Device for on-line ultrasonic dressing of coarse-grained superhard abrasive grinding wheel

A superabrasive and ultrasonic technology, applied in abrasive surface adjustment devices, grinding machine parts, grinding/polishing equipment, etc., can solve problems such as grinding wheel clogging, reduction of workpiece surface quality and shape accuracy, and reduction of chip space , to save time, improve processing quality and save time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below with reference to the accompanying drawings and embodiments; however, the detection and sharpening device of the present invention is not limited to the embodiments.

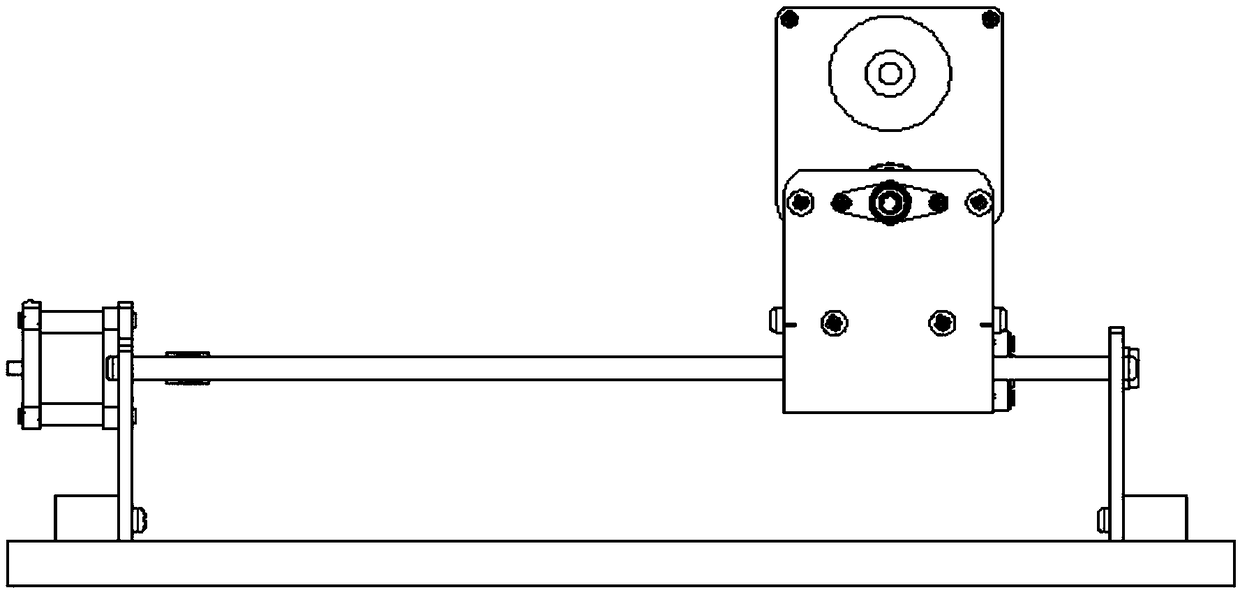

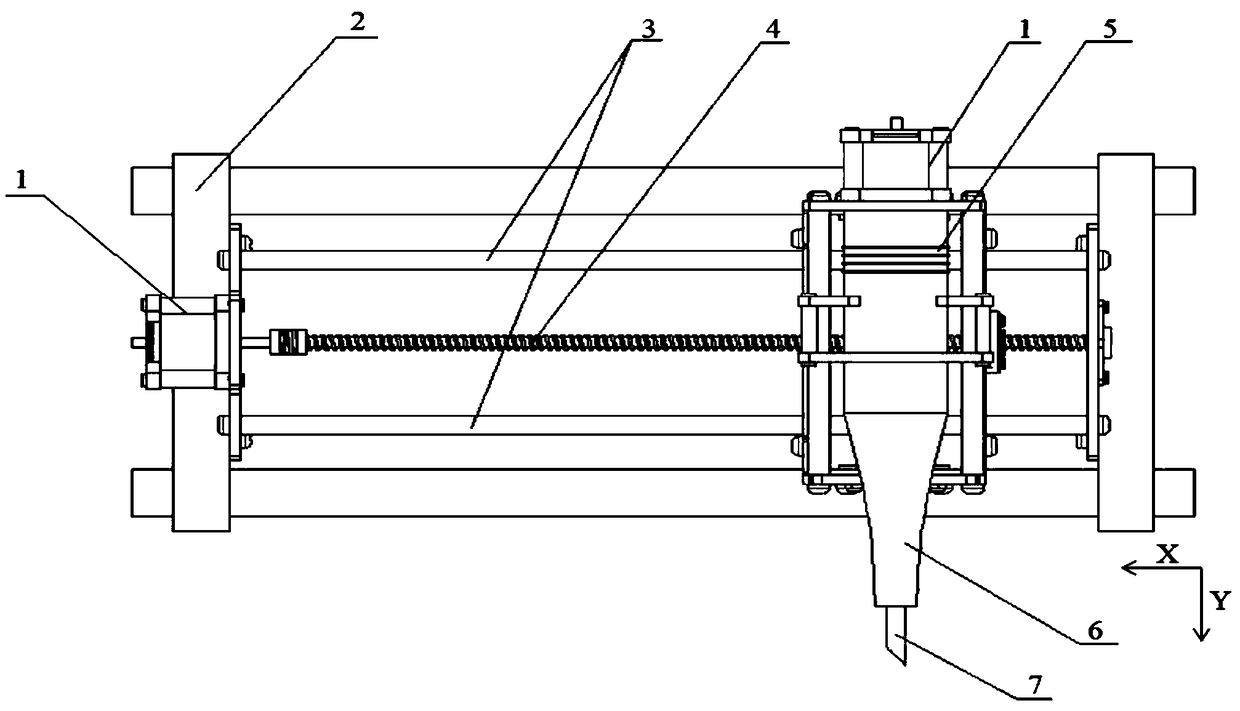

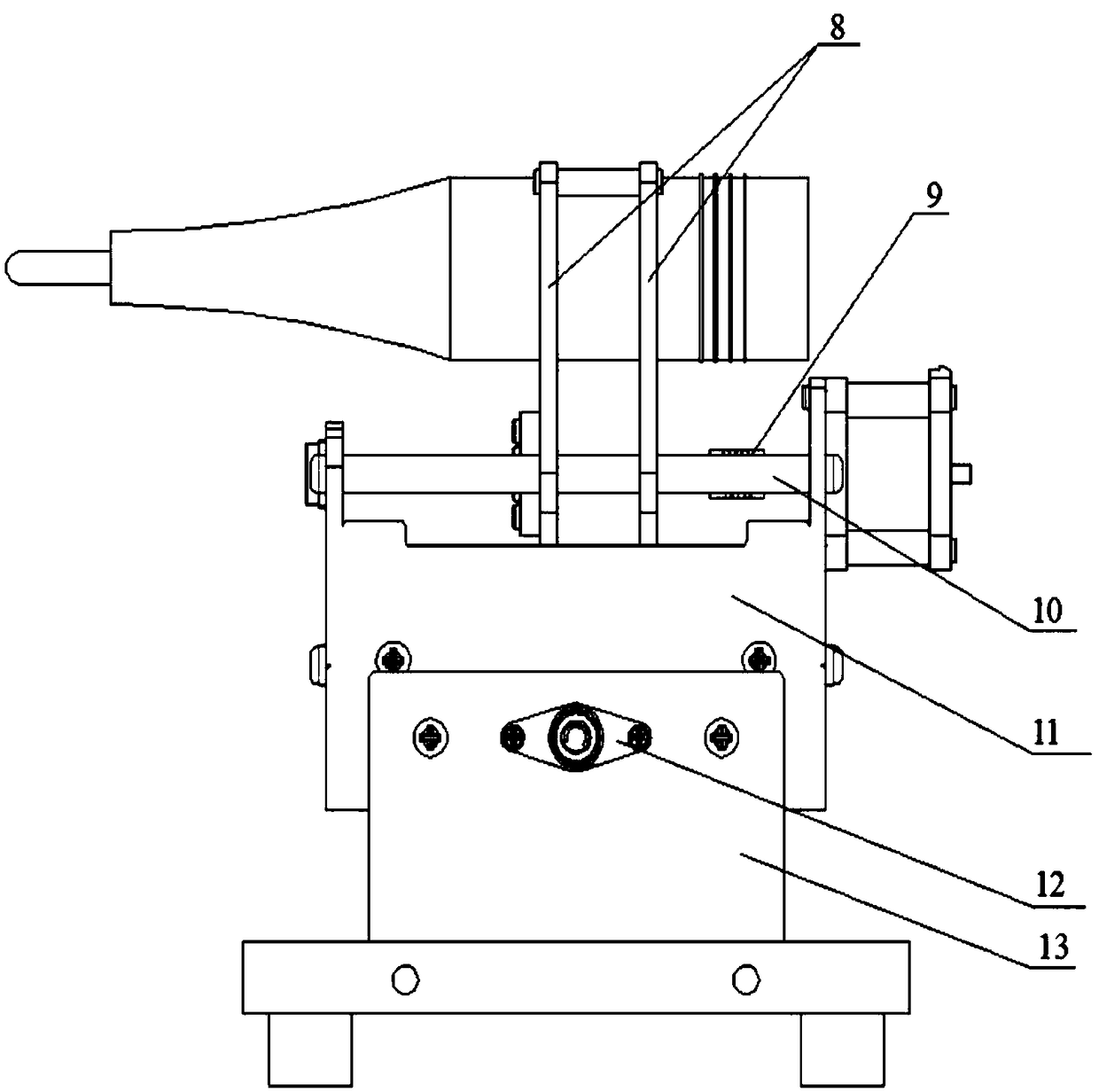

[0028] see Figure 1-Figure 6 As shown, a device for online ultrasonic sharpening coarse-grained superabrasive grinding wheel, including: an online detection device and a sharpening device;

[0029] The specific structure of the sharpening device is as follows: the X-direction bracket 11 is fixed on the base 2 of the sharpening device; the stepper motor a1 is fixed on the side wall of the X-direction bracket 11; the ball screw a4 and the guide rail a3 are fixed in parallel with each other at intervals On the X-direction support 11; the stepper motor a1 and the ball screw a4 are connected by a coupling transmission; the ball screw support seat a is fixed on the X-direction support 11 through the ball screw a4;

[0030] The Y-direction bracket 13

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap