Manufacturing method of high manganese steel spectrum standard sample

A technology for spectral standard sample and preparation method, which is applied in the field of standard sample preparation, can solve the problems of low yield, high price of high-manganese steel spectral standard sample, analysis error, etc., and achieves high accuracy, high economy, and improved uniformity. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

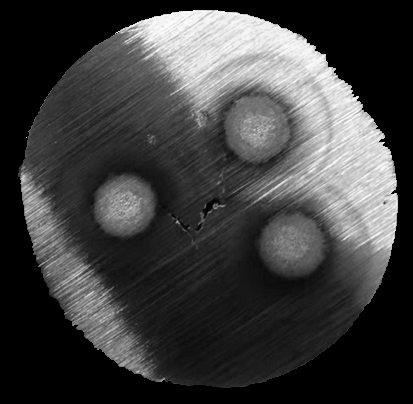

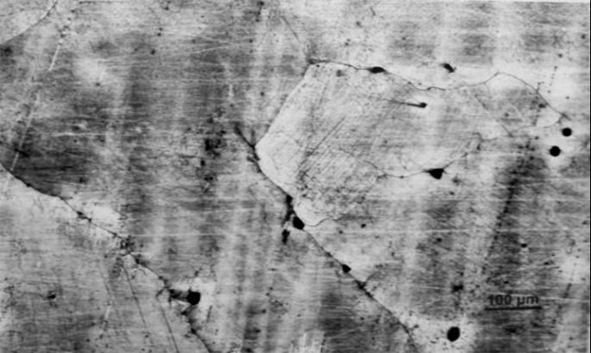

Image

Examples

Embodiment Construction

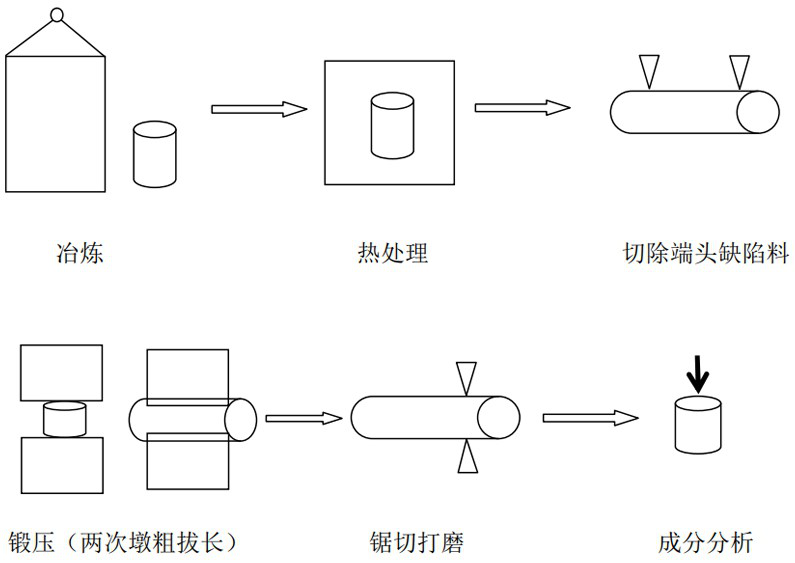

[0032] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments.

[0033] A method for making a spectral standard sample of high manganese steel, comprising the following steps:

[0034] S1, material preparation smelting: carry out material preparation according to the middle limit of high manganese steel composition, the high manganese steel adopted in this specific embodiment is ZGMn13Mo, and its chemical composition is as shown in table 1 below:

[0035]

[0036] The vacuum smelting test furnace (50kg) was used for smelting, and the bar with a diameter of 100mm was obtained by casting and molding, and the casting temperature was 1420°C;

[0037] S2, heat treatment: the bar obtained in step S1 is heated to 1080 °C, kept for 2 hours, and then quenched after the heat preservation, the quenching medium is water, and the water temperature is 20 °C;

[0038] S3. Forging:

[0039] S3-1, remove the casting defect

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap