Online forecasting method of continuously cast bloom real-time temperature field based on infrared thermal imaging

A technology of infrared thermal imaging and infrared thermal imager, which is applied in the direction of casting equipment, indicating equipment/measuring equipment configuration, manufacturing tools, etc., can solve the problem of inability to guarantee spatial continuity, low accuracy of temperature measurement data, and inability to truly reflect Issues such as the internal temperature of the slab

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

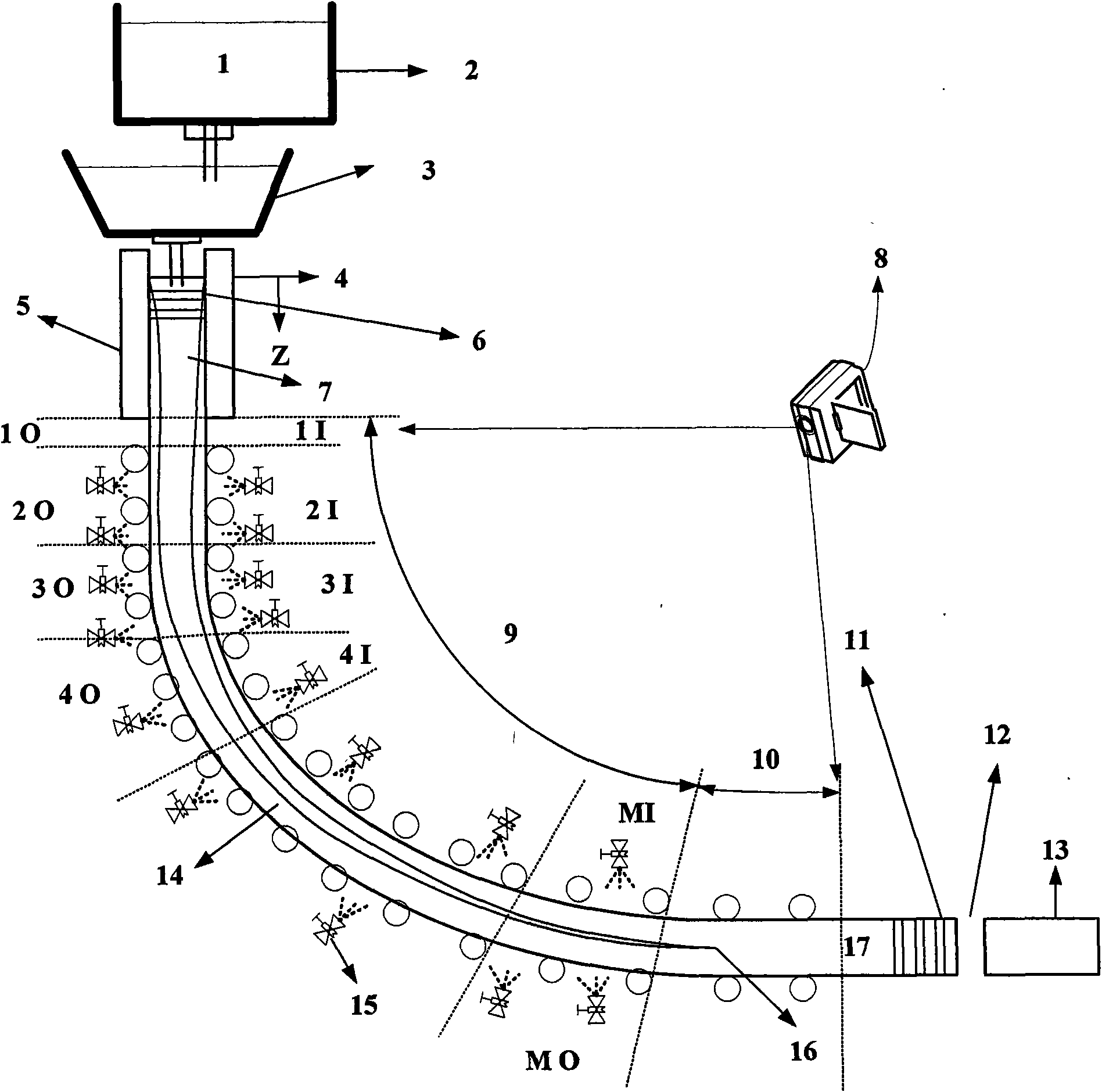

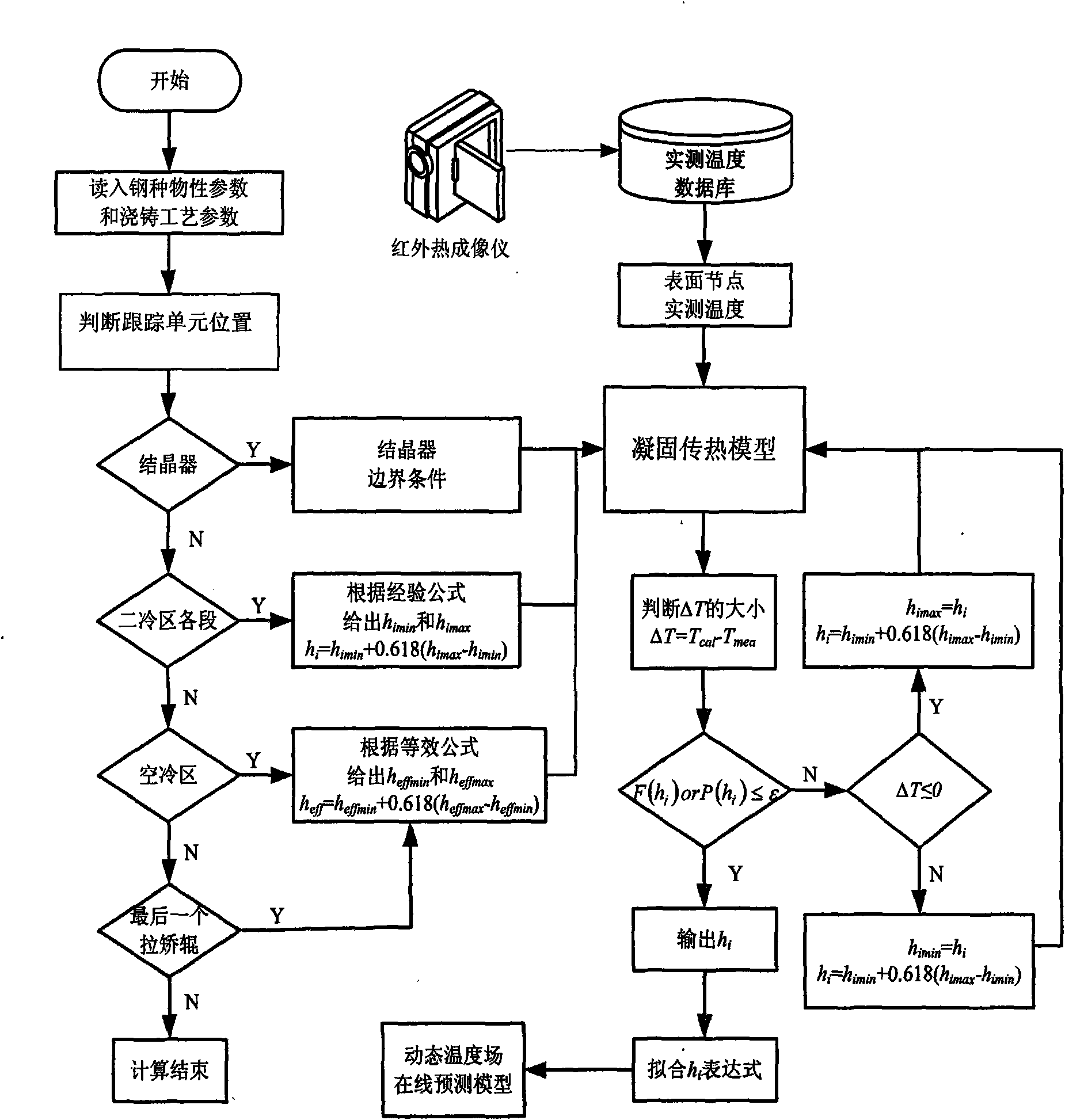

[0055] The present invention will be further described in conjunction with accompanying drawing: figure 1 It is a schematic diagram of continuous casting process and thermal imaging temperature measurement. The molten steel 1 in the ladle 2 enters the crystallizer 5 through the tundish 3, and the first tracking unit 6 is formed at the meniscus 4 of the mold 5, and the first tracking unit 6 enters the secondary cooling section 9 along the liquid direction hole 7, and the second Both the inner arc I and the outer arc O of the cold section 9 are provided with aerosol nozzles 15, the tracking unit enters the air cooling section 10, the strand 17 solidifies at the solidification end point 16, and the infrared thermal imager 8 collects the temperature of the secondary cooling section 9 and the air cooling section 10. Thermal image, the last tracking unit 11 cuts at the cutting point 12 to form a strand 13 .

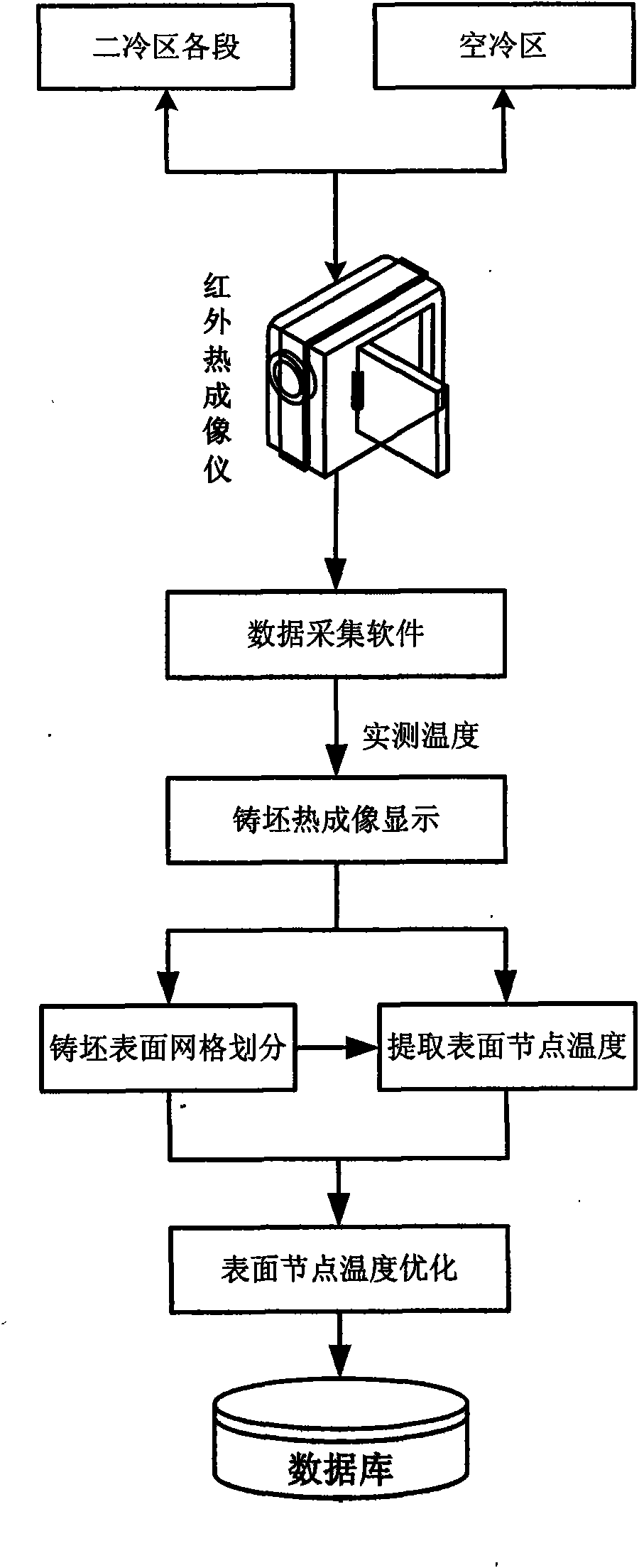

[0056] Install the infrared thermal imager in the secondary cooling zone and

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap