Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

44 results about "Chemical composition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical composition refers to the identity and relative number of the chemical elements that make up any particular compound.

Rose vinegar

The invention discloses rose vinegar. A process method of the rose vinegar includes: subjecting roses serving as raw materials to dry crushing, extraction by edible alcohol, alcoholic strength adjustment, acetic fermentation, clarifying, ageing, filtering, mixing, filling and sterilization so that a rose vinegar finished product is obtained. The rose vinegar fully retains nutrition and efficacy of the roses, is rich in multiple amino acids, vitamins, mineral substances and antioxidant components of polyphenol, flavone and the like, and has the efficacy of detoxification, keeping young, promoting qi to activate blood, inducing resuscitation, removing stasis, soothing the liver, refreshing the mind, promoting biliation, easing digestion and regulating mechanism. The rose vinegar is free from addition of any spice and chemical component, rich in nutrition, sweet in aroma and suitable for ladies to drink and has the efficacy of maintaining beauty and keeping young.

Owner:HEBEI NORMAL UNIVERSITY OF SCIENCE AND TECHNOLOGY

Carbon nanofibers and procedure for obtaining said nanofibers

ActiveUS20090035569A1Quality improvementGuaranteed specific surface areaMaterial nanotechnologyCarbon compoundsFiberChemical composition

The object of the present invention is carbon nanofibers mainly characterized by their high specific volume of mesopores, their high gas adsorption capacity and presenting a graphitic hollow structure. A second object of this invention is a procedure for obtaining such carbon nanofibers, which makes use of a metallic nickel catalyst and specific process furnace parameters that combined with the chemical composition of the furnace atmosphere and the fluidodynamic conditions of the gas stream inside the furnace, result in a faster growth of the carbon nanofibers and also in a higher quality of the carbon nanofibers obtained.

Owner:GRP ANTOLIN ING SA

Deformed Al-Mn series alloy and preparing process thereof

Owner:ZHENGZHOU UNIV

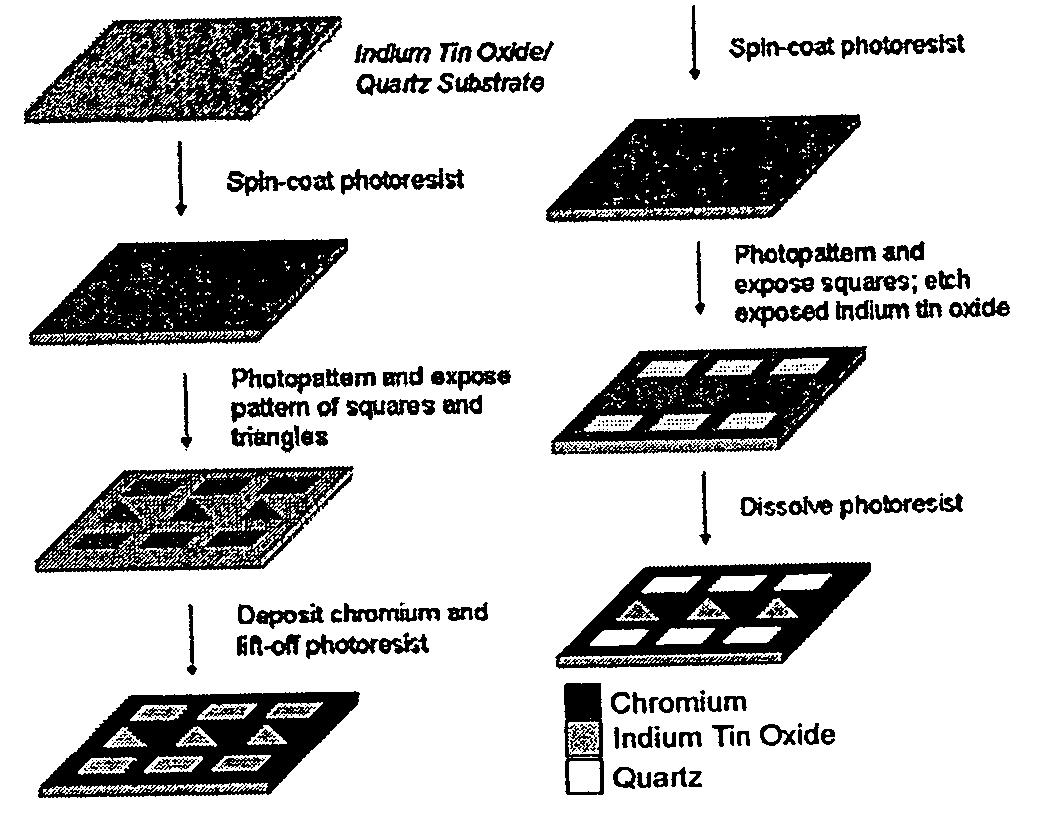

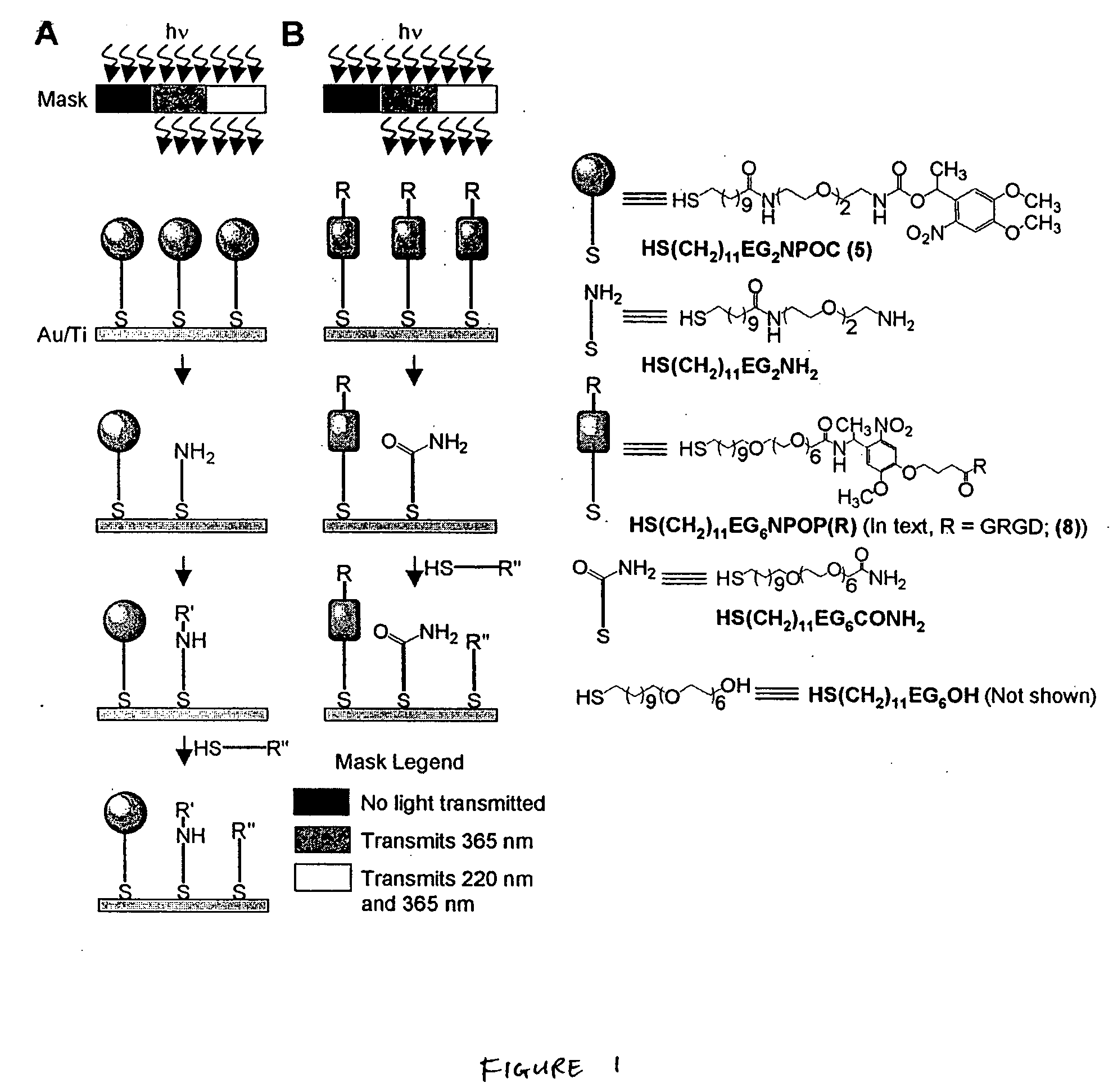

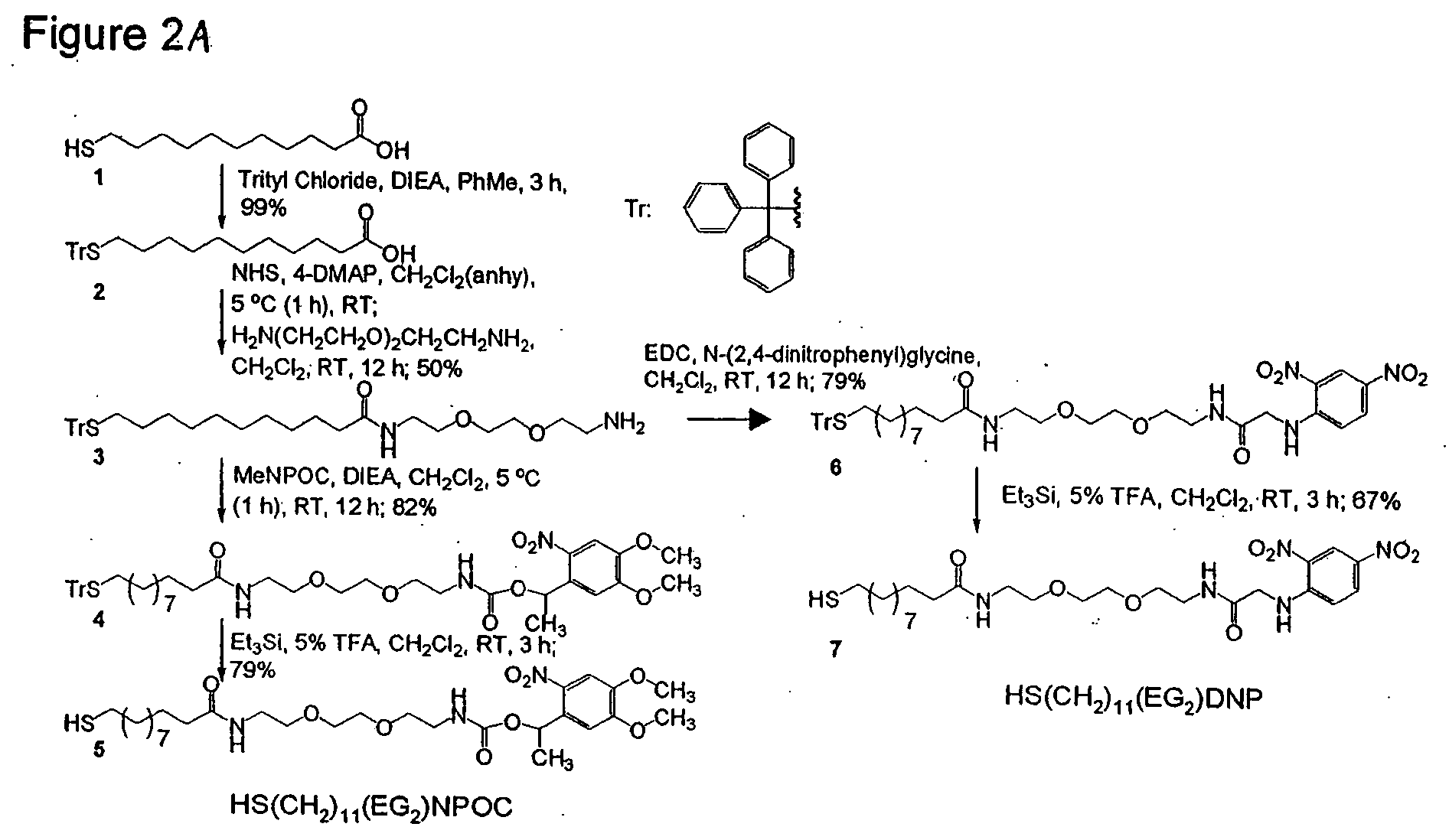

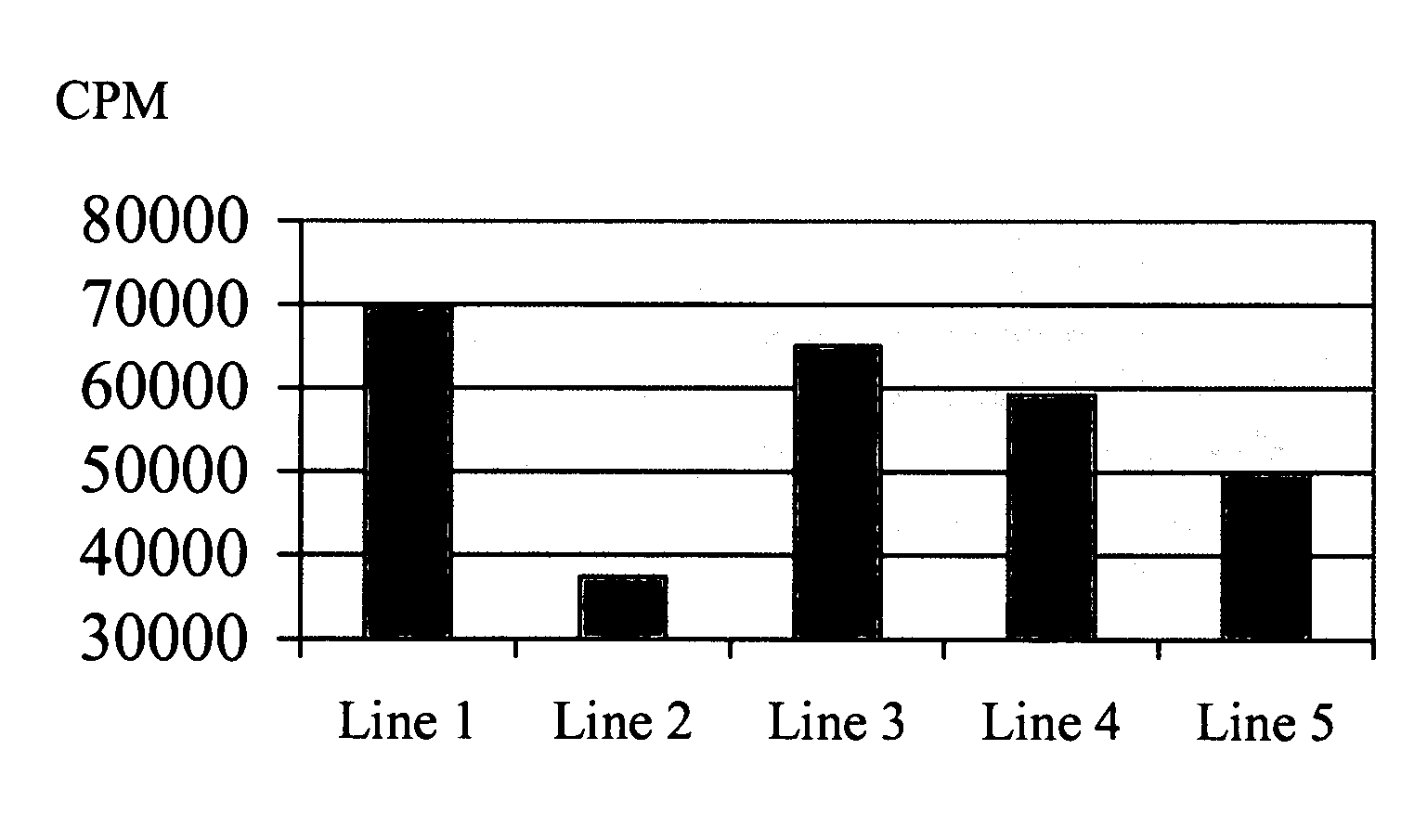

Patterning and alteration of molecules

Owner:RYAN DECLAN +7

Method for retarding unhealth manifestations brought by ageing of human beings

InactiveUS20090053200A1Reduce functionReduced stress resistancePeptide/protein ingredientsHydrolasesDna antibodyBlood plasma

Owner:CLS THERAPEUTICS

Bismuth sodium titanate-barium titanate base piezoelectric ceramic and its prepn process

InactiveCN1673178ALower coercive fieldLow resistivityPiezoelectric/electrostrictive/magnetostrictive devicesBarium titanateAdhesive

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Subtractive methods for creating dielectric isolation structures within open features

ActiveUS20160300756A1Semiconductor/solid-state device manufacturingChemical compositionMaterials science

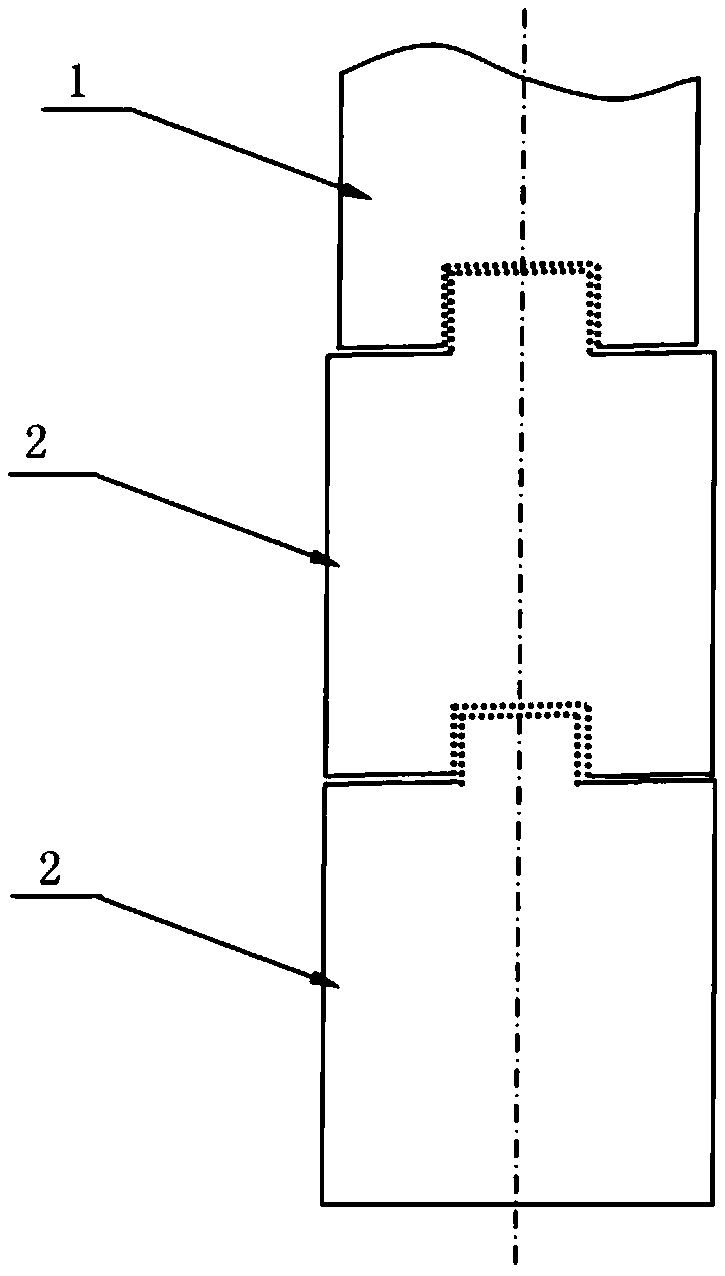

A method for partially filling an open feature on a substrate includes receiving a substrate having a layer with at least one open feature formed therein, wherein the open feature penetrates into the layer from an upper surface and includes sidewalls extending to a bottom of the open feature. The open feature is overfilled with an organic coating that covers the upper surface of the layer and extends to the bottom of the open feature. The method further includes removing a portion of the organic coating to expose the upper surface of the layer and recessing the organic coating to a pre-determined depth from the upper surface to create an organic coating plug of pre-determined thickness at the bottom of the open feature, and converting the chemical composition of the organic coating plug to create an inorganic plug.

Owner:TOKYO ELECTRON LTD

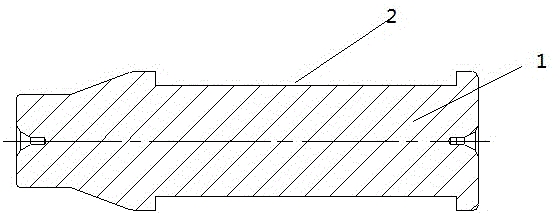

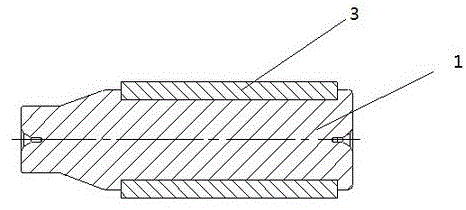

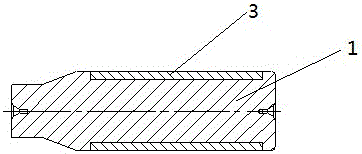

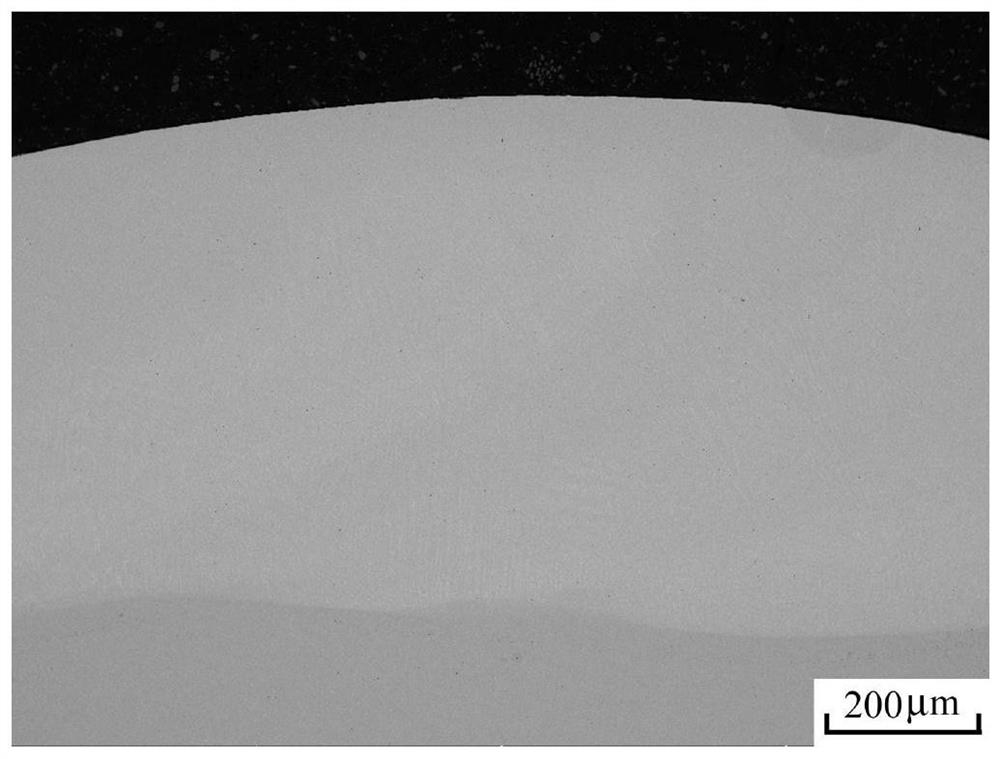

Working roll for rolling medium-thickness plate with high grade and high strength and manufacture method thereof

ActiveCN101954378AImprove wear resistanceImproved roll shape retentionRollsMetal rolling arrangementsChemical compositionWork roll

The invention discloses a working roll for rolling a medium-thickness plate with high grade and high strength and a manufacture method thereof. The working roll is applied to a medium-thickness plate rolling mill of a rolling steel industry. A working layer comprises the following alloy components in percentage by weight: 3.00-3.50 percent of C, 0.40-1.20 percent of Si, 0.50-1.20 percent of Mn, not more than 0.10 percent of P, not more than 0.05 percent of S, 1.30-2.50 percent of Cr, 3.20-4.50 percent of Ni, 0.20-1.00 percent of Mo, 0.20-2.00 percent of W and 1.00-1.50 percent of V. A roll core comprises the following chemical components in percentage by weight: 2.80-3.50 percent of C, 2.00-2.50 percent of Si, 0.50-1.00 percent of Mn, not more than 0.10 percent of P, not more than 0.05 percent of S, 0.20-0.50 percent of Cr, 0.20-0.60 percent of Ni, not more than 0.20 percent of Mo and not more than 0.30 percent of Re. The working roll manufactured by adopting a centrifugal composite casting process and two-section tempering production at 400-550 DEG C for 25-30 hours is the working roll for rolling the medium-thickness plate with high grade and high strength, which has the advantages of high abrasion resistance and less hardness reduction.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Preparation method of copper alloy spectral standard sample

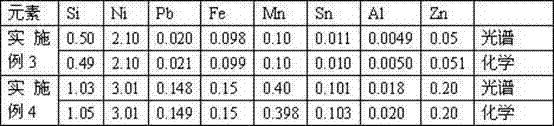

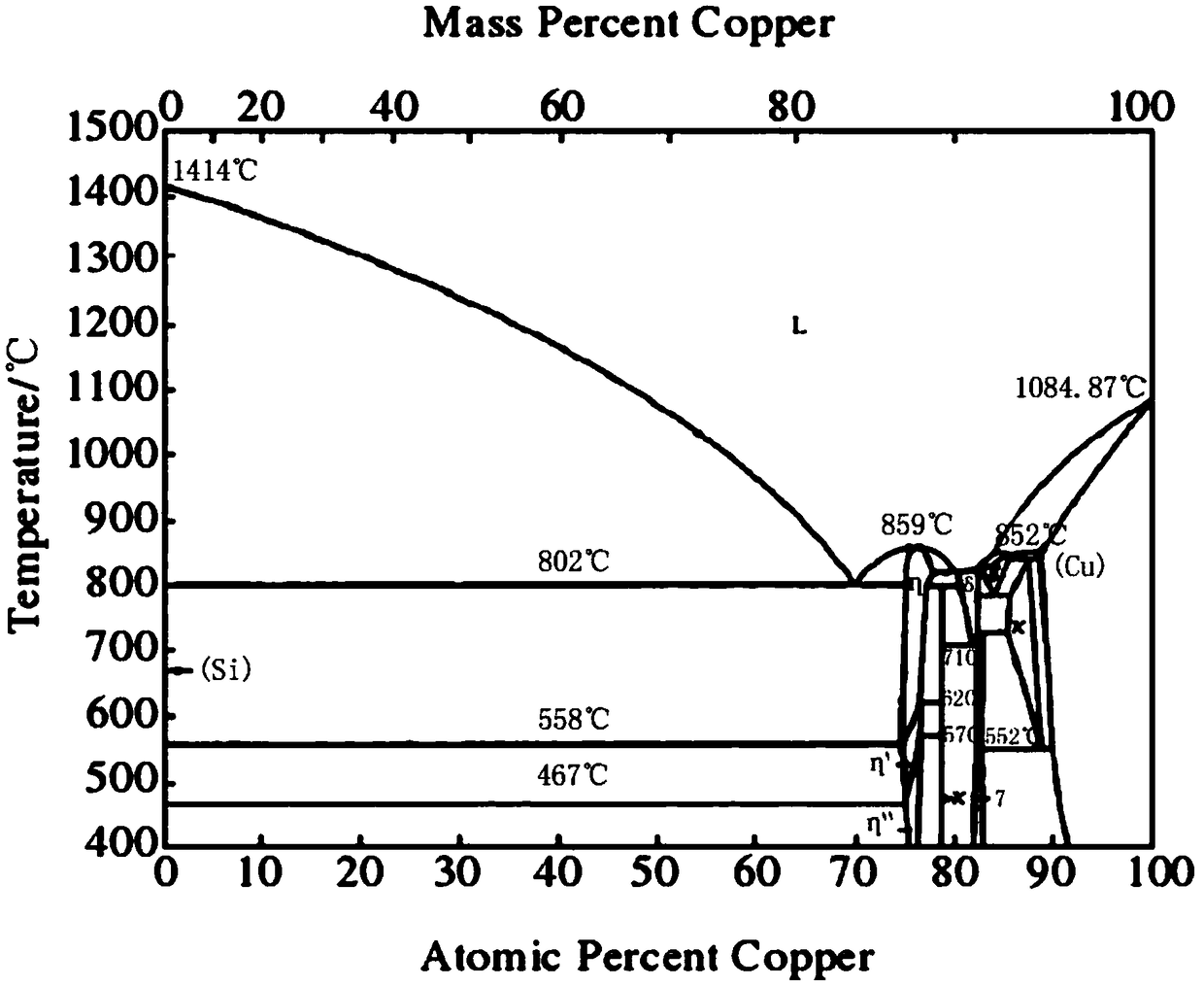

The invention discloses a preparation method of a copper alloy spectral standard sample. The copper alloy spectral standard sample comprises the following elements by weight percent: 0.09-2.50% of Si, 0.40-4.70% of Ni, 0.018-0.55% of Fe, 0.004-0.17% of Pb, 0.03-1.20% of Mn, 0.008-0.60% of Sn, 0.004-0.10% of Al and 0.04-1.60% of Zn. The preparation method comprises the following steps of: preparing materials, smelting, casting an ingot, performing homogenizing treatment and lathing the skin. The copper alloy spectral standard sample contains not only copper, but also a defined amount of Si, Ni, Pb, Fe, Mn, Zn, Al and Sn elements and can meet the requirements of the chemical composition analysis and control of the copper alloy.

Owner:白银有色西北铜加工有限公司

Preparation of a molybdenum amide additive composition and the lubricating oil compositions containing same

Owner:CHEVRON ORONITE CO LLC

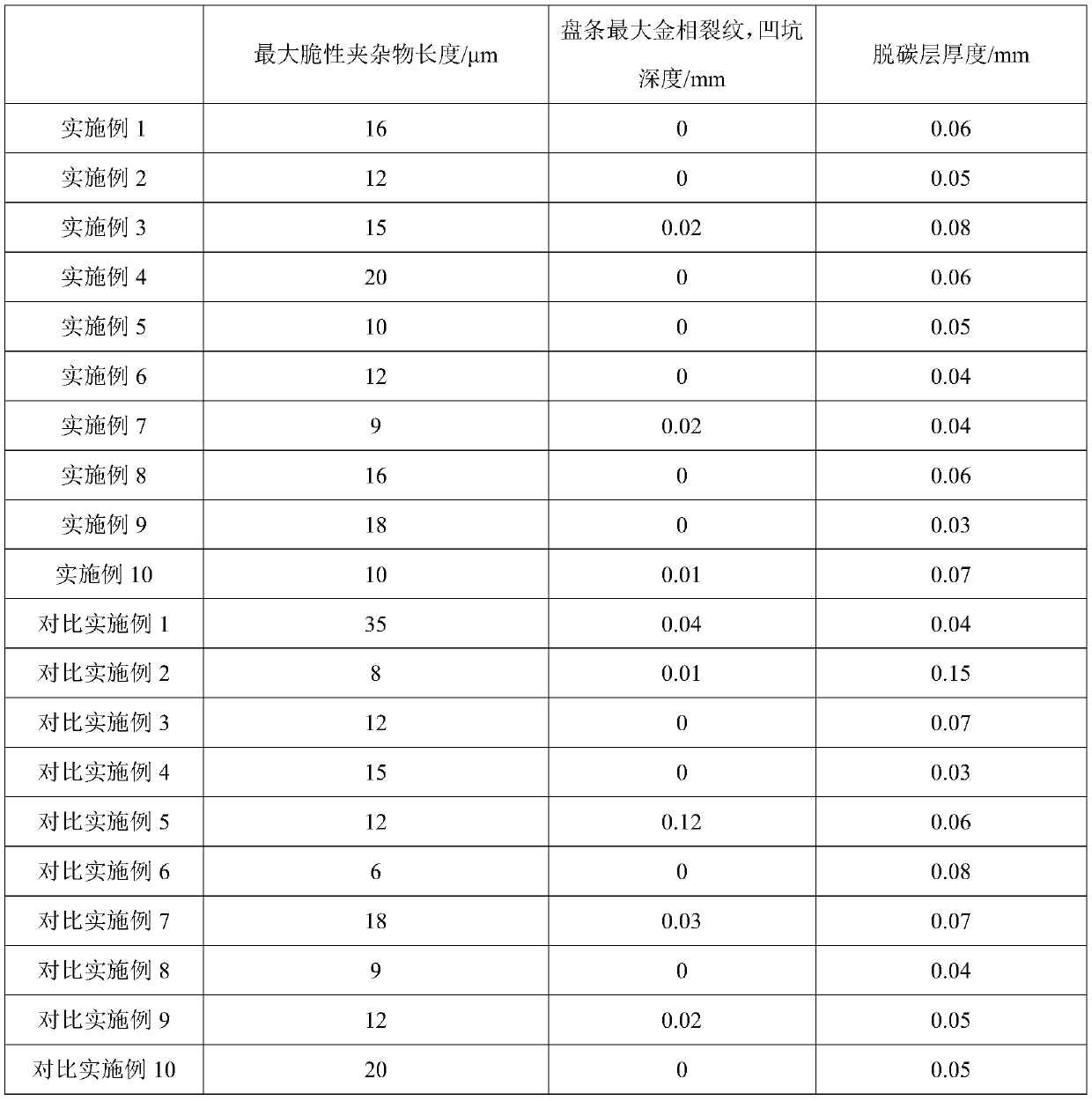

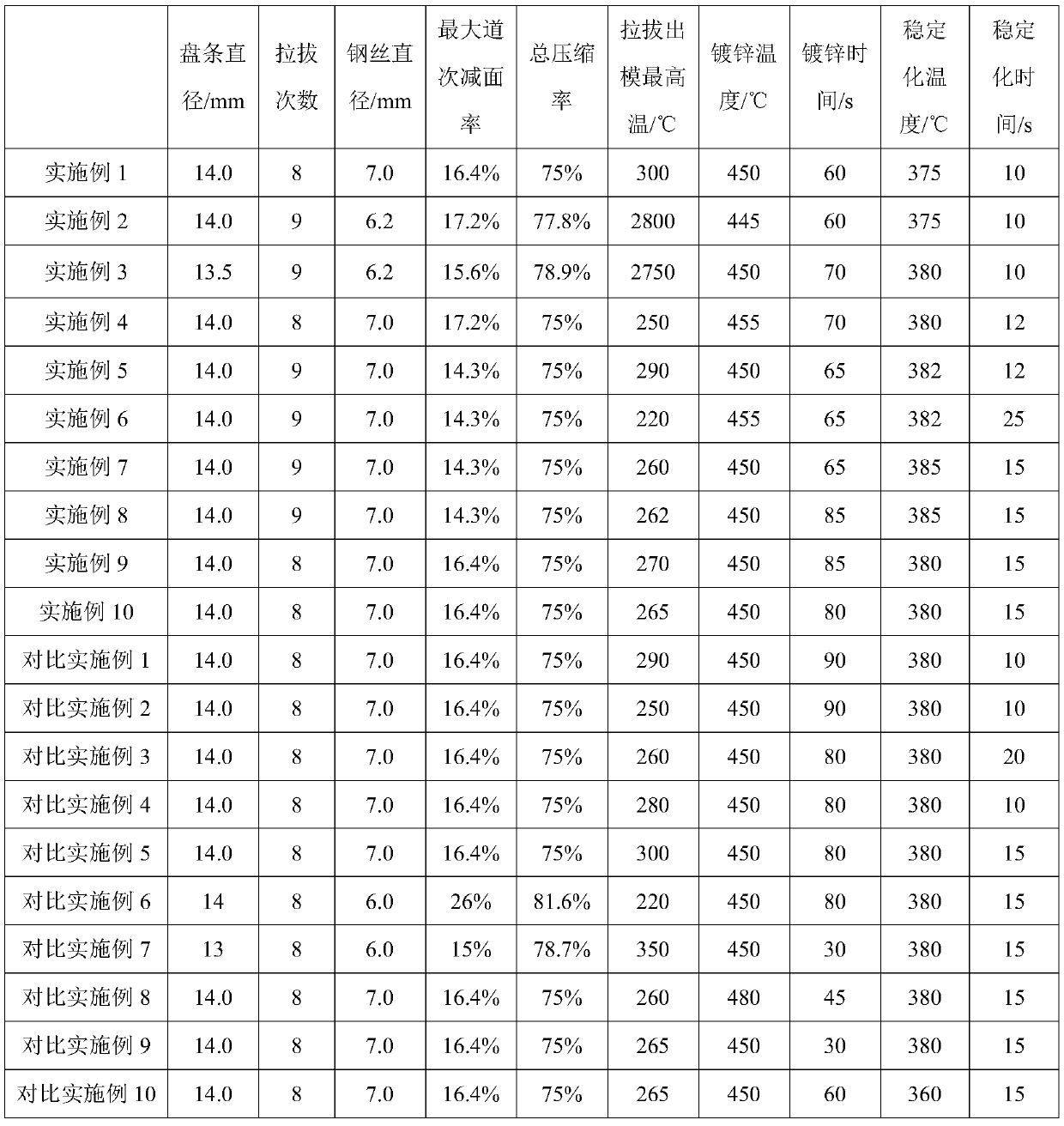

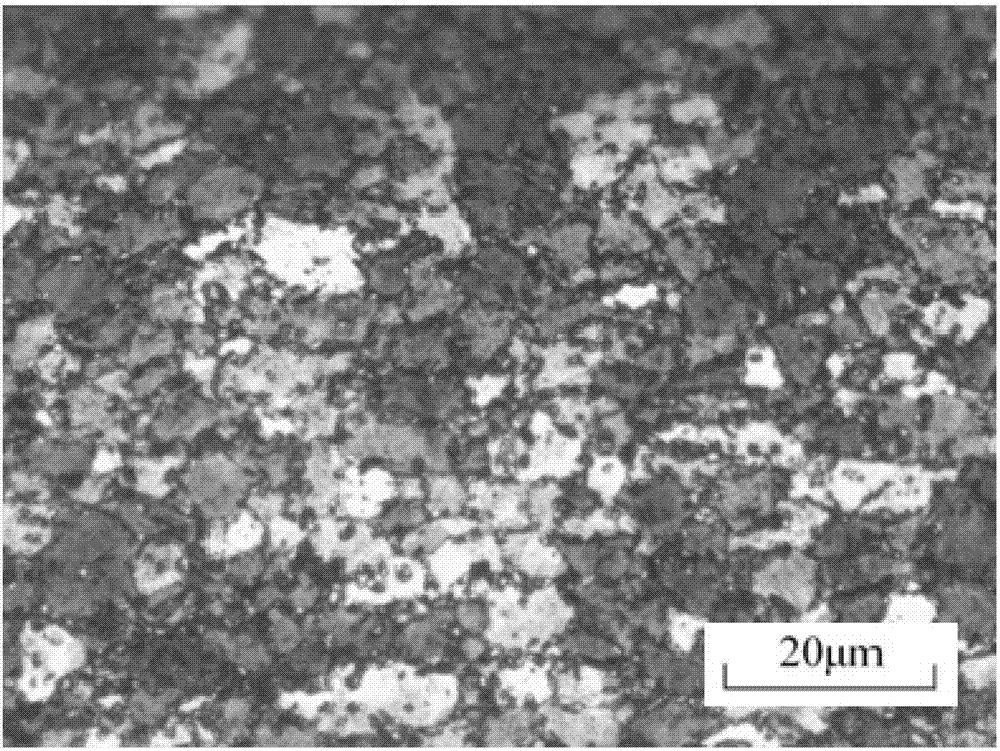

2000 MPa-grade bridge cable galvanized steel wire and preparation method thereof

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

High-surface-quality hot-galvanized transformation induced plasticity (TRIP) steel plate and manufacturing method thereof

ActiveCN106868403AImprove performanceGood coating performanceHot-dipping/immersion processesFurnace typesSteelmakingHigh surface

Owner:MAGANG (GROUP) HOLDING CO LTD +1

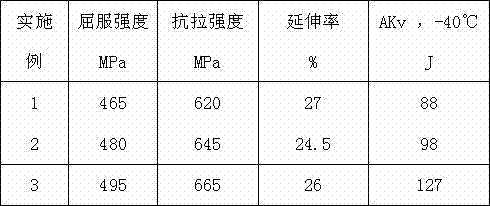

Chromium-containing alloy bar material and preparation method thereof

ActiveCN109112398AImproved particle sizeAchieve fine grain strengthening effectChemical compositionEconomic benefits

The invention relates to a chromium-containing alloy bar material and a preparation method thereof. Al and N are added in a process of smelting steel with the trade mark of 40Cr to obtain the chromium-containing alloy bar material containing 0.020 to 0.030 weight percent of the Al and 0.007 to 0.010 weight percent of the N. Under the condition that existing equipment and technology are not changed, the problem that the grain size of the alloy bar material is large in a 40Cr steel low-rolling-ratio processing process is solved through adjusting chemical components; the grain size of a steel product is obviously changed under the matching effect of the Al and the N and a fine crystal reinforcing effect is realized. Under the same rolling condition, the grain size can be improved by 1.5 to 2.0 grades when being compared with that of existing 40Cr steel, and the problem that the capability of existing equipment is not enough so that the grain size is relatively high solved; the equipment investment is reduced and the chromium-containing alloy bar material has good economic benefits and application prospect.

Owner:CHENGDE JIANLONG SPECIAL STEEL

Low-cost high-strength steel plate for engineering machinery, and production method thereof

Owner:HEBEI IRON AND STEEL

Forging method of driving shaft for gearbox

ActiveCN102989982AExtend your lifeReduce contaminationMetallic material coating processesEngine componentsChemical compositionDrive shaft

Owner:CHANGLI FORGING

Hic-resistant thick steel plate and uoe steel pipe

InactiveUS20120121453A1Easily segregatedIncrease resistanceFurnace typesHeat treatment furnacesSteel platesChemical composition

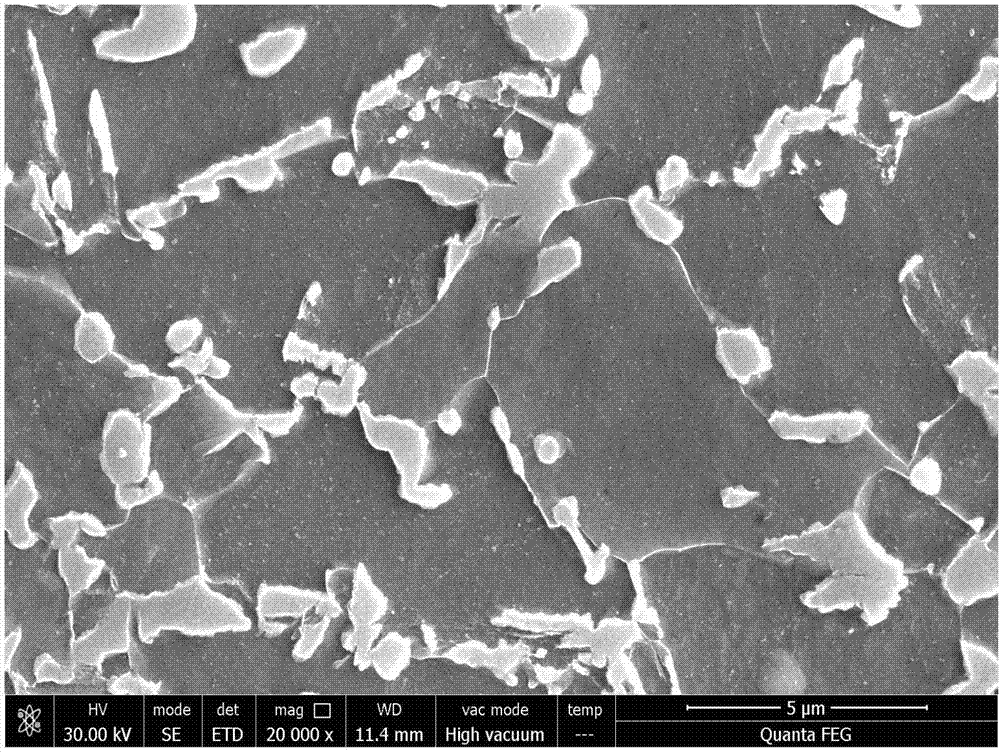

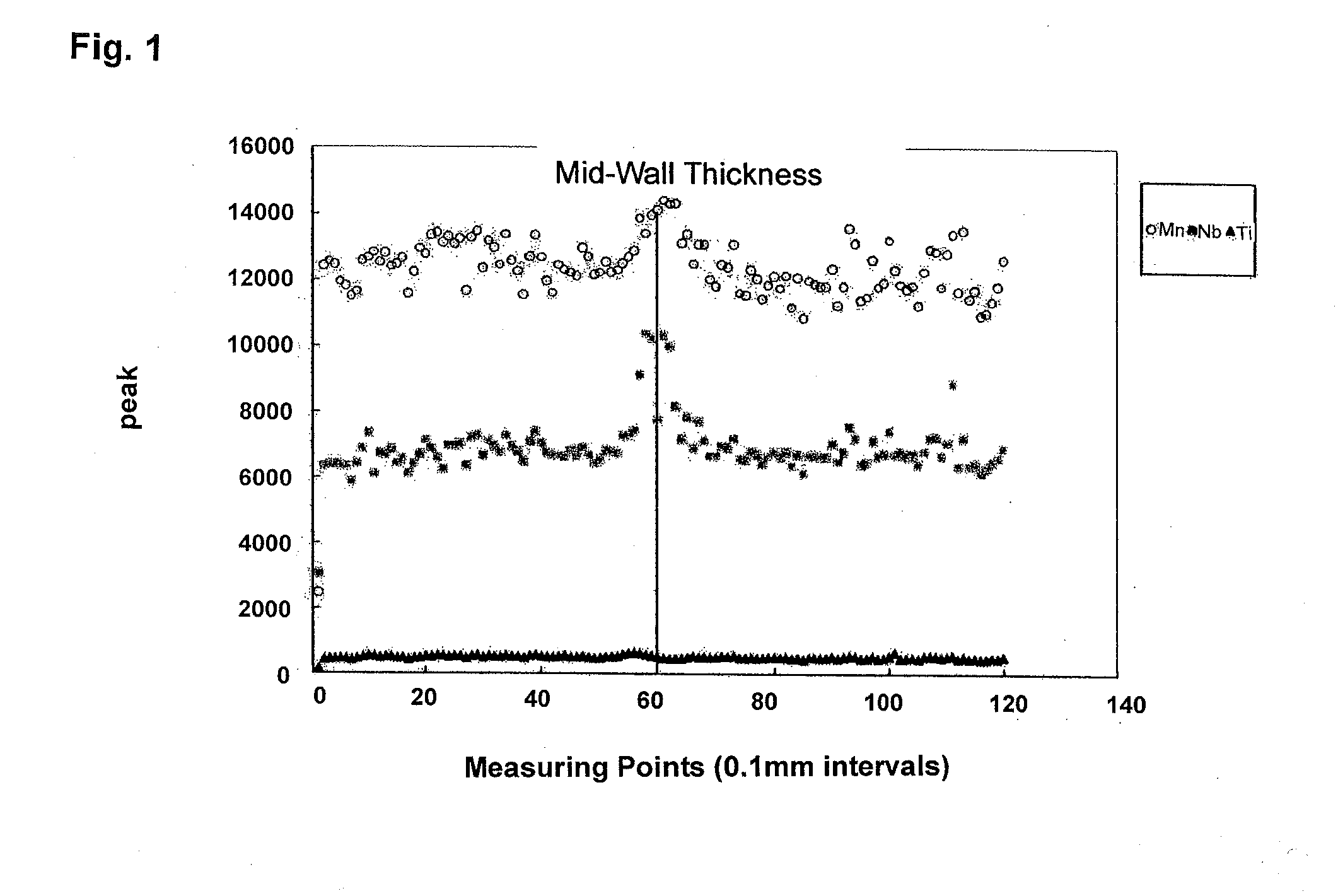

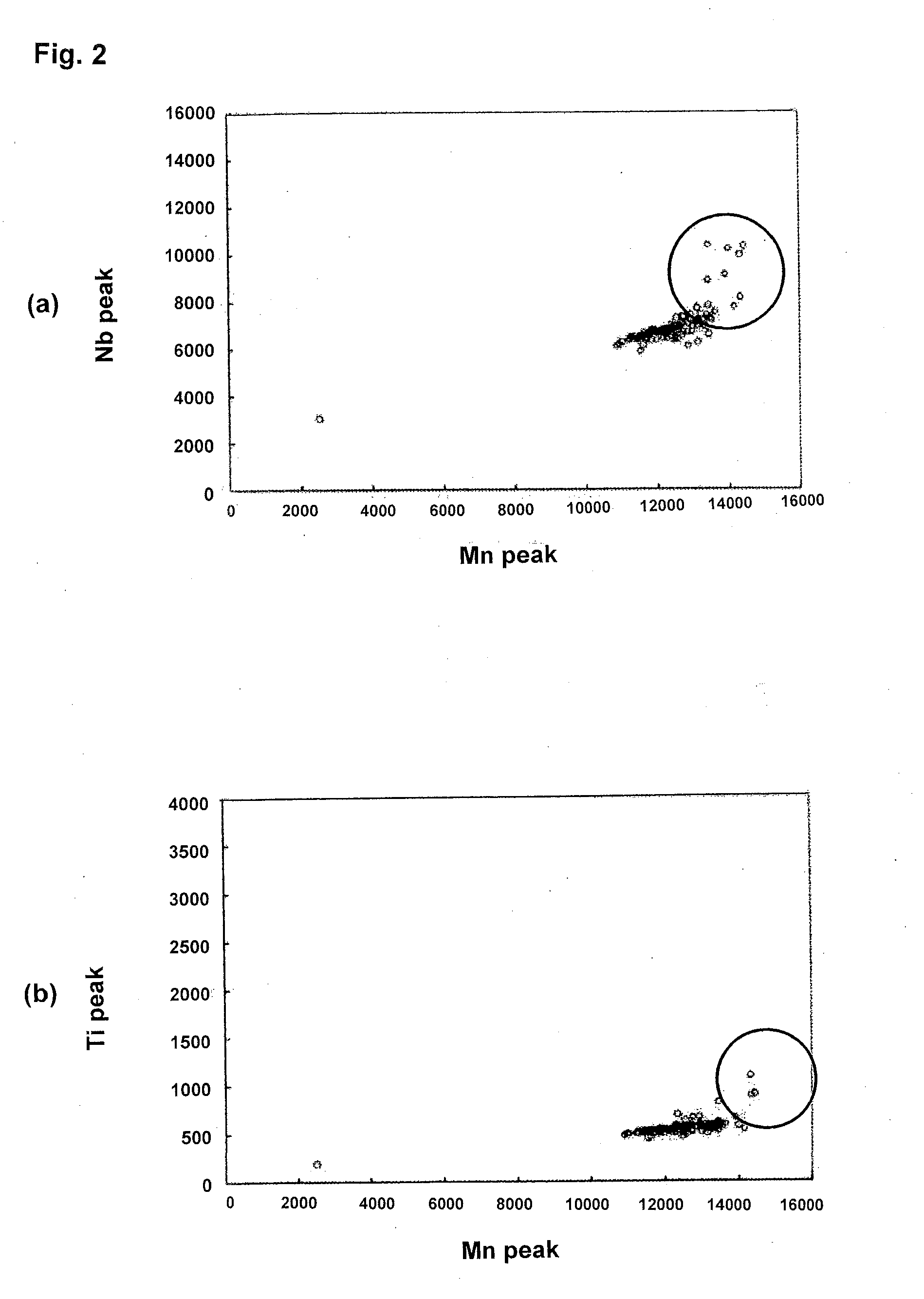

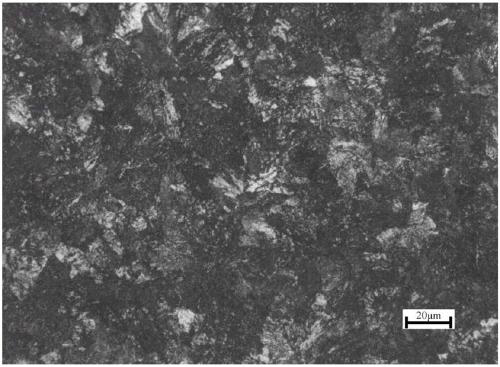

A thick steel plate and a UOE steel pipe having a high strength of at least X60 grade and improved resistance to HIC have a chemical composition consisting essentially of, in mass percent, C: 0.02-0.07%, Si: 0.05-0.50%, Mn: 1.1-1.6%, P: at most 0.015%, S: at most 0.002%, Nb: 0.005-0.060%, Ti: 0.005-0.030%, Al: 0.005-0.06%, Ca: 0.0005-0.0060%, N: 0.0015-0.007%, at least one of Cu, Ni, Cr, and Mo in a total amount of greater than 0.1% and less than 1.5%, and a remainder of Fe and impurities, wherein the degrees of segregation of Nb and Ti are both at most 2.0, and the ratio of (the degree of Nb segregation) / (the degree of Mn segregation) and the ratio of (the degree of Ti segregation) / (the degree of Mn segregation) are both at least 1.0 and at most 1.5.

Owner:SUMITOMO METAL IND LTD

Cord steel wire rod and decarburized layer control method thereof

Owner:ANGANG STEEL CO LTD

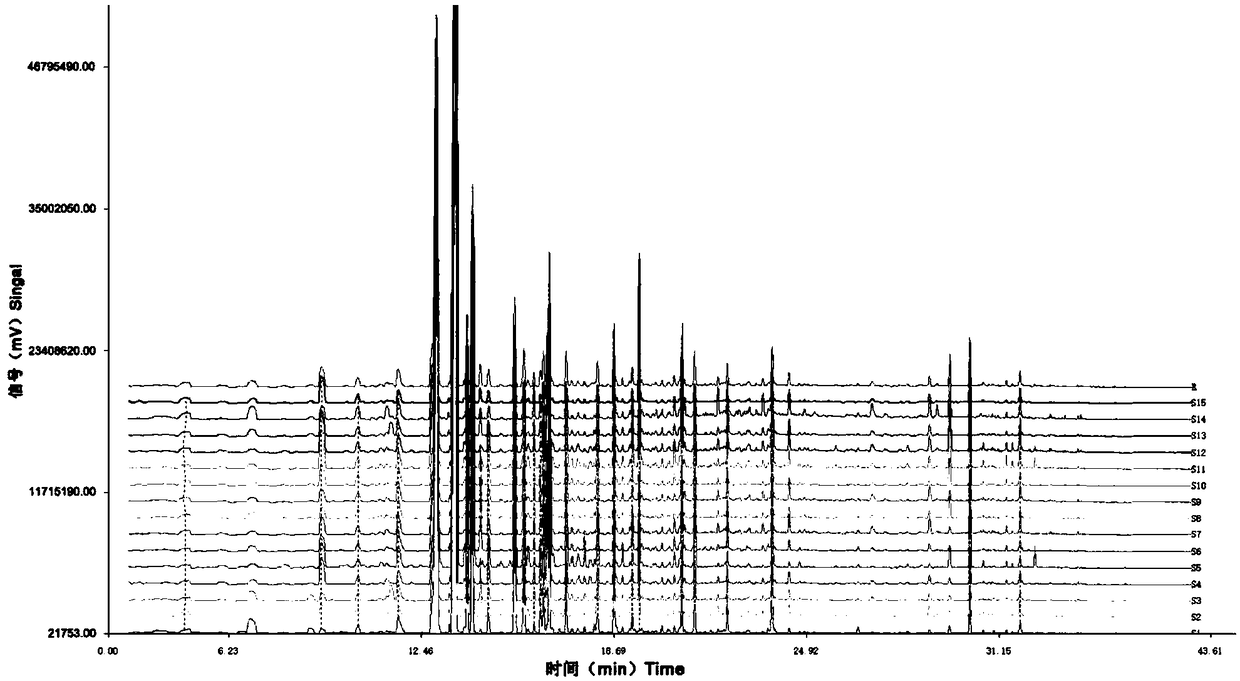

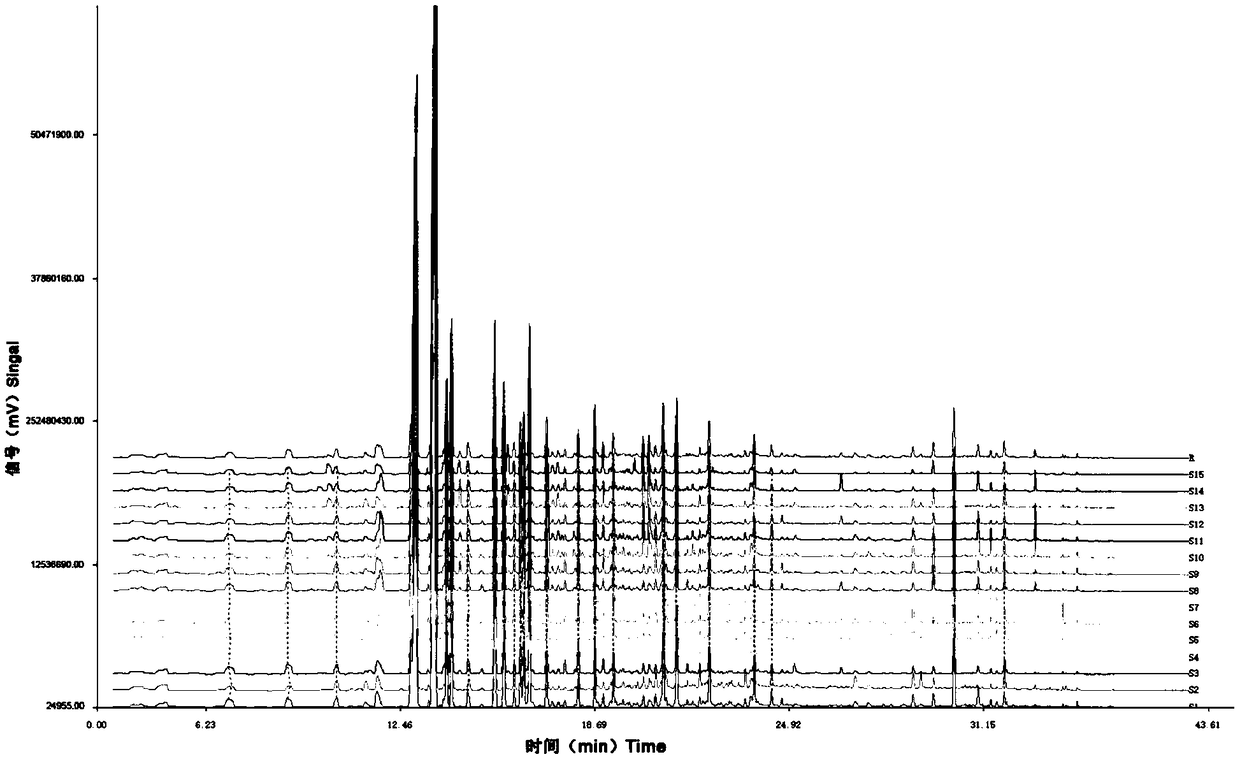

Construction method and identification application of fingerprint spectra of natural apis cerana honey of lychee flowers and natural apis mellifera honey of lychee flowers

ActiveCN109470779AFix the problem of indistinguishableHigh detection sensitivityComponent separationApis ceranaSocial benefits

Owner:INST OF ZOOLOGY GUANGDONG ACAD OF SCI

Antibacterial stainless steel for handrails or handles

ActiveCN108728767AIncrease Ga contentImprove antibacterial propertiesSeparated stateChemical composition

The invention discloses antibacterial stainless steel for handrails or handles, and belongs to the technical field of stainless steel materials. The stainless steel comprises the following chemical components of, by weight, less than or equal to 0.08% of C, less than or equal to 0.50% of Si, less than or equal to 1.00% of Mn, less than or equal to 0.05% of P, less than or equal to 0.05% of S, 8.0-12.0% of Ni, 18.0-20.0% of Cr, 3.0-5.0% of Cu, 0.50-1.50% of Ga and the balance Fe. The antibacterial stainless steel is subjected to solid solution heat treatment, and then based on the supersaturation and solid solution of the Ga and the Cu in a matrix, the Ga and the Cu exist in two forms, namely a solid solution state and a gallium-rich phase separated state. The use environment of the handrails or the handles is generally the air environment, and when the handrails or the handles are in contact with sweat, gallium ions can be effectively dissolved out due to the existence of the gallium-rich phase, so that the effects that reproduction and propagation of pathogenic bacteria among human hands are obviously inhibited, and the probability of occurrence of group-occurring bacterial infection events is reduced are achieved. According to the antibacterial stainless steel, the propagation risk of the pathogenic bacteria among the human hands is reduced, and the antibacterial stainless steel can be widely applied to the stair handrails, railings, the door handles and the like for living decoration.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Low-aging sensitivity hot rolled plate with high strength and toughness and manufacturing method thereof

InactiveCN103757548AAddress uneven performanceSolve the costManufacturing convertersChemical compositionSmelting process

Owner:ANGANG STEEL CO LTD

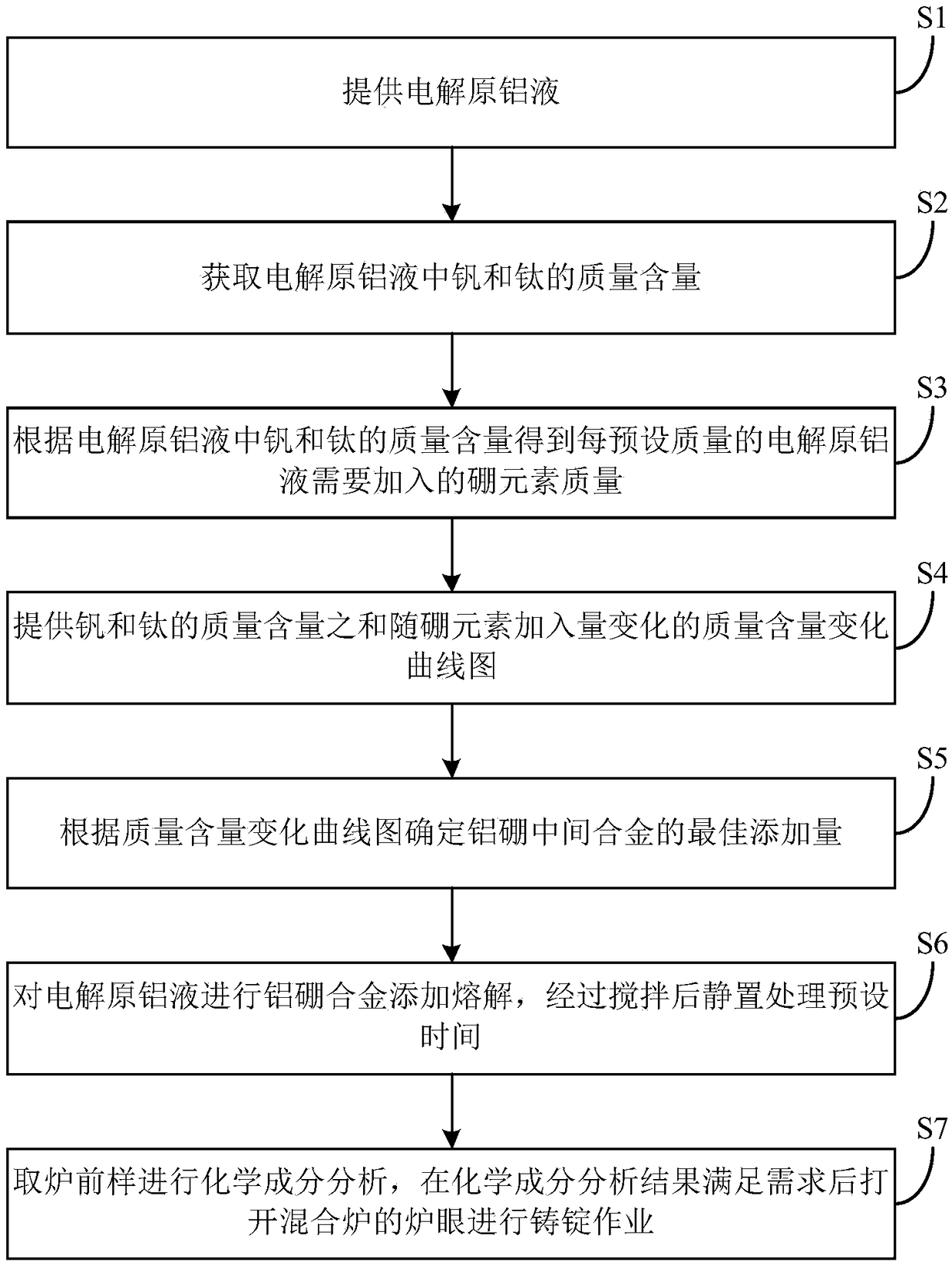

Preparation method of aluminum ingot

Owner:YUNNAN YONGXIN ALUMINUM

A herbicidal composition containing florasulam and isoxaflutole

InactiveCN102283218ADelay drug resistanceExpand the spectrum of weed controlBiocideAnimal repellantsChemical compositionHas active ingredient

The invention relates to a weeding composition containing florasulam and isoxaflutole. The weeding composition is mainly characterized by containing 1-60 percent of florasulam with effective components, 1-80 percent of isoxaflutole, addition agent and the balance of other excipients. The weeding composition is prepared into wettable powder, water dispersible granules, suspending agents, microemulsion, aqueous emulsion and the like and can be used for controlling various weeds.

Owner:SHAANXI MEIBANG PHARMA GRP CO LTD

High heat input welding resistant building steel and production method thereof

ActiveCN114150228AImprove welding effectGood anti-fatigueHeat treatment process controlProcess efficiency improvementNiobiumHeat cycling

Owner:NORTHEASTERN UNIV

Hot-dip galvanized plate suitable for low-temperature environment for gas meter shell and production method thereof

InactiveCN111118405AHot-dipping/immersion processesManufacturing convertersSteel platesChemical composition

Owner:MAANSHAN IRON & STEEL CO LTD

Copper-silicon alloy material, electroslag remelting preparation method thereof and copper-silicon alloy wire material

Owner:沈阳赛美特新材料科技有限公司

Visible-light responsive photocatalyst Sr3Ce2Ti6O19 and preparing method thereof

ActiveCN103418368AImprove catalytic performanceHas decomposed harmful chemicalsTitanium compoundsMetal/metal-oxides/metal-hydroxide catalystsChemical compositionLight responsive

Owner:安徽上阡科技信息咨询有限公司

Manufacturing process for improving abrasion resistance of outer circle surface of plunger

InactiveCN106011724ATechnical requirements are metImprove wear resistanceMolten spray coatingThermal sprayingChemical composition

Owner:中石化四机石油机械有限公司 +1

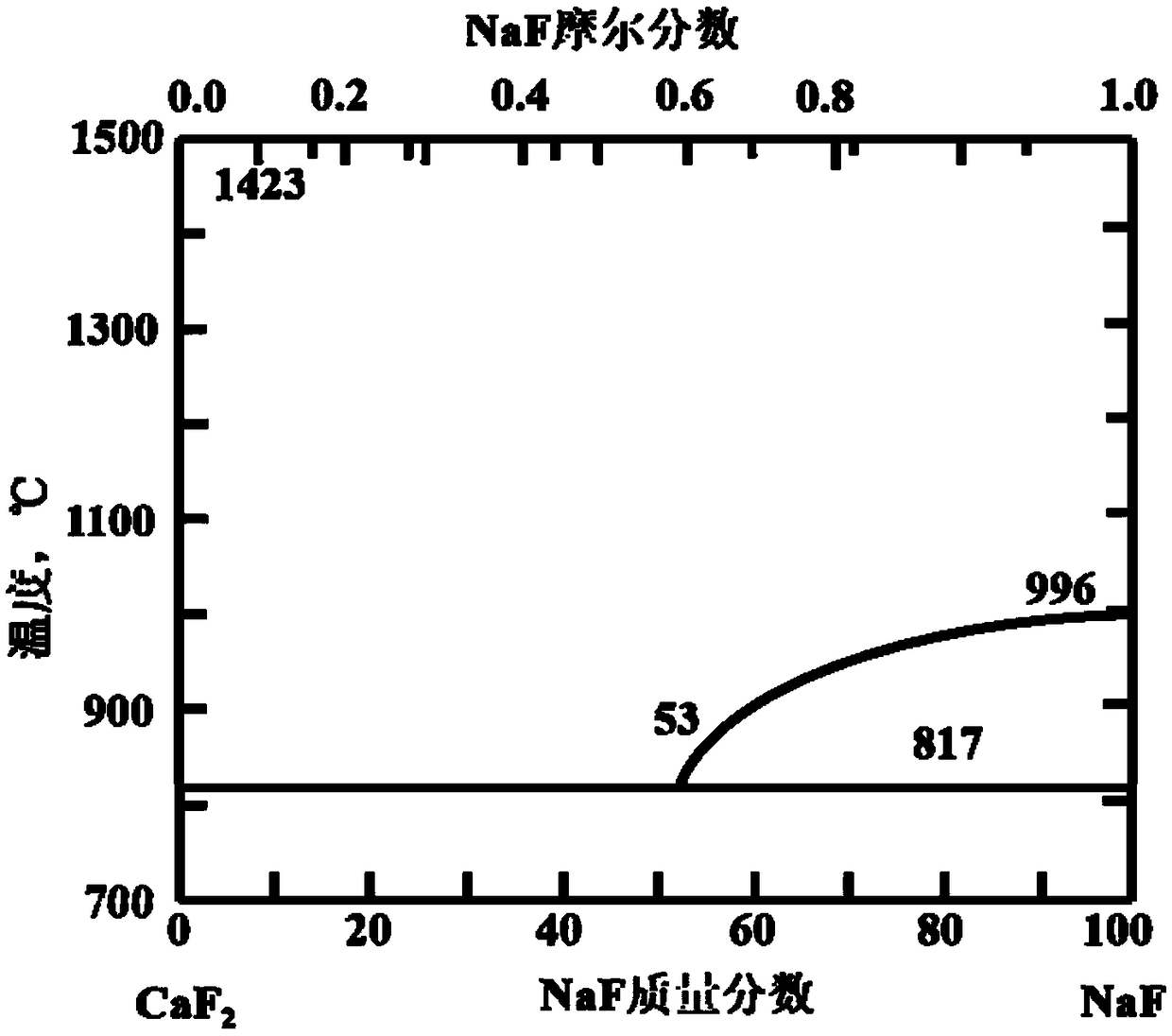

Coating for high-temperature chlorine corrosion protection and preparation method thereof

ActiveCN111778502ALow melting pointReduce meltingMolten spray coatingChemical compositionSand blasting

Owner:XIAN THERMAL POWER RES INST CO LTD

Method for preparing high-performance hydrophilic modified polyacrylonitrile membrane by combining in-situ modification with phase separation technology

InactiveCN111686595AReduce productionImprove development efficiencySemi-permeable membranesWater/sewage treatment bu osmosis/dialysisPolymer scienceChemical composition

Owner:XILONG SCI CO LTD

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap