Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

36 results about "Air cooling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Air cooling is a method of dissipating heat. It works by expanding the surface area or increasing the flow of air over the object to be cooled, or both. An example of the former is to add cooling fins to the surface of the object, either by making them integral or by attaching them tightly to the object's surface (to ensure efficient heat transfer). In the case of the latter, it is done by using a fan blowing air into or onto the object one wants to cool. The addition of fins to a heat sink increases its total surface area, resulting in greater cooling effectiveness.

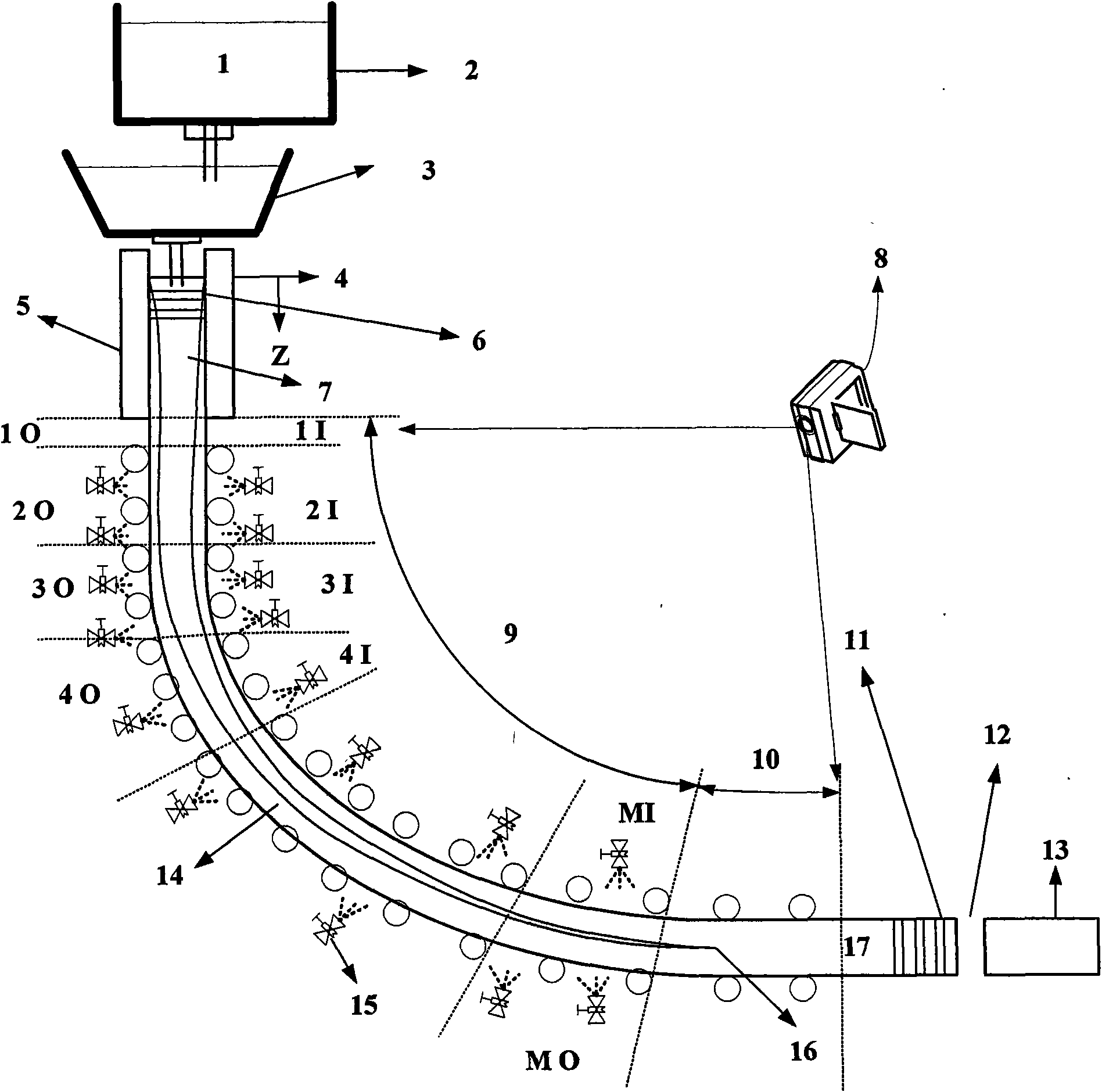

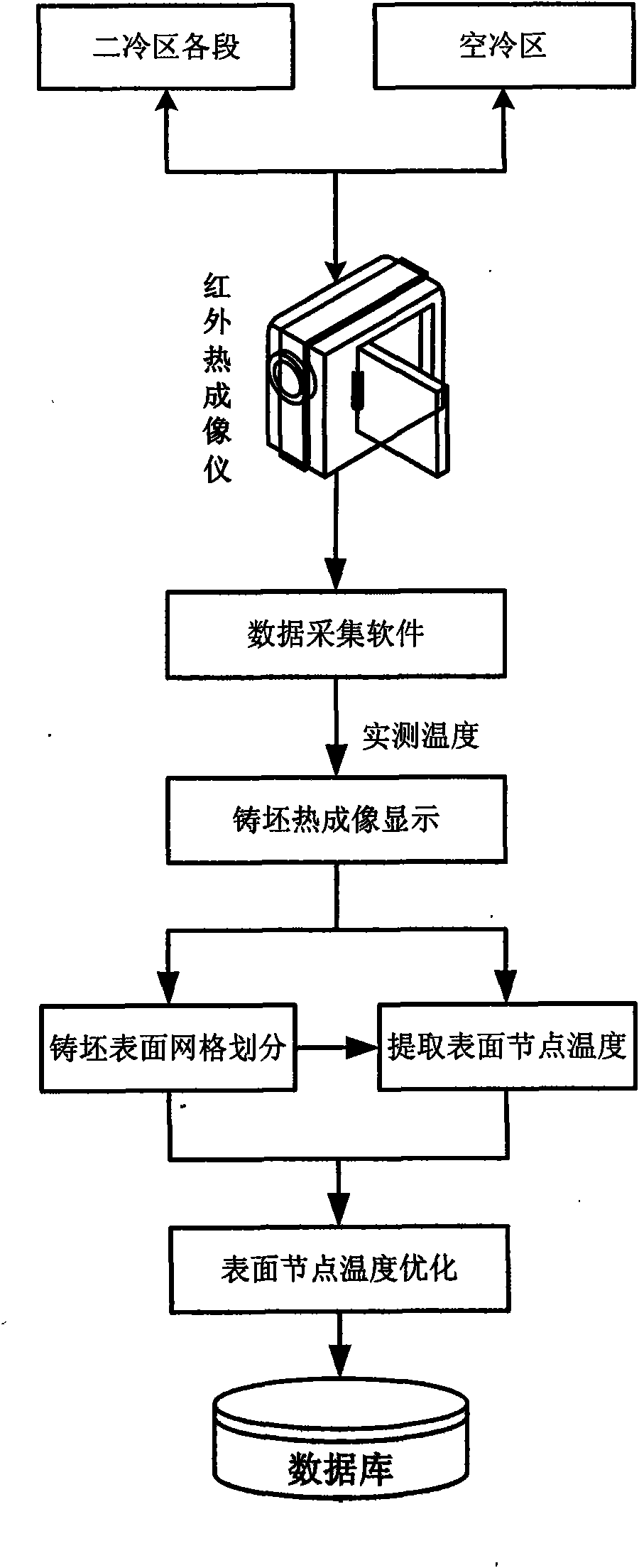

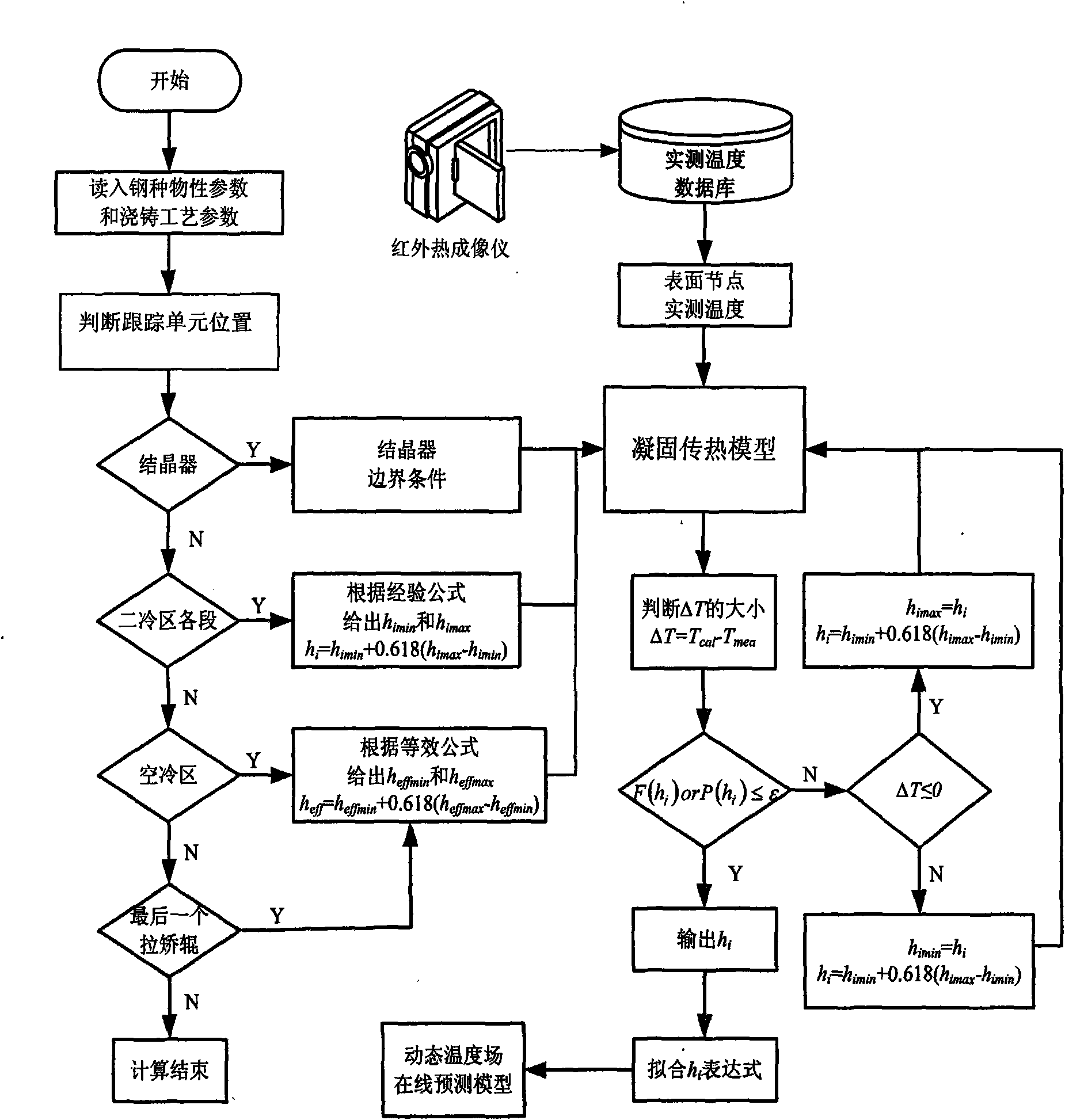

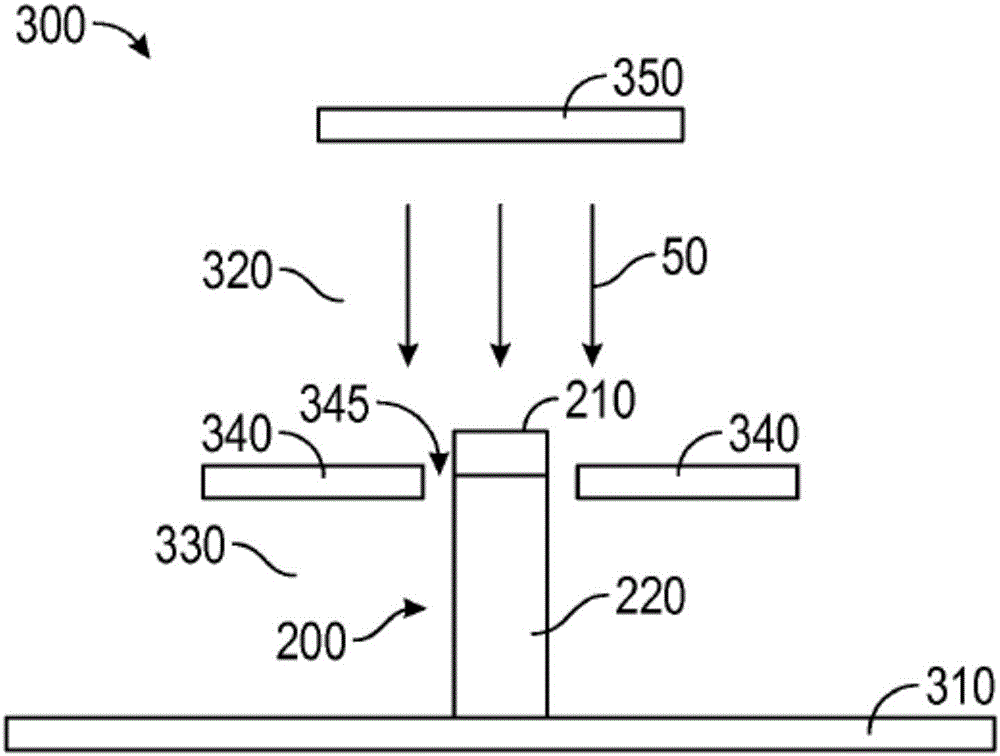

Online forecasting method of continuously cast bloom real-time temperature field based on infrared thermal imaging

Owner:NORTHEASTERN UNIV

Ionic nitriding heat treatment technique of 35CrMoV toothed sleeve or toothed ring for centrifugal compressor

ActiveCN106893822AHigh strengthHigh hardnessFurnace typesSolid state diffusion coatingHardnessUltimate tensile strength

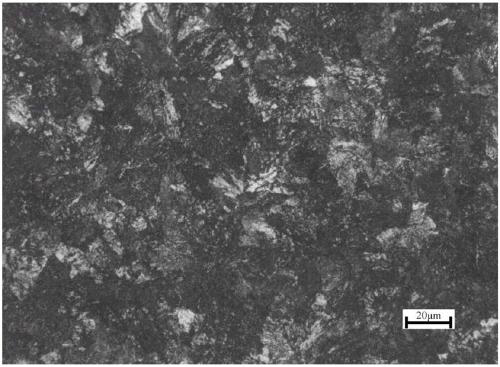

The invention discloses an ionic nitriding heat treatment technique of a 35CrMoV toothed sleeve or toothed ring for a centrifugal compressor and belongs to the technical field of heat treatment techniques. The ionic nitriding heat treatment technique comprises the following steps that (1) normalizing treatment is conducted, specifically, the normalizing temperature is 900 DEG C, the heat preservation time is (effective thickness / 40mm) hours, and then air cooling is conducted; (2) quenching treatment is conducted, specifically, the quenching temperature is 900 DEG C, the heat preservation time is (effective thickness / 40mm) hours, and then oil cooling is conducted; (3) tempering treatment is conducted, specifically, the tempering temperature is 600 DEG C, the heat preservation time with the unit being hour is 1.5 times the quenching heat preservation time, and then air cooling is conducted; and (4) ionic nitriding treatment is conducted, specifically, ionic nitriding is conducted at the temperature of 520 DEG C for 18.0-25.0 h, furnace cooling is conducted till the temperature is lowered to be 200 DEG C, and then a product is moved out of a furnace and subjected to air cooling. The contact-fatigue strength of a workpiece treated through ionic nitriding heat treatment can be greatly improved owing to the fact that the core strength and hardness are improved.

Owner:SHENYANG TURBO MASCH CORP

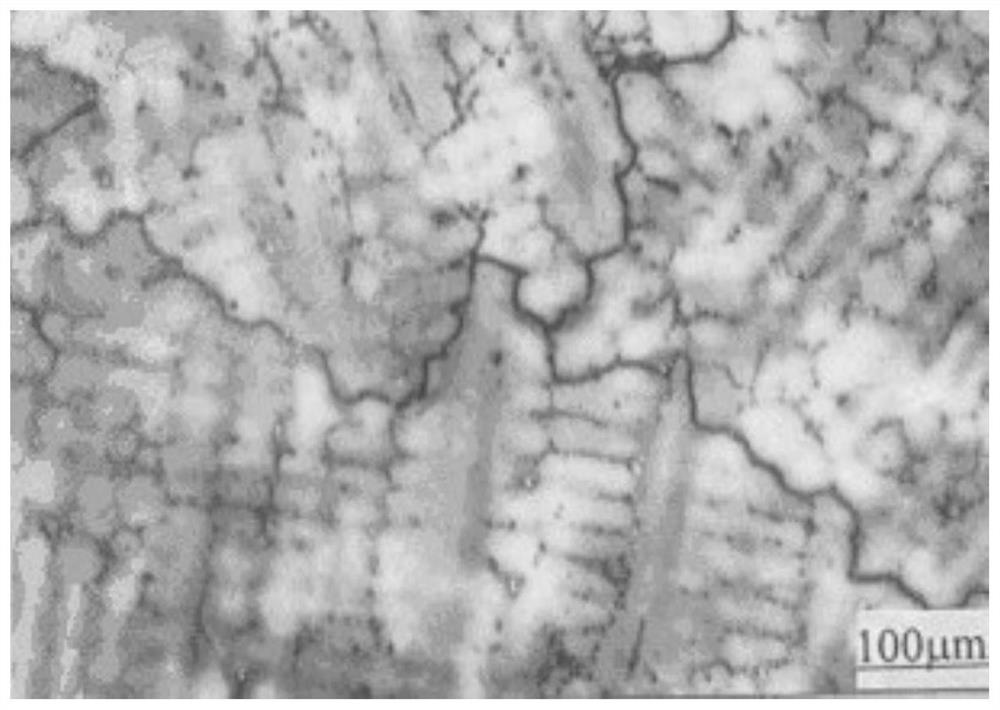

Novel high-chromium ferritic heat resistant steel and thermo-mechanical treatment process

InactiveCN102994888AImprove high temperature performanceIncrease service temperatureRoom temperatureThermal stability

Owner:TIANJIN UNIV

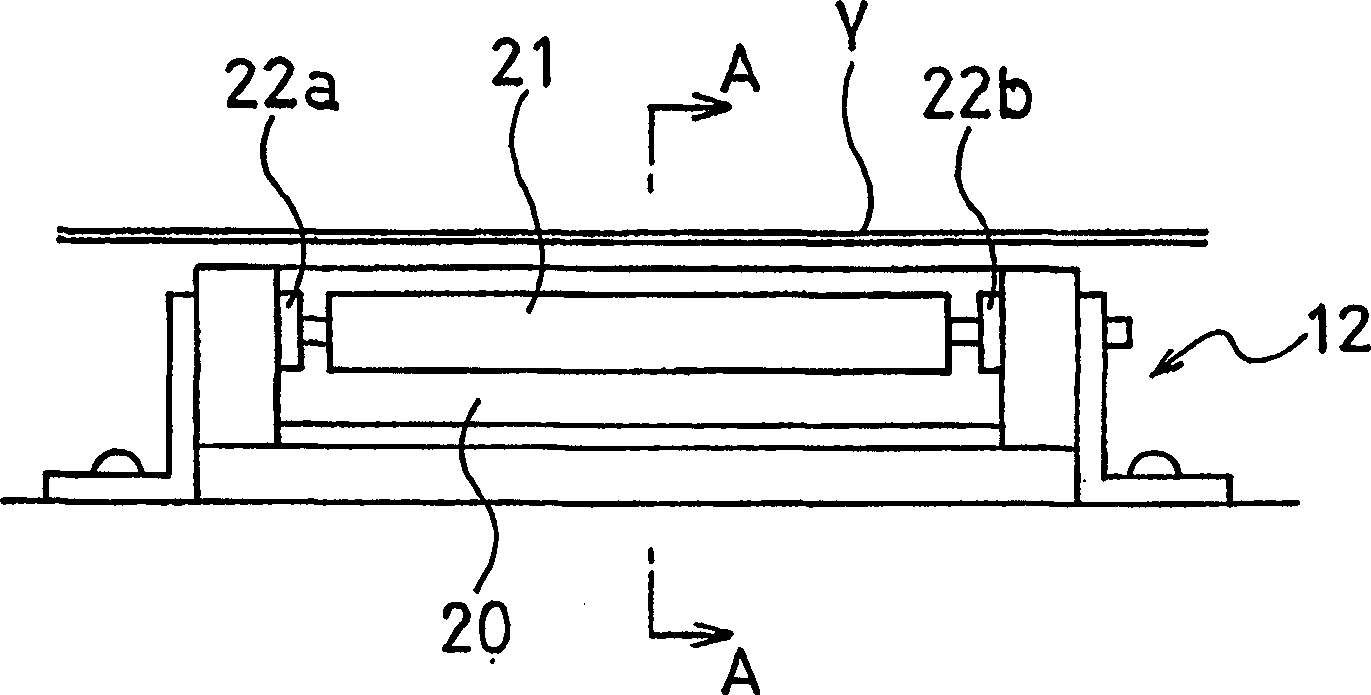

Polyester fiber and production method therefor

InactiveCN1392906AQuality improvementIncrease processing tensionFilament/thread formingArtificial filament heat treatmentPolyesterYarn

Owner:TORAY ENG CO LTD

Small-dimension British standard deformed steel bar B500B and manufacturing technology thereof

The invention discloses a small-dimension British standard deformed steel bar B500B and a manufacturing technology thereof. The chemical component requirements of the small-dimension British standard deformed steel bar B500B are: C: 0.19-0.22 wt%, Si: 0.20-0.60 wt%, Mn: 0.70-0.90 wt%, Cr: 0.5-0.8%, P, S: less than or equal to 0.035 wt%, Ni, Cu: less than or equal to 0.25 wt%, Mo, Al: less than or equal to 0.10 wt%, and N: less than or equal to 0.011 wt%; the balance is Fe; carbon equivalent Ceq is less than or equal to 0.50%. The technology comprises converter or electric furnace smelting, LF refining or argon blowing refining, CCM bloom or billet continuous casting, bar controlled rolling, and controlled cooling. The component design takes chromium to replace expensive vanadium for alloying, is matched with reasonable-design controlled rolling temperature and air cooling temperature, realizes production of the small-dimension British standard deformed steel bar B500B with qualified performance in low cost, and acquires favorable economical and social benefits.

Owner:NANJING IRON & STEEL CO LTD

Cord steel wire rod and decarburized layer control method thereof

Owner:ANGANG STEEL CO LTD

Noodles with blood glucose reducing efficacy and preparation method of noodles

InactiveCN107114679ALower postprandial blood sugarMeet the DiabeticsFood ingredient functionsCold airYeast Proteins

Owner:诺和生物技术(天津)有限公司

Heat dissipation measuring method for electromechanical equipment

Owner:DALIAN MARITIME UNIVERSITY

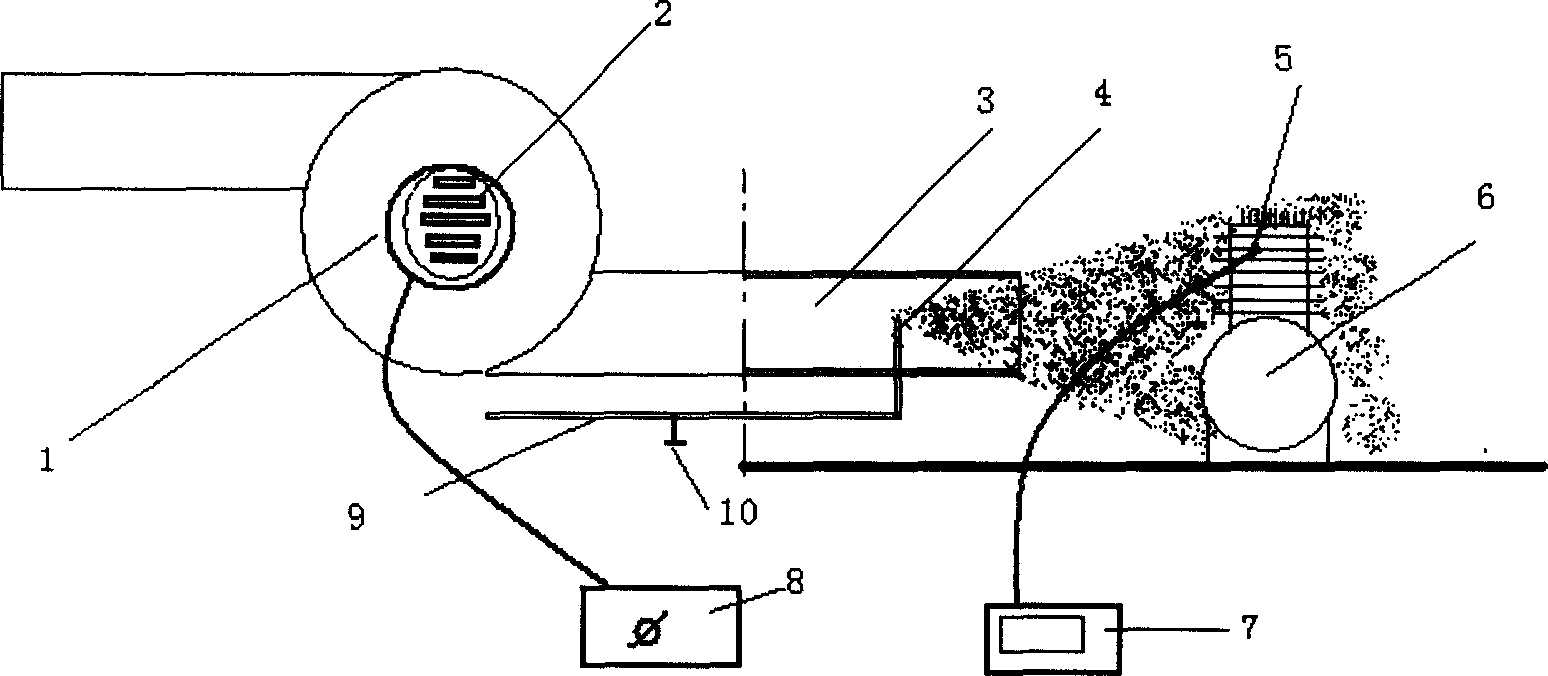

Low-noise air supply system for nois detecting of blower cooled engine

Owner:TIANJIN UNIV

Heat treatment process for powder part

InactiveCN102732699AReduce the temperature difference between inside and outsideReduce crackingIncreasing energy efficiencyTemperature differenceHeat treated

Owner:鑫光热处理工业(昆山)有限公司

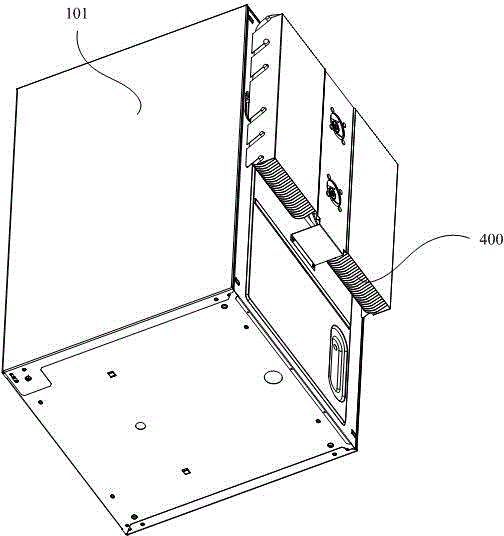

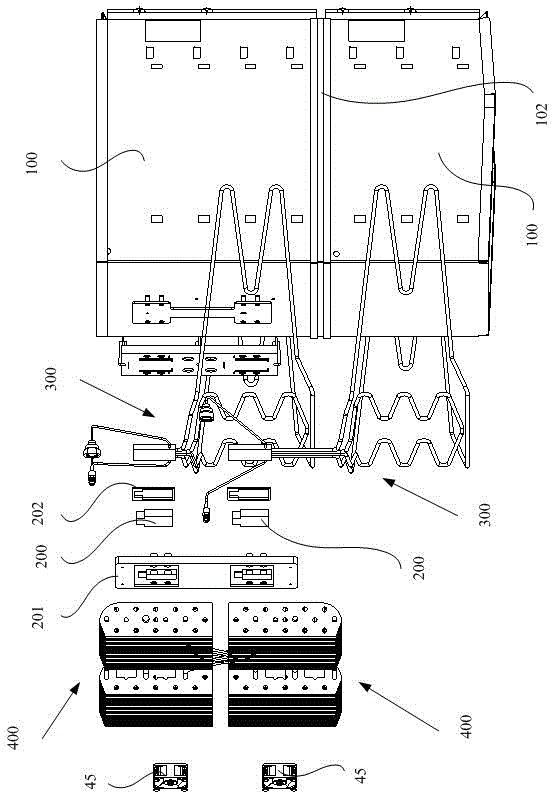

Diode rectification direct-current-based deicing device capable of deep pressure regulation

InactiveCN103280756ALow lossLow calorific valueOverhead installationAc-dc conversion without reversalHarmonicEngineering

Owner:STATE GRID CORP OF CHINA +2

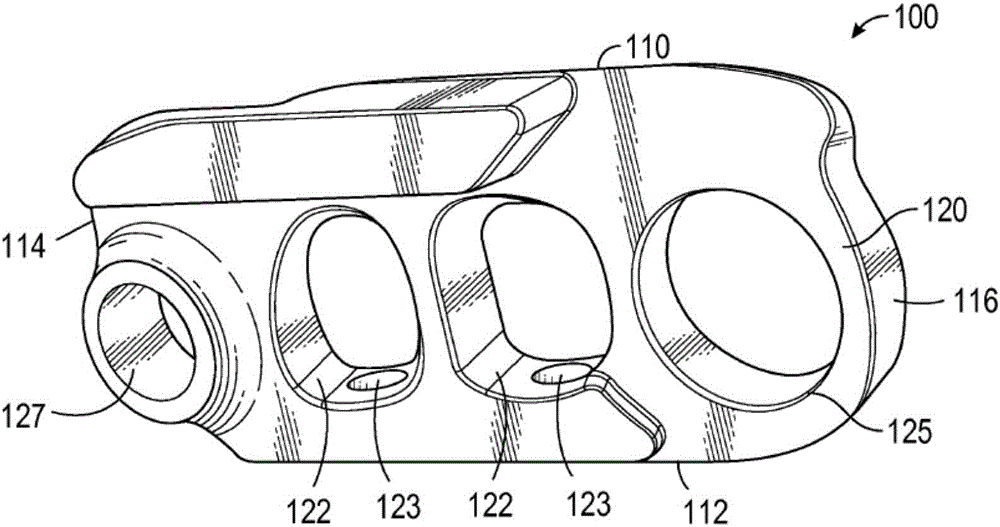

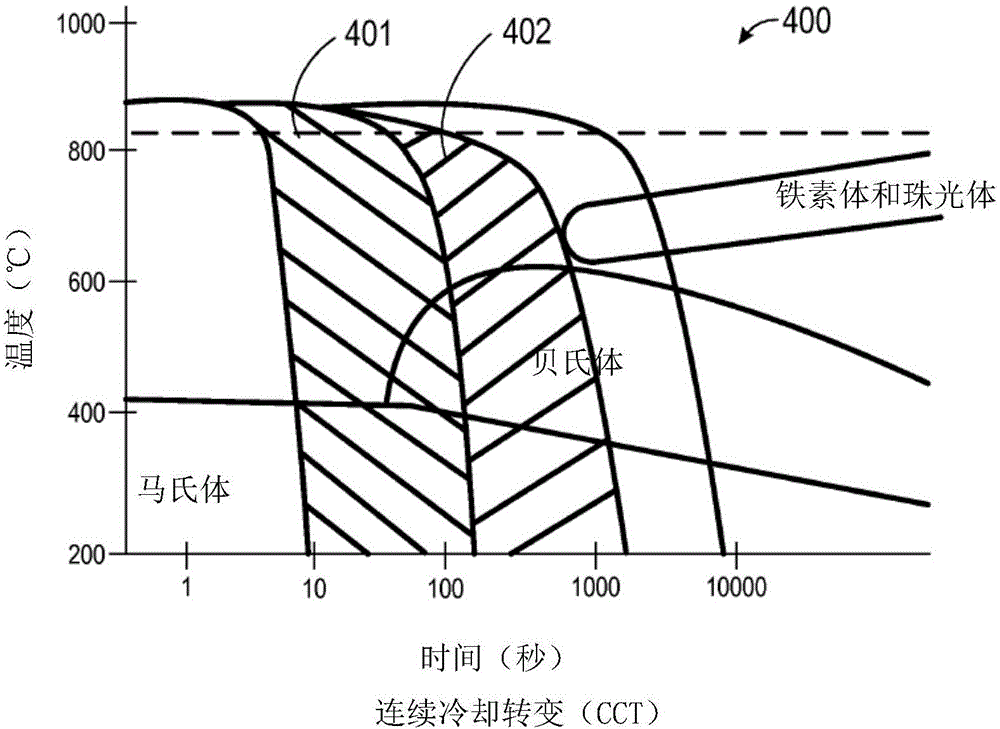

Air-hardenable bainitic steel part

Owner:CATERPILLAR INC

Heat treatment quenching technology for high-carbon chromium-molybdenum-vanadium powder hubbing steel precise parts

The invention discloses a heat treatment quenching technology for high-carbon chromium-molybdenum-vanadium powder hubbing steel precise parts. The technology comprises the following steps that 1, workpieces with the average thickness being 32 mm are put into a quenching furnace to be preheated twice to reach the temperature being 150 DEG C; 2, heating is conducted in the quenching furnace in two stages to reach the quenching temperature being 1,018 DEG C, and heat preservation is conducted; 3, the workpieces are subjected to discharge and air cooling till the temperature is 65 DEG C; 4, the workpieces are put into a tempering furnace twice, heat preservation and tempering are conducted at 510 DEG C, and discharge and air cooling are conducted. The workpieces with the average thickness being 32 mm are put into the quenching furnace to be preheated twice, for the first time, the temperature is raised to 100 DEG C at the heating speed smaller than 75 DEG C / hour, and for the second time, the temperature is raised to 150 DEG C at the heating speed smaller than 115 DEG C / hour. Accordingly, the excellent performances such as the extremely high abrasive wear resistance and high pressure resistance strength, good toughness and good size stability of heat treatment of the precise parts are reliably guaranteed, and the use requirements of the precise parts are met.

Owner:HUBEI ENG INST

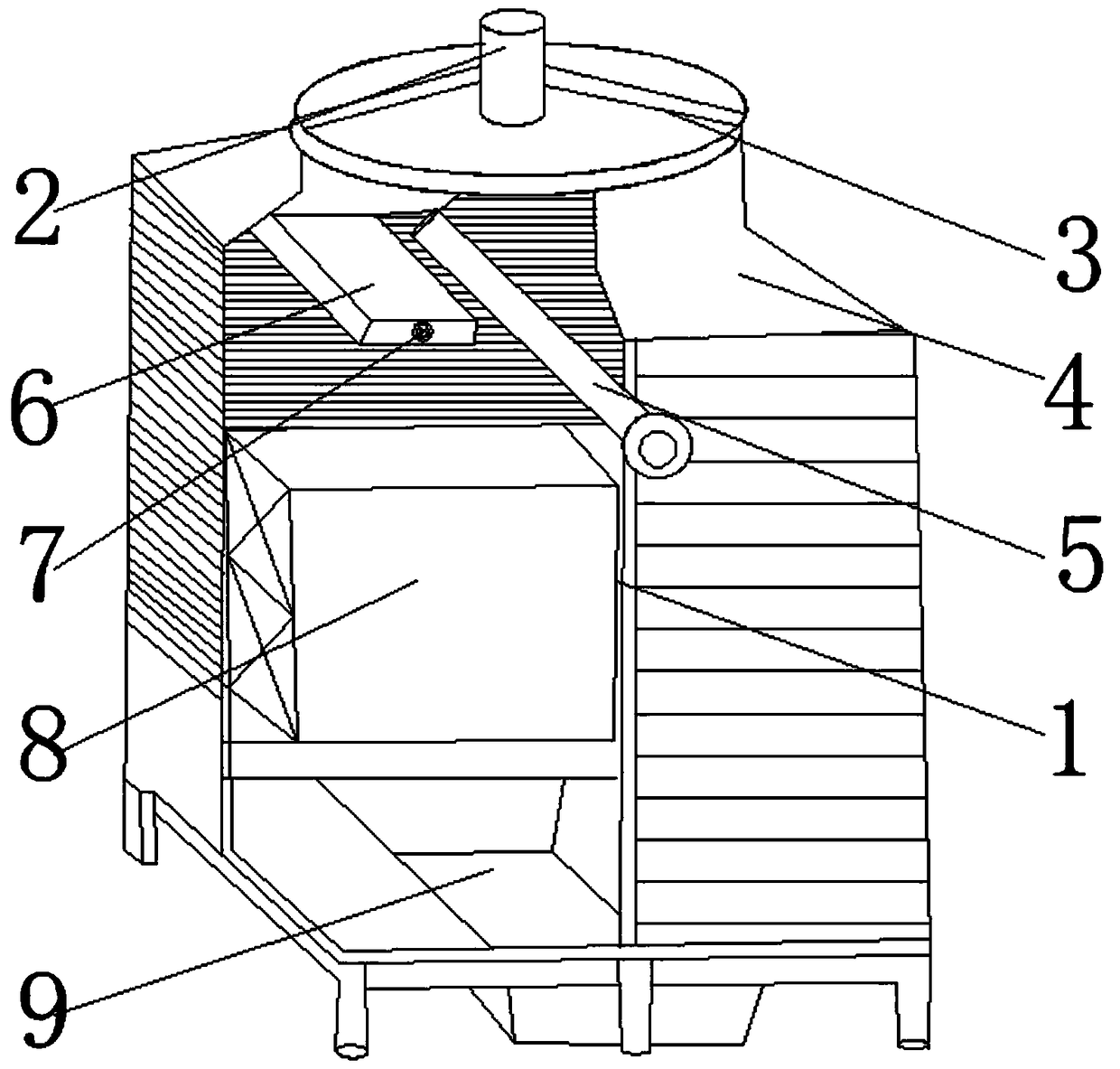

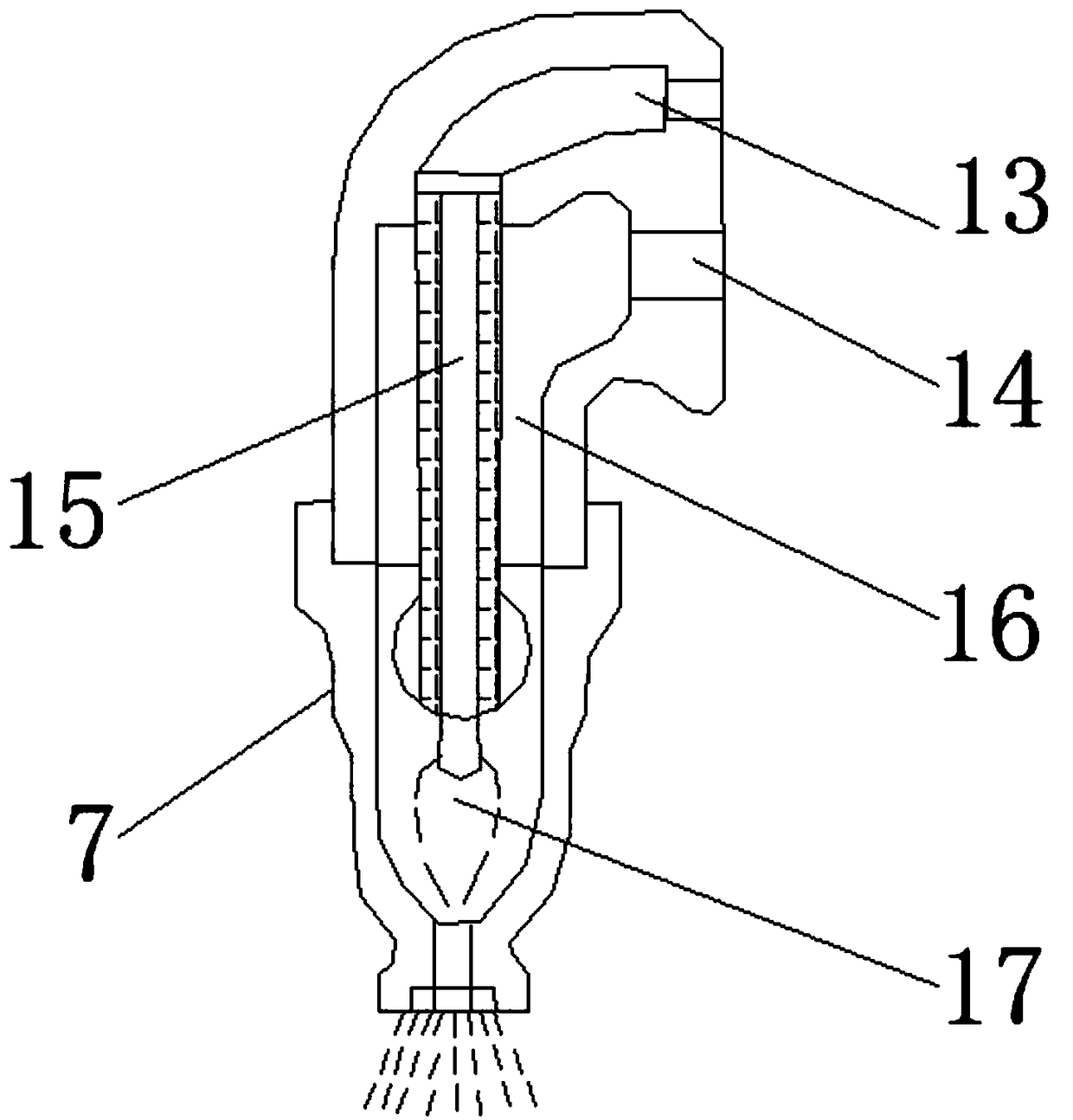

Mine automatic intelligent management and control system based on three-dimensional information technology

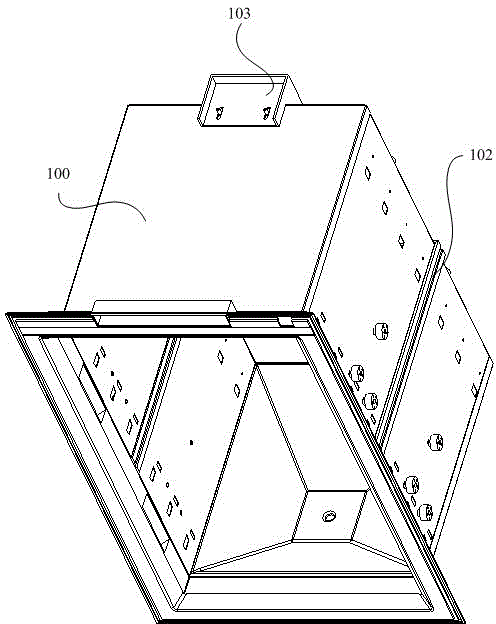

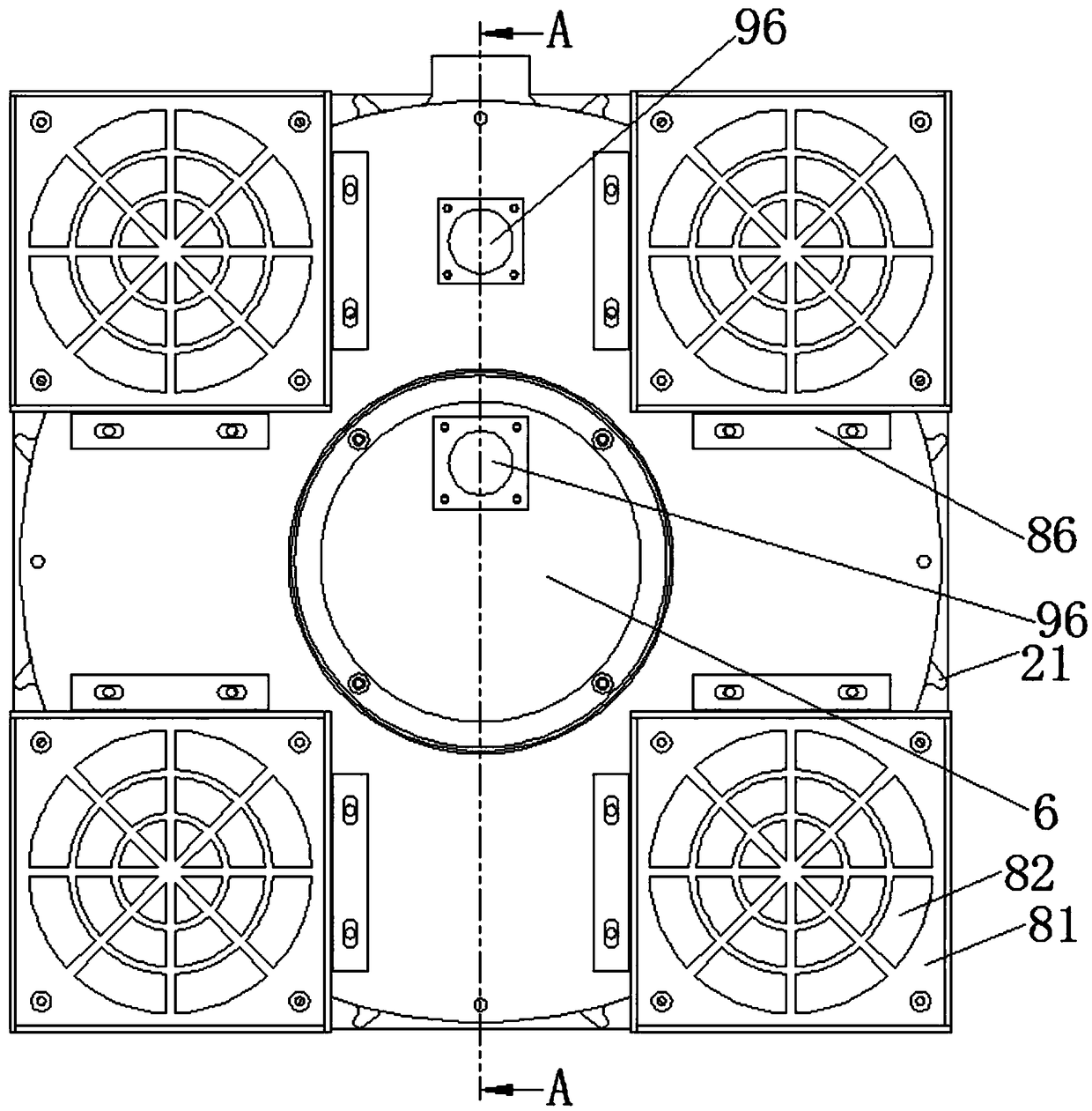

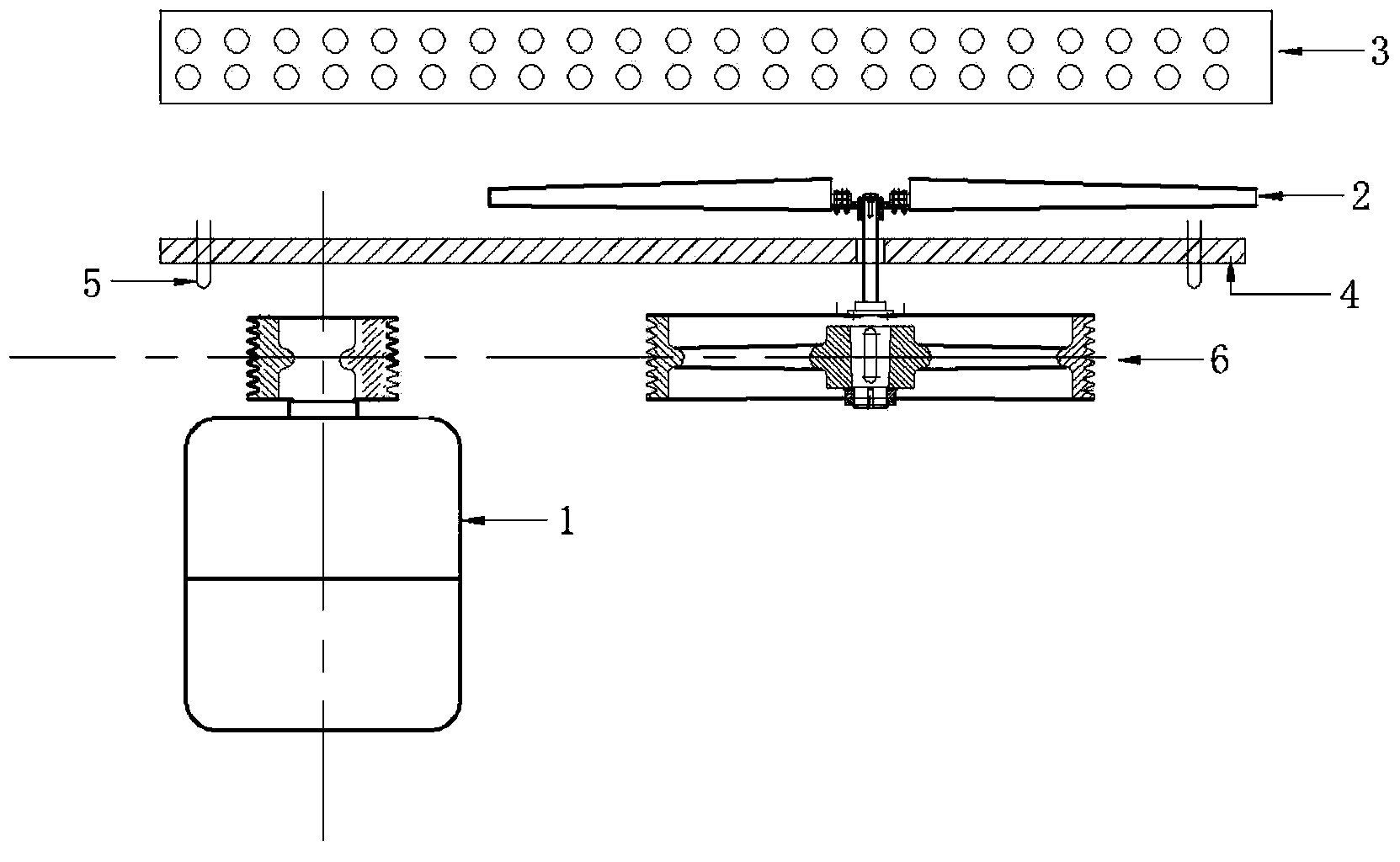

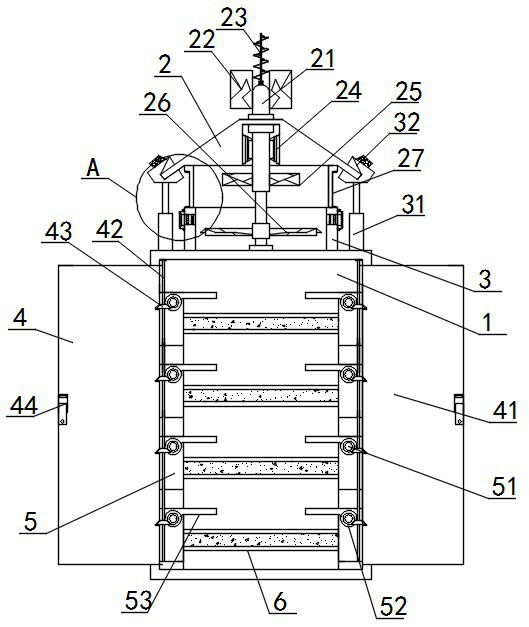

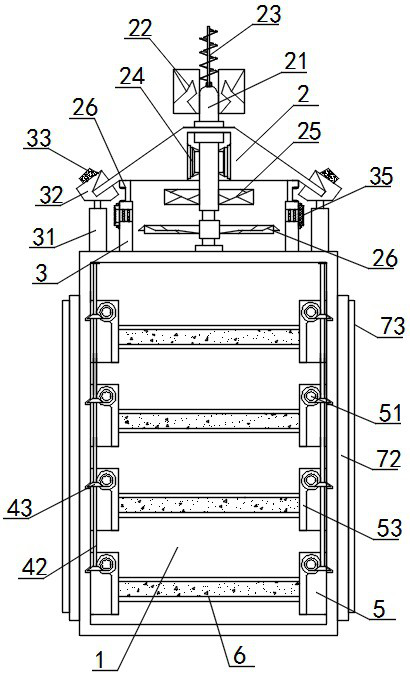

InactiveCN113645801AImprove cooling effectImprove uniformityTelevision system detailsMining devicesControl systemEngineering

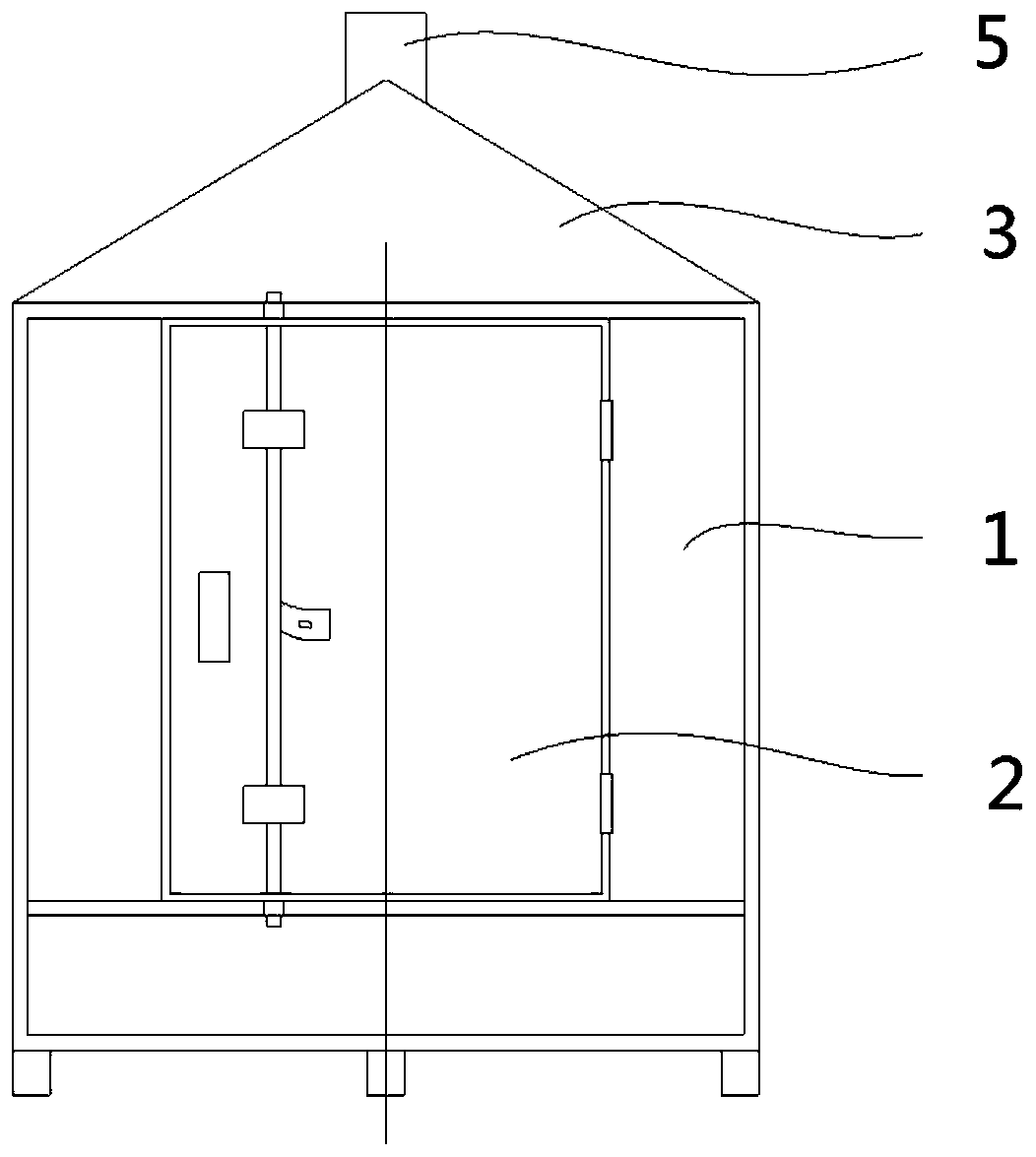

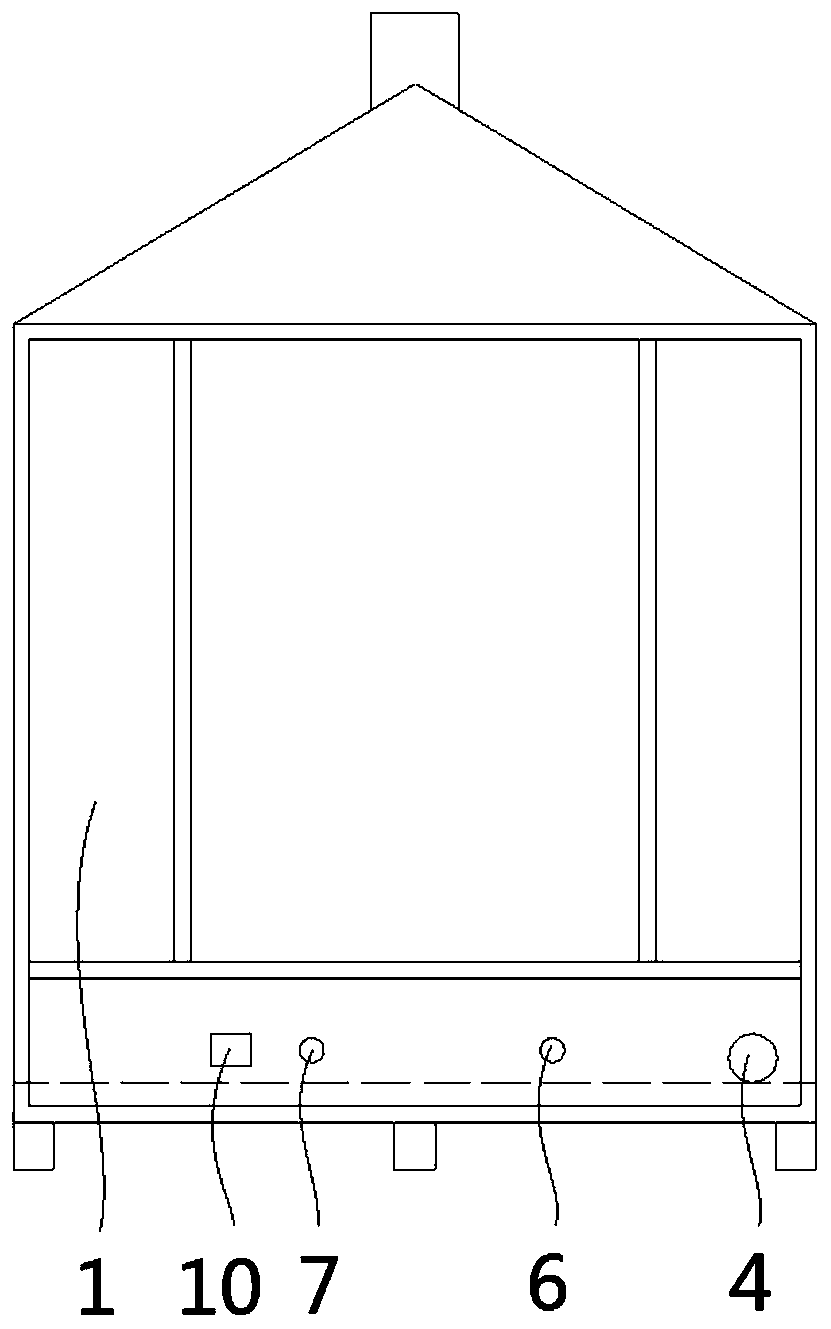

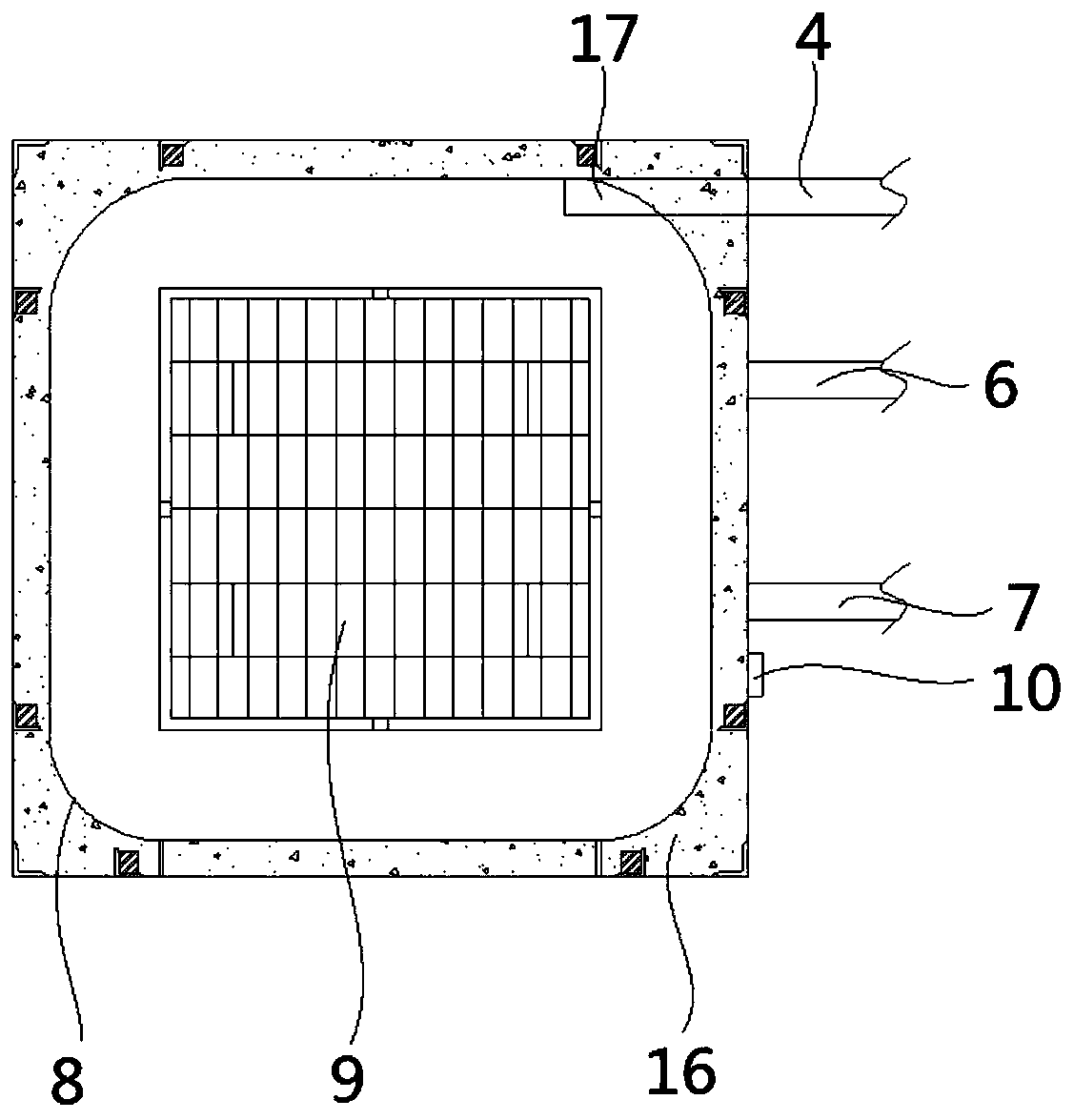

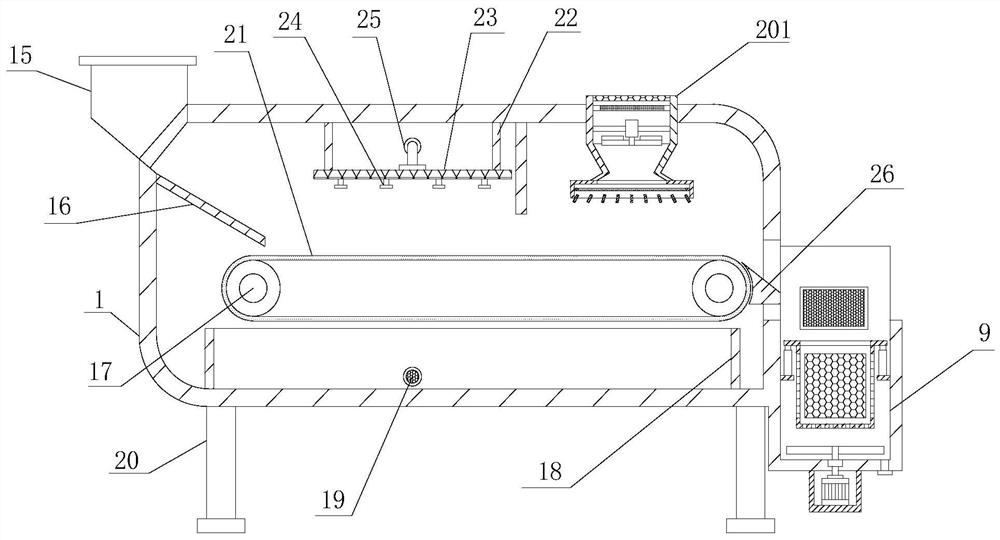

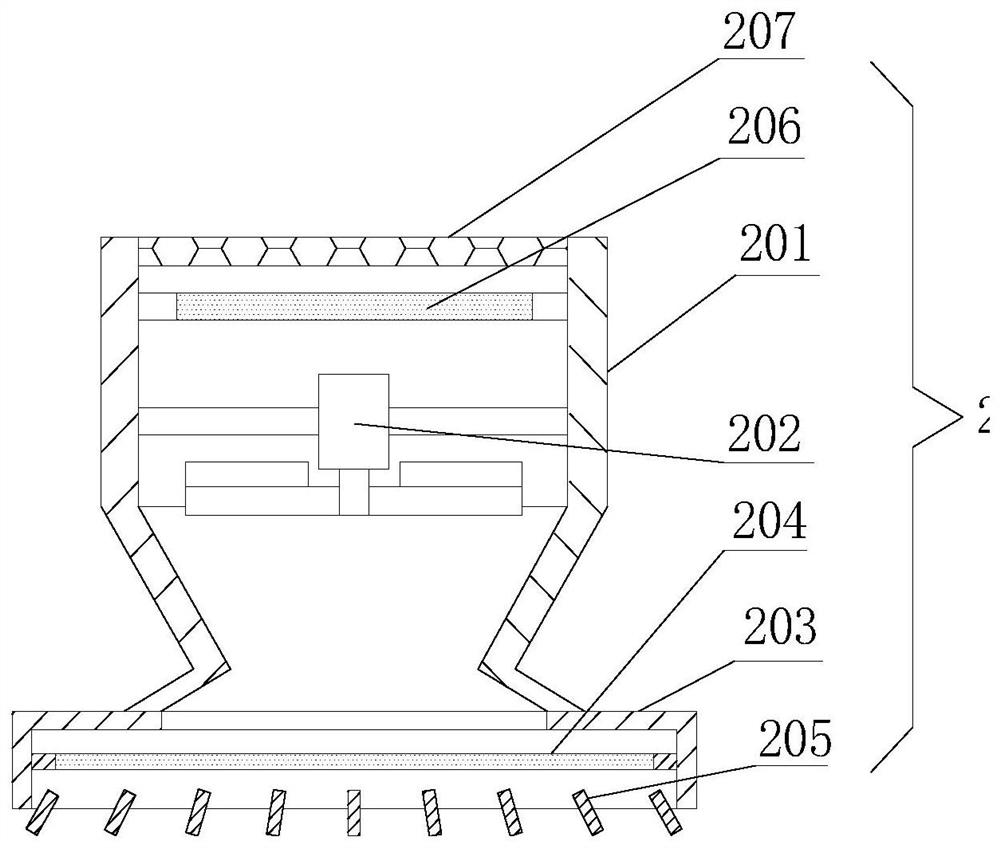

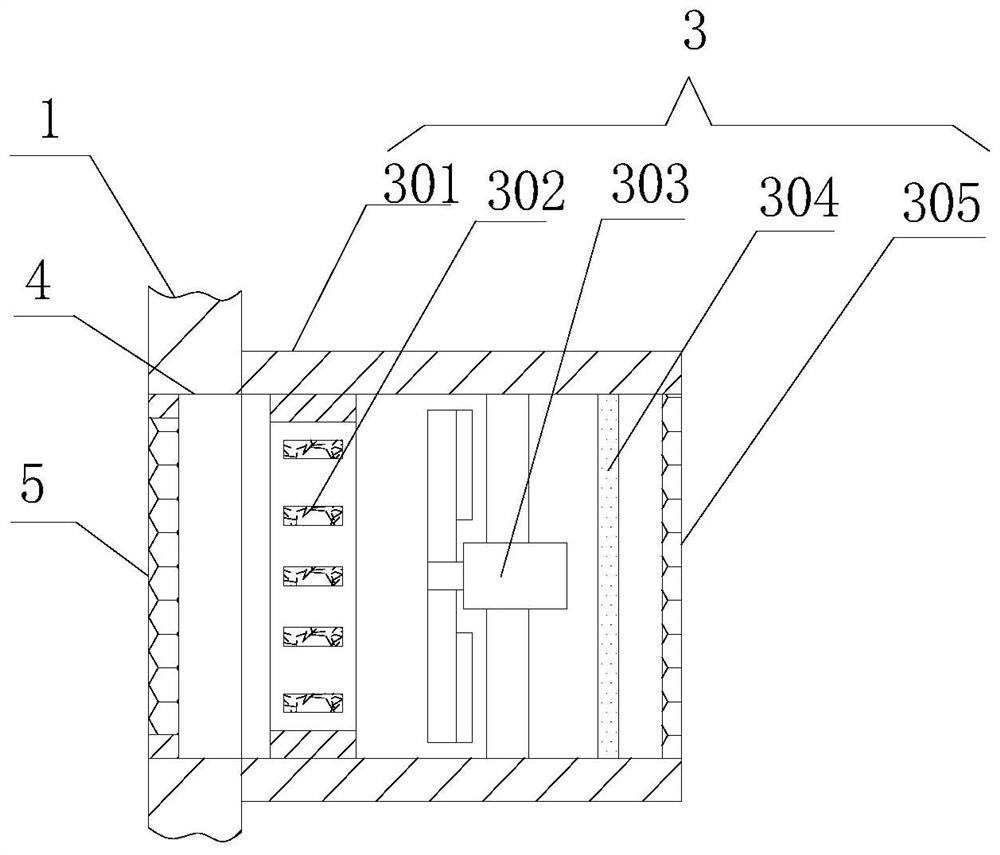

The invention discloses a mine automatic intelligent management and control system based on a three-dimensional information technology. The system comprises camera shooting equipment. The camera shooting equipment comprises an explosion-proof camera shooting instrument, a cooling fin, a water dripping device and an air cooling device; the air cooling device comprises a dustproof box body, a cleaning rod piece, a second driving structure arranged in the dustproof box body and used for controlling the cleaning rod piece to move in a reciprocating mode, and an air cooling structure arranged above the dustproof box body. The explosion-proof camera shooting instrument and the cooling fin are arranged, so that the monitoring effect is improved; the water dripping device and the air cooling structure are arranged, so that the heat dissipation effect of the cooling fin is improved; the second driving structure is arranged, so that the cleaning effect of the cleaning rod piece on dust on the cooling fin and the rotating stability of the cooling fin are improved; according to the invention, the heat of the explosion-proof camera shooting instrument can be better dissipated outwards, and the monitoring effect is improved, so that the real-time monitoring of the working conditions of other system equipment is improved through the monitoring accuracy, and efficient scheduling management work and decision command are carried out.

Owner:ZHEJIANG JIAOTOU MINING CO LTD

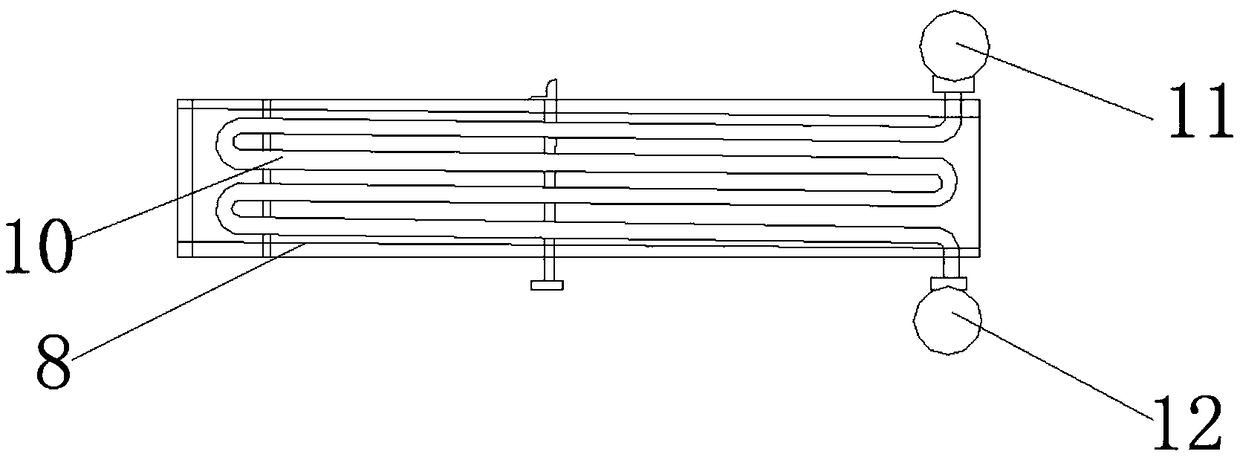

Cooling device and semiconductor refrigeration equipment

ActiveCN105716317AReduce energy consumptionMake full use of cooling capacityIndirect heat exchangersMachines using electric/magnetic effectsComputer moduleEngineering

Owner:QINGDAO HAIER SPECIAL ICEBOX

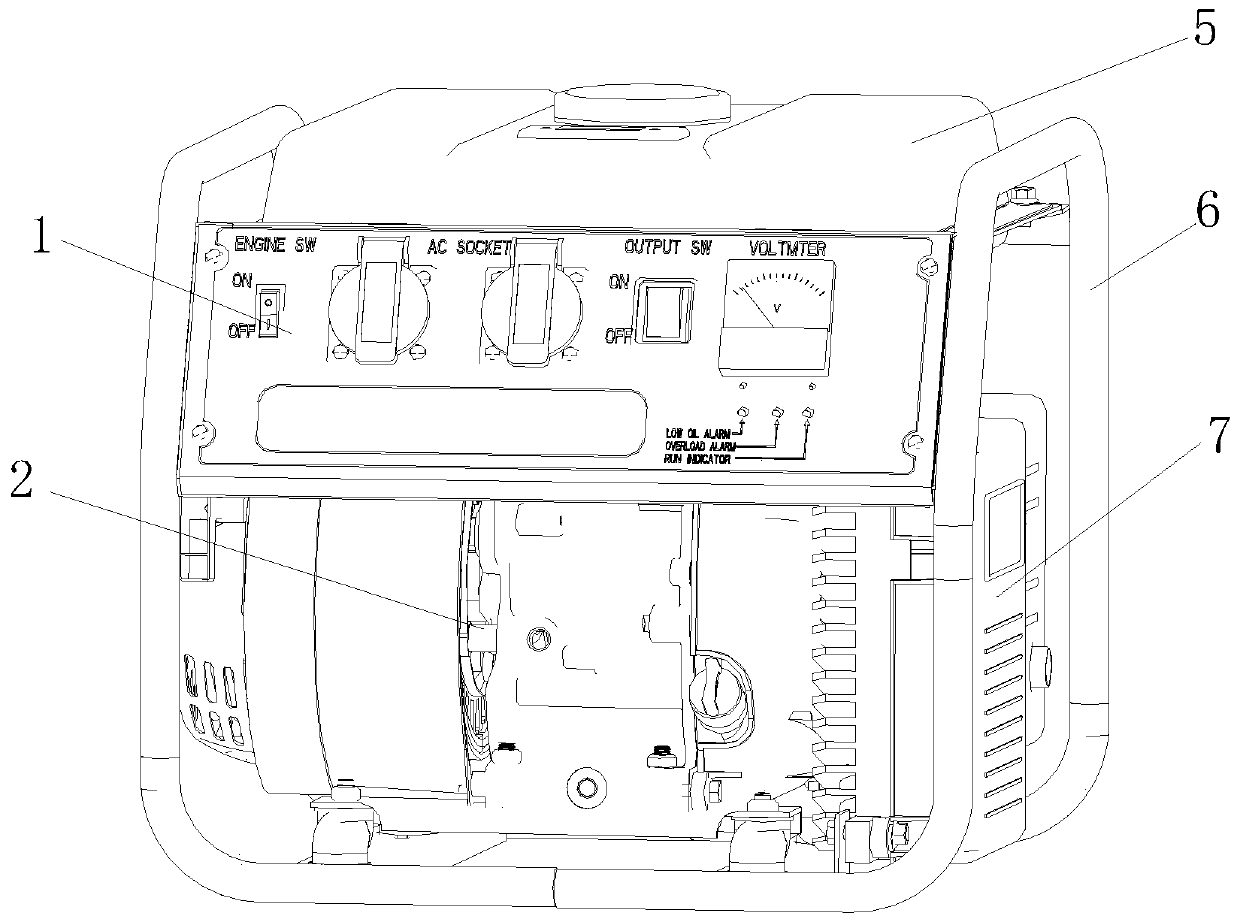

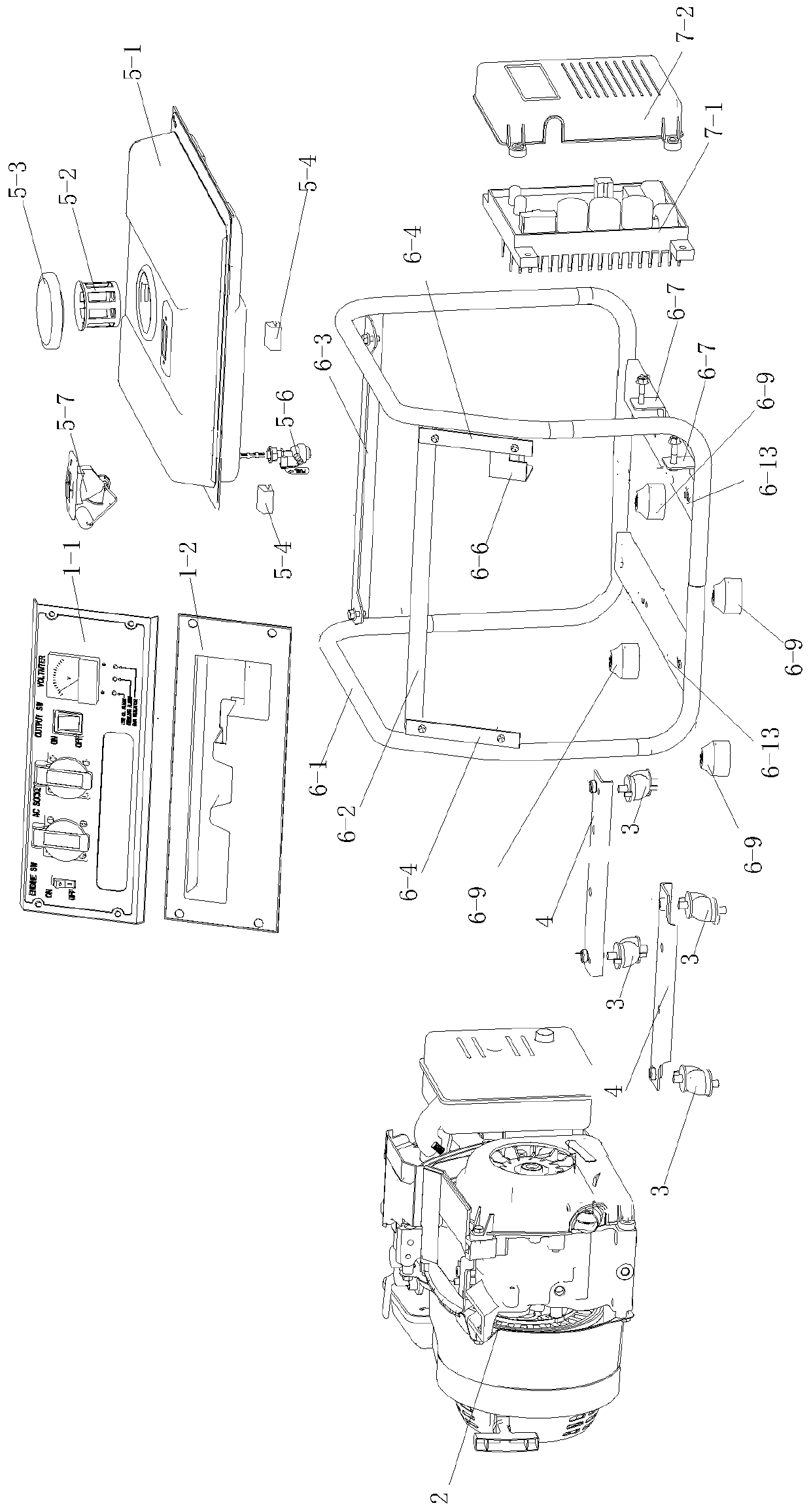

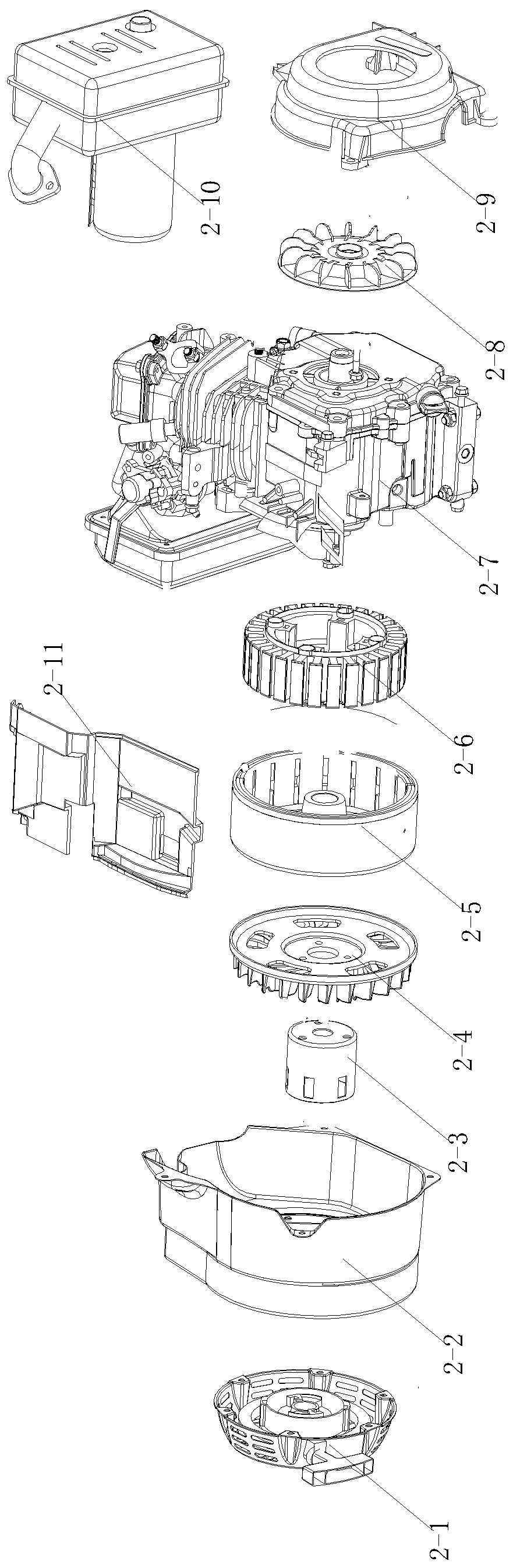

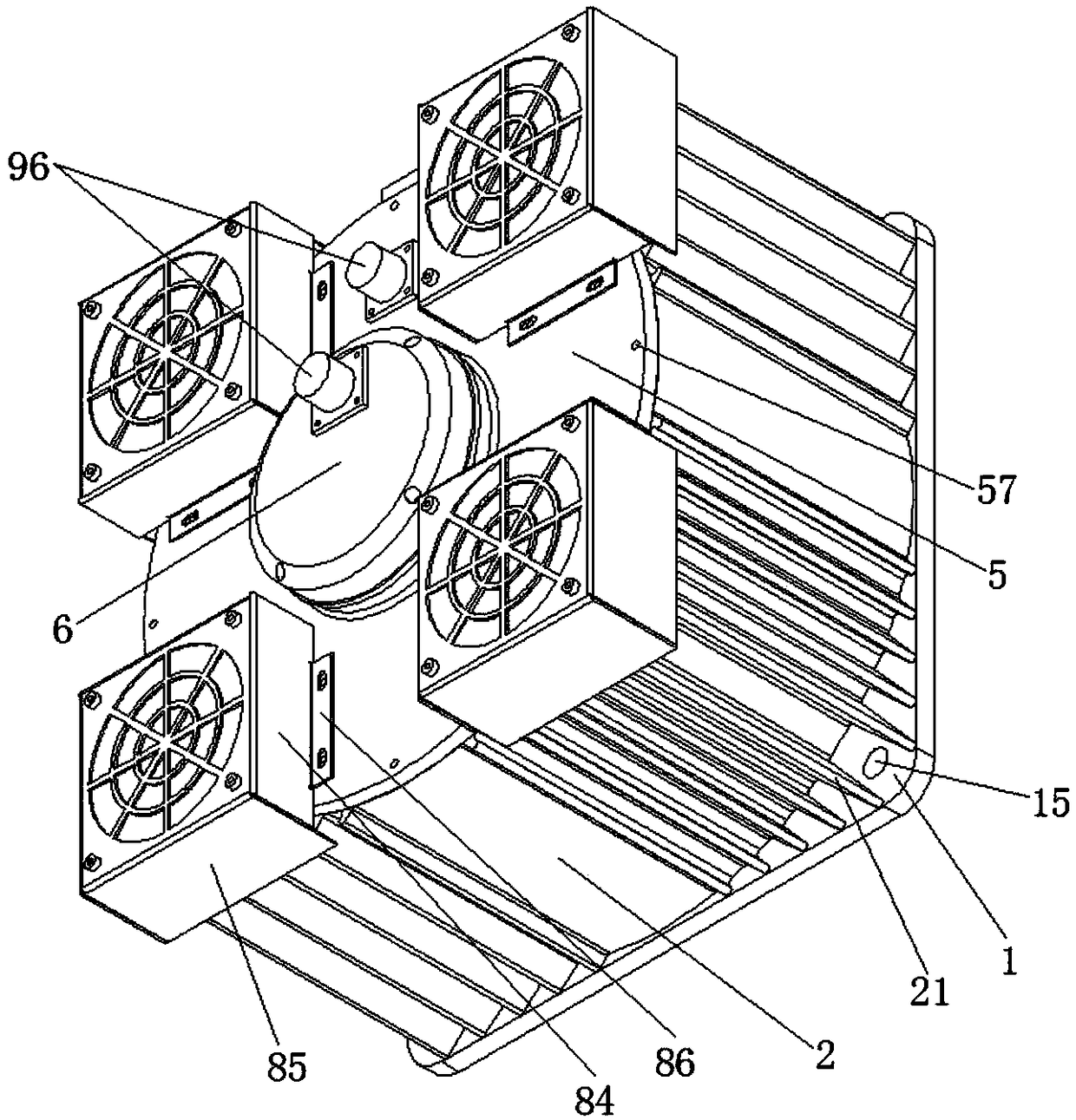

Frame-portable type variable frequency generator set

PendingCN111140346AReduce output noiseIncrease powerSpeed sensing governorsMachines/enginesFrequency changerFuel tank

Owner:宁德市犇田动力有限公司

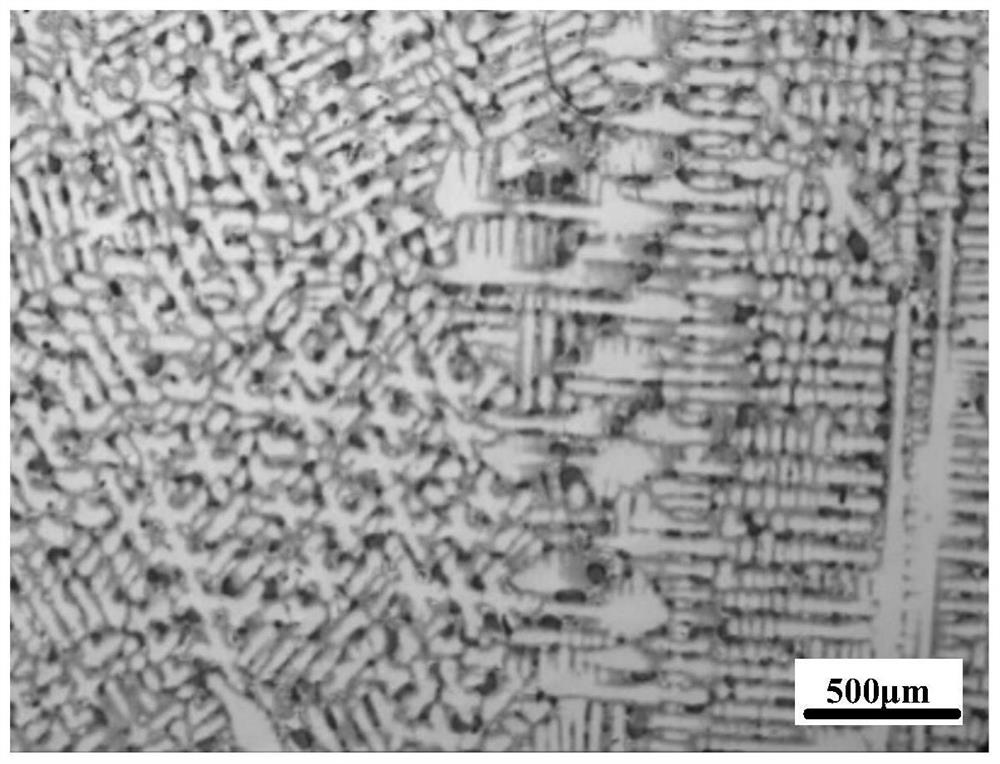

Chromium-free SWRH82B high-carbon steel wire rod and production method

InactiveCN114395723AIncreasing trendReduce critical cooling rateWire rodHigh pressure water

The invention discloses a chromium-free SWRH82B high-carbon steel wire rod and a production method. The wire rod comprises the following components: (0.80-0.84) wt% of C, (0.15-0.30) wt% of Si, (0.70-0.80) wt% of Mn, less than or equal to 0.015 wt% of P, less than or equal to 0.010 wt% of S, less than or equal to 0.10 wt% of Cr, less than or equal to 0.005 wt% of Al and the balance of Fe. The method comprises the following steps: (1) smelting raw materials by adopting a top-bottom combined blown converter, wherein chromium is not added during smelting; (2) refining by adopting an LF (Ladle Furnace) after smelting, wherein chromium is not added during refining; (3) carrying out continuous casting on a square billet with the size of (150mm * (150-180) mm after refining; (4) heating the steel billet after continuous casting; (5) after the steel billet is heated, high-pressure water is adopted for descaling; (6) carrying out high-speed wire rod rolling after descaling; and (7) carrying out controlled cooling by adopting a Stelmor air cooling line after rolling. According to the method, ferrochrome is not added into a converter and a refining furnace, steel billets are evenly heated, chemical component homogenization is promoted, the cooling speed before air cooling line phase change is increased to 10 DEG C / s or above from 7.5 DEG C / s, the sorbite proportion reaches 90% or above, steel billet element segregation is controlled, the martensite content and grade are reduced, and meanwhile it is guaranteed that the strength and area shrinkage of the wire rod meet the quality requirement.

Owner:HENAN JIYUAN IRON & STEEL (GRP) CO LTD

LED automobile instrument with heat dissipation effect

InactiveCN106891725AHas cooling effectImprove heat transfer efficiencyVehicle componentsCooling/ventilation/heating modificationsEngineeringAir cooling

The invention discloses an LED automobile meter with heat dissipation effect, which comprises an LED automobile meter body, the LED automobile meter body includes a left meter case and a right meter case, a cooling box is arranged at the bottom of the LED car meter body, the left meter body Both the shell and the right instrument shell include an inner shell and an outer shell. A heat exchange layer is arranged between the inner shell and the outer shell. On the inner side of the heat exchange layer are evenly distributed inner heat conducting strips. On the outer side of the heat exchange layer Evenly distributed outer heat conduction strips are arranged on the top, and spirally evenly distributed cooling pipes and cooling liquid storage pipes are arranged inside the outer casing. The LED automotive instrument with heat dissipation effect effectively improves the efficiency of heat transfer and the natural heat dissipation efficiency of the LED automotive instrument body. Through the mutual cooperation of water cooling and air cooling, the effect of heat dissipation can be better, and the heat dissipation can be improved. The efficiency can be higher, which provides a higher guarantee for the normal operation of the LED car instrument body.

Owner:魏建华

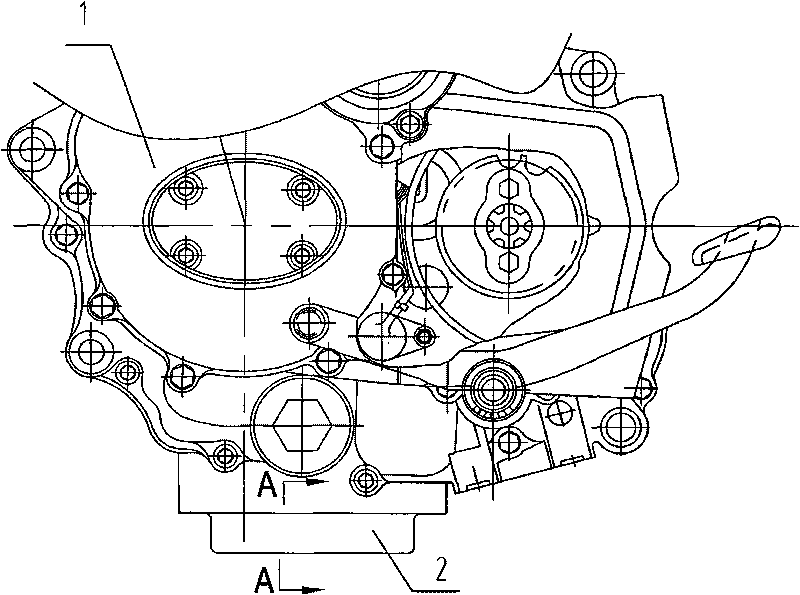

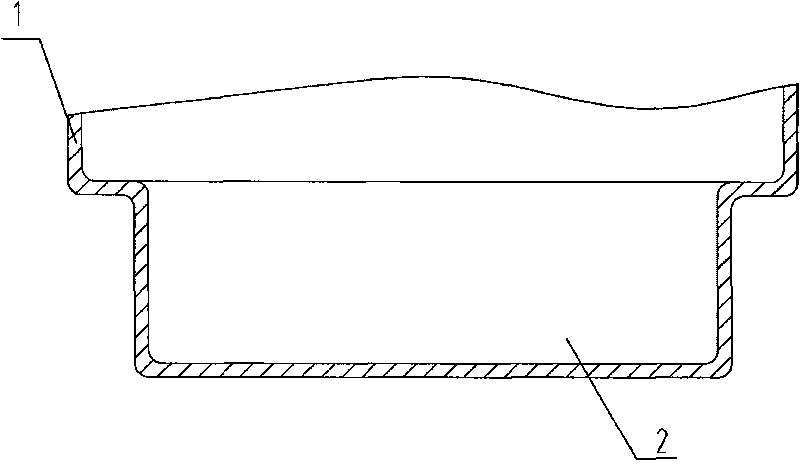

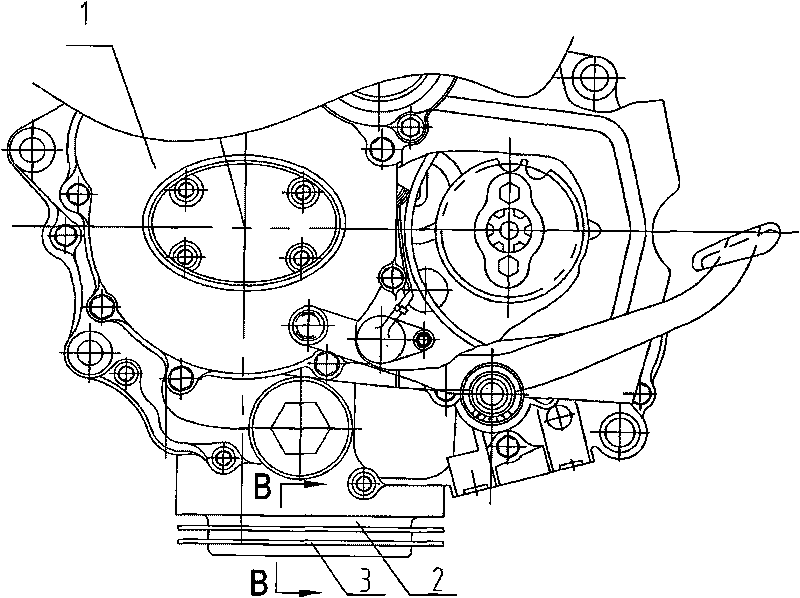

Oil storage air-cooled structure for motorcycle engine

InactiveCN101725387AWill not affect normal performanceImprove cooling effectMachines/enginesLubrication temperature controlInterior spaceCooling effect

Owner:CHONGQING LONCIN MOTOR

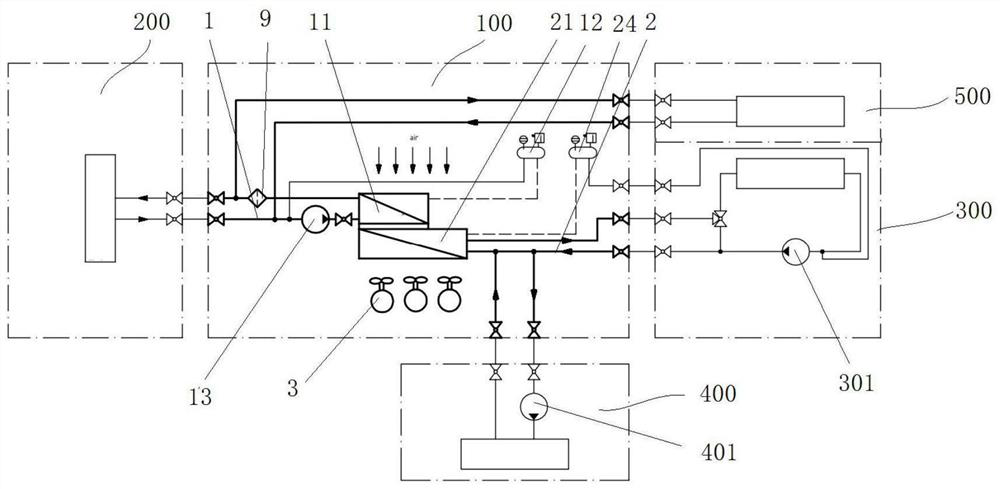

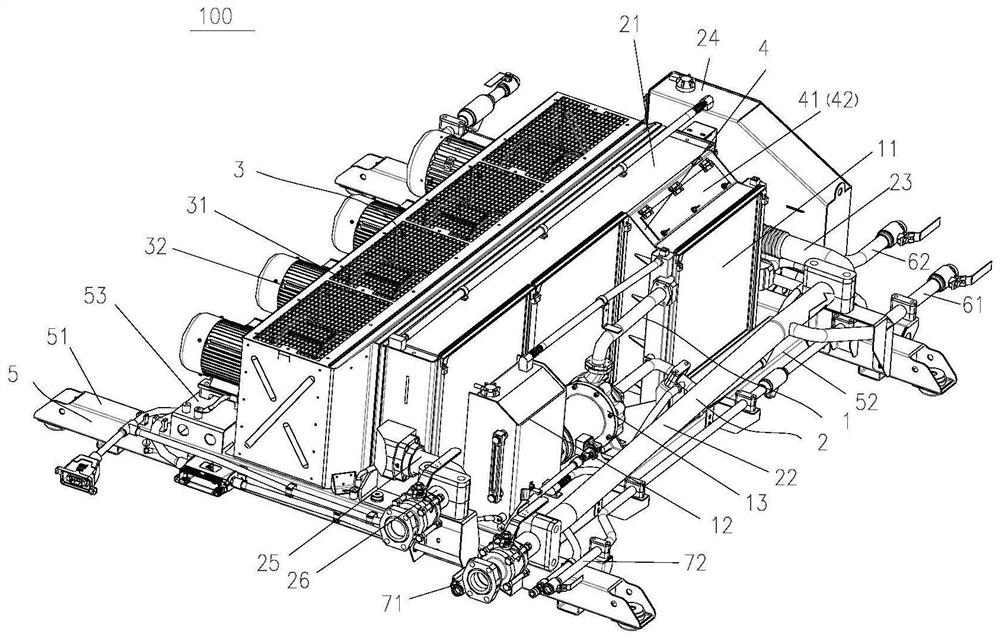

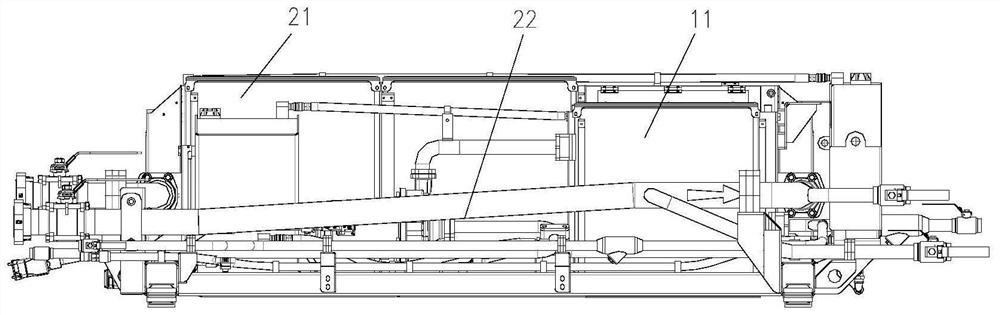

Cooling device

PendingCN113133266AImprove effective utilizationSmall form factorRailway vehiclesBattery/fuel cell control arrangementLow noiseFuel cells

Owner:HUNAN LIANCHENG TRACK EQUIP CO LTD

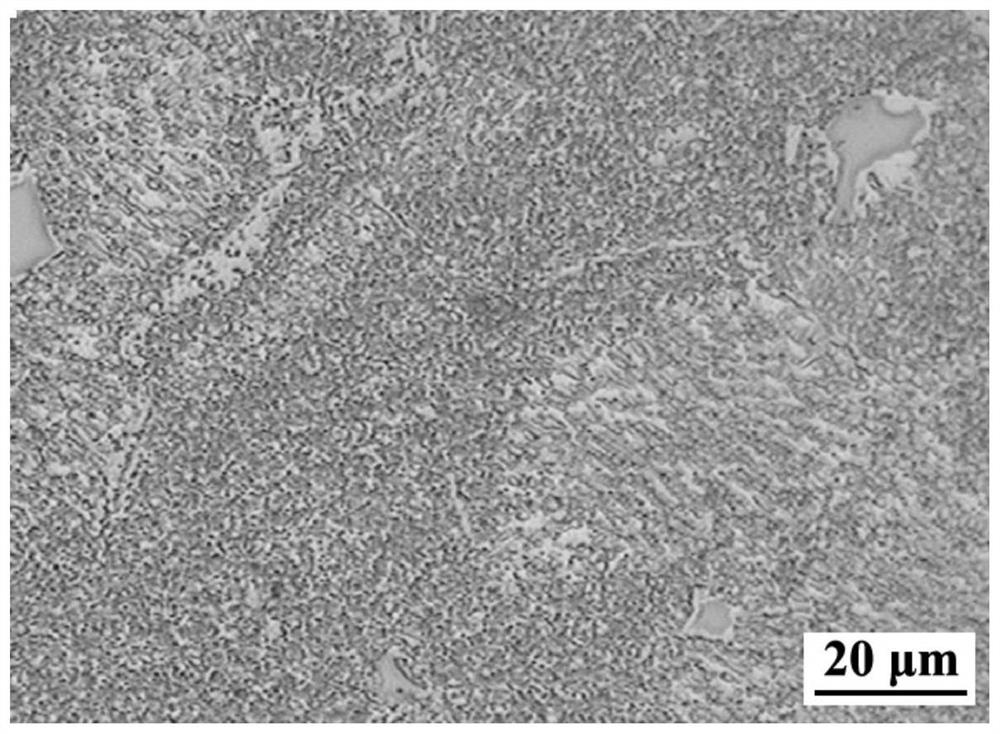

Sigma-phase precipitation control method for hot-corrosion-resistant nickel-based superalloy

ActiveCN114231767APlay a role in precipitation strengtheningAddresses long-term performance issues such as low durabilityHeat conservationSuperalloy

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Device for cooling heat release component and on textile machine

PendingCN109440275AImprove thermal conductivityIncrease the speed of diffusionAuxillary apparatusHydrogenCooling effect

Owner:安徽好莱克纺织科技有限公司

Permanent-magnet direct-driving motor for sawing machine

PendingCN108347133ACompact structureNovel structureMagnetic circuit rotating partsMagnetic circuit stationary partsCooling effectHeat sink

Owner:孙建林

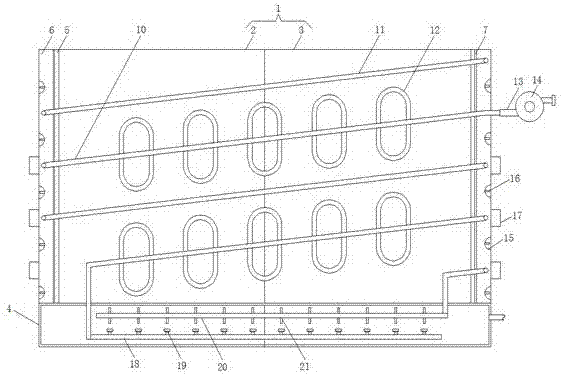

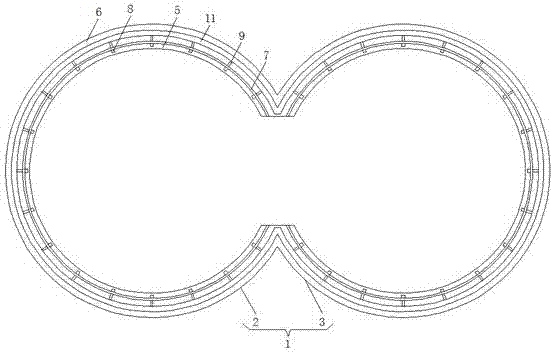

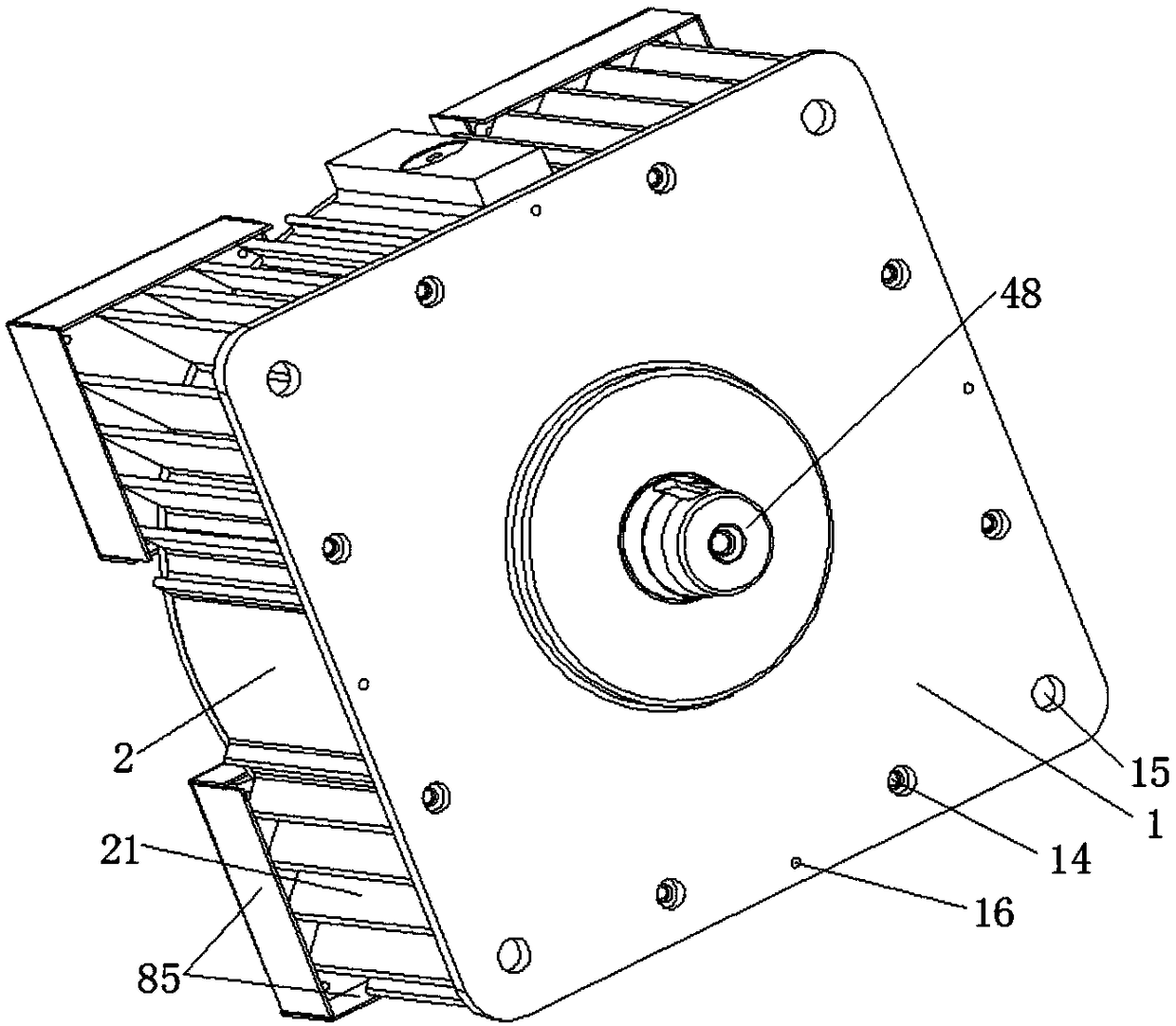

Interlayer type multi-functional bearing pedestal for Roots blower

InactiveCN102705239AImprove cooling effectRotary piston pumpsRotary piston liquid enginesWater channelEngineering

The invention discloses an interlayer type multi-functional bearing pedestal for a Roots blower, which comprises a bearing pedestal body; countersunk head plug holes, an air flow channel and two bearing holes are formed in the bearing pedestal body; the countersunk head plug holes consist of two flow channel upper countersunk head plug holes, two flow channel lower countersunk head plug holes, an upper countersunk head plug hole, a lower countersunk head plug hole, a left countersunk head plug hole and a right countersunk head plug hole; the upper countersunk head plug hole, the lower countersunk head plug hole, the left countersunk head plug hole and the right countersunk head plug hole are distributed on the edge of the air flow channel in sequence; the two flow channel upper countersunk head plug holes are distributed at the inner sides of the upper parts of the two bearing holes; and the two flow channel lower countersunk head plug holes are distributed at the outer sides of the lower parts of the two bearing holes. The interlayer type multi-functional bearing pedestal has the beneficial effect that after one-time processing, the different countersunk head plug holes are blocked by countersunk head plugs to realize different distribution of air cavities, air passages and water channels , so that the same Roots blower realizes the multiple applications of water cooling, air cooling, vacuum countercurrent cooling and the like according to the different requirements, and the heat radiation effect is better.

Owner:NANTONG RONGHENG ENVIRONMENTAL PROTECTION EQUIP CO LTD

Waterproof device for motor and air cooling fan impeller of blowing type horizontal air cooler

Owner:SHANDONG SHIDA SHENGHUA CHEM GROUP

High-protection-performance electric power cabinet capable of stably classifying internal circuits and used for electric power

InactiveCN113241614AImprove practicalityReduce failureBus-bar/wiring layoutsSubstation/switching arrangement cooling/ventilationActivated carbonControl theory

Owner:南京飞阳输变电工程有限公司

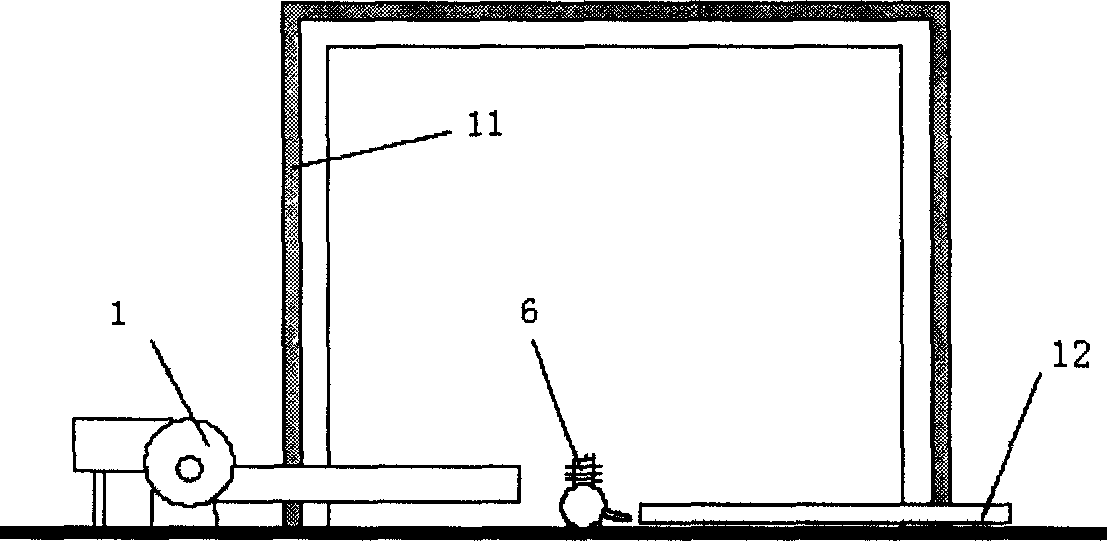

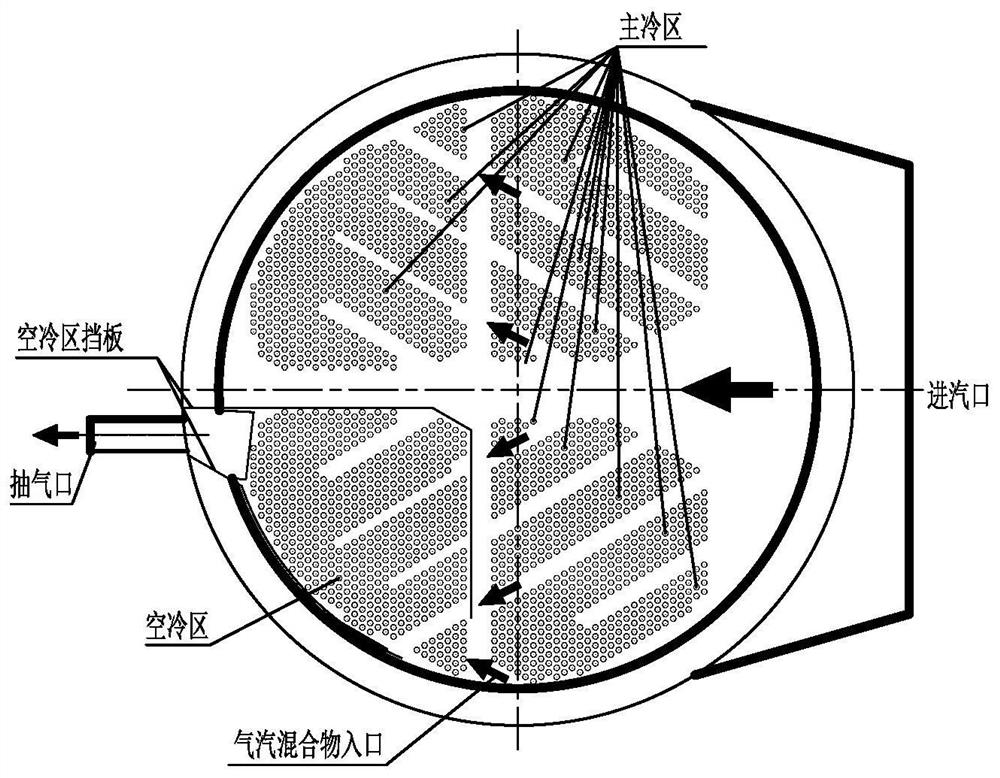

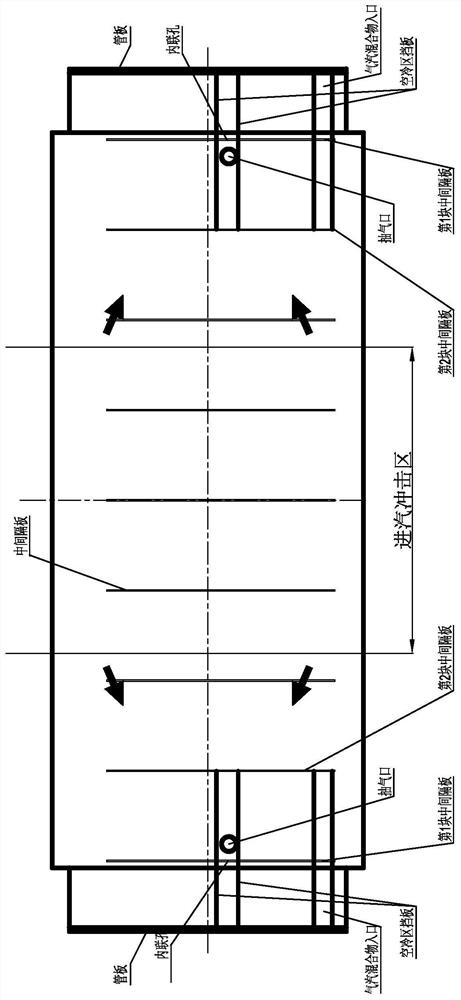

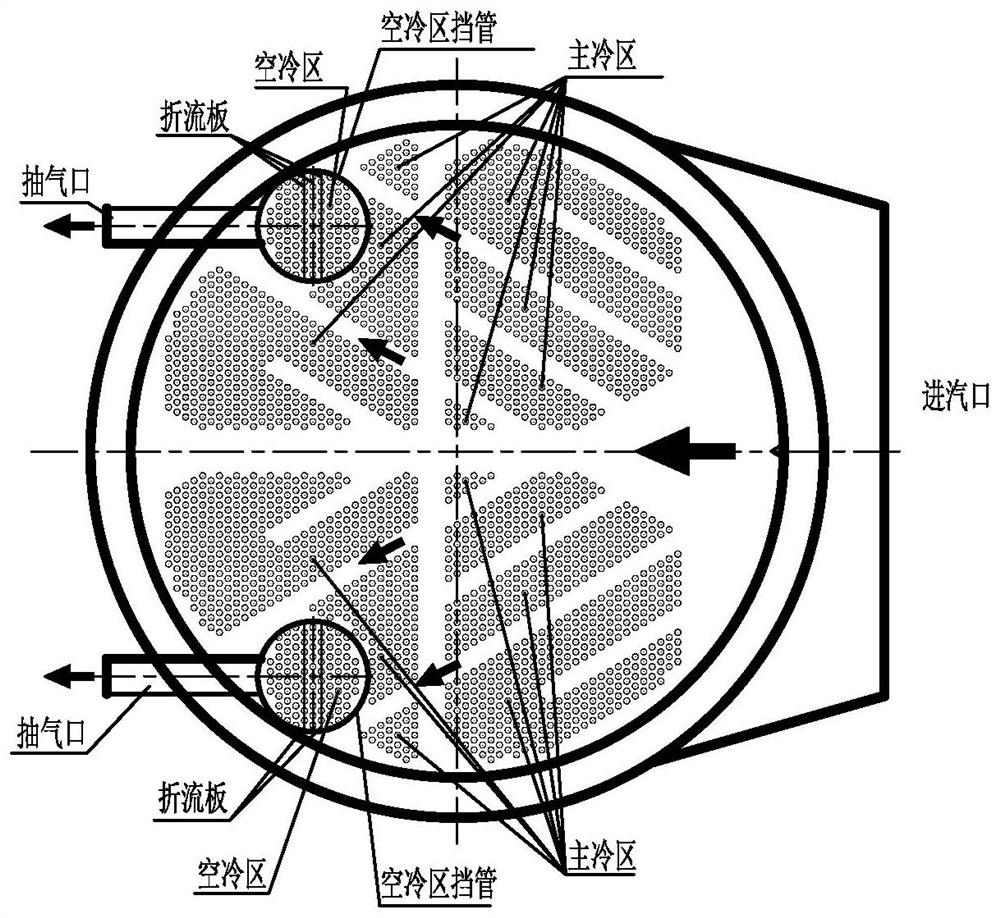

Air cooling area arrangement method of large-length-diameter-ratio lateral steam admission condenser

ActiveCN113686166AImprove heat transfer efficiencyReduce trafficSteam/vapor condensersMechanicsThermal efficiency

Owner:HANGZHOU GUONENG STEAM TURBINE ENGINEER

CPU radiating device for 1U server

InactiveCN107526419ADigital data processing detailsEnergy efficient computingEmbedded systemAir cooling

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

Efficient bleaching process of white cement clinkers

InactiveCN109206031AHigh whitenessIncrease the rate of temperature dropLiquid nitrogenCalcination

The invention discloses an efficient bleaching process of white cement clinkers. The efficient bleaching process of the white cement clinkers comprises the following steps of performing high-temperature firing on the white cement clinkers by a rotary kiln; discharging the white cement clinkers into a grate cooler from the discharging end of the rotary kiln for cooling; after the high-temperature cement clinkers enter the grate cooler, falling the high-temperature cement clinkers onto a first grate bed for cooling; performing sharp cooling on the cement clinkers in the first grate bed through providing mixed liquid nitrogen and air; cooling the cement clinkers to 600 to 800 DEG C; then, falling the cement clinkers onto a second grate bed to be cooled; performing air cooling in the second grate bed completely through the air; cooling the cement clinkers to 80 to 100 DEG C; discharging the cement clinkers out of the grate cooler. The invention aims at providing the efficient bleaching process of the white cement clinkers so as to solve the problems of whiteness improvement limitation and more heat consumption requirement during white cement clinker calcination.

Owner:JIANGXI YINSHAN WHITE CEMENT CO LTD

Environment-friendly and energy-saving cooling device for refractory material production

InactiveCN112460882AReduce surface temperatureAvoid crackingDomestic cooling apparatusLighting and heating apparatusWater storageWater storage tank

Owner:浙江德清炜烨新材料股份有限公司

Popular searches

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap