Feeding device of resin co-grinding and burdening

A feeding device and feeding device technology, applied in the field of resin co-grinding batching and feeding devices, can solve the problems of inorderly combination, low degree of automation, inconvenient control, etc., and achieve accurate weighing, high degree of automation, easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

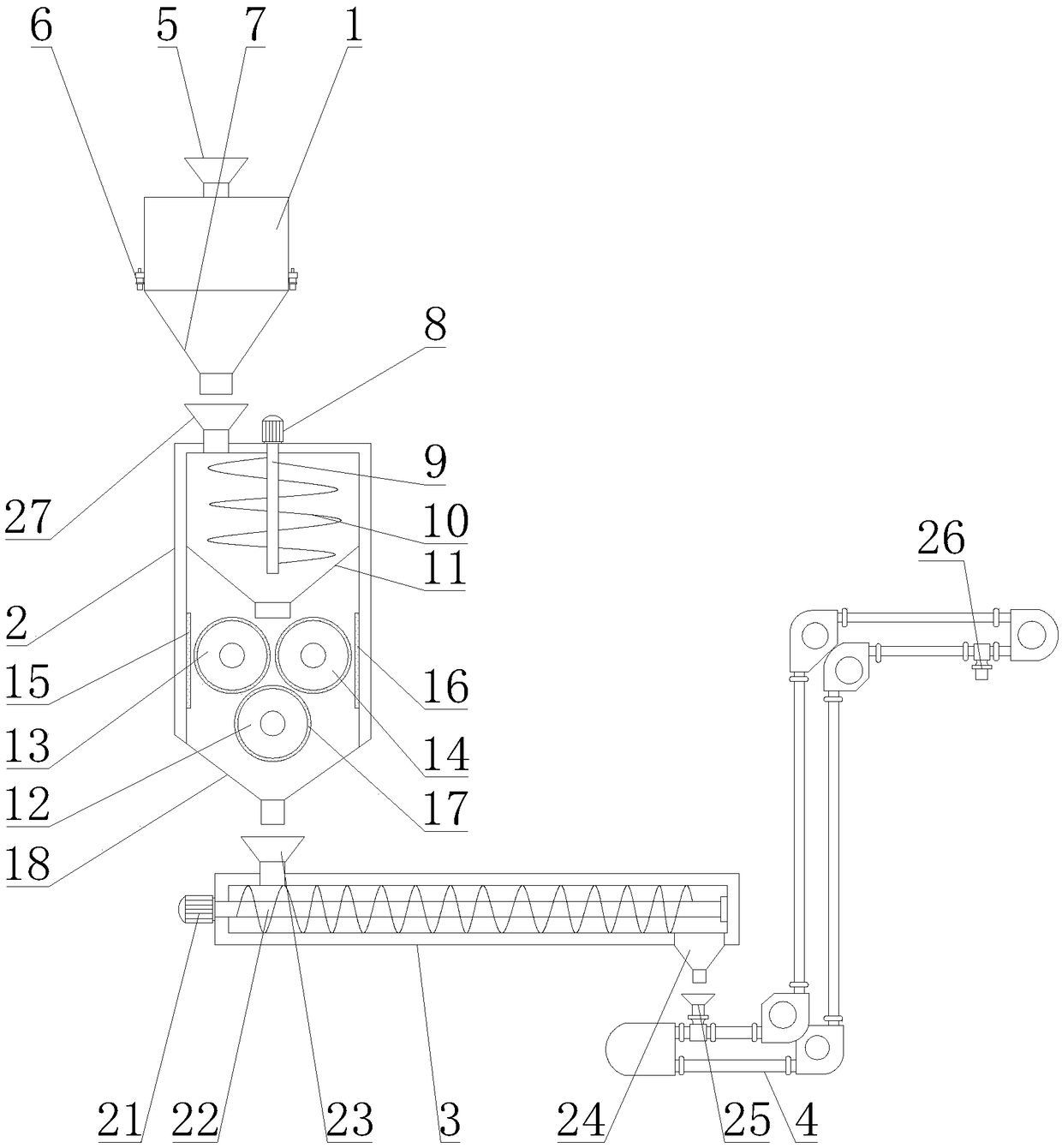

[0026] like Figure 1-3 as shown, figure 1 It is a structural schematic diagram of a resin co-grinding ingredient feeding device proposed by the present invention.

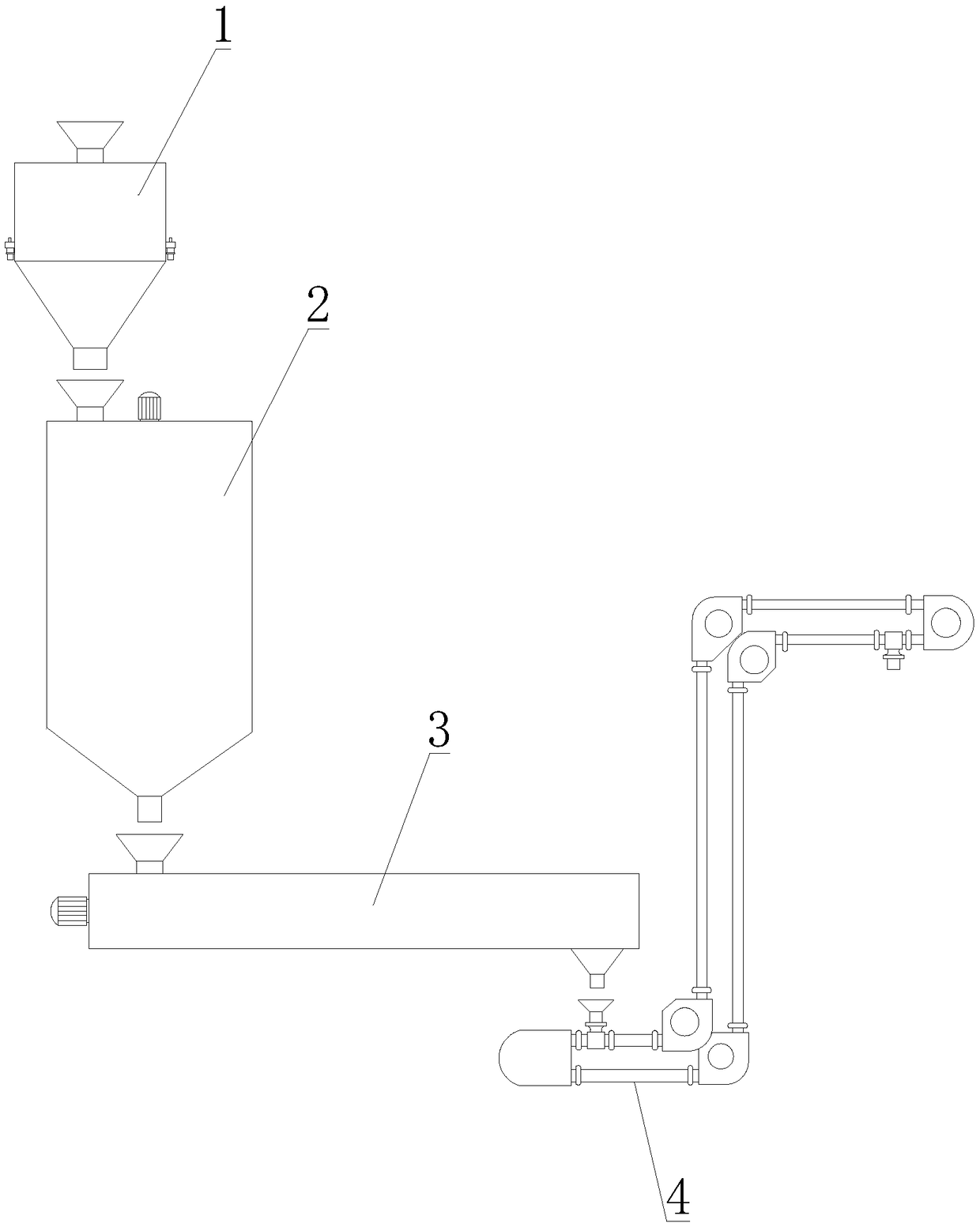

[0027] figure 2 It is a front view of a resin co-grinding ingredient feeding device proposed by the present invention.

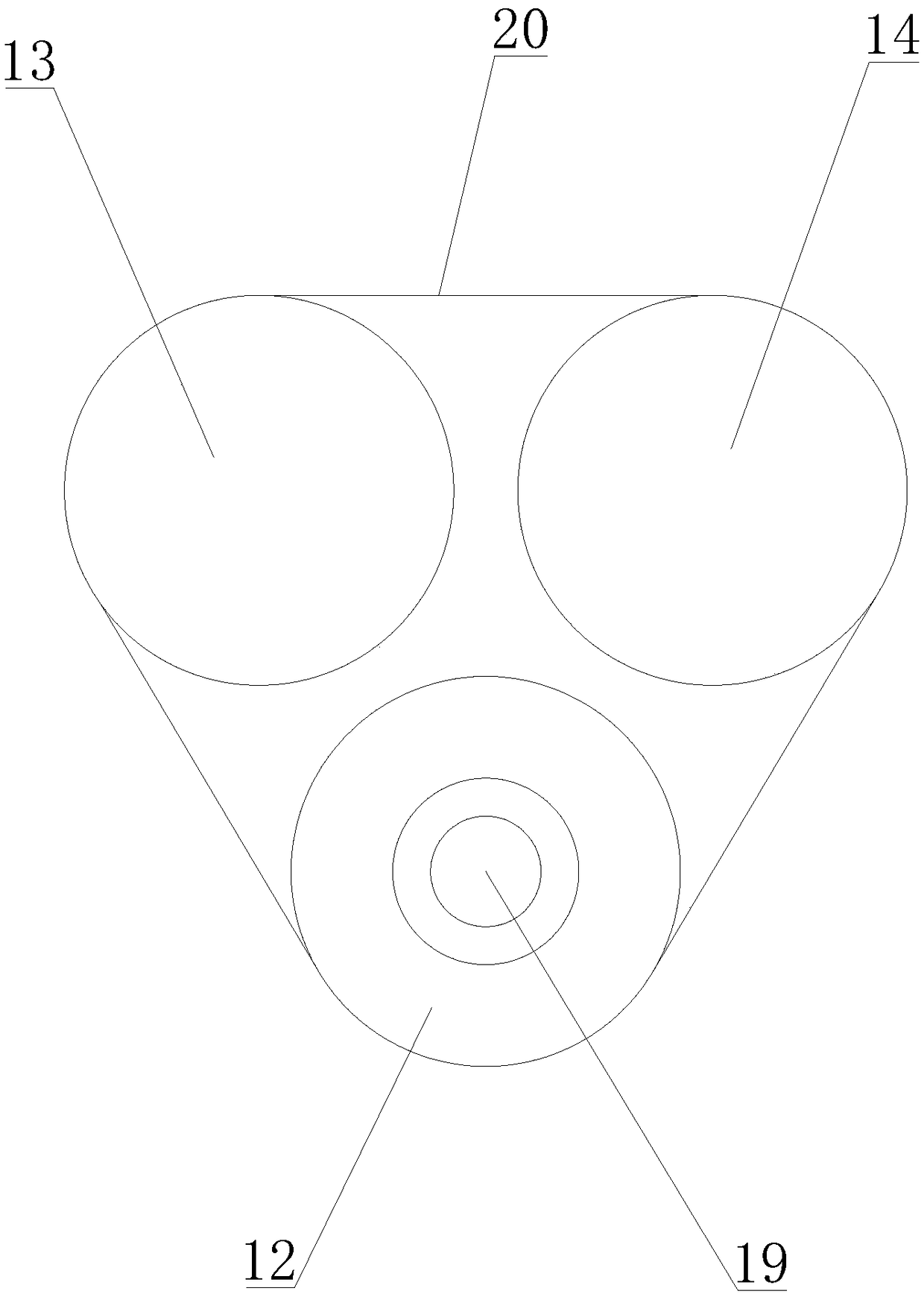

[0028] image 3 It is a connection diagram of the second motor, the first grinding roller, the second grinding roller and the third grinding roller in a resin co-grinding ingredient feeding device proposed by the present invention.

[0029] refer to Figure 1-3 , a kind of resin co-grinding batching feeding device that the present invention proposes, comprises weighing hopper 1, stirring abrasive device 2, feeding device 3, pipe chain conveyor 4, stirring assembly and abrasive assembly;

[0030] The inside of the weighing hopper 1 is hollow, the top of the weighing hopper 1 is provided with the first feeding part 5 for feeding, and the bottom of the weighing hopper 1 is provided with the firs

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap