Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

14 results about "Abrasive" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An abrasive is a material, often a mineral, that is used to shape or finish a workpiece through rubbing which leads to part of the workpiece being worn away by friction. While finishing a material often means polishing it to gain a smooth, reflective surface, the process can also involve roughening as in satin, matte or beaded finishes. In short, the ceramics which are used to cut, grind and polish other softer materials are known as abrasives.

Chemical Mechanical Polishing Slurry Composition for Polishing Phase-Change Memory Device and Method for Polishing Phase-Change Memory Device Using the Same

InactiveUS20090001339A1Increase chanceMinimize occurrenceOther chemical processesSolid-state devicesHigh ratePhase-change memory

Owner:CHEIL IND INC

Abrasive tools made with a self-avoiding abrasive grain array

InactiveUS20050076577A1Pigmenting treatmentRevolution surface grinding machinesMaximum diameterAbrasive

Abrasive tools contain abrasive grains oriented in an array according to a non-uniform pattern having an exclusionary zone around each abrasive grain, and the exclusionary zone has a minimum dimension that exceeds the maximum diameter of the desired grit size range for the abrasive grain. Methods for designing such a self-avoiding array of abrasive grain and for transferring such an array to an abrasive tool body are described.

Owner:SAINT GOBAIN ABRASIVES INC

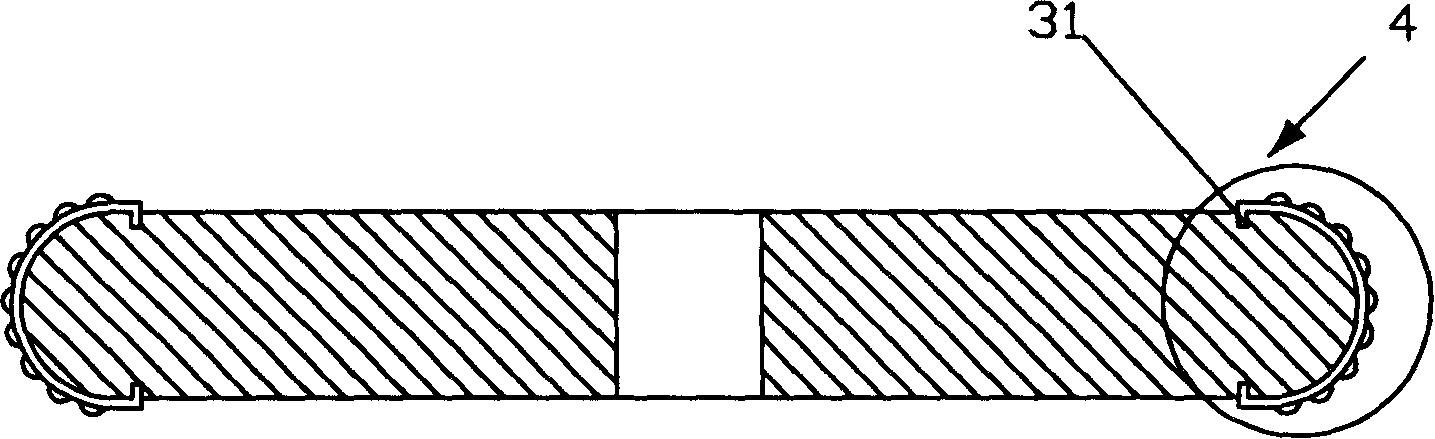

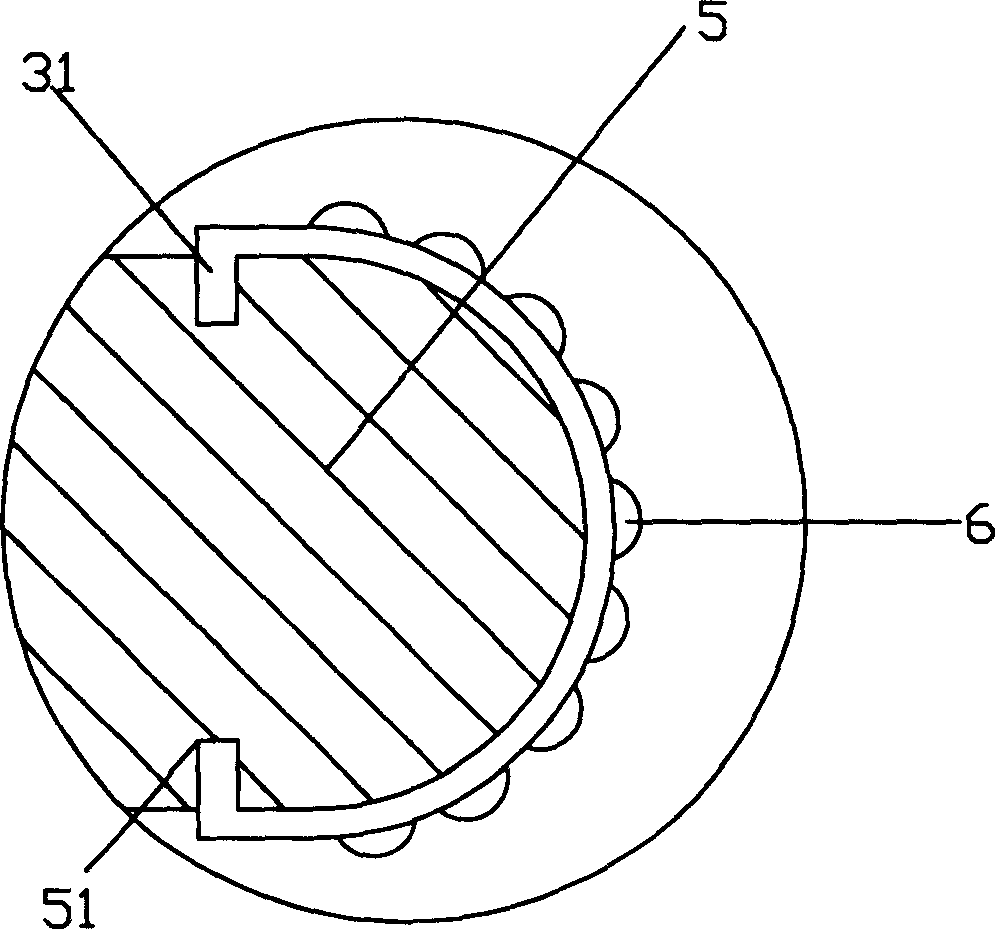

Annular super-hard abrasive wire and method for manufacturing same

ActiveCN102873401AUniform particle distributionHigh tensile strengthMetal sawing tool makingElectrical conductorHigh intensity

The invention discloses an annular super-hard abrasive wire and a method for manufacturing the same. The annular super-hard abrasive wire comprises a rope, super-hard abrasive particles and a coating, wherein the size of the rope ranges from 0.1mm to 6mm, the super-hard abrasive particles are solidified on the surface of the rope, and the coating is used for solidifying the super-hard abrasive particles. The method for manufacturing the annular super-hard abrasive wire includes braiding the thin rope to form a ring with an optional perimeter; and then solidifying the super-hard abrasive particles on the surface of the annular rope by means of coating to form the high-strength annular super-hard abrasive wire with the uniform outer diameter and a long service life. The annular super-hard abrasive wire is low in cost, high in fatigue strength, long in service life, good in cutting quality and high in cutting efficiency, and a cutting machine with the annular wire can be used for cutting conductors, semiconductors and non-conductor materials.

Owner:CHINA NONFERROUS METAL (GUILIN) GEOLOGY & MINING CO LTD

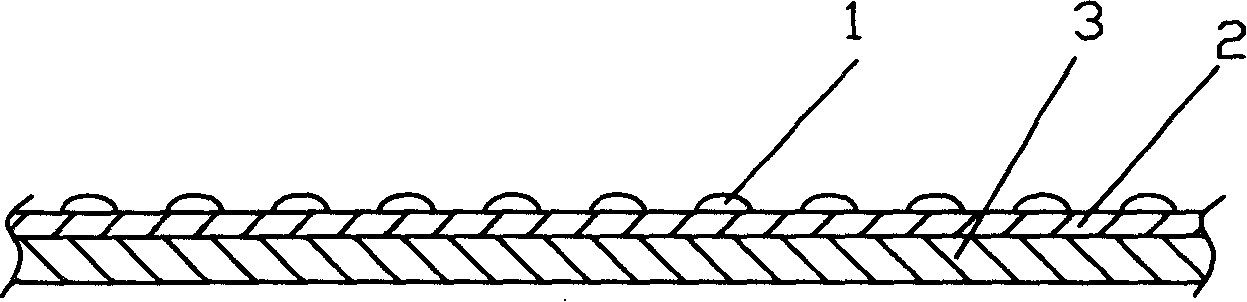

Production process of polyester water-resistant emery cloth with high adhesive power

InactiveCN107139087AImprove waterproof performanceLower surface energyNon-macromolecular adhesive additivesLiquid surface applicatorsEpoxyRubber material

The invention discloses a production process of high-adhesion polyester water-resistant abrasive cloth, which adopts water-resistant sandpaper as a cloth base for production; after scraping the sand-planted surface of the cloth base, corona treatment is performed on the sand-planted surface of the cloth base; Squeegee coating material, base rubber material and re-adhesive compound are all added with heat-dissipating materials and heat-conducting materials; the abrasive used for sand planting is diamond abrasive grain; the diamond abrasive grain layer (3) is coated with a re-adhesive layer (4) , the substrate (1) is a non-woven material; by mass percentage, the components of the primer layer (2) and the contents of each component are: 50% to 75% of epoxy modified phenolic resin, 15% to 15% of softening agent 35%, thickening lubricant 2%~5%, tackifier 8%~15%, the sum of the mass percentages of the above-mentioned components is 100%; by mass percentage, the components and The content of each component is: 60%-75% of water-based epoxy resin, 2%-10% of internal mixed antistatic agent, 15%-35% of auxiliary materials, and the sum of the mass percentages of the above-mentioned components is 100%.

Owner:JIANGSU FENGMANG COMPOUND MATERIAL SCI&TECH GRP CO LTD

Elastic abrasive cloth and abrasive wheel

Owner:厦门致力金刚石工具有限公司

Machine for blasting abrasives

ActiveUS20120252327A1Simple structureSimple and novel structureRevolution surface grinding machinesGrinding drivesEngineeringAbrasive

The object of the present invention is to provide a machine for blasting abrasives that has a simple structure and that solves the problem of abrasives falling when the door for the gateway for the work is opened or closed. The machine for blasting abrasives comprises a chamber 11 for processing, a nozzle 13 that is provided within the chamber 11 for shooting the abrasives (shots) S onto the work W, and a jig 15 for holding the work W at a position facing the nozzle 13. A gateway 17 with a door 19 is formed in the ceiling 11a of the chamber 11. The size of the gateway 17 enables the work W to protrude from the chamber 11 by means of the jig 15 at a position corresponding to the jig 15 that is linearly moving up and down. The door 19 is provided within the chamber 11 so as to seal the gateway by linearly moving up and down and so as to create a vacant plane on the gateway for passing the work by horizontally moving.

Owner:SINTOKOGIO LTD

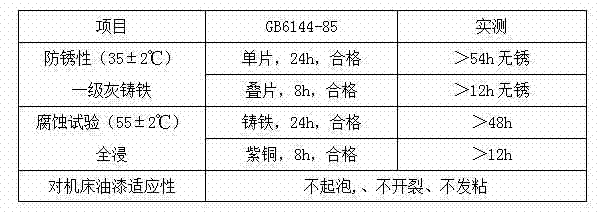

Abrasive-containing emulsifying compound metal cutting solution and preparation method thereof

ActiveCN104120020AExcellent lubricating and anti-wear propertiesImprove the lubrication effectLubricant compositionWater basedSodium metasilicate

Owner:山东斯瑞药业有限公司

Efficient preparation method of ultra-precision cutting abrasive sand

ActiveCN103937451AFine and uniform particle sizeCause gagOther chemical processesEngineeringParticle-size distribution

Owner:LIANYUNGANG LONGHE GARNET

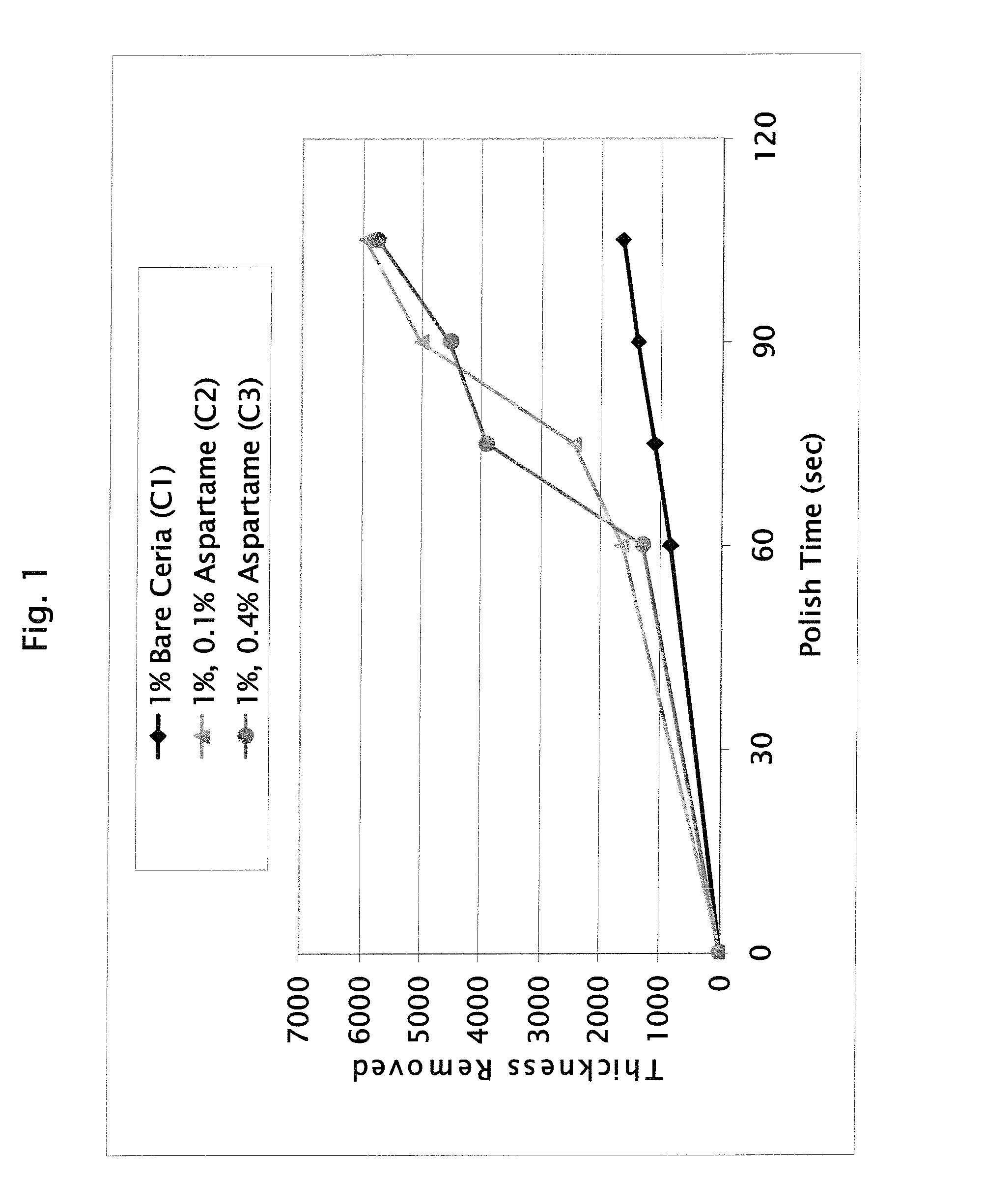

Device for on-line ultrasonic dressing of coarse-grained superhard abrasive grinding wheel

PendingCN108772782AImprove processing qualityEasy to replaceGrinding feed controlAbrasive surface conditioning devicesCamera lensEngineering

Owner:HUAQIAO UNIVERSITY

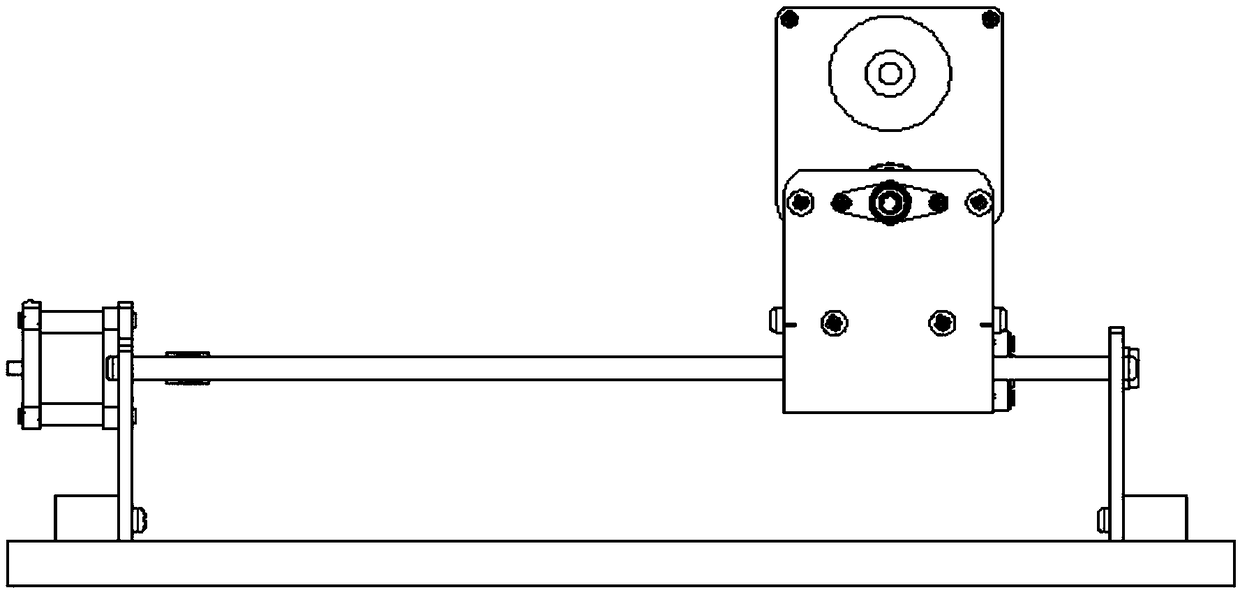

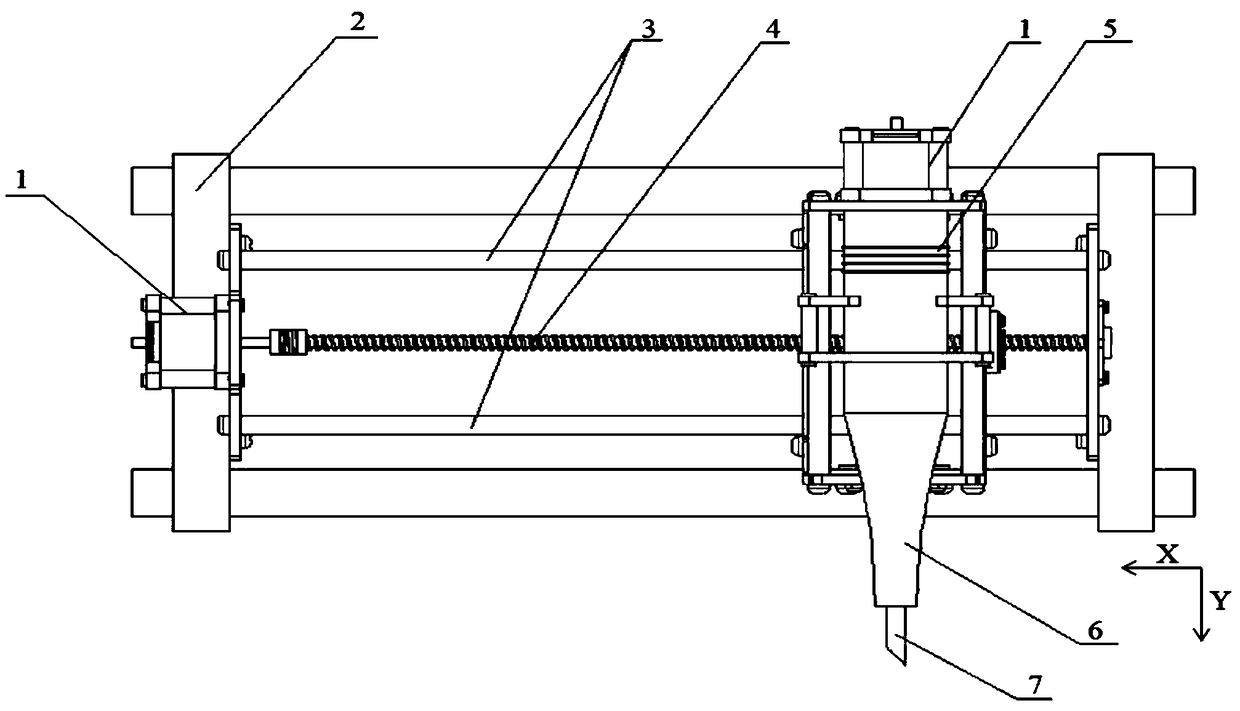

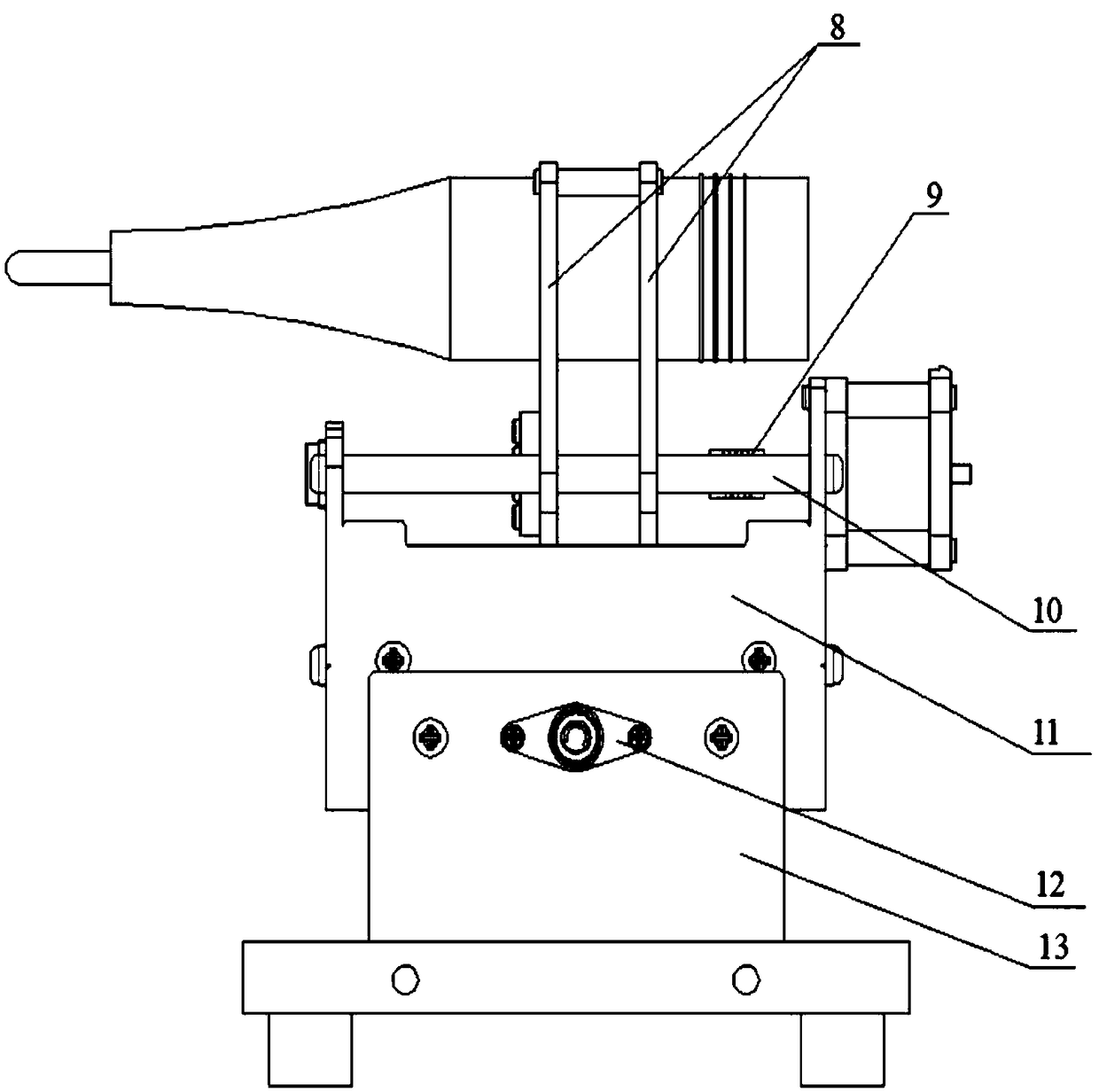

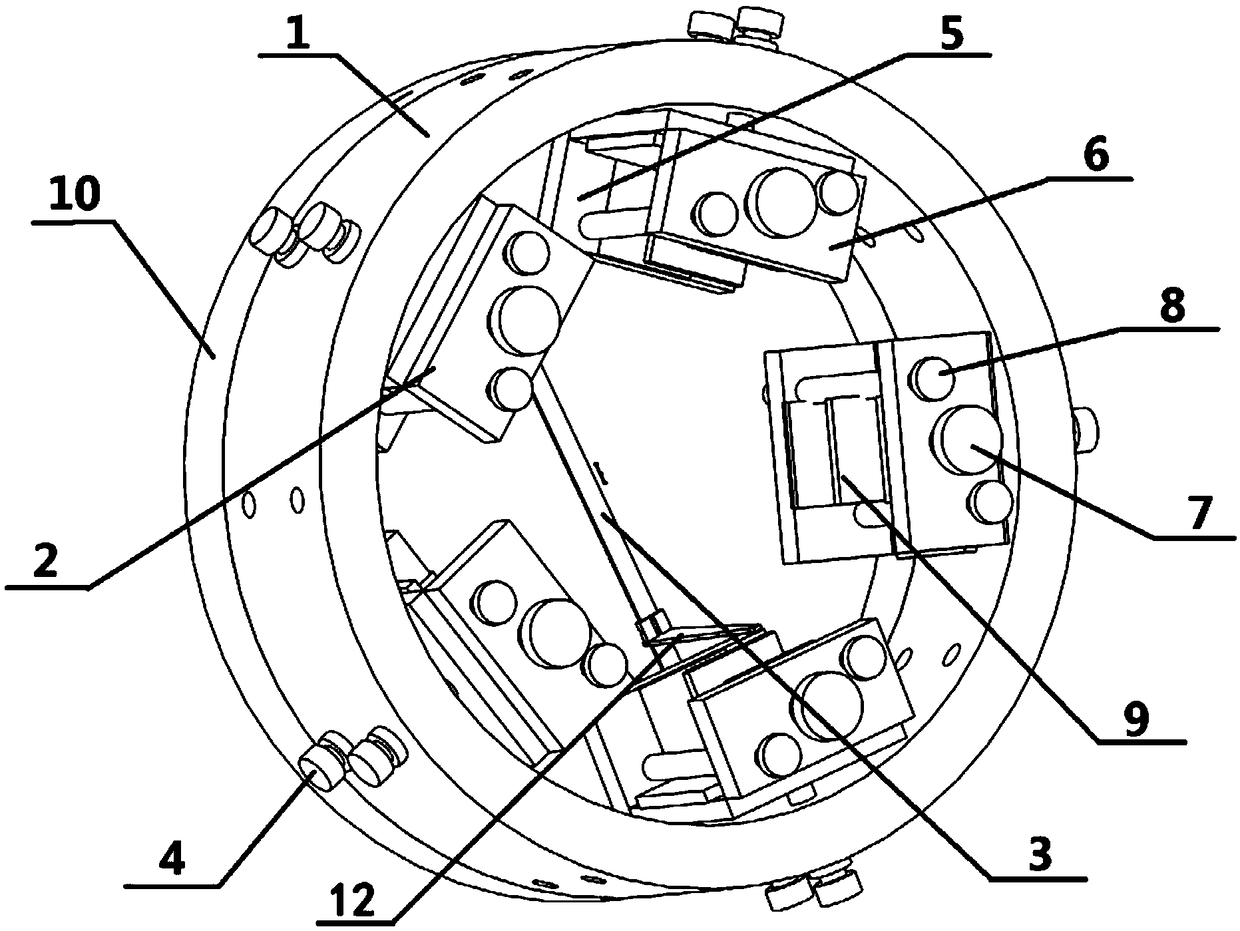

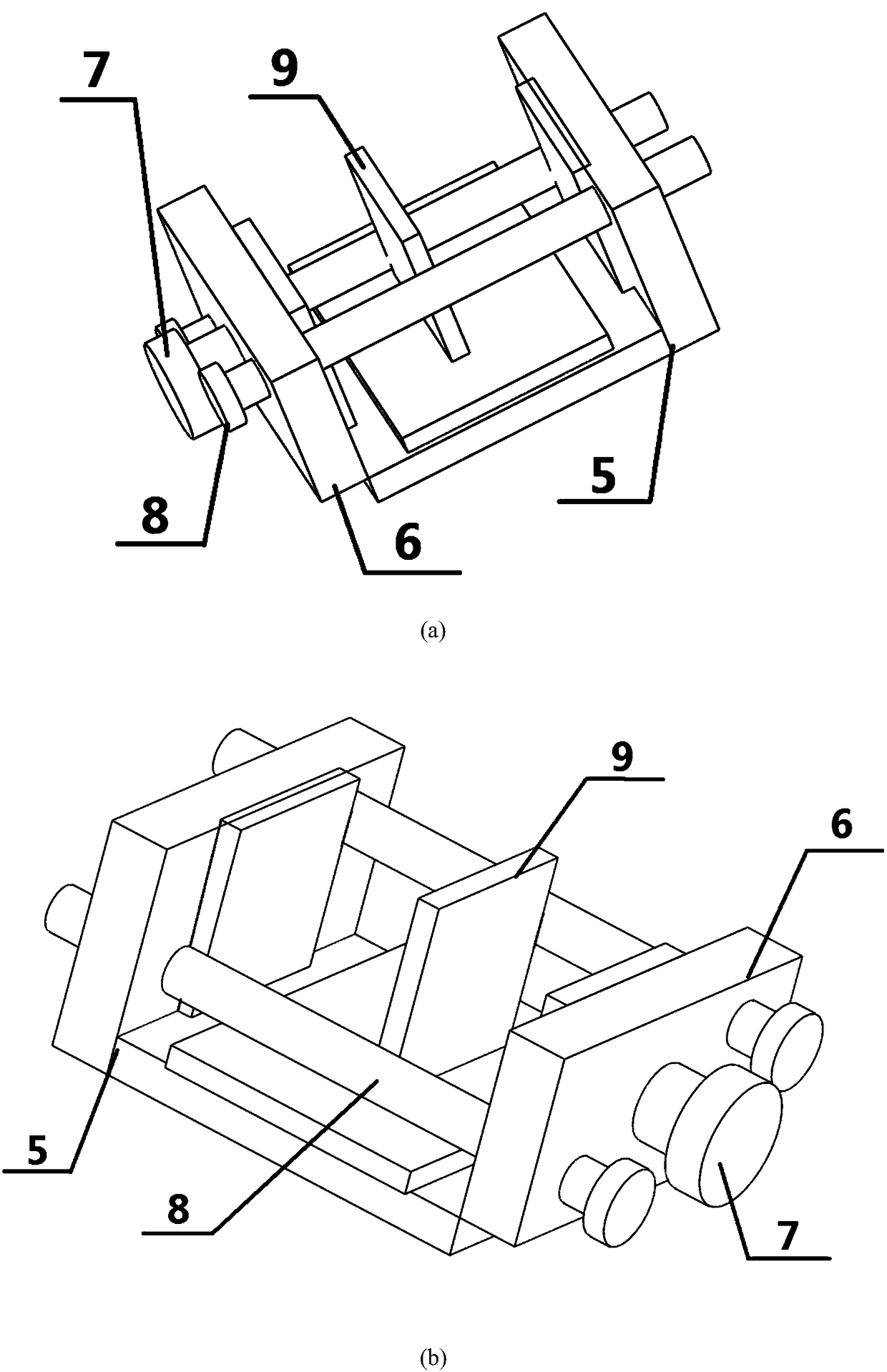

Clamping device applied to trimming arc surfaces of abrasive blocks of grinding wheel

Owner:SHENYANG JIANZHU UNIVERSITY

Sponge abrasive material and preparation method thereof

InactiveCN108000377AAvoid indistinguishableRealization of long-term continuous productionAbrasion apparatusFire retardantUltimate tensile strength

The invention discloses a sponge abrasive material and a preparation method thereof, and relates to the field of abrasive materials. The sponge abrasive material comprises the following components of,by weight, 0.999-1 part of a polyurethane elastic material, 0.001-0.01 part of color paste, 1-20 parts of hard abrasive materials and 0.02-0.08 part of a flame retardant, the hard abrasive materialsare evenly distributed between foam formed by the polyurethane elastic material and the flame retardant, the color paste has different colors, and the hard abrasive materials are one or several of steel sand, brown corundum, garnet and the like. The sponge abrasive material and the preparation method thereof have the beneficial effects that the problem that the type of the hard abrasive materialsis difficult to distinguish after the hard abrasive materials are wrapped with polyurethane sponge is avoided, according to the preparation method of the sponge abrasive material, the wrapping strength of the sponge abrasive material is improved, the service life is prolonged, meanwhile, the problem of continuous production of the sponge abrasive material is solved, the efficiency is improved, theyield is increased,, and consumption is reduced.

Owner:SHANDONG TAA CLOUD IND ENG TECH CO LTD

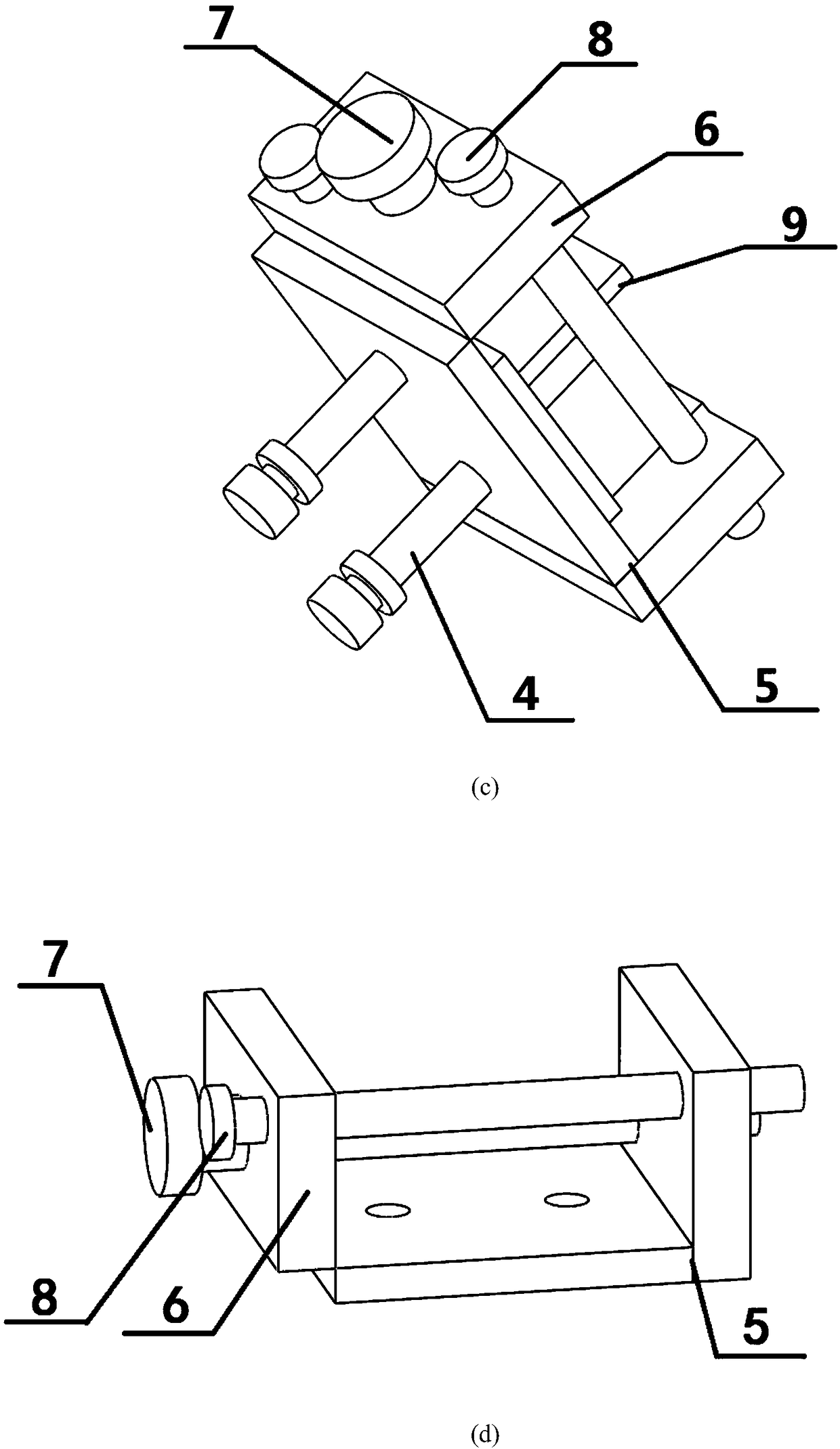

Chemical-Mechanical Polishing Compositions Containing Aspartame And Methods Of Making And Using The Same

InactiveUS20080314872A1Low rateOther chemical processesDecorative surface effectsCompound (substance)Slurry

Owner:FERRO CORP

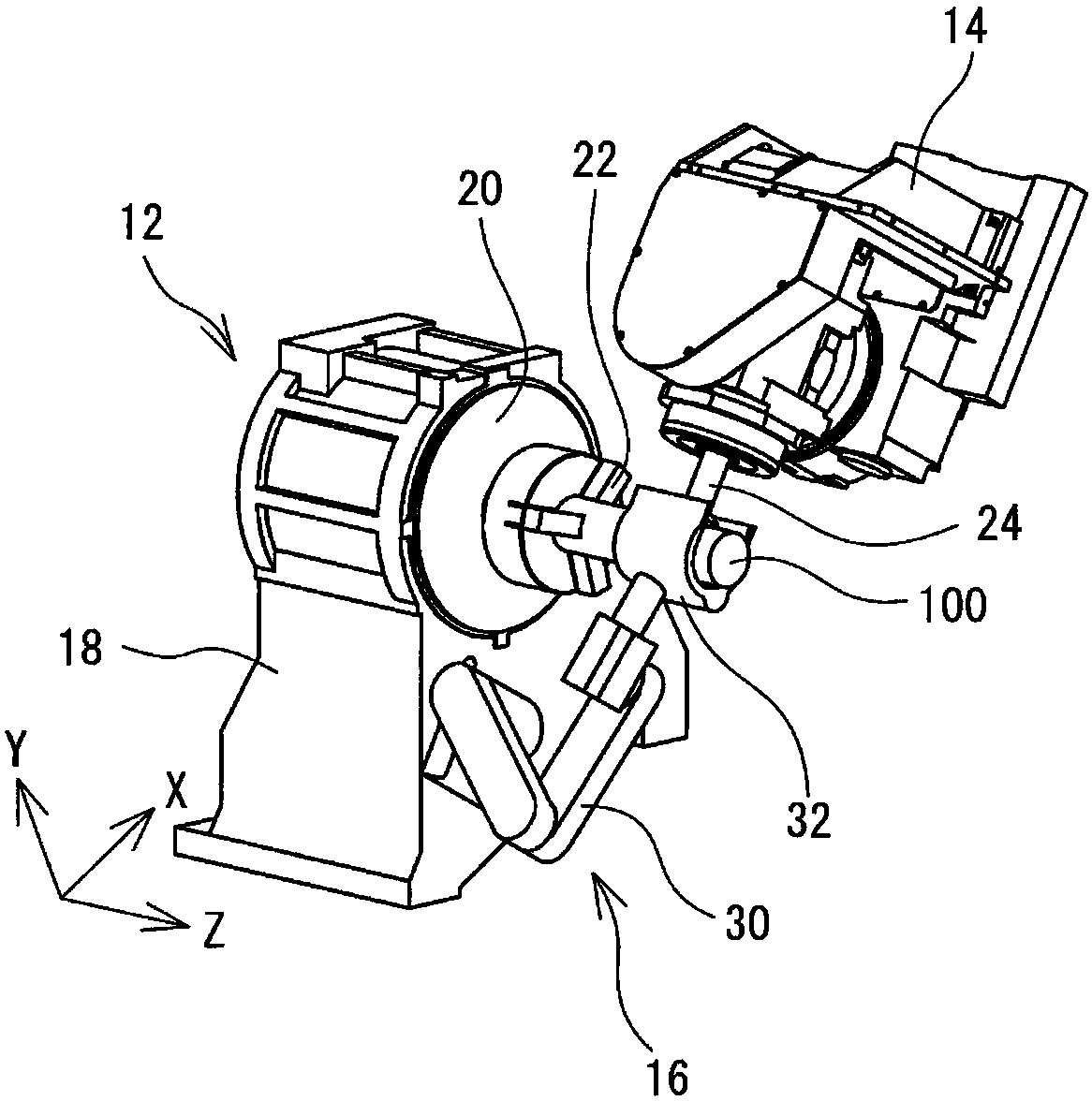

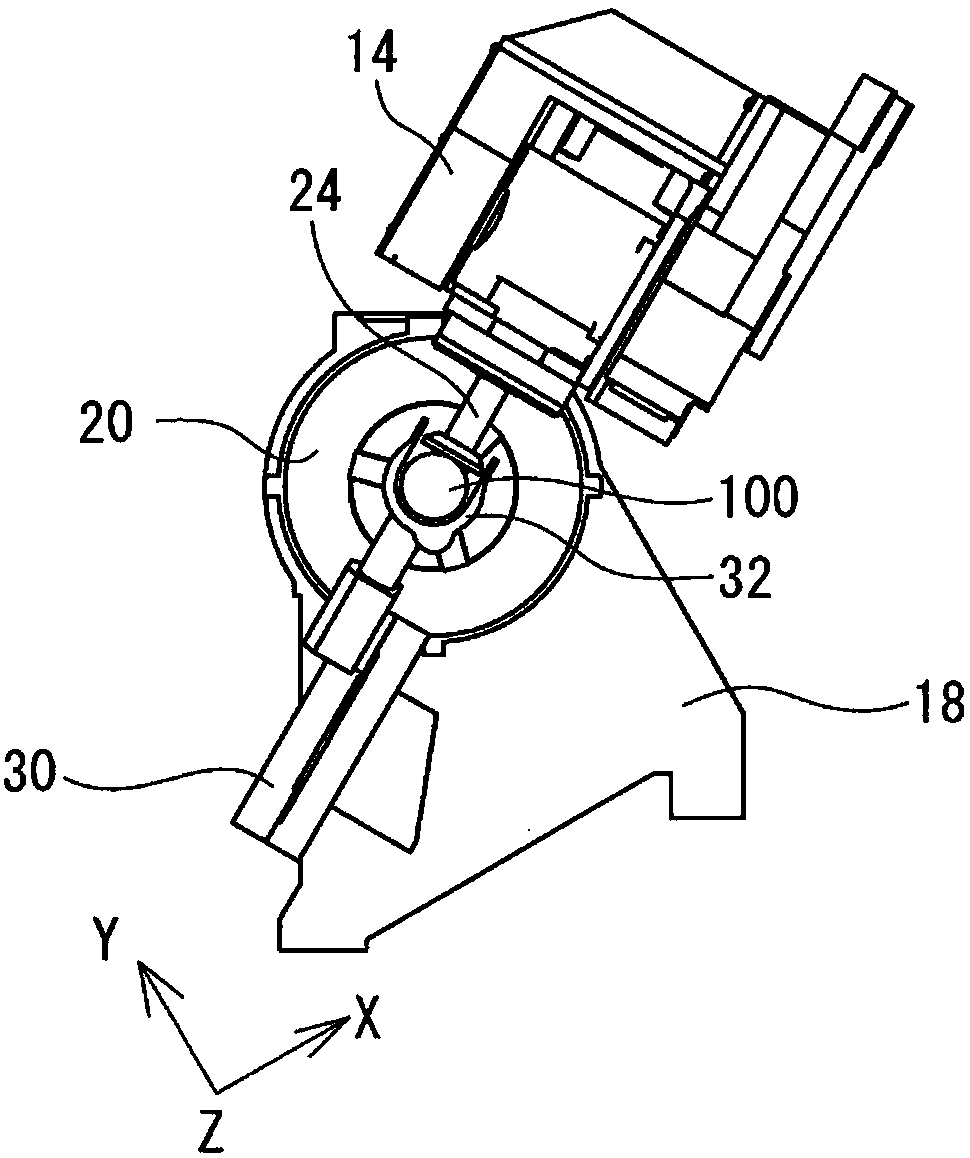

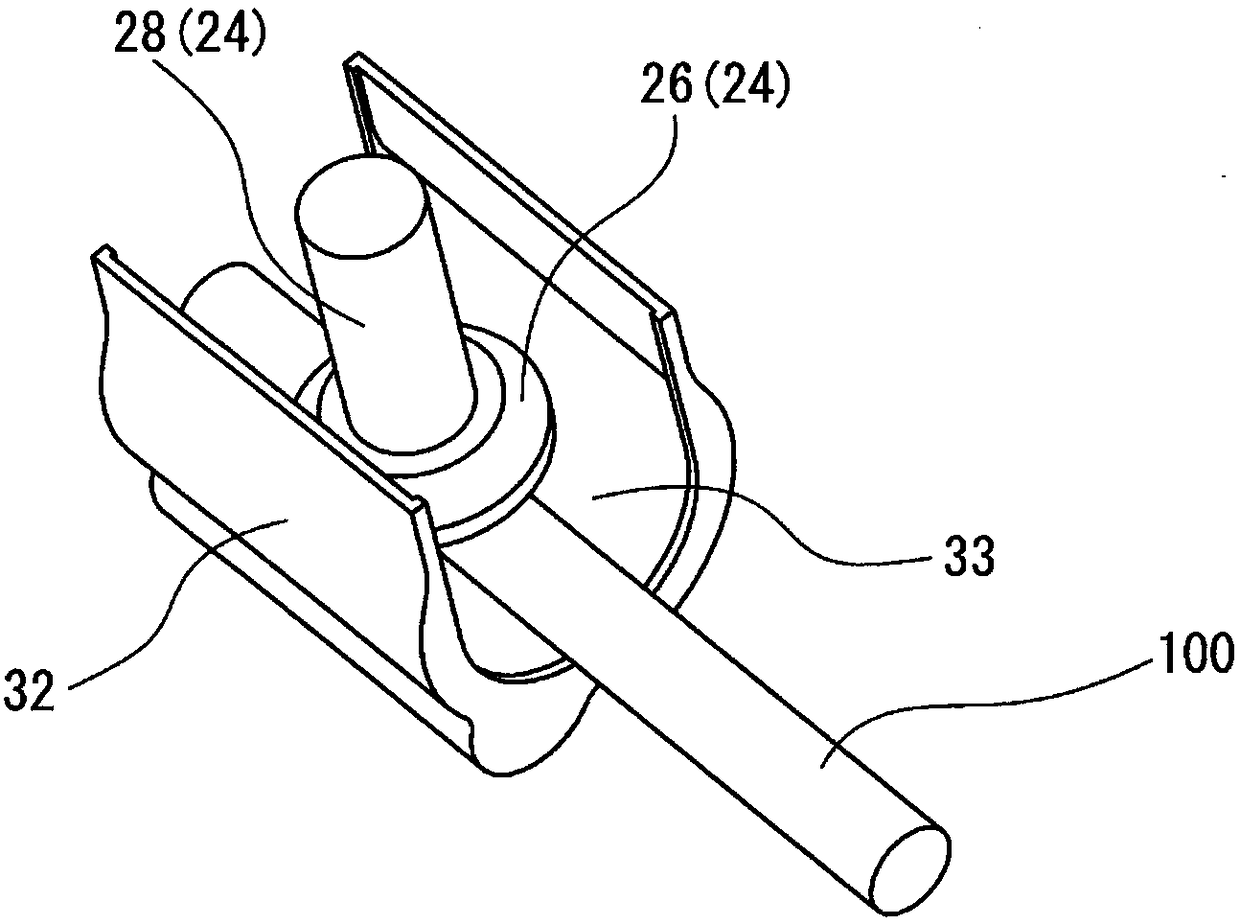

Machine tool

ActiveCN108723965AAvoid oversizingIncreased freedom of movementRevolution surface grinding machinesPolishing machinesEngineeringMachine tool

Owner:OKUMA CORP

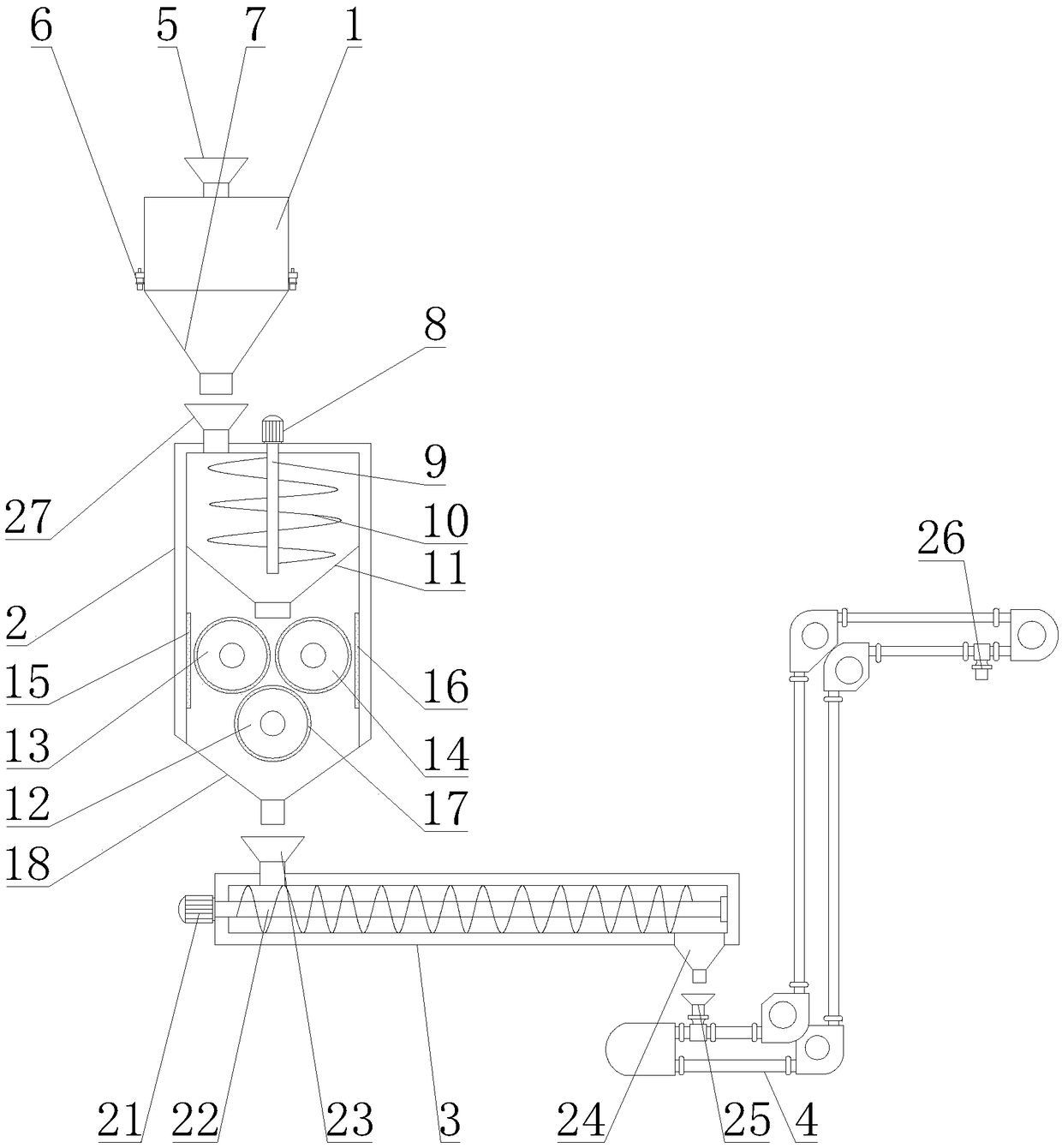

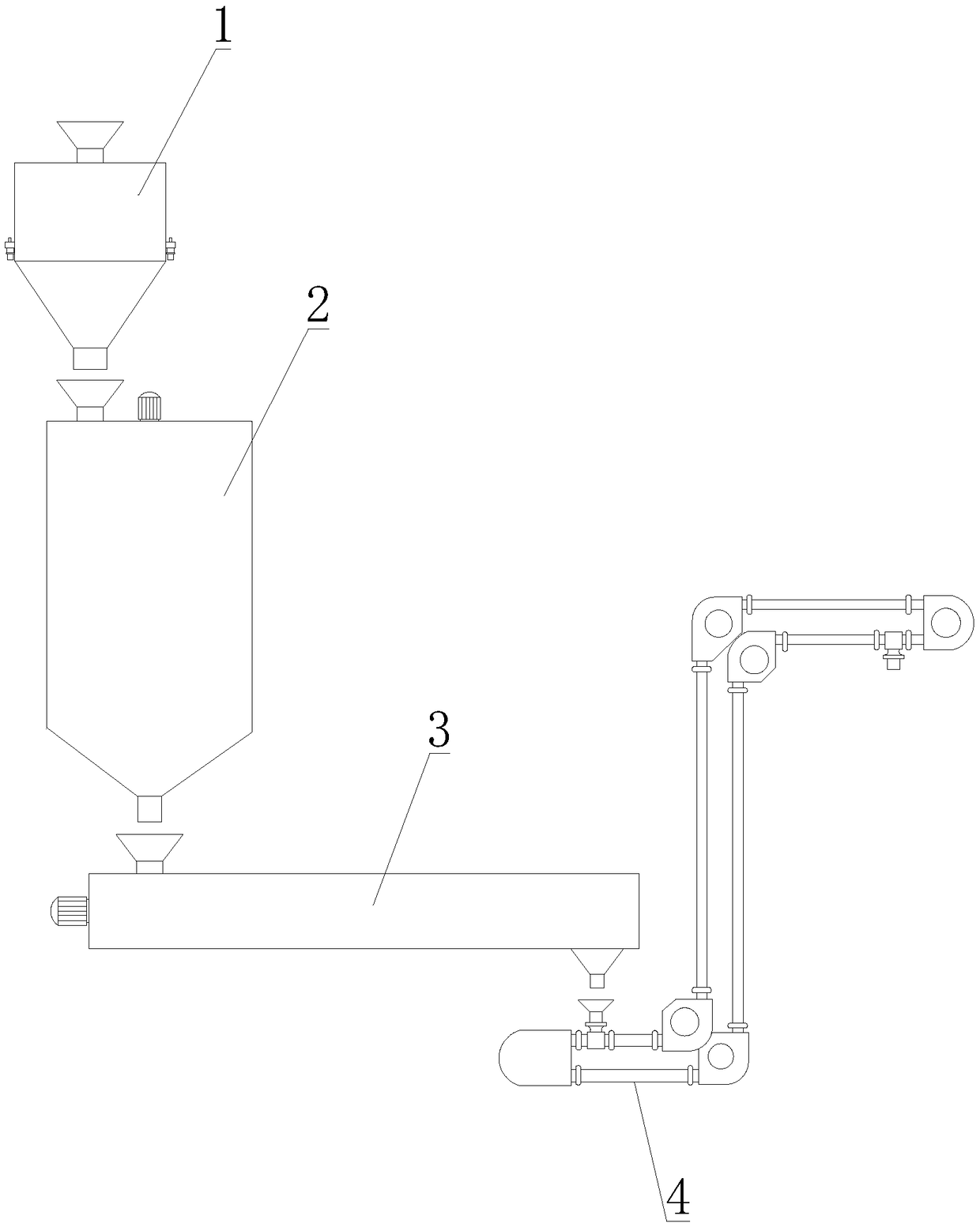

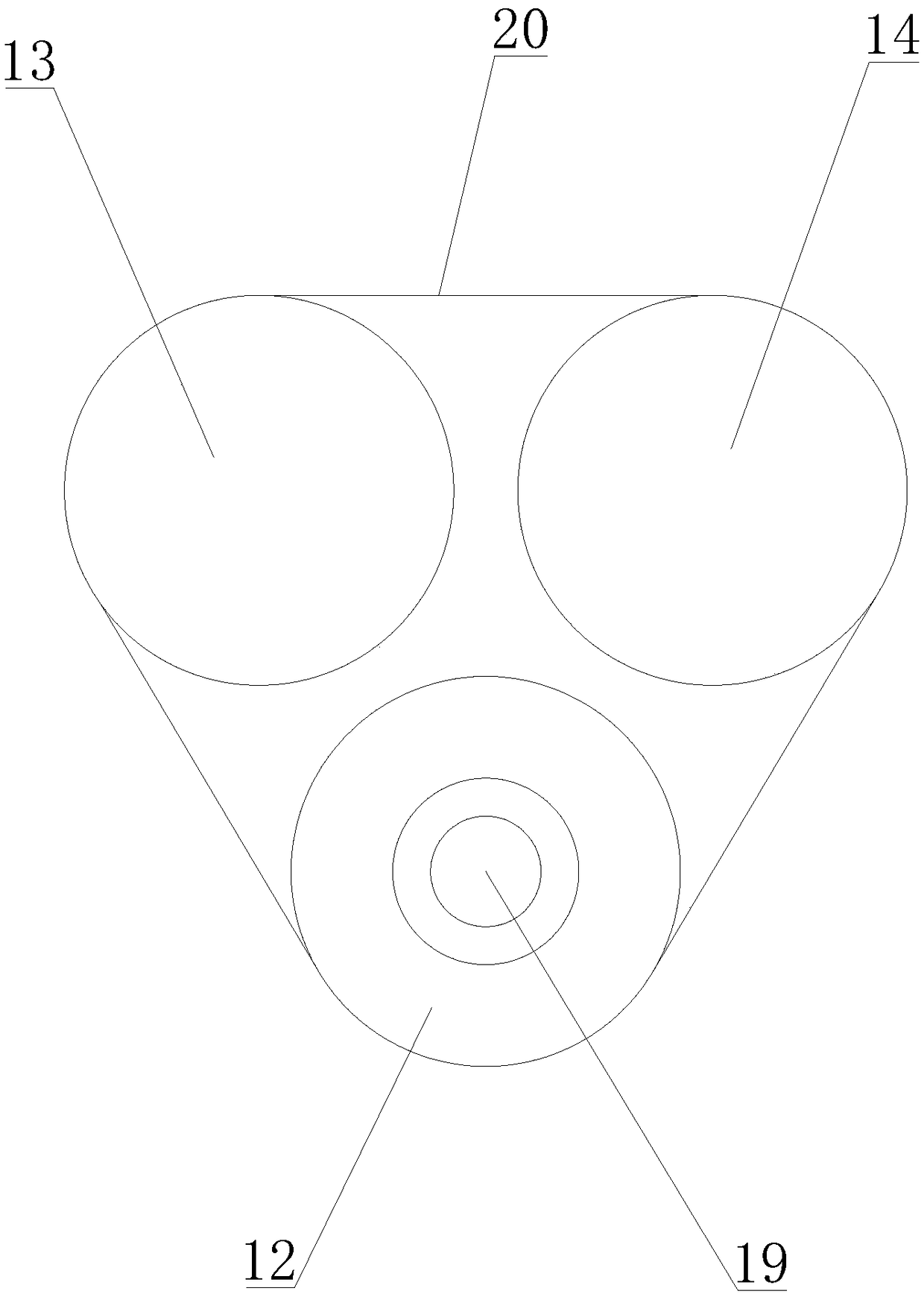

Feeding device of resin co-grinding and burdening

Owner:ZHENGZHOU NEO LOOP TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap