides a manufacturing method of the seamless tube. The manufacturing method comprises the following steps: smelting; tube blank thermal processing;steel tube thermal processing; and thermal treatment, wherein the heating temperature of tube blank thermal processing is 1200-1280 DEG C, the heating temperature of tube manufacturing by means of anextruding method is 1150-1250 DEG C, the heating temperature of tube manufacturing by means of a perforating cold rolling method is 1200-1280 DEG C, and the temperatures for thermal treatment are as follows: quenching at 900-1050 DEG C and tempering at 550-680 DEG C. The seamless tube provided by the invention has excellent strength and corrosion resistance in a CO2 and Cl<-> coexisting corrosionenvironment and in high-temperature and high pressure conditions.

Owner:TAIYUAN IRON & STEEL (GRP) CO LTD

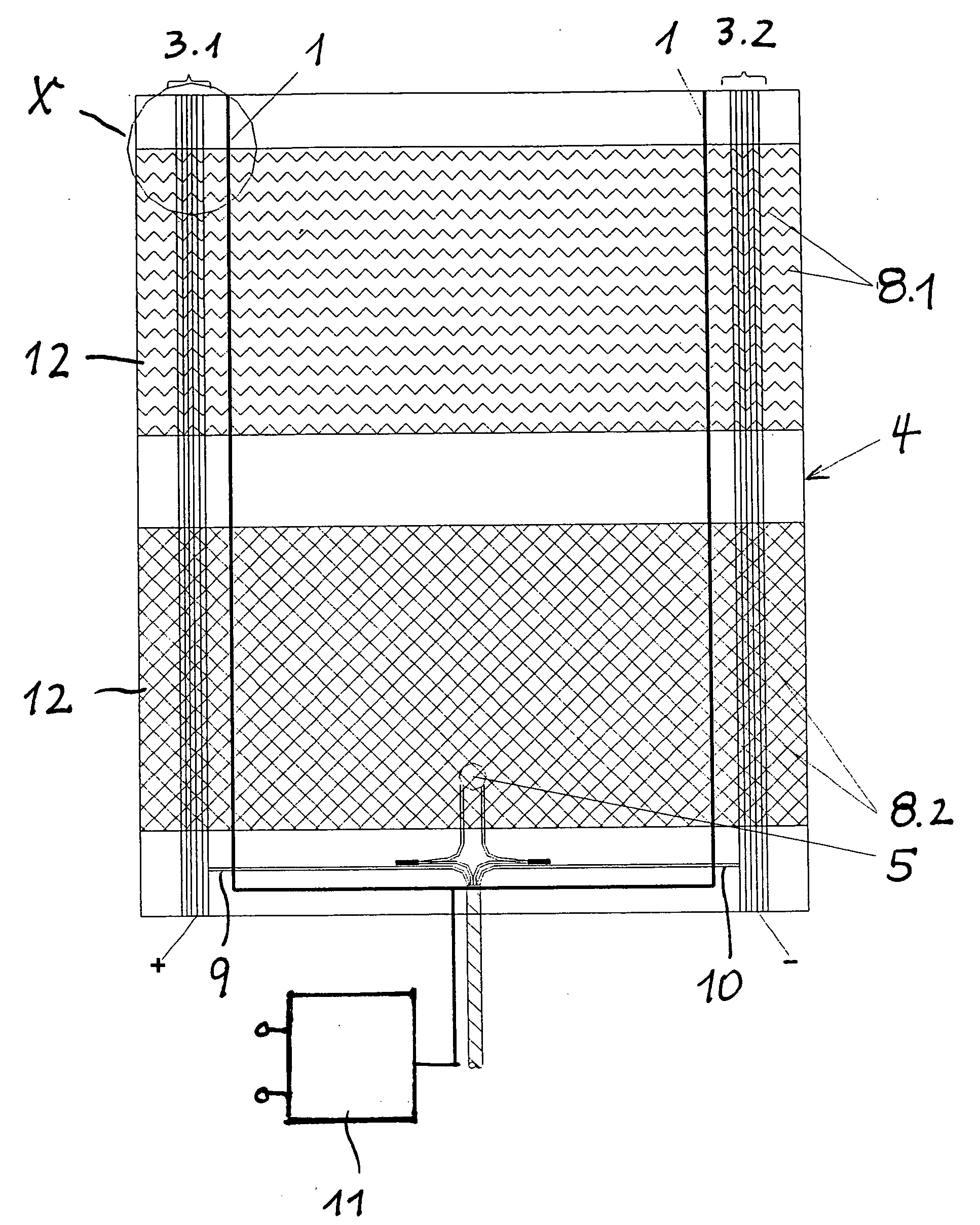

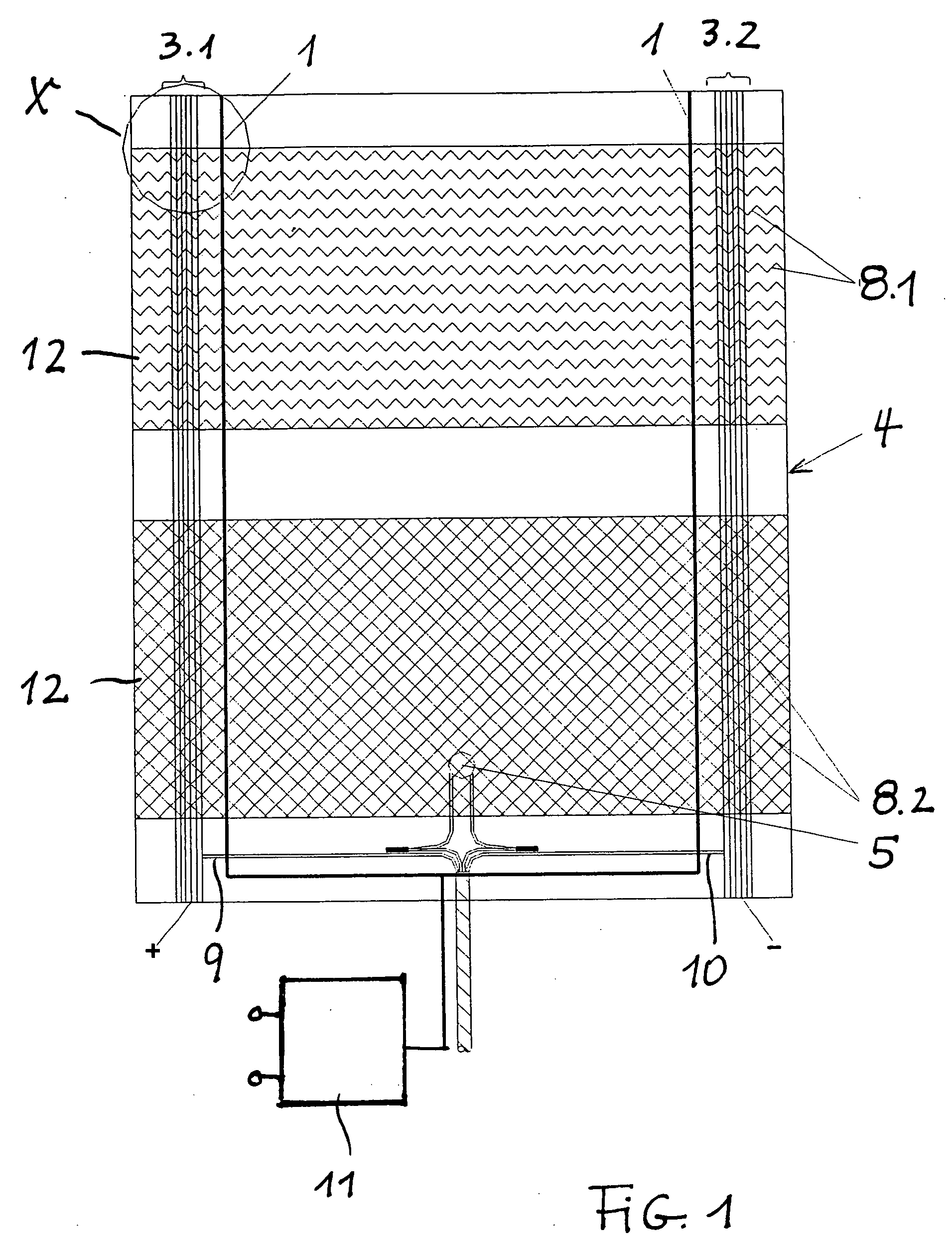

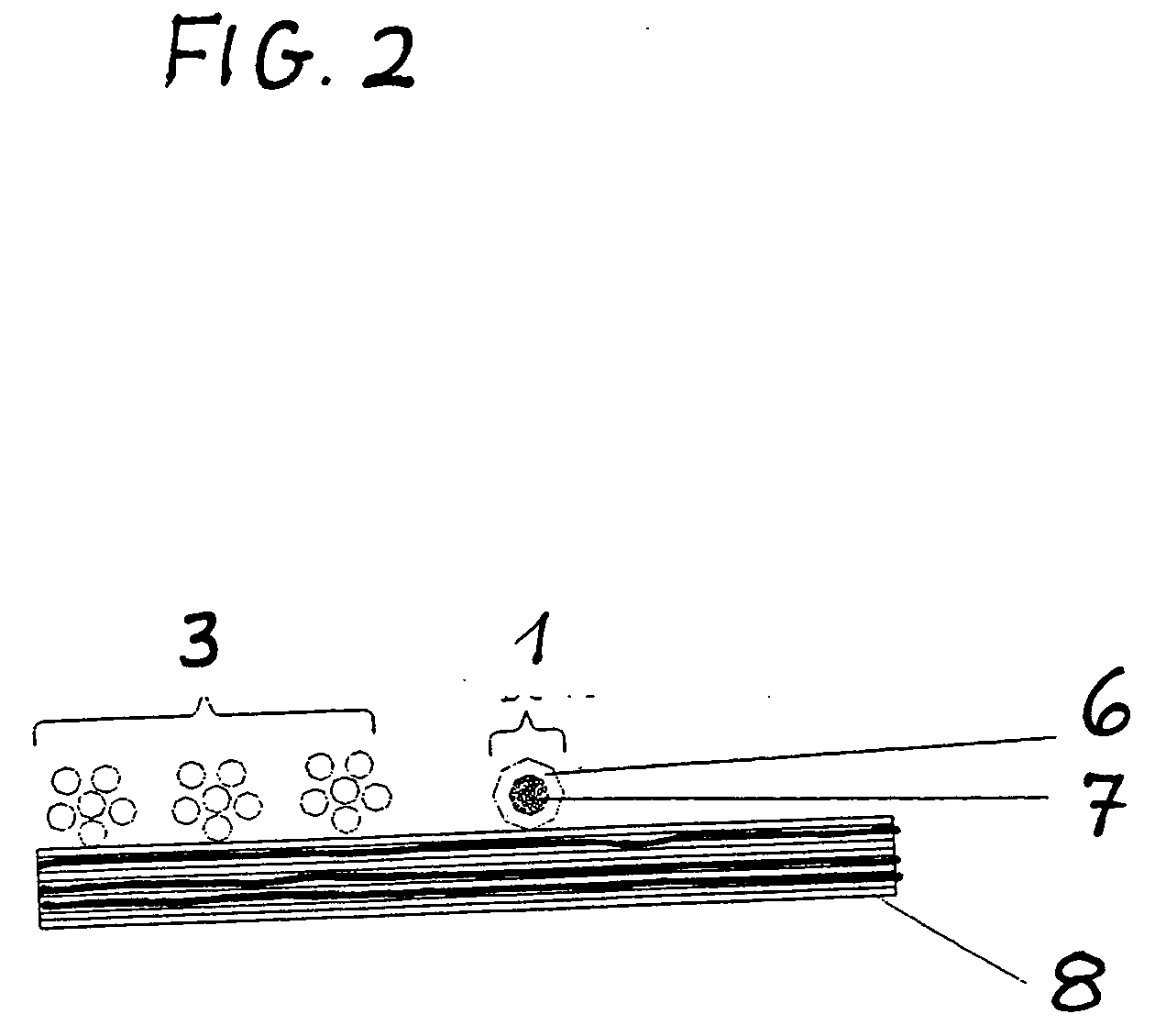

Monitoring device for flexible heating elements

Owner:I G BAUERHIN GMBH

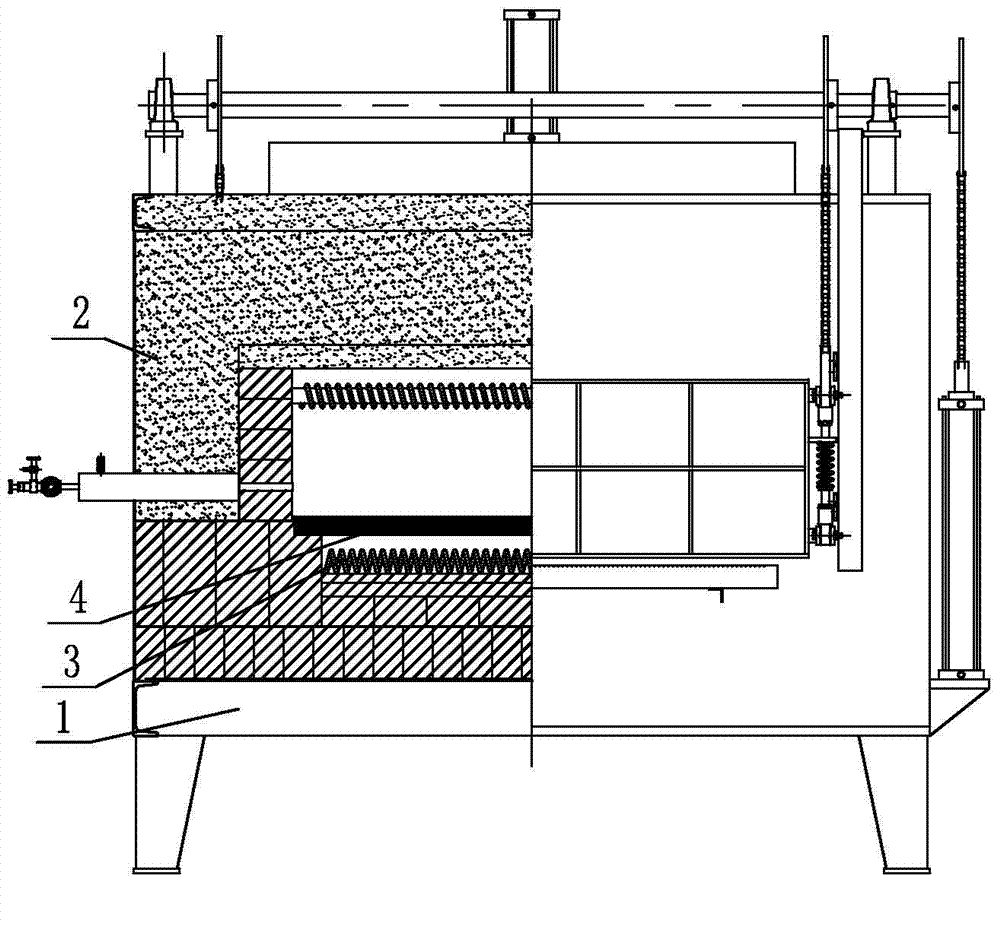

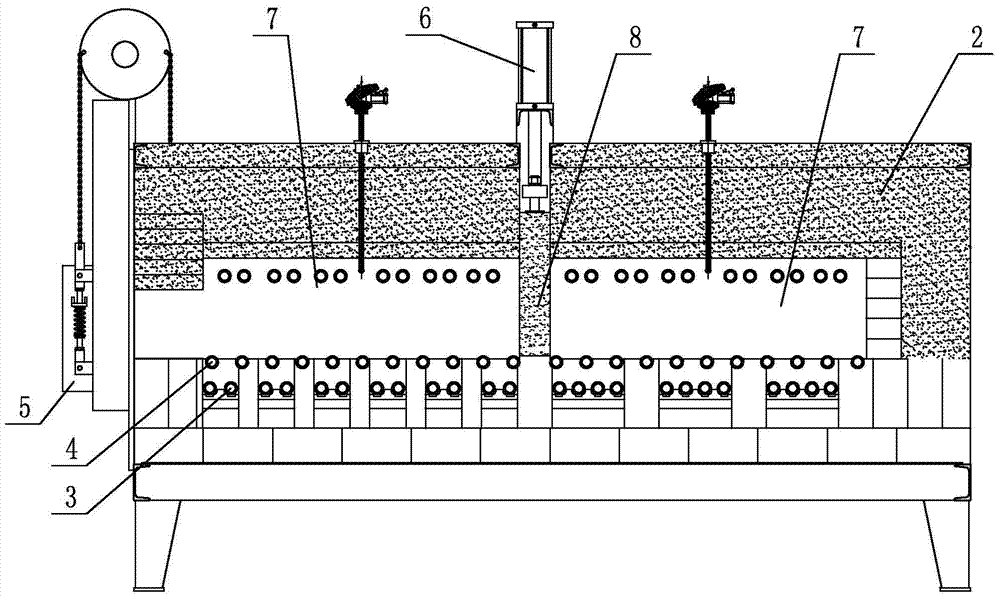

Mobile roller-type van-type heating furnace and hot-forming subsection strengthening technique

ActiveCN104729278AReduce volumeLess investmentFurnace typesHeat treatment furnacesPunchingRoom temperature

Owner:YANCHENG KEAO MECHAICAL

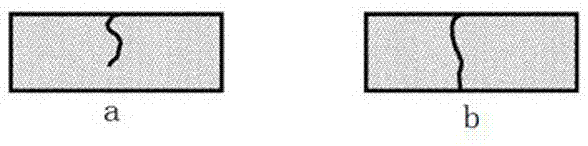

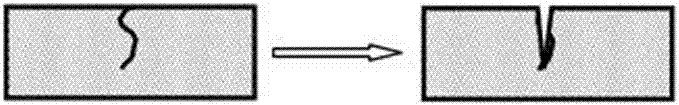

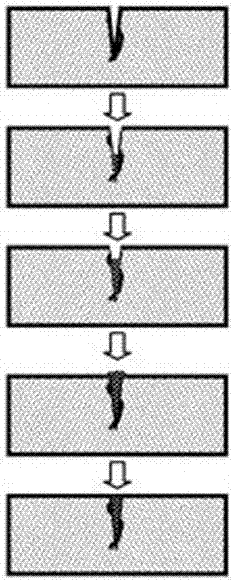

Restorative method for ceramic cores with crack defects

Owner:DONGFANG TURBINE CO LTD

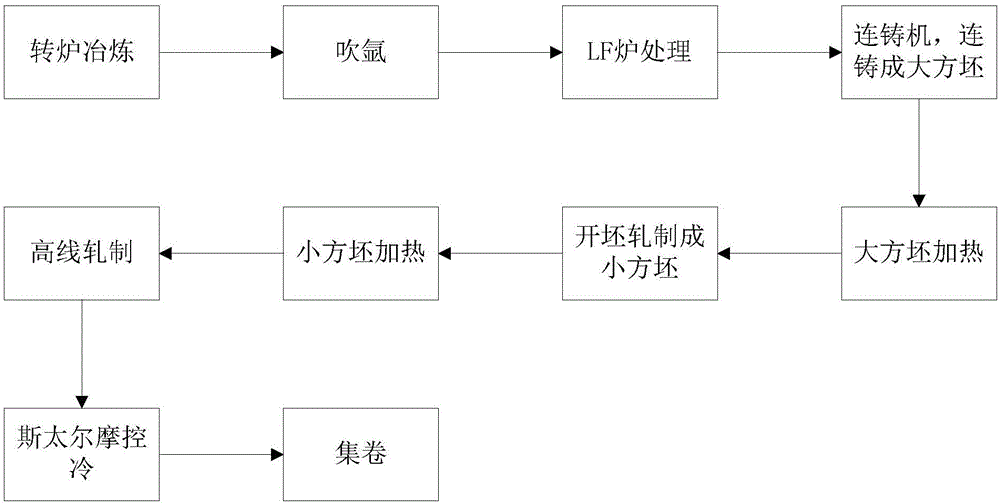

Method for relieving pattern segregation of spring steel

ActiveCN106399654ASolve the problem of resentmentReduce manufacturing costTemperature differenceSpring steel

Owner:武汉钢铁有限公司

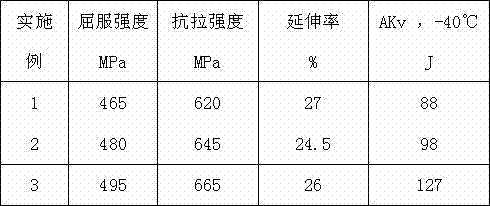

Low-aging sensitivity hot rolled plate with high strength and toughness and manufacturing method thereof

InactiveCN103757548AAddress uneven performanceSolve the costManufacturing convertersChemical compositionSmelting process

Owner:ANGANG STEEL CO LTD

Belt conveyor with variable discharge port

ActiveCN112830281AQuick storageEnsure safetyConveyorsControl devices for conveyorsAir velocityAir volume

The invention relates to the field of belt conveyors, and discloses a belt conveyor with a variable discharge port, which is characterized in that a controller is started, a humidity detector detects the humidity of grains, a detection signal is transmitted into the controller through a data line after detection, the detected humidity is compared with a numerical value set by the controller, an air supply motor and a heating frame are started according to the humidity comparison result, so that the air supply motor enables a fan to rotate to different speeds according to the control of the controller, meanwhile, a heating wire is controlled to heat to different temperatures, the fan rotates to generate a certain amount of air, and the air is blown into the heating frame, heated through the heating wire and then blown into an anti-skid groove, so that the grains can be dried, and meanwhile, the air speed and the heating temperature are controlled through the controller according to the humidity comparison value, and therefore the purpose of saving energy is achieved.

Owner:COFCO ENG EQUIP WUXI CO LTD

Al-Co-W alloy with alternating lamellar microstructure characteristics and preparation method thereof

The invention discloses an Al-Co-W alloy with alternating lamellar microstructure characteristics and a preparation method thereof, relates to preparation of novel materials and in particular relates to an alloy with alternating lamellar microstructure characteristics and a preparation method thereof. The structure of the alloy comprises an alternating lamellar structure, and the lamellar pairs occur periodically. In the Al-Co-W alloy system, Al component can diffuse quickly, Co component can diffuse slowly and W component is immovable basically. The preparation method comprises the following steps: preparing a CoxWy type intermetallic compound or a (Co-W) solid solution by using components Co and W of which the diffusion rates are different, and grinding the intermetallic compound or solid solution into small particles; controlling the heating temperature and reaction mode in a protective atmosphere so that the component Al in solid state, liquid state or gas state reacts with the CoxWy type intermetallic compound or the (Co-W) solid solution; reacting for a proper period of time, rapidly cooling to room temperature, thereby obtaining the alloy with alternating lamellar microstructure characteristics. According to the invention, a novel path is provided for preparation of novel composite materials and connection of out-phase materials.

Owner:CHANGZHOU UNIV

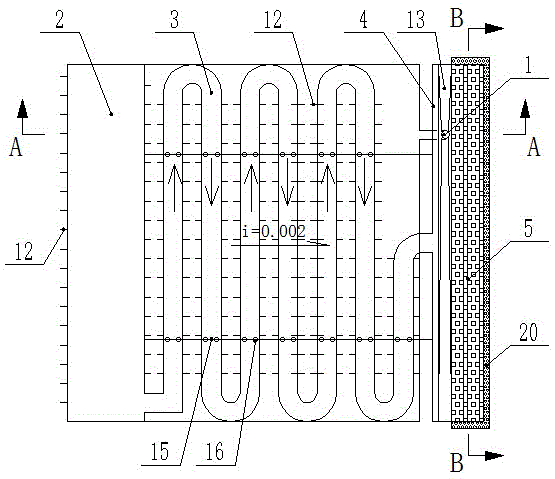

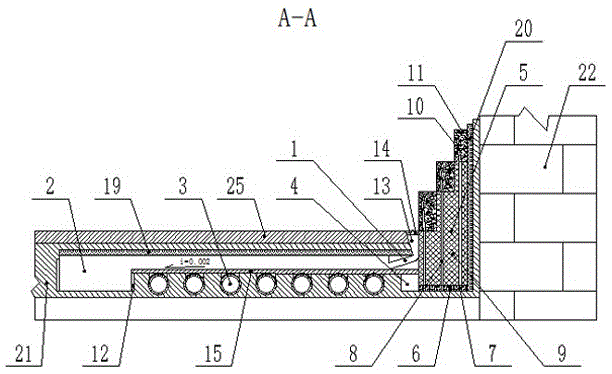

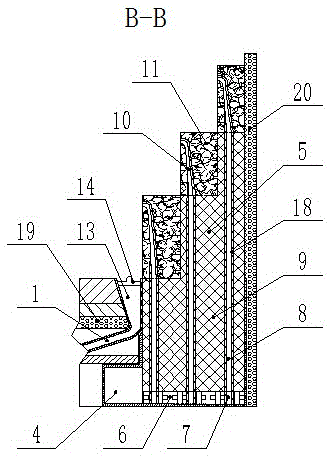

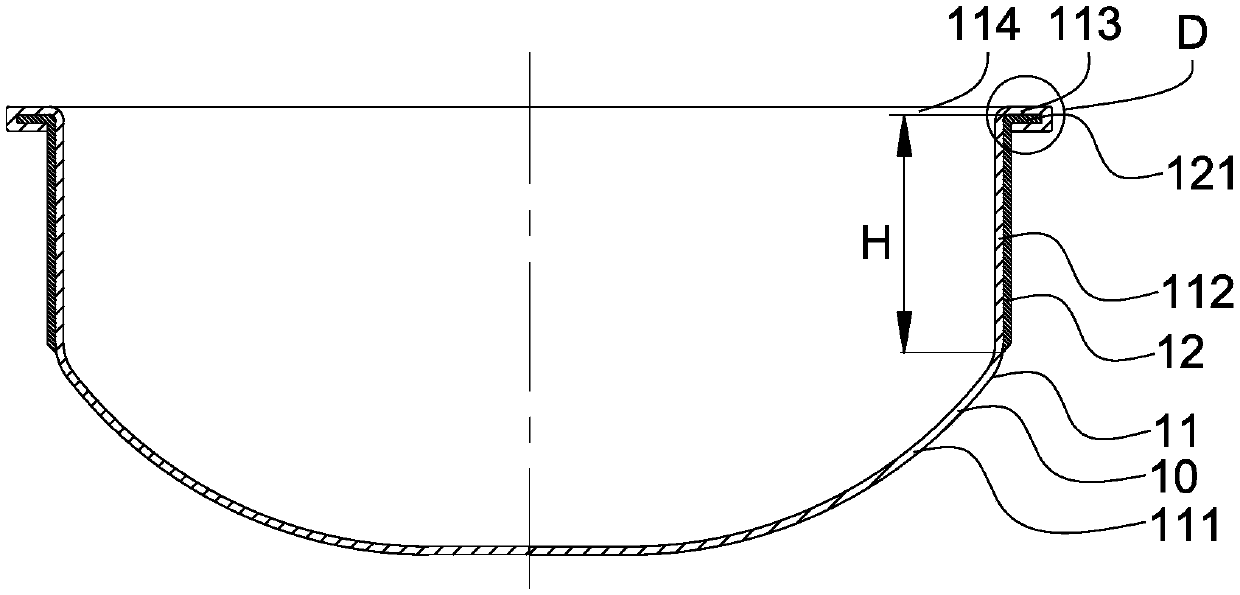

Invisible humidifier of floor heating system

InactiveCN105650793AIncrease surface areaRegulate humidityLighting and heating apparatusAir humidification systemsElectricityWarm water

Owner:ZHONGBEI UNIV

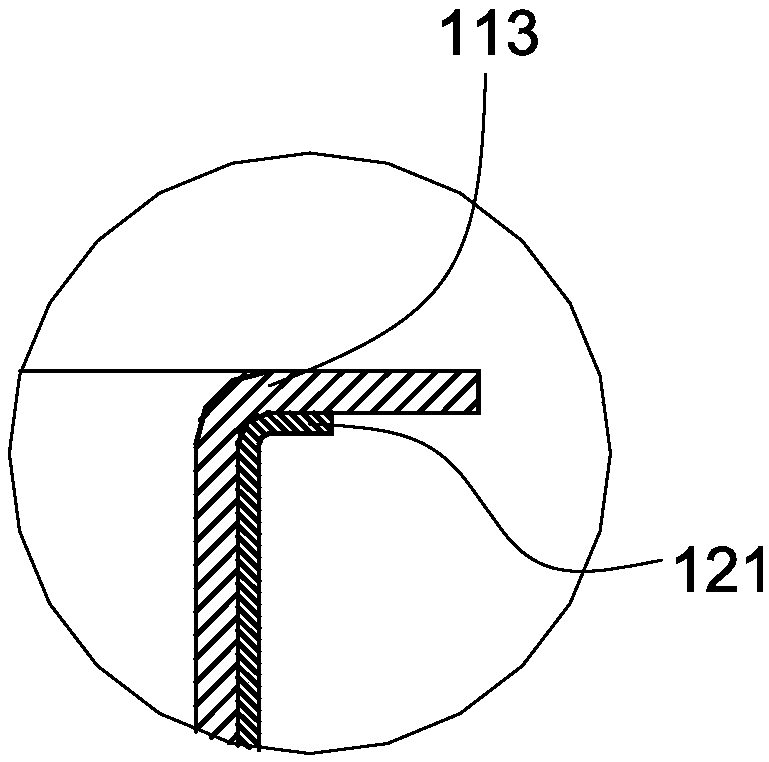

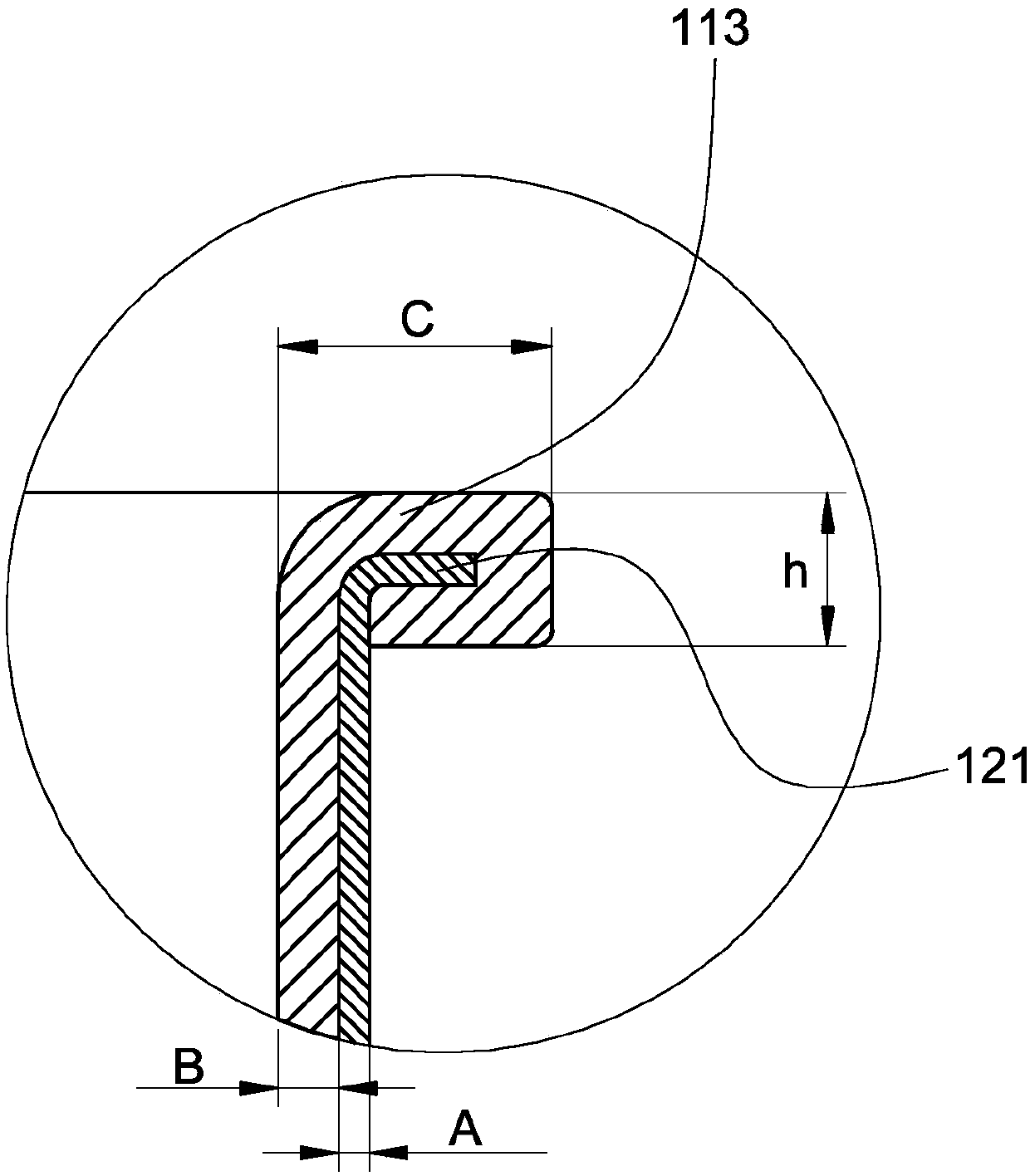

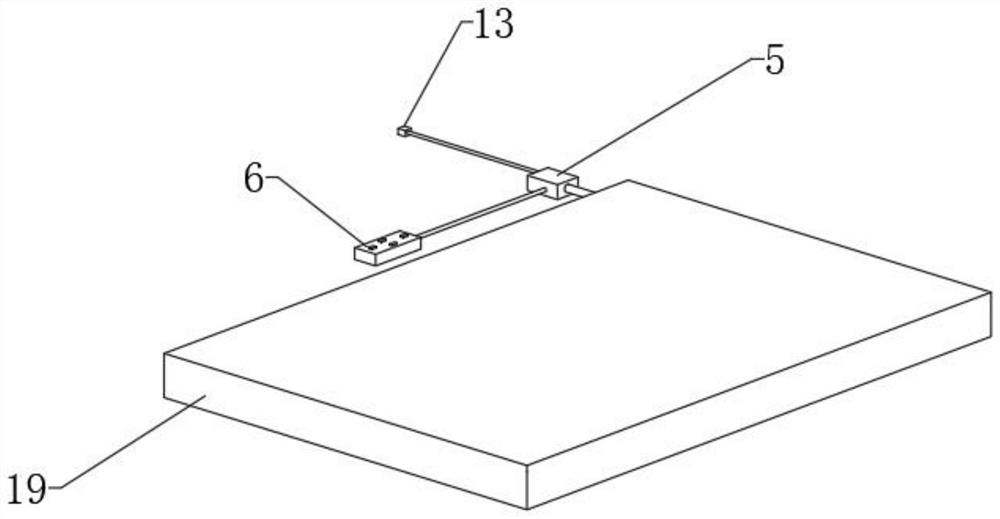

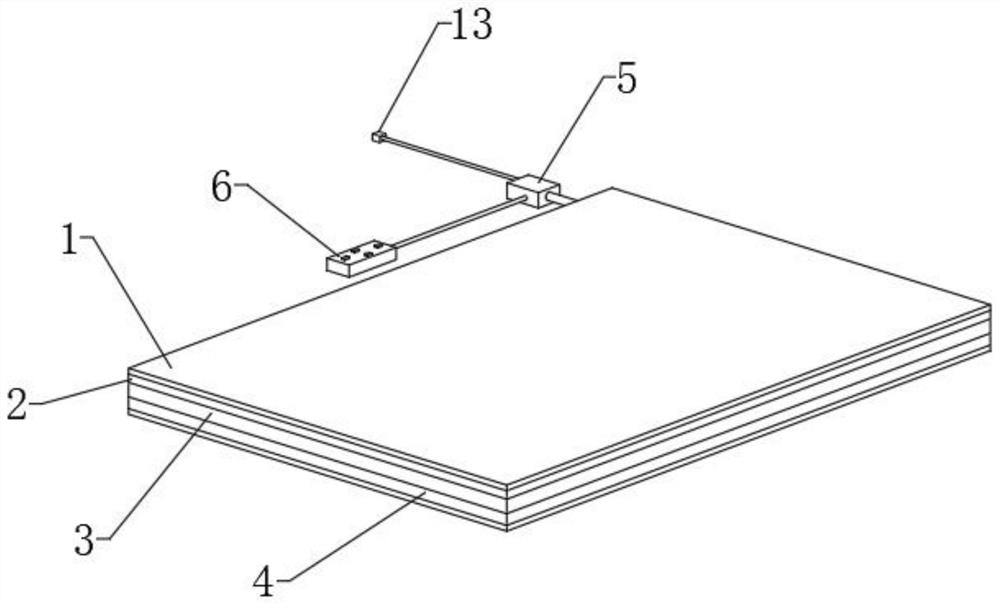

Inner pot for cooking utensils, cooking utensils and method for manufacturing inner pot

PendingCN109662557AIncrease wall thicknessHigh strengthCooking-vessel materialsDomestic vesselsEngineeringFood material

Owner:ZHEJIANG SUPOR ELECTRICAL APPLIANCES MFG CO LTD

5CrNiMo tempering process

InactiveCN105755240ALow experience requirementEasy to operateFurnace typesHeat treatment furnacesRoom temperatureHardness

Owner:CHONGQING HUANDE TECH CO LTD

Graphene intelligent temperature control bed warming pad and use method thereof

PendingCN113576200ADifferentiate heating temperatureHeating temperature adjustmentStuffed mattressesSpring mattressesTemperature controlEngineering

Owner:CHENGDU QUSHUI TECH CO LTD

Automotive transmission gear forging method

InactiveCN105018685AImprove mechanical propertiesExtended service lifeFurnace typesSolid state diffusion coatingEnvironmental resistanceMechanical property

Owner:苏州优金金属成型科技有限公司

Manufacturing method for carbon fiber forming mold capable of controlling heating temperature

The invention relates to the technical field of mold manufacturing, and discloses a manufacturing method for a carbon fiber forming mold capable of controlling the heating temperature. The manufacturing method comprises the following steps that 1, a mold body is manufactured; and the step 1 comprises the sub-steps that a, foam models of a corresponding female mold and a mold sleeve are machined and manufactured according to a drawing of the mold needing to be manufactured; b, the female mold obtained in the step a is fixed to the center of the mold sleeve obtained in the step a, and an overall mold cavity for manufacturing the mold is obtained; and c, the interior of the mold cavity is coated with a material protecting layer firstly, standing and curing are conducted, and when the mold is in a high-temperature working state, hot deformation of the surface material bears influences of a supporting portion. The manufacturing method for the carbon fiber forming mold capable of controlling the heating temperature has the advantages that light weight of mold production is achieved, the overall manufacturing process is fast and convenient to operate, the mold production efficiency is improved, and the quality and the service life of the mold are guaranteed.

Owner:SHENYANG WANLONG WEIYE MASCH MFG CO LTD

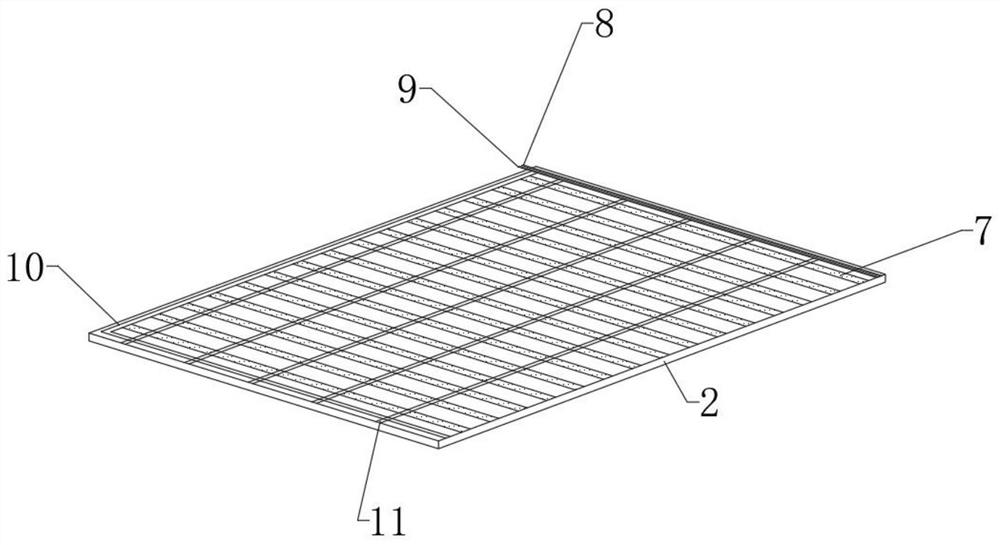

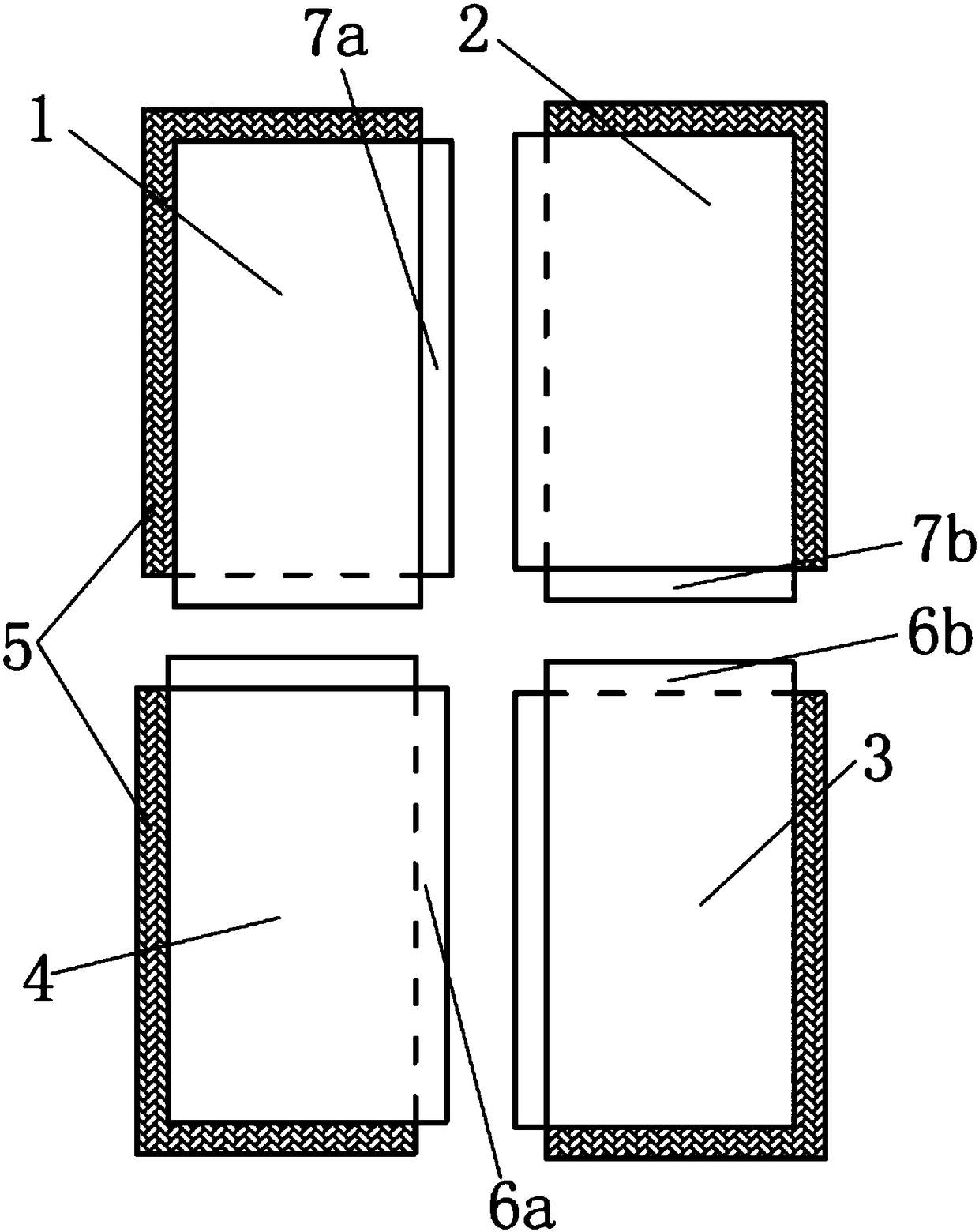

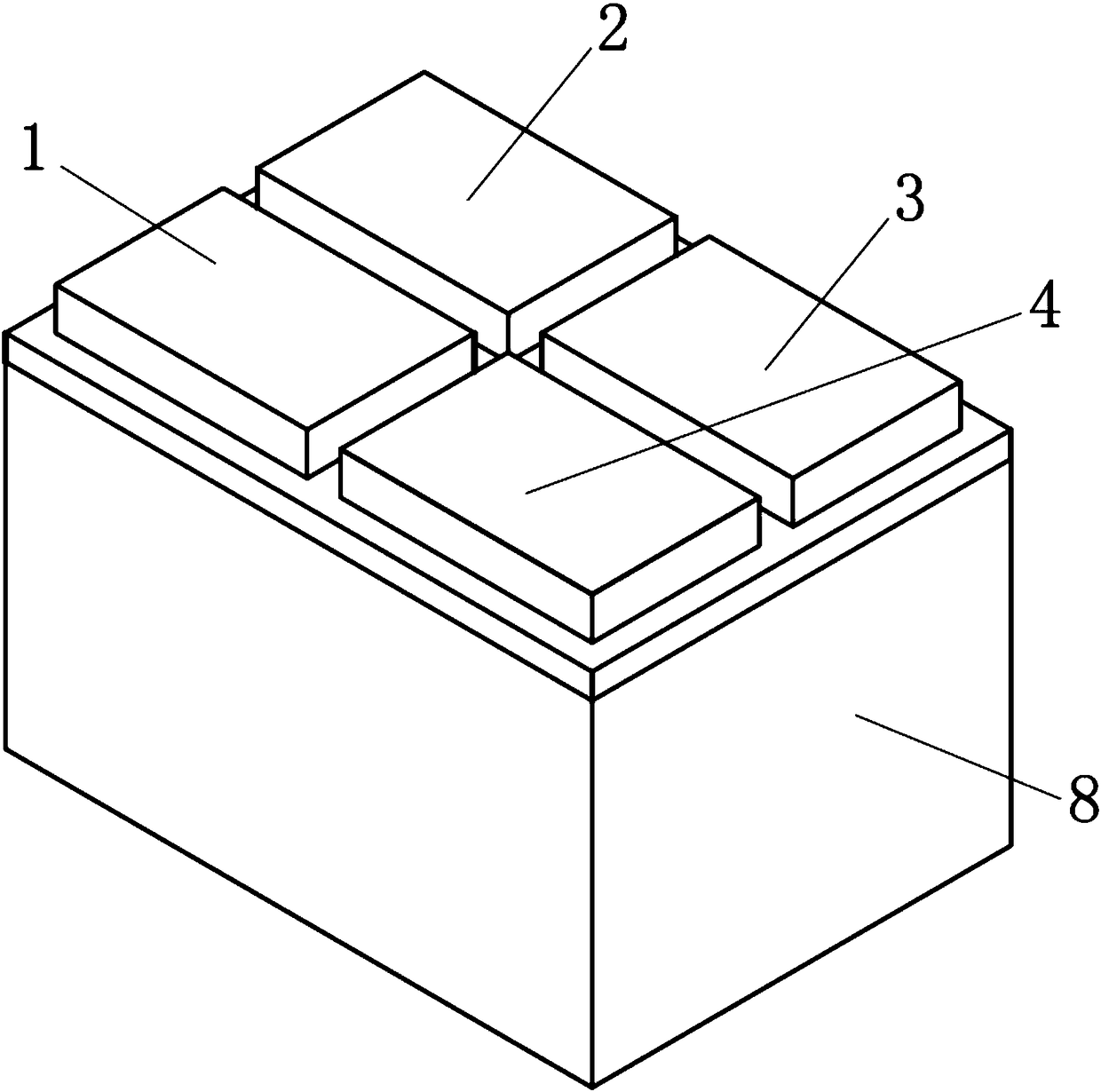

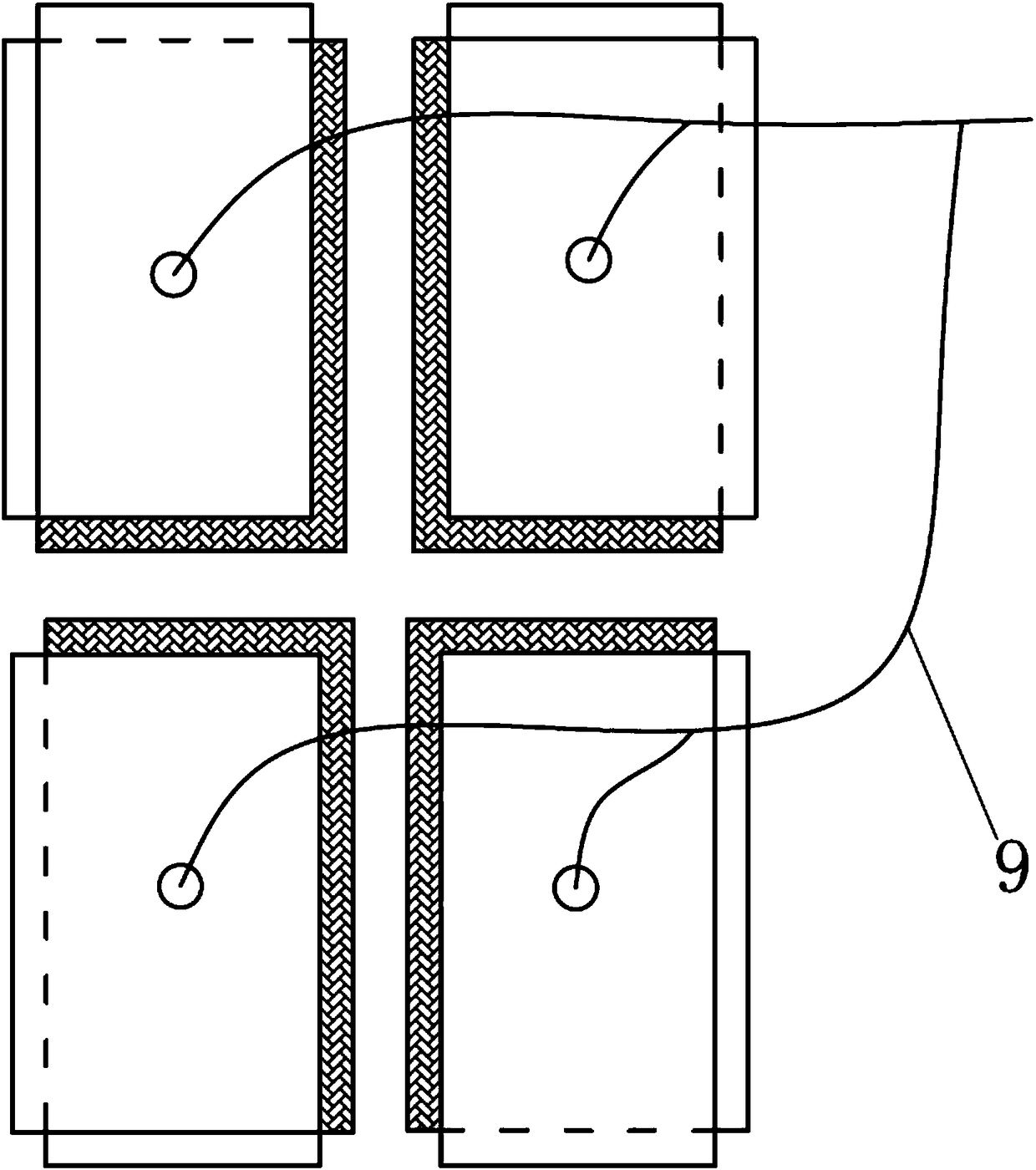

Detachable heating plate

InactiveCN108633112AReduce heating efficiencyImprove space utilizationHeating or cooling apparatusOhmic-resistance heating detailsEngineeringThermocouple device

Owner:苏州威格半导体材料有限公司

Preparation method of feed additive and product prepared thereby

InactiveCN108371237AHigh in crude fiberFast satietyAnimal feeding stuffAccessory food factorsFood additiveCellulose

Owner:上海同化益生纤生物科技有限公司

Solar automatic thermal compensation baking system

ActiveCN105532770BTake advantage ofIncrease profitClimate change adaptationBaking ovenCold airCombustor

Owner:SISHUI DELI FOOD MACHINERY

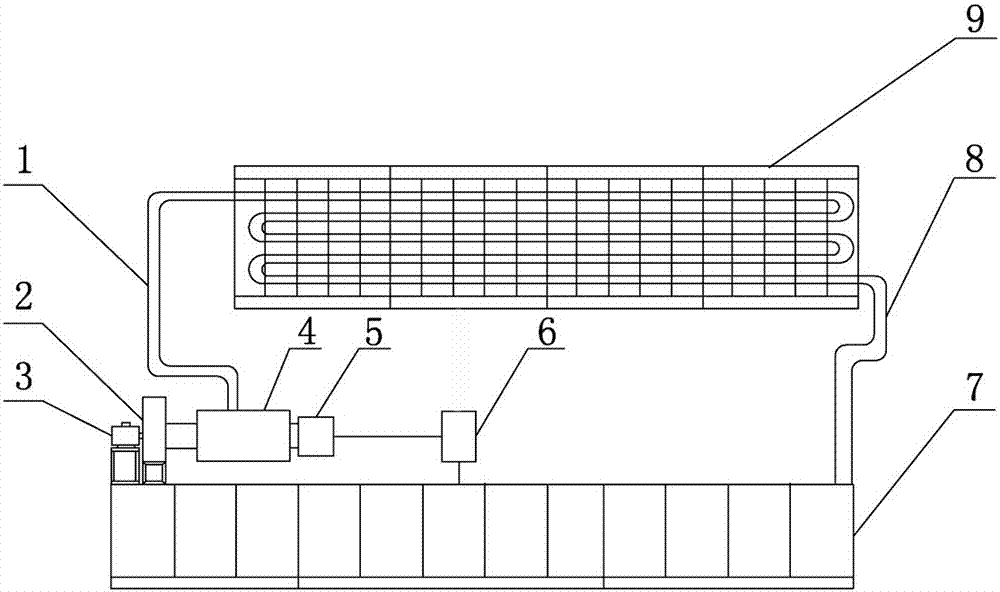

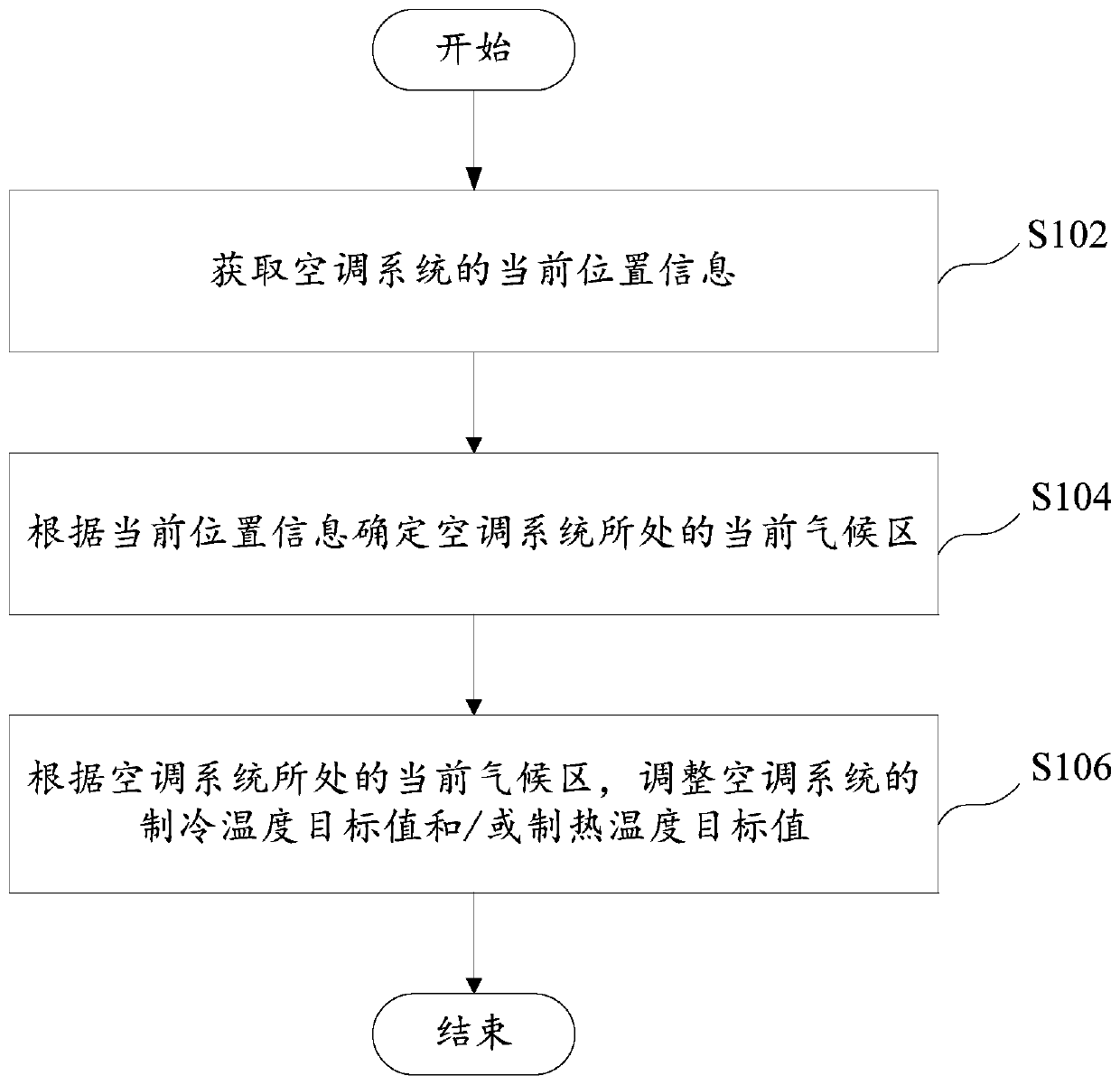

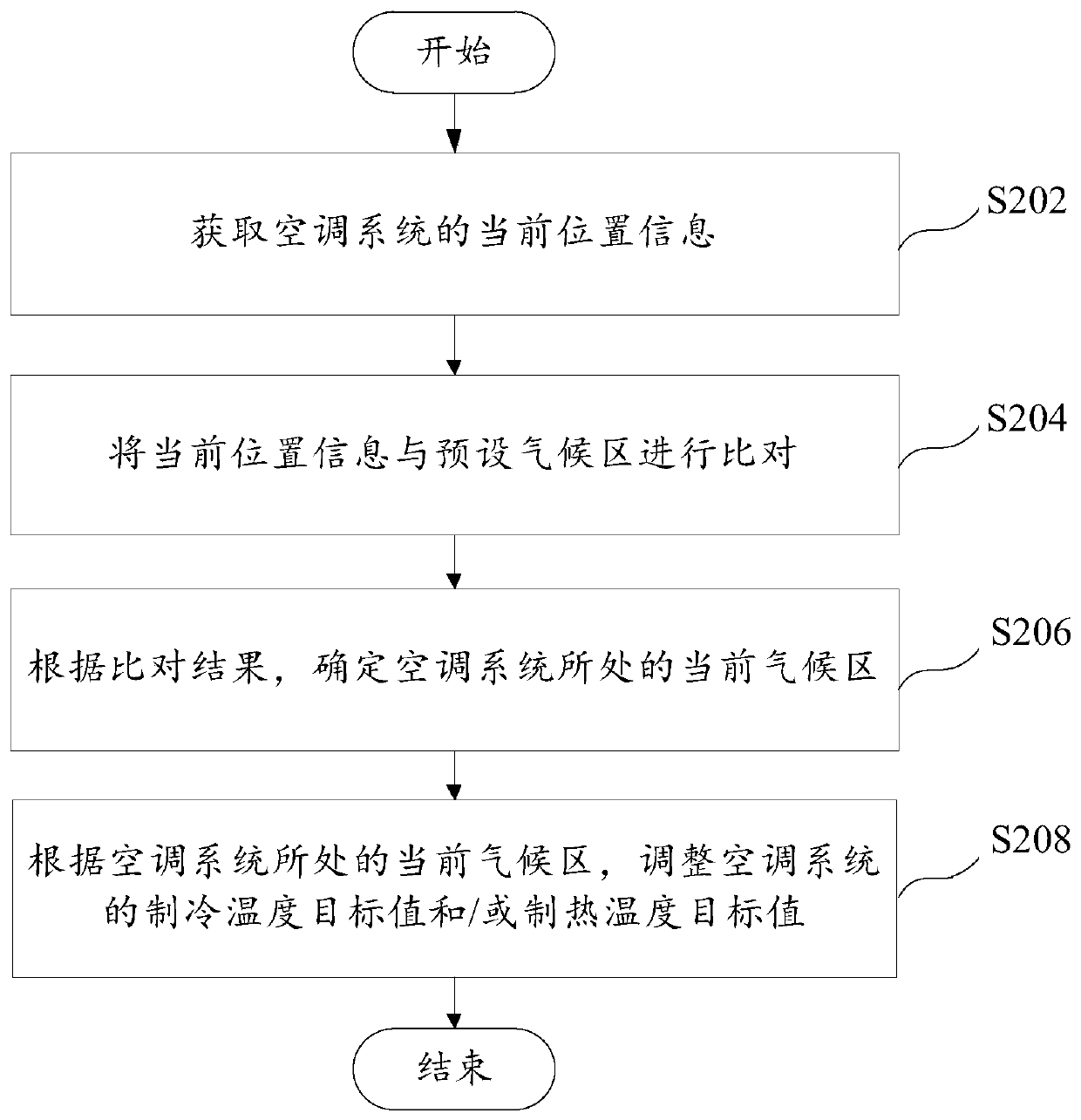

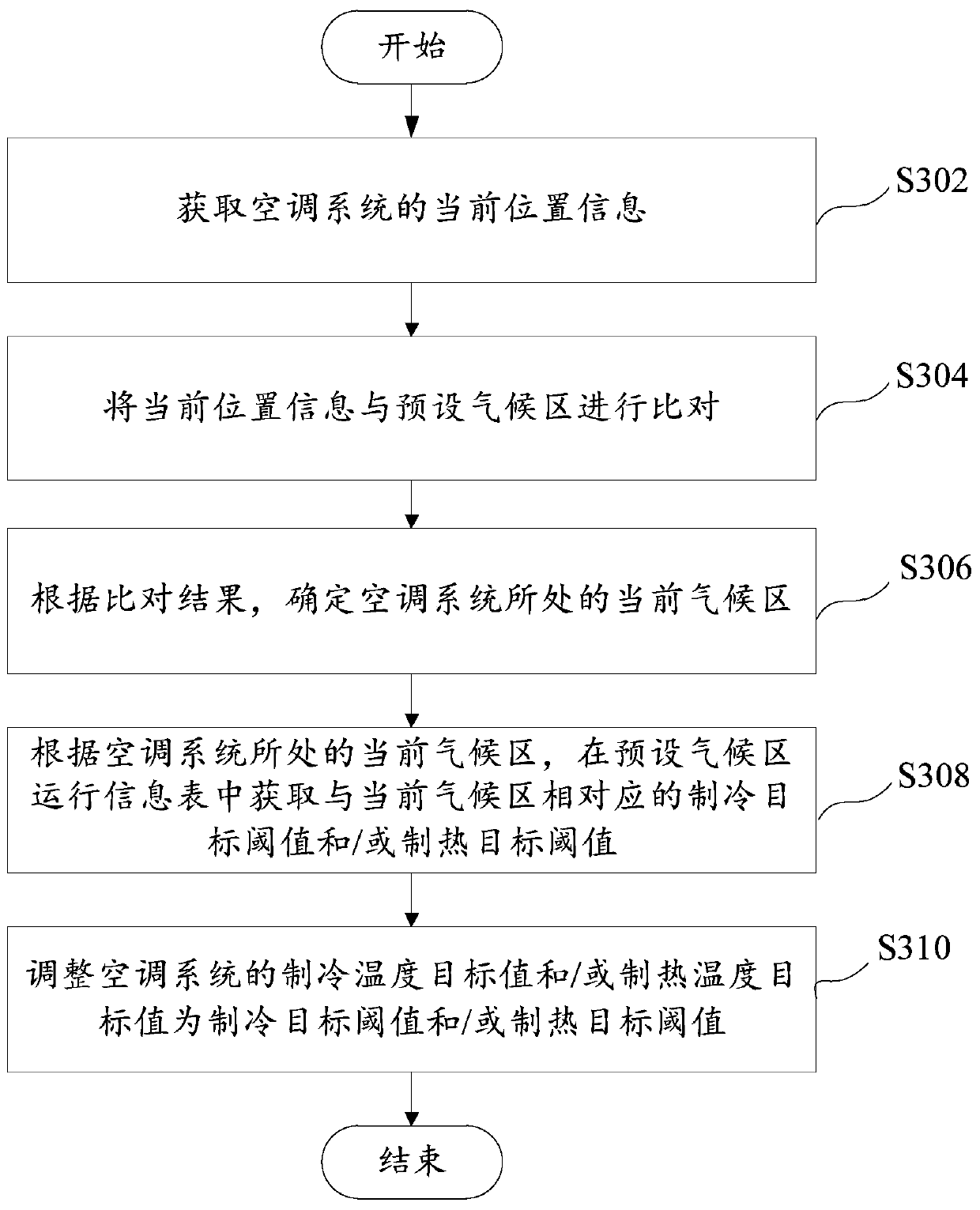

Control method of air-conditioning system, air-conditioning system and computer storage medium

InactiveCN111426008AFlexible and intelligent adjustmentImprove user experienceMechanical apparatusLighting and heating apparatusControl engineeringRefrigeration temperature

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

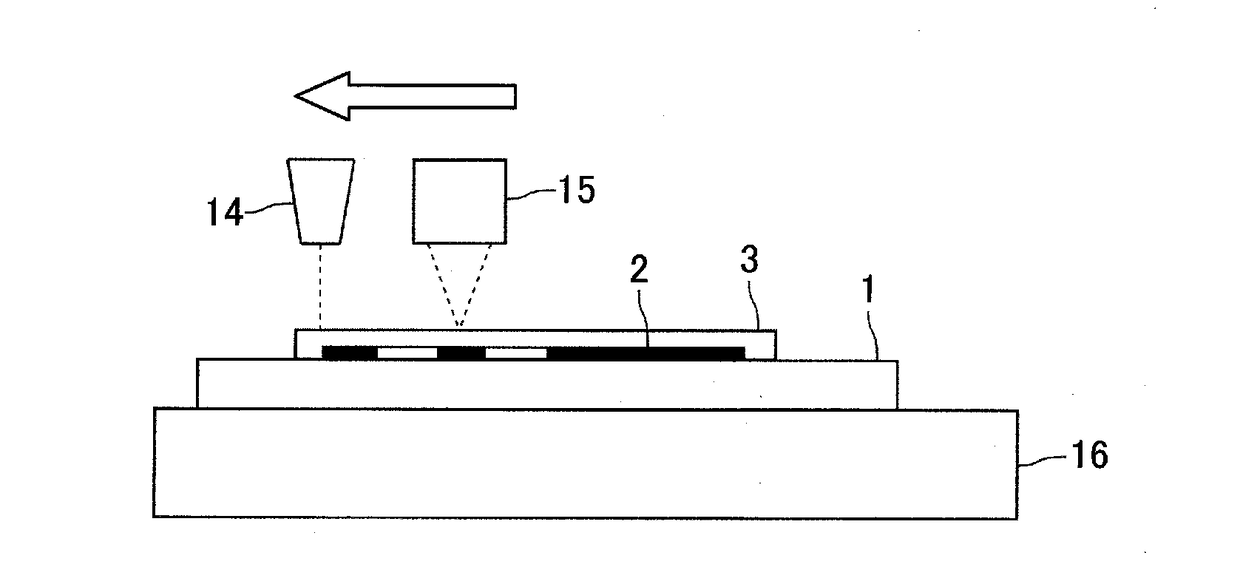

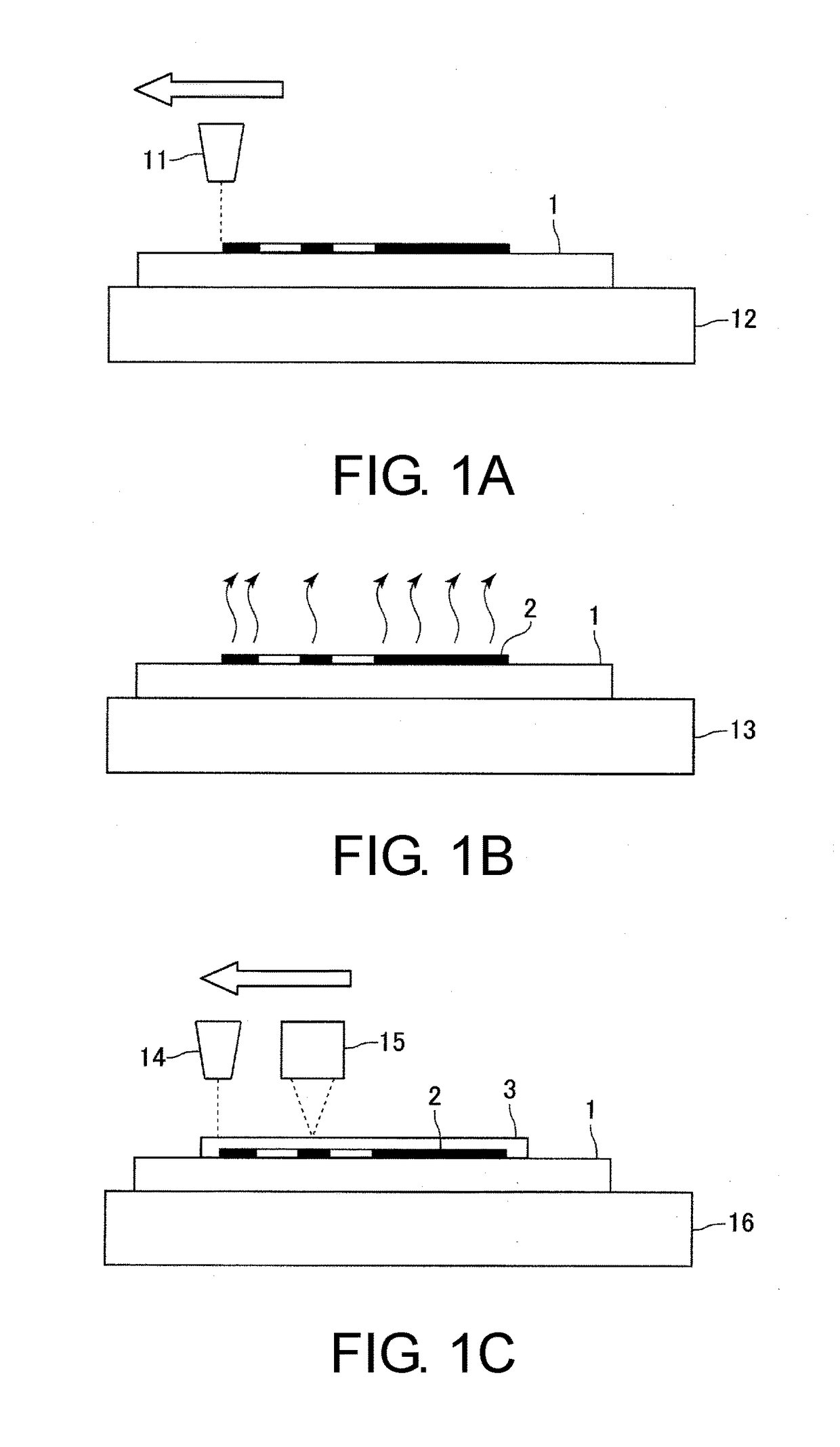

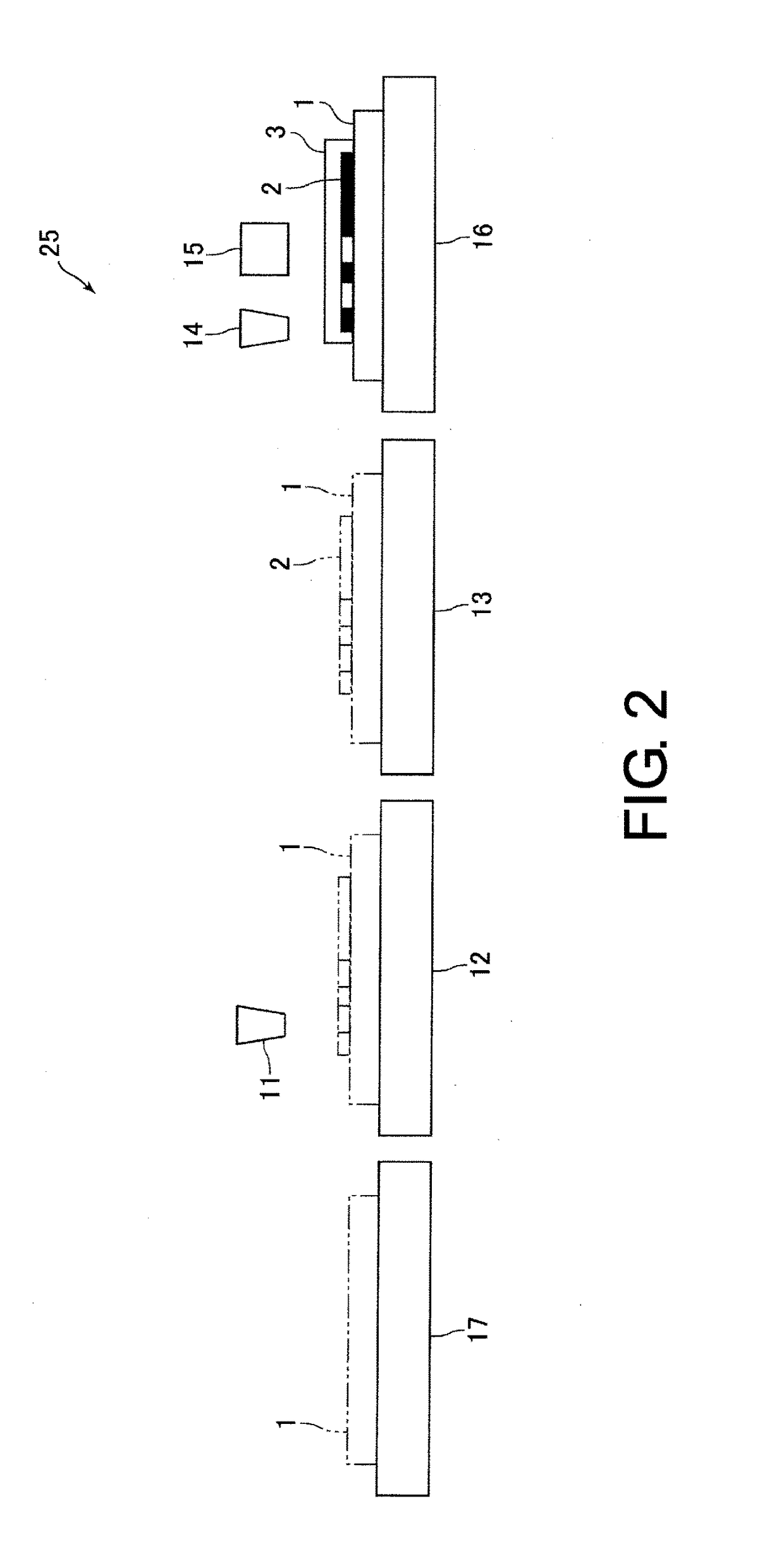

Metallic decoration method and metallic decoration apparatus

InactiveUS20170129257A1Low pour pointSolvent is vaporizedDuplicating/marking methodsTypewritersSolventHeating temperature

Owner:MIMAKI ENG

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap