Voltage conversion device and method for electric vehicle and electric driving system

An electric drive system and voltage conversion technology, applied in electric vehicle charging technology, output power conversion devices, electric vehicles, etc., can solve the problems of high unit cost, increased vehicle cost, unfavorable vehicle layout and light weight, etc. , to achieve the effect of saving charging costs, reducing the weight of the vehicle, and optimizing the layout of the vehicle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

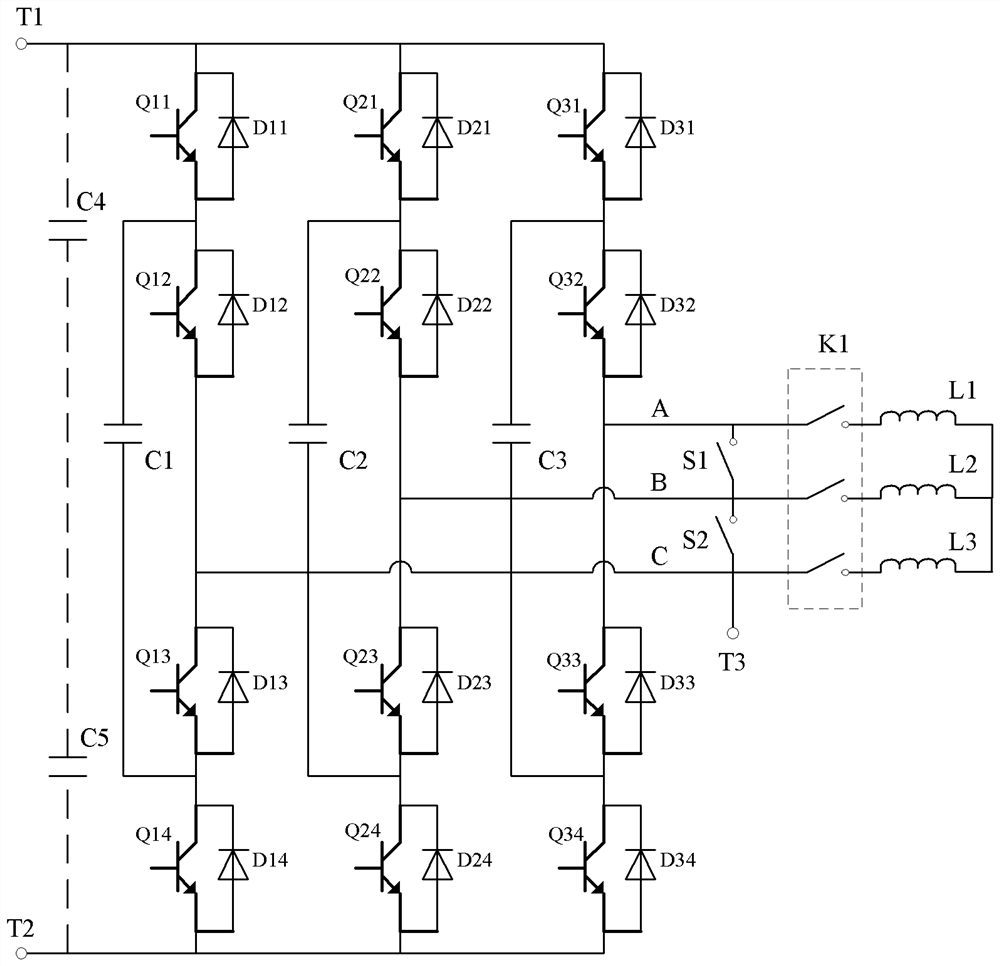

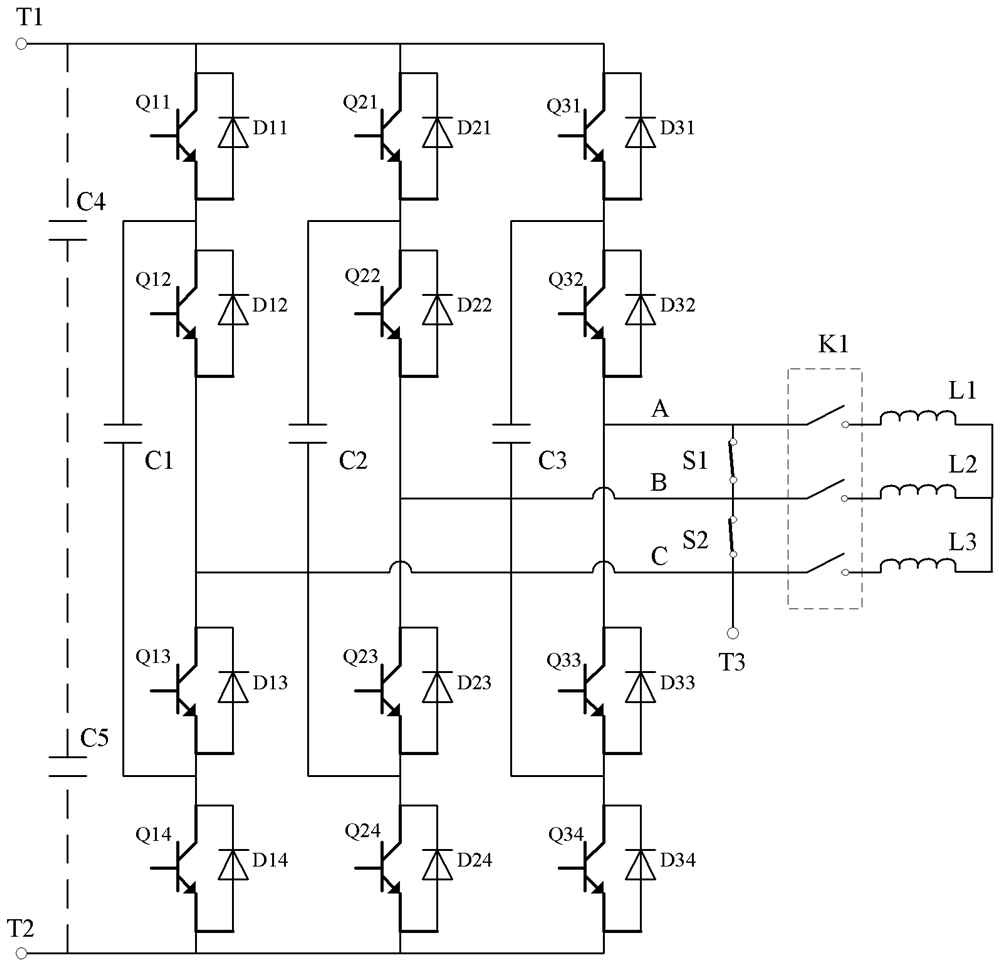

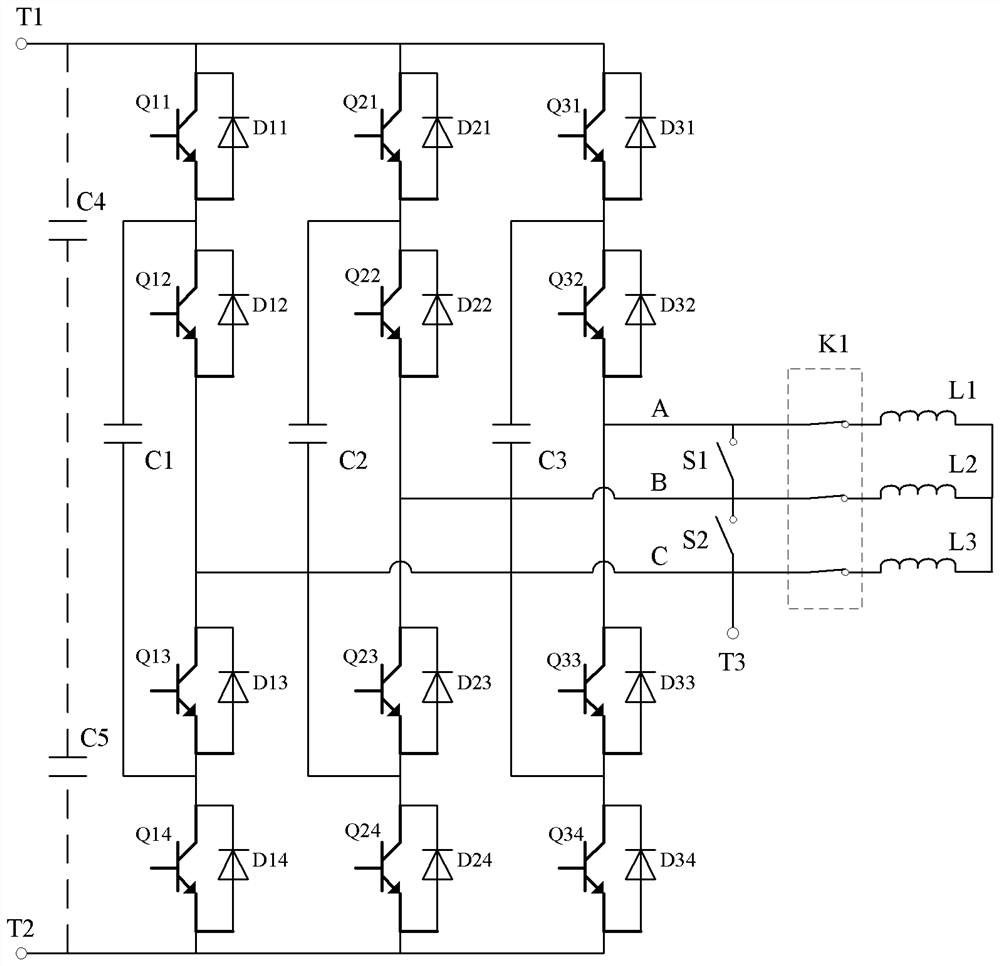

Image

Examples

Example Embodiment

[0015]Specific details are proposed in the following description to provide a thorough understanding of the present invention. However, those skilled in the art will clearly known that embodiments of the present invention can be implemented even without these specific details. In the present invention, specific digital references, such as "first components", "second device", and the like. However, specific digital references should not be understood as must be subject to its literal order, but should be understood as "first components" different from "second components".

[0016]The specific details presented in the present invention are merely exemplary, and the specific details can be varied, but still fall within the spirit and scope of the invention. The term "coupling" is defined as an interconnect connection to the assembly directly or indirectly connected to the component through another component.

[0017]A preferred embodiment of a method, system, and apparatus suitable for implemen

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap