Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6 results about "Tempering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

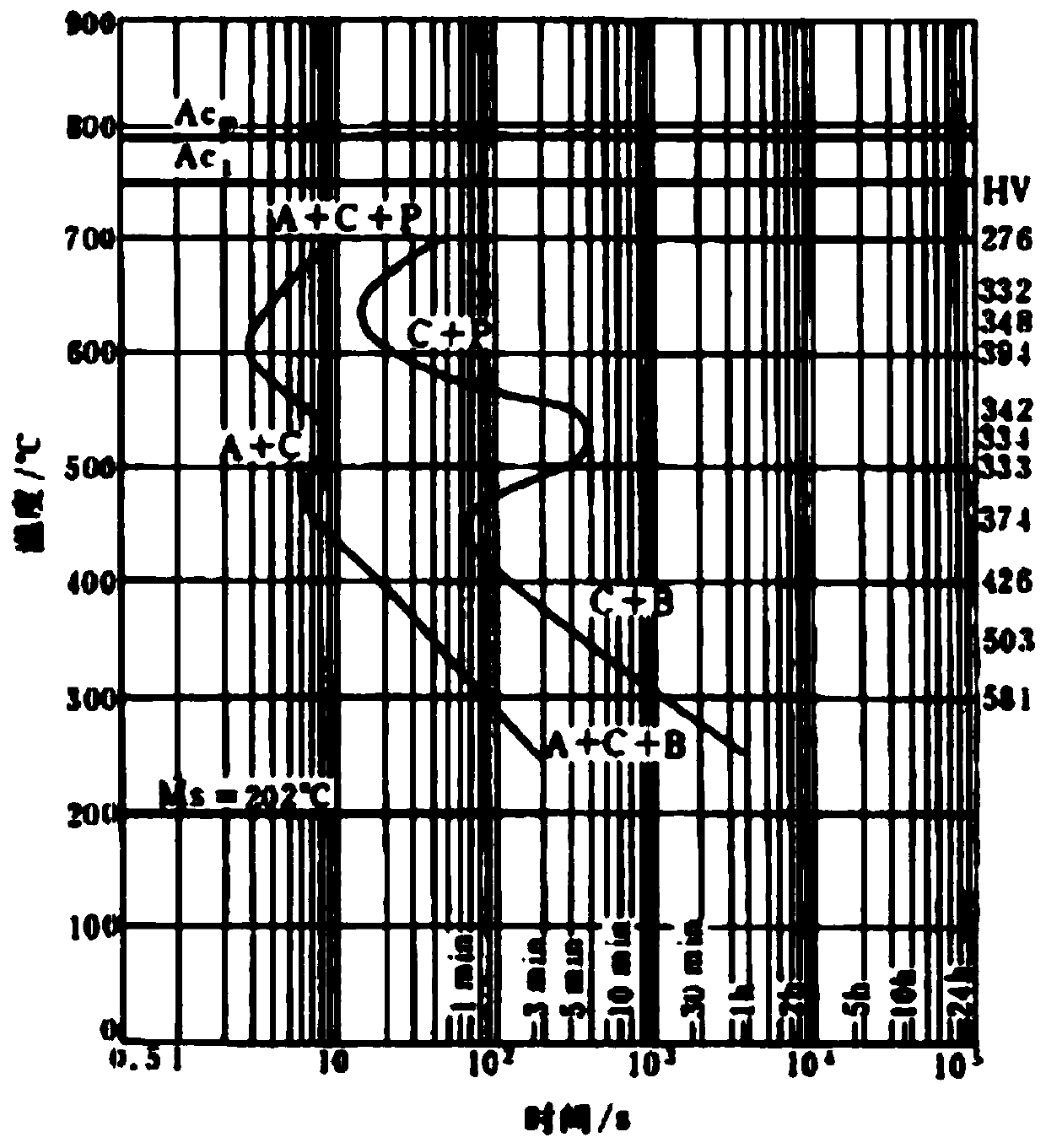

Tempering is a process of heat treating, which is used to increase the toughness of iron-based alloys. Tempering is usually performed after hardening, to reduce some of the excess hardness, and is done by heating the metal to some temperature below the critical point for a certain period of time, then allowing it to cool in still air. The exact temperature determines the amount of hardness removed, and depends on both the specific composition of the alloy and on the desired properties in the finished product. For instance, very hard tools are often tempered at low temperatures, while springs are tempered at much higher temperatures.

Heat treatment process for lowering yield ratio of ultra-high-strength marine steel

Owner:SUQIAN NANGANG JINXIN STEEL ROLLING CO LTD

Curved glass flexible shaft bending tempering forming method

Owner:LUOYANG LANDGLASS TECH CO LTD

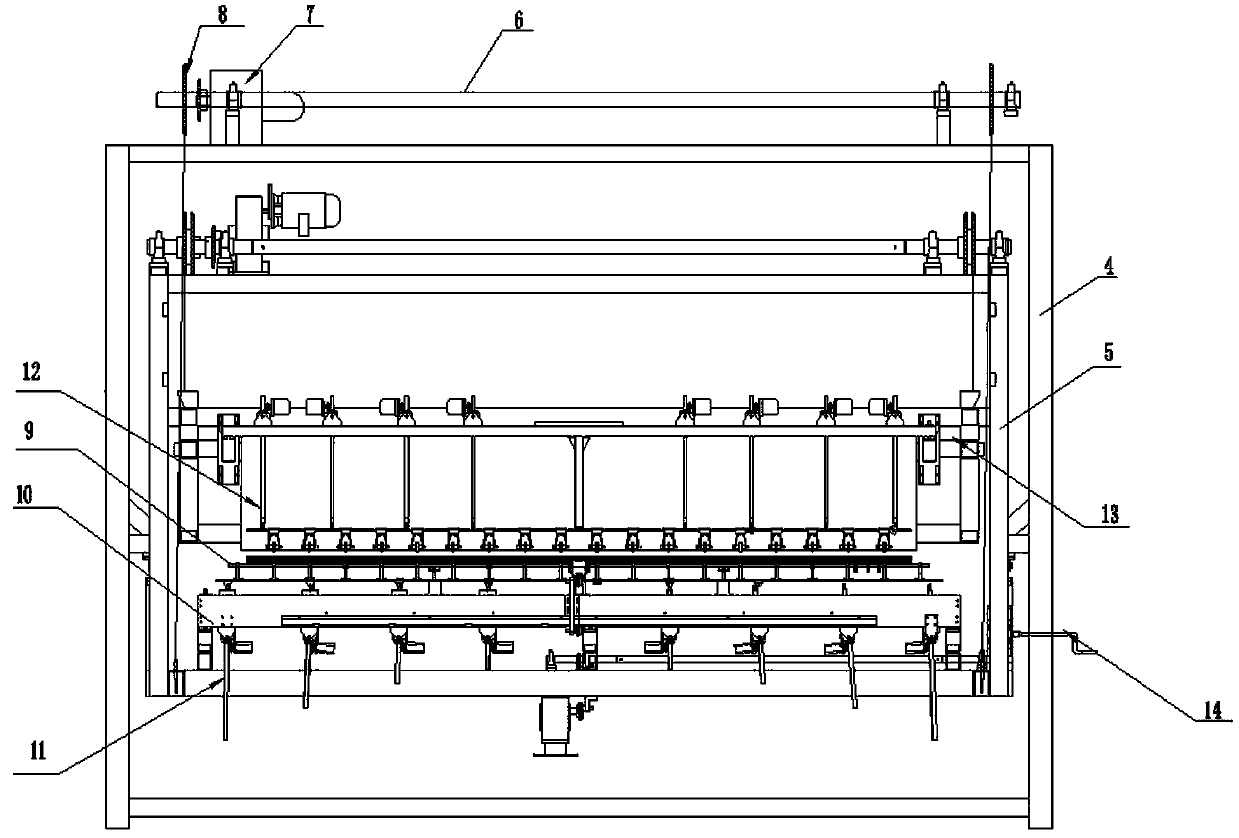

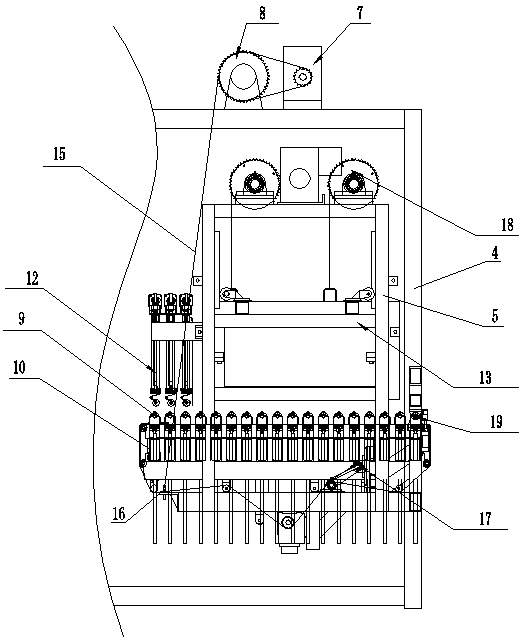

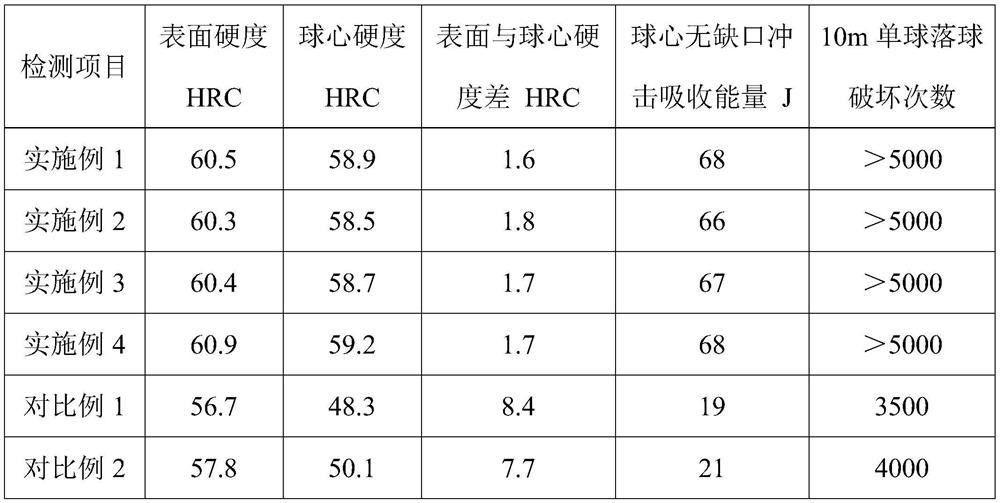

Large-diameter medium-carbon low-alloy wear-resistant steel ball and preparation method thereof

Owner:ANHUI RUITAI NEW MATERIALS TECH

High-stability die steel surface combined dual-treatment technology

Owner:苏州奥维精密机械有限公司

S460QLO thick plates used for offshore weldable structures and production method

Owner:NANJING IRON & STEEL CO LTD

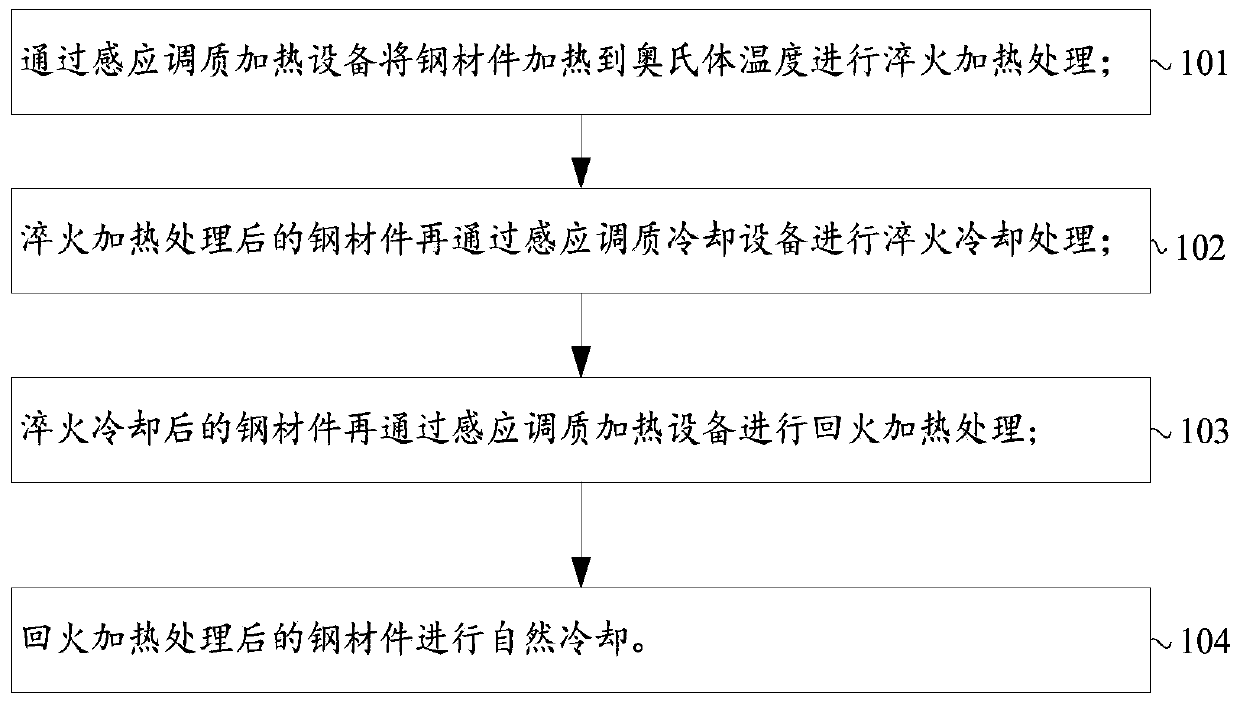

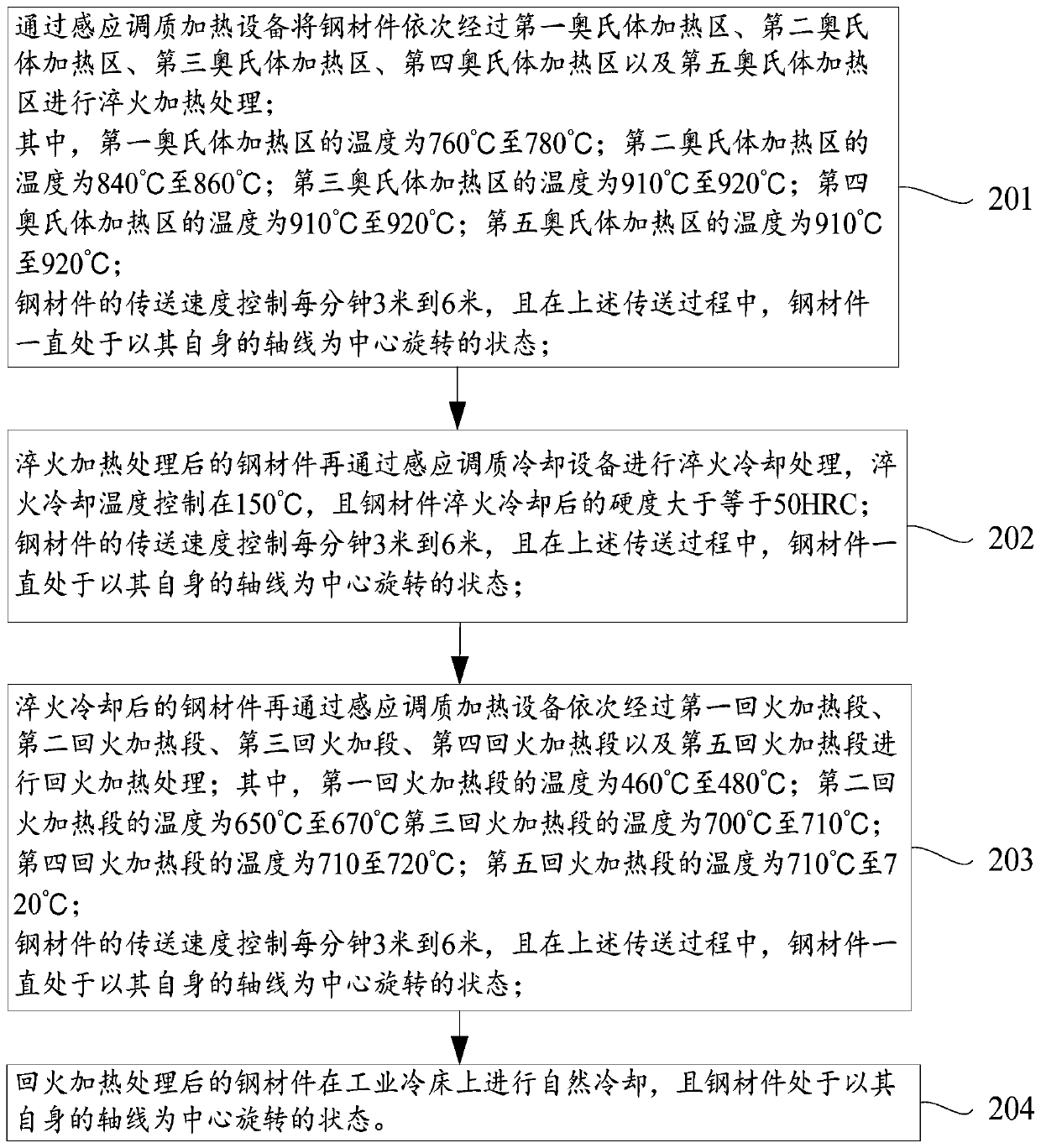

GCr15 heat treatment process

InactiveCN111118260AHardness dispersion is smallReduce distortionIncreasing energy efficiencyHeat treatment process controlTemperature controlTempering

Owner:江苏南钢通恒特材科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap