Preparation method of copper alloy spectral standard sample

A spectral standard sample and copper alloy technology, which is applied in the field of preparation of copper alloy spectral standard samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] The weight content of each element in the copper alloy spectral standard sample is:

[0020] Si 0.10±0.01% Ni 4.5±0.2% Fe 0.02±0.002% Pb 0.005±0.001% Mn 0.05±0.006% Sn 0.50±0.03% Al 0.040±0.01% Zn 1.50±0.1%

[0021] (1) Material preparation: Calculated by 50Kg thrown into the furnace. 37.008Kg of pure metal copper, Cu-Si (20% by weight of Si) 0.25Kg, 10.598Kg of Cu-Ni (21.23% by weight of Ni), 10.598Kg of Cu-Mn (20% by weight of Mn content of 31.58%) 0.079Kg, Cu-Fe (the weight percentage of Fe is 4.34%) 0.230Kg, Cu-Zn (the weight percentage of Zn is 49.47%) 1.516Kg, Cu-Al (the weight percentage of Al content of 32.2%) 0.062Kg, pure Pb 0.0025Kg, pure Sn 0.25Kg;

[0022] (2) Melting: High-frequency furnace is used, and the melting temperature is 1130~1170°C. After the oven, according to the proportion of each element and the degree of oxidation difficulty, the order of feeding is to add copper + charcoal first, and then add Cu-Si to dissolve→Cu-Ni to dissolve→Cu-Mn to ...

Embodiment 2

[0027] The weight content of each element in the copper alloy spectral standard sample is:

[0028] Si 0.25±0.02% Ni 1.0±0.06% Fe 0.04±0.005% Pb 0.010±0.002% Mn 0.20±0.02% Sn 0.02±0.01% Al 0.010±0.002% Zn 0.10±0.02%

[0029] Get the raw materials ready: in embodiment 2, use pure metal copper 46.09Kg, Cu-Si (the weight percent composition of Si is 20%) 0.625Kg, Cu-Ni (the weight percent composition of Ni is 21.23%) 2.355Kg, Cu -Mn (31.58% by weight of Mn) 0.317Kg, Cu-Fe (4.34% by weight of Fe) 0.461Kg, Cu-Zn (49.47% by weight of Zn) 0.101Kg, Cu-Al (the weight percentage of Al is 32.2%) 0.016Kg, pure Pb 0.005Kg, pure Sn 0.010Kg;

[0030] Melting, ingot casting, homogenization treatment and wagon steps are the same as in Example 1.

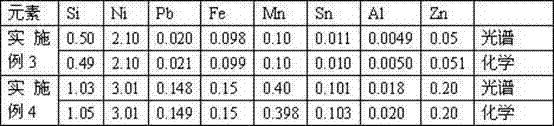

Embodiment 3

[0032] The weight content of each element in the copper alloy spectral standard sample is:

[0033] Si 0.50±0.05% Ni 2.10±0.2% Fe 0.10±0.25% Pb 0.020±0.002% Mn 0.10±0.02% Sn 0.010±0.01% Al 0.005±0.001% Zn 0.05±0.002%

[0034] Raw materials: 40.144Kg of pure metal copper, Cu-Si (20% by weight of Si) 1.25Kg, 4.946Kg of Cu-Ni (21.23% by weight of Ni), 4.946Kg of Cu-Mn (20% by weight of Mn The percentage content is 31.58%) 0.158Kg, Cu-Fe (the weight percentage of Fe is 4.34%) 1.152Kg, Cu-Zn (the weight percentage of Zn is 49.47%) 0.051Kg, Cu-Al (the weight percentage of Al is The weight percentage is 32.2%) 0.008Kg, pure Pb 0.010Kg, pure Sn 0.005Kg;

[0035] Melting, ingot casting, homogenization treatment and wagon steps are the same as in Example 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap