Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

17 results about "Rolling mill" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

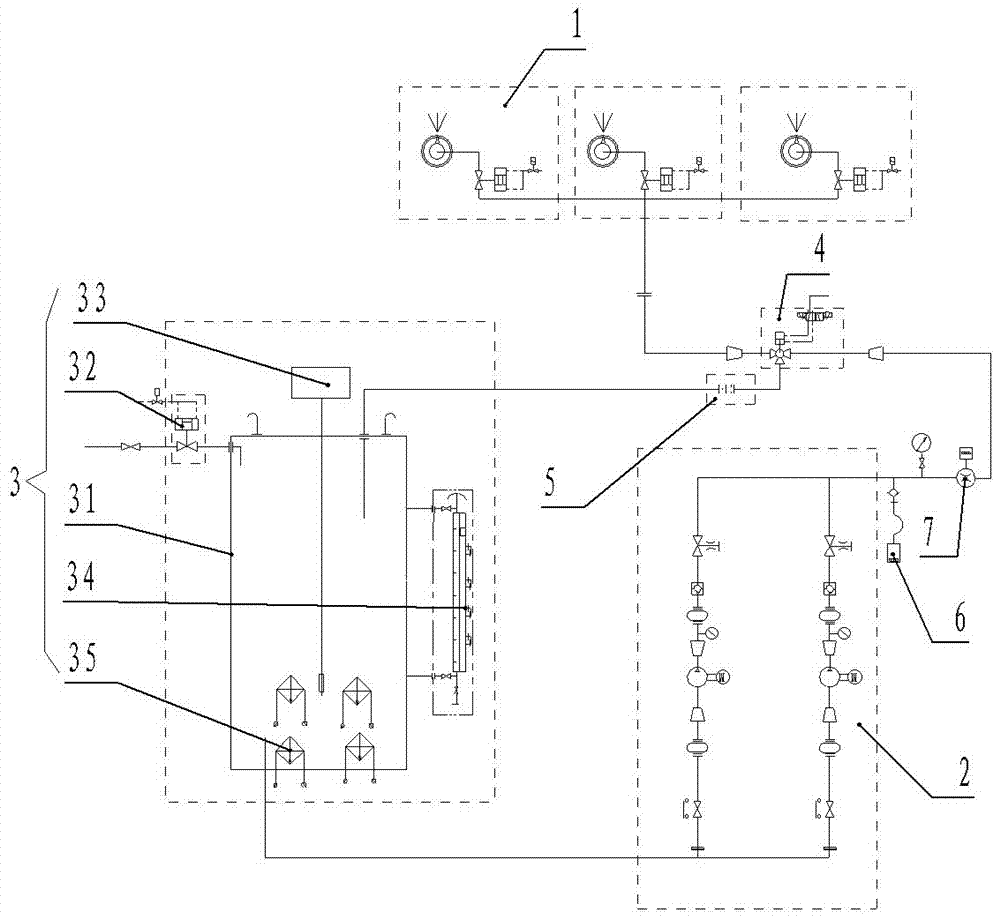

Method for controlling temperature of crude oil for emulsion of rolling mill and control device

InactiveCN101575044AUniform temperatureImprove the heating effectTank wagonsTemperature controlEmulsion

The invention relates to a method for controlling temperature of crude oil for emulsion of a rolling mill and a control device. The method comprises the steps of: arranging a heating device on the outer part of a crude oil tank; adopting a circulation heating pump arranged at the tail of the crude oil tank to transfer crude oil to a heat exchanger for heat exchange; simultaneously adopting a temperature controller on the crude oil tank to control the on and off of the heating device; and transferring crude oil to the top of the crude oil tank for outer circulation heating so as to keep the temperature of crude oil inside the crude oil tank at a preset value. A control device comprises the heating device consisting of the circulation heating pump and the heat exchanger, the temperature controller, a steam control valve, a steam trap and pipelines connecting the components, wherein the circulation heating pump is arranged at the tail of the crude oil tank, the heat exchanger is arranged on the side of the crude oil tank and the temperature controller is arranged on the crude oil tank. The invention has the advantages of good heating effect, equal crude oil temperature, high temperature-control property and precision, simple and convenient operation process, non-steam entering the crude oil and non-impact on crude oil quality.

Owner:BAOSTEEL ENG & TECH GRP

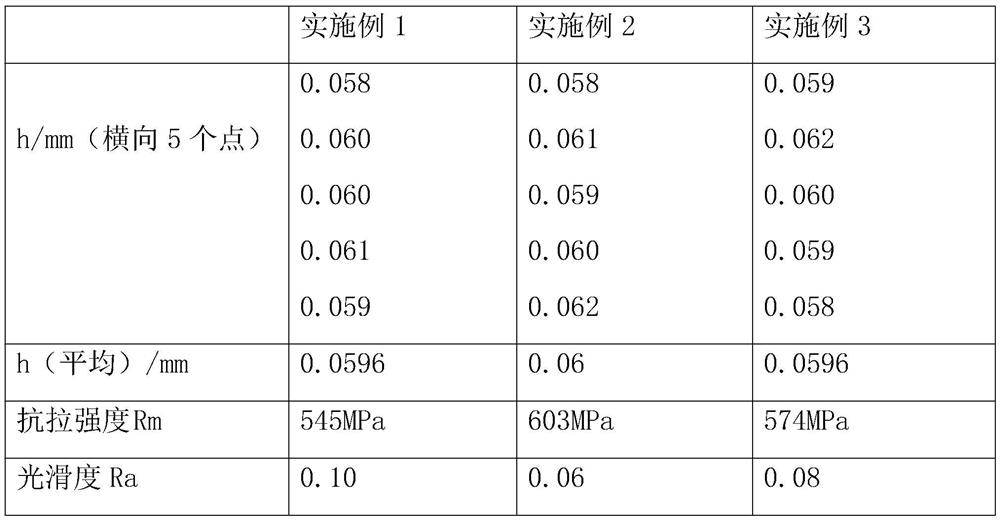

Control method for cold-rolled product size precision

ActiveCN107442576AHigh dimensional accuracyHigh yieldMetal rolling stand detailsRoll mill control devicesRegression analysisContinuous annealing

The invention relates to the field of cold rolling, in particular to a control method for the cold-rolled product size precision. The control method comprises the steps that regression analysis is conducted on relevant parameters of the raw material texture, an acid pickling and cold rolling technology of an acid pickling and cold rolling unit and a continuous annealing technology of a continuous annealing unit by adopting a five-stand six-roll UCM rolling mill, and a final reasonable regression equation and main influence factors are determined through multiple times of analysis and selection. According to the control method, the improving direction is provided for size precision control of various cold-rolled varieties, main points of new variety size precision control and size precision control of all unit products obtained after technology optimization are adjusted, and the good guiding significance is achieved. In addition, reference is provided for galvanized product size precision control according to analysis on the factors influencing the product size precision.

Owner:BENGANG STEEL PLATES

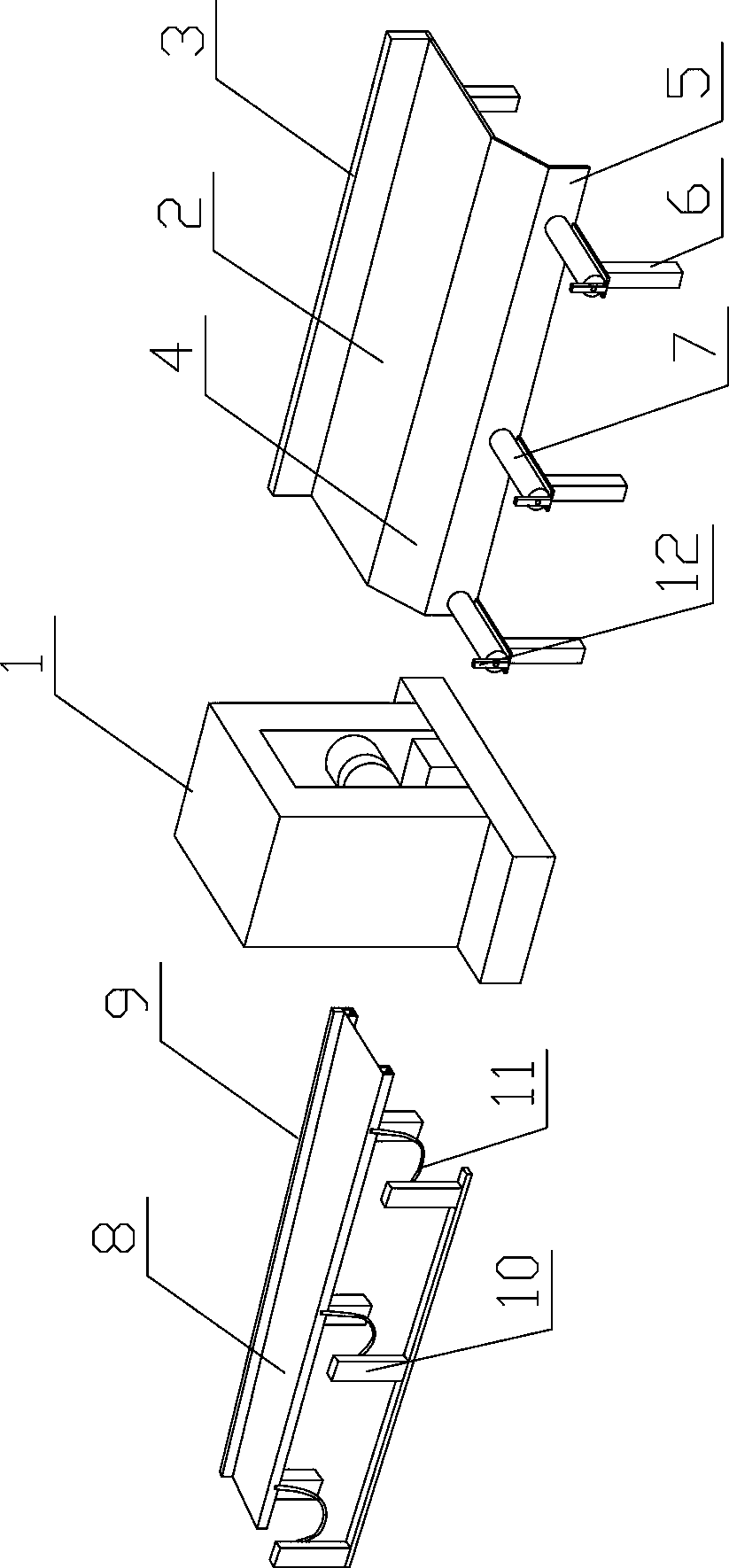

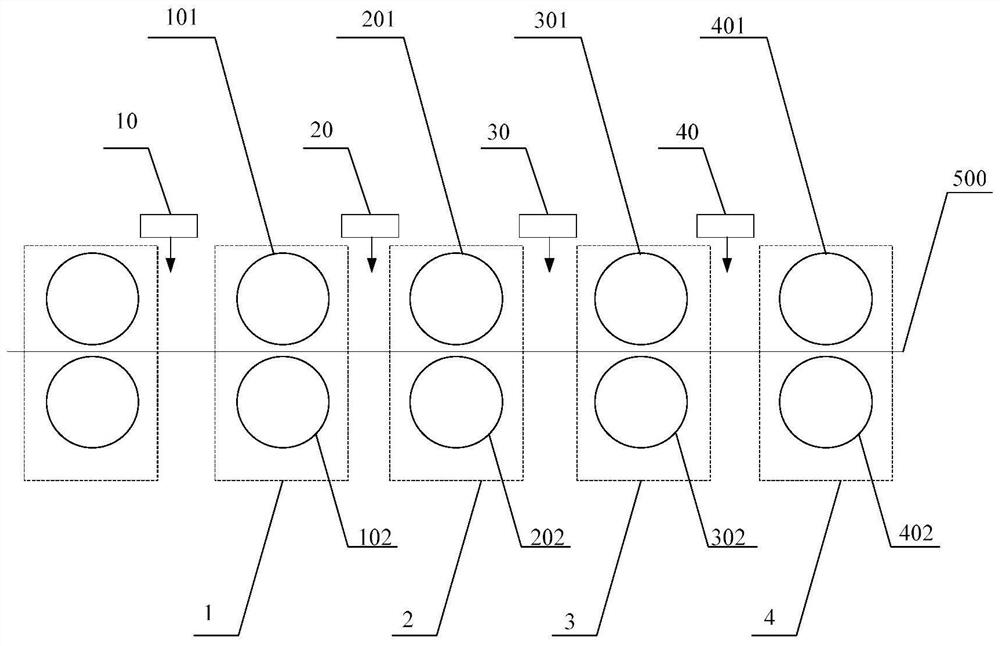

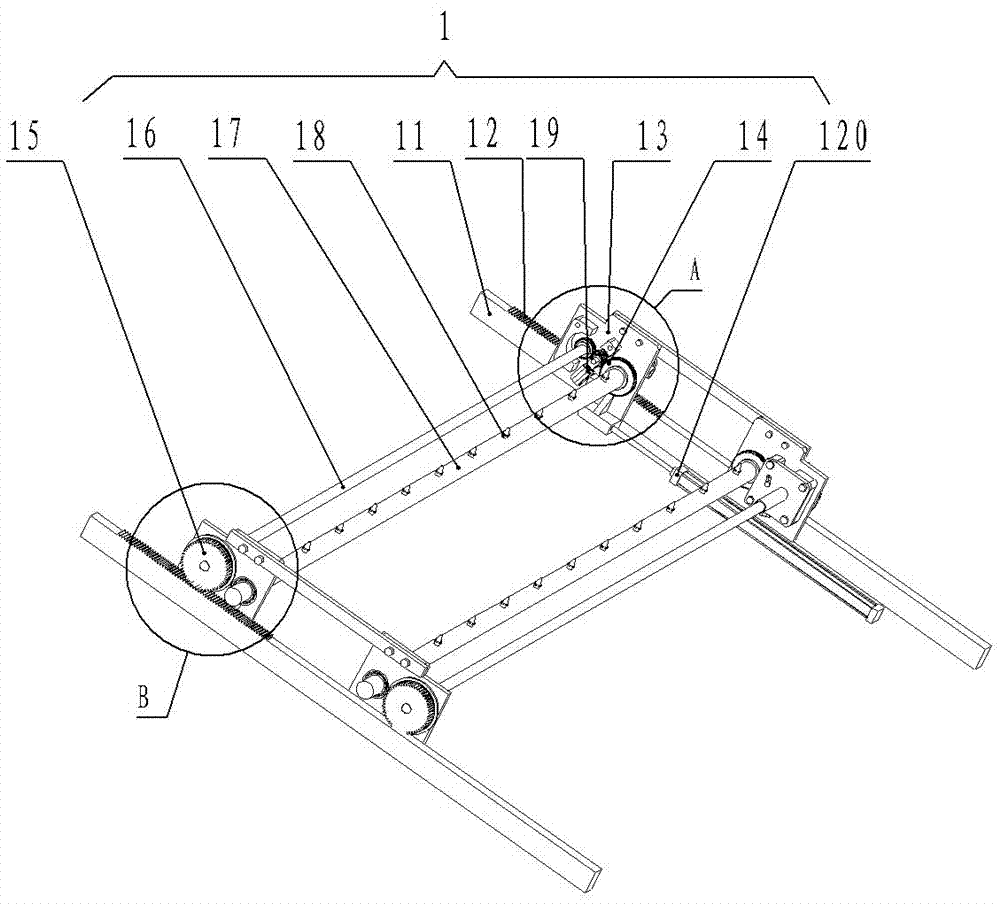

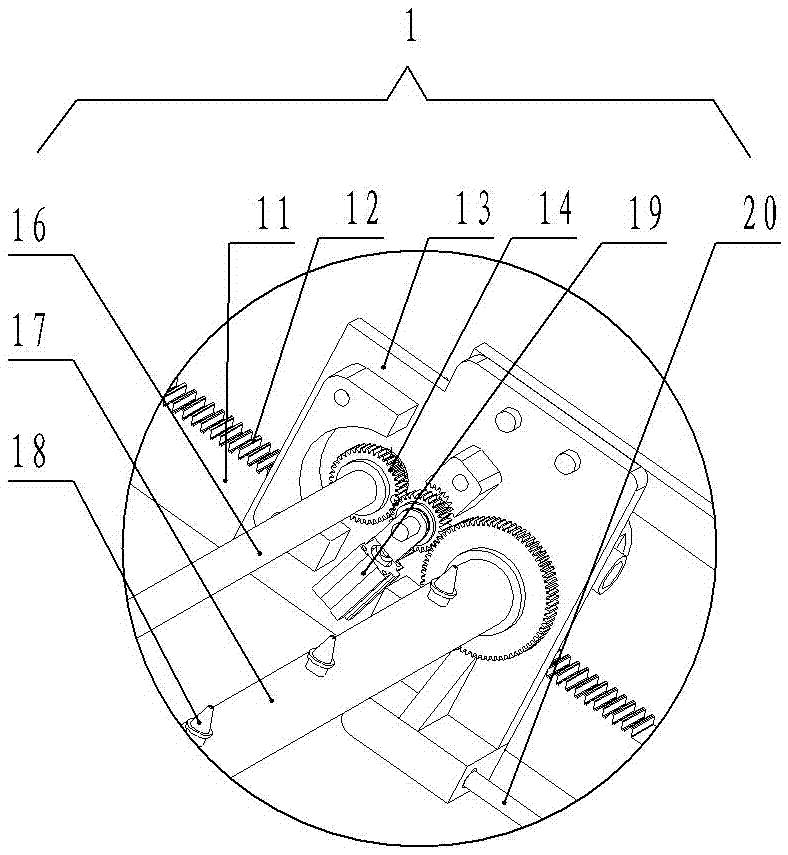

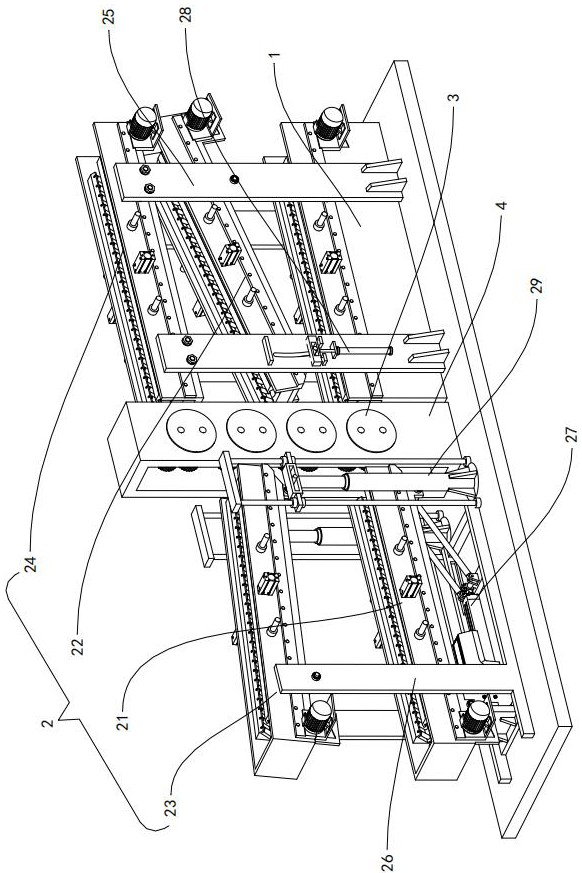

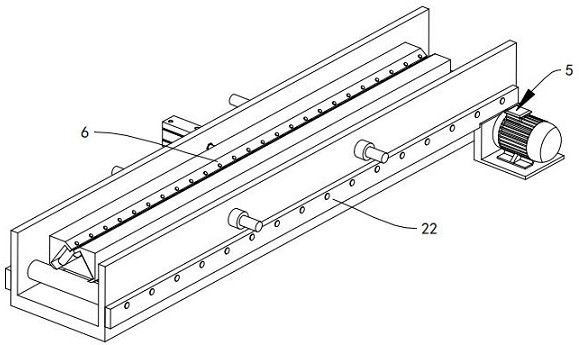

Processing equipment and manufacturing method of hollow train shaft

ActiveCN104646576ASave materialIncrease productivityMetal-working feeding devicesMetal rollingProcess equipmentStructural engineering

The invention relates to processing equipment and a manufacturing method of a hollow train shaft. The processing equipment of the hollow train shaft comprises a feeding system, a pushing device, a cross wedge rolling mill, a core rod driving and reversing mechanism and a sensor. The feeding system, the pushing device, the cross wedge rolling mill and the core rod driving and reversing mechanism are arranged in a straight line shape; the pushing device is mainly formed by an air source, an air cylinder and a feedbed; the core rod driving and reversing mechanism is mainly formed by an oil cylinder, a core rod and a core rod rotating device; the sensor is an optoelectronic switch, or a proximity switch, or a magnetic switch. According to the processing equipment and the manufacturing method of the hollow train shaft, the metal streamline of the hollow train shaft keeps smooth and continuous, and the streamline arrangement conforms to the longitudinal cross-section shape of the hollow train shaft-approximate to the final product shape, so that the materials are saved, and the production efficiency is greatly improved.

Owner:SHANDONG TAIJIN PRECISION FORGING CO LTD

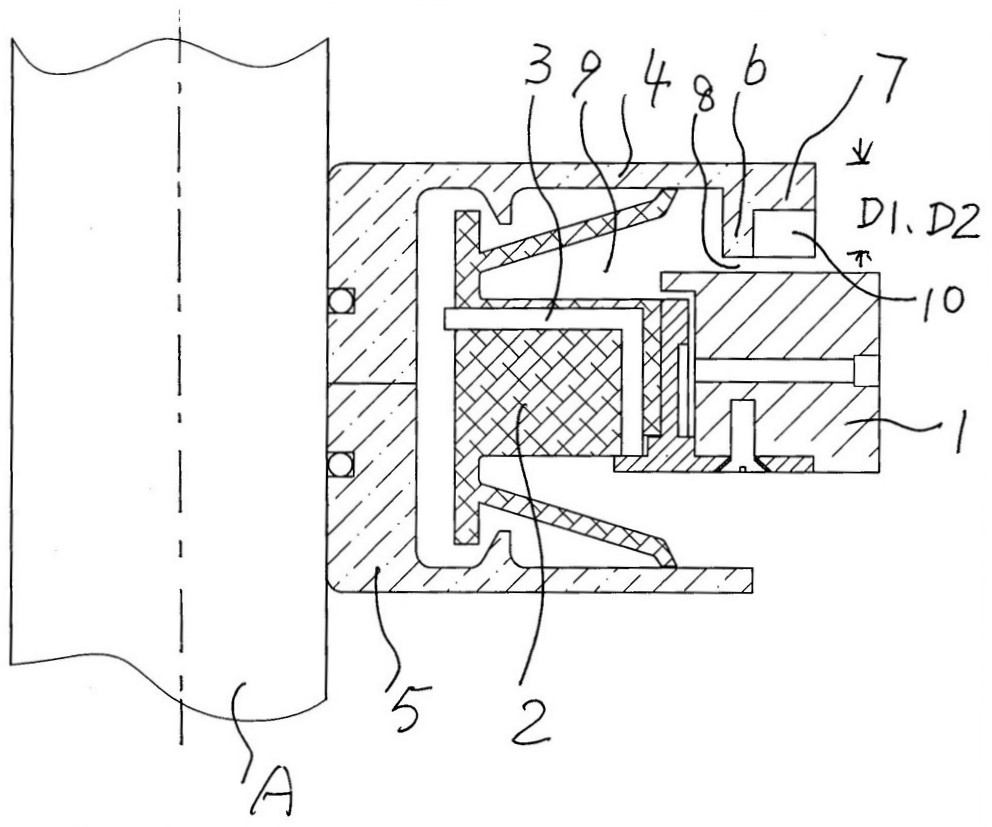

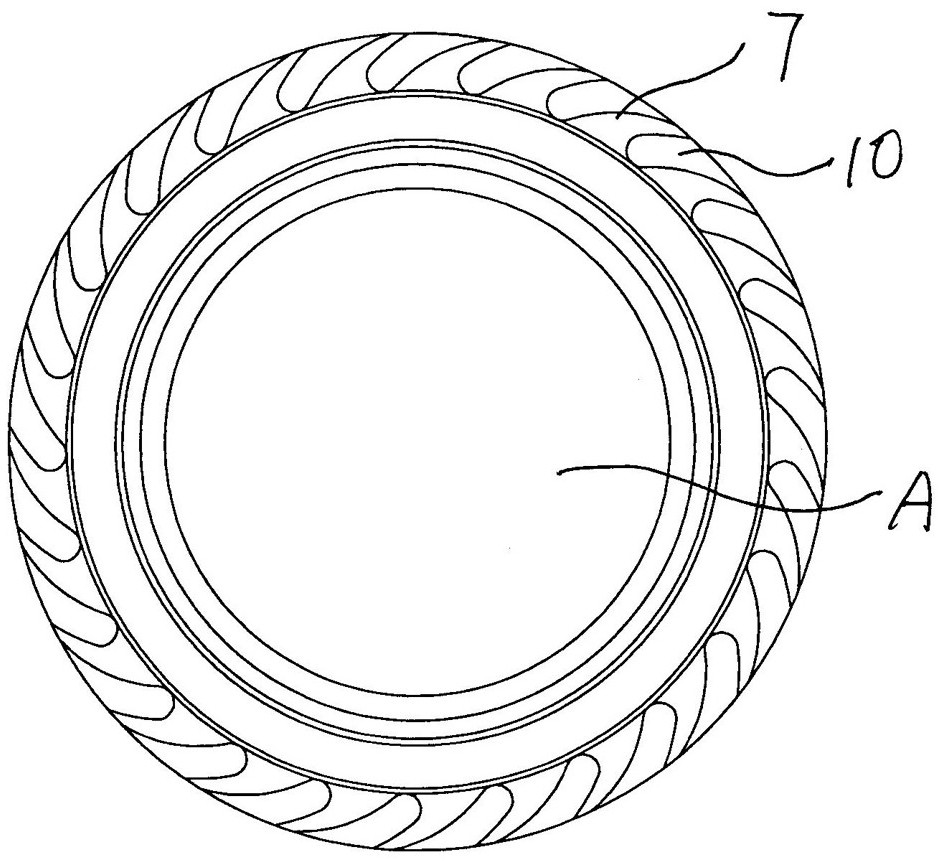

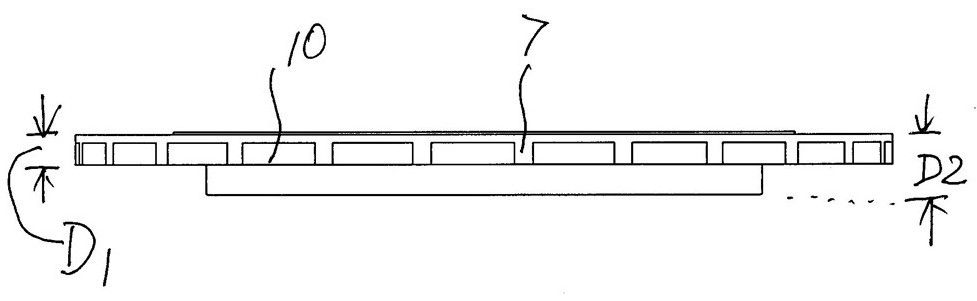

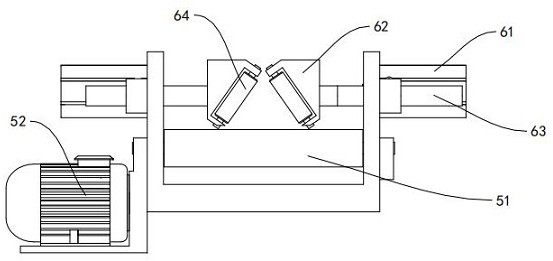

Cold rolling mill with feeding device and discharging device

InactiveCN109719127AEasy to placeSimple structureMetal rolling arrangementsBiochemical engineeringUltimate tensile strength

Owner:黄石市龙飞精密金属加工有限公司

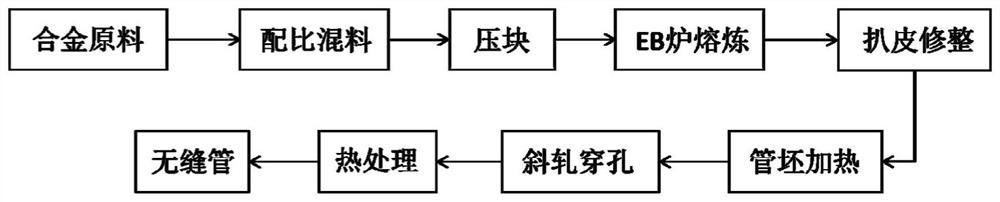

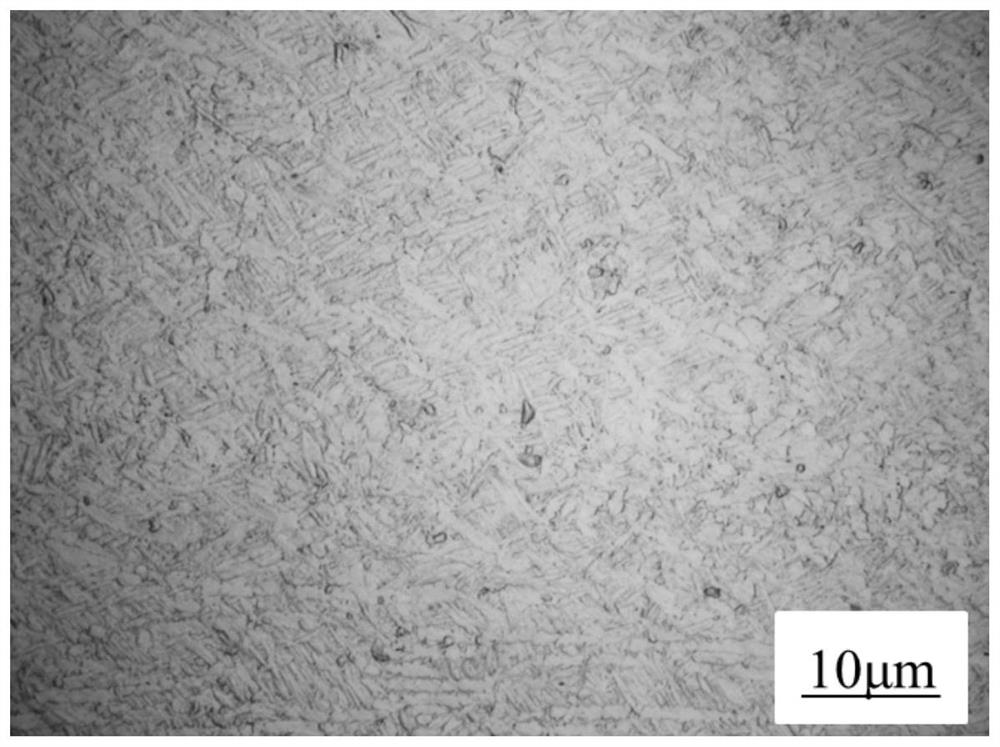

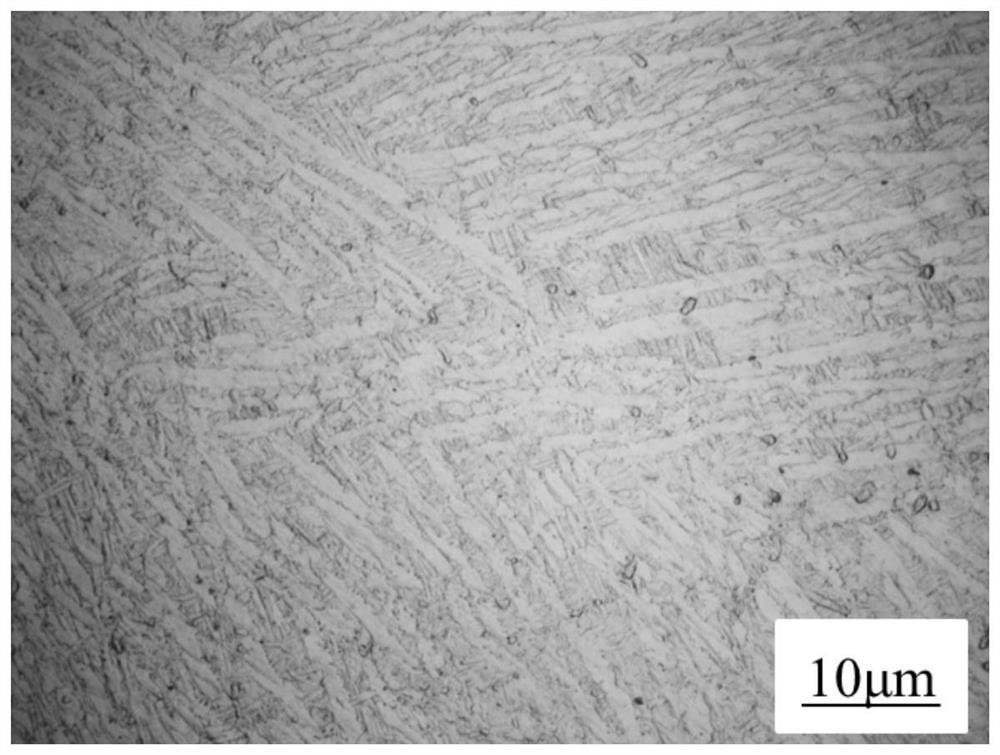

Short-process preparation method of Ti-Al-V-Fe alloy seamless tube

Owner:KUNMING UNIV OF SCI & TECH

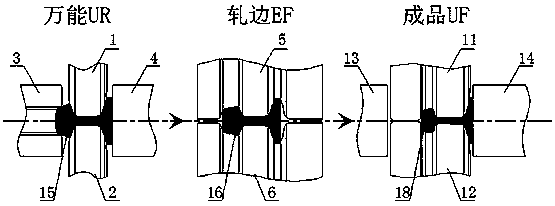

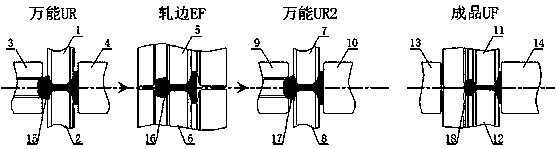

Steel rail production process with limited participation of universal mill

ActiveCN111112327ASolve sizeSolve the problem of high and low pointsMetal rolling stand detailsRoll mill control devicesMaterials scienceIndustrial engineering

Owner:HANDAN IRON & STEEL GROUP +1

Device and method for rapid replacement of lower connecting shaft of horizontal rolling mill

ActiveCN104891323AQuick changeEfficient replacementMetal working apparatusLoad-engaging elementsEngineeringRolling mill

The invention provides a device and method for rapid replacement of a lower connecting shaft of a horizontal rolling mill. The device comprises suspension mechanisms and driving mechanisms, wherein the suspension mechanisms are used for being movably arranged on an upper connecting shaft of the horizontal rolling mill, and the driving mechanisms are arranged on the suspension mechanisms and are used for driving the suspension mechanisms to move on the upper connecting shaft of the horizontal rolling mill. The analysis result shows that the lower connecting shaft can be replaced rapidly and efficiently, and the purposes that the operation difficulty is reduced, and the labor efficiency is improved are achieved.

Owner:LAIWU IRON & STEEL GRP

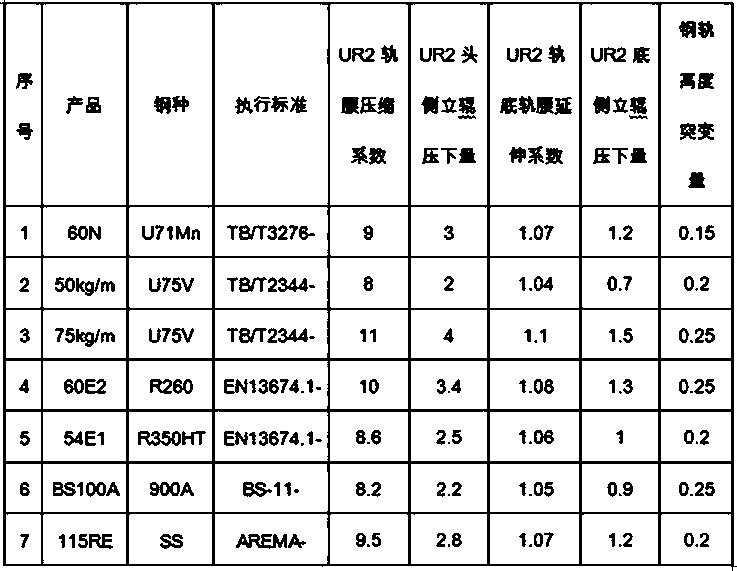

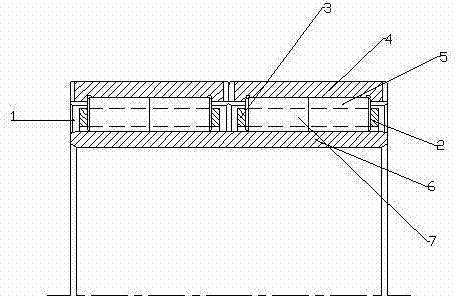

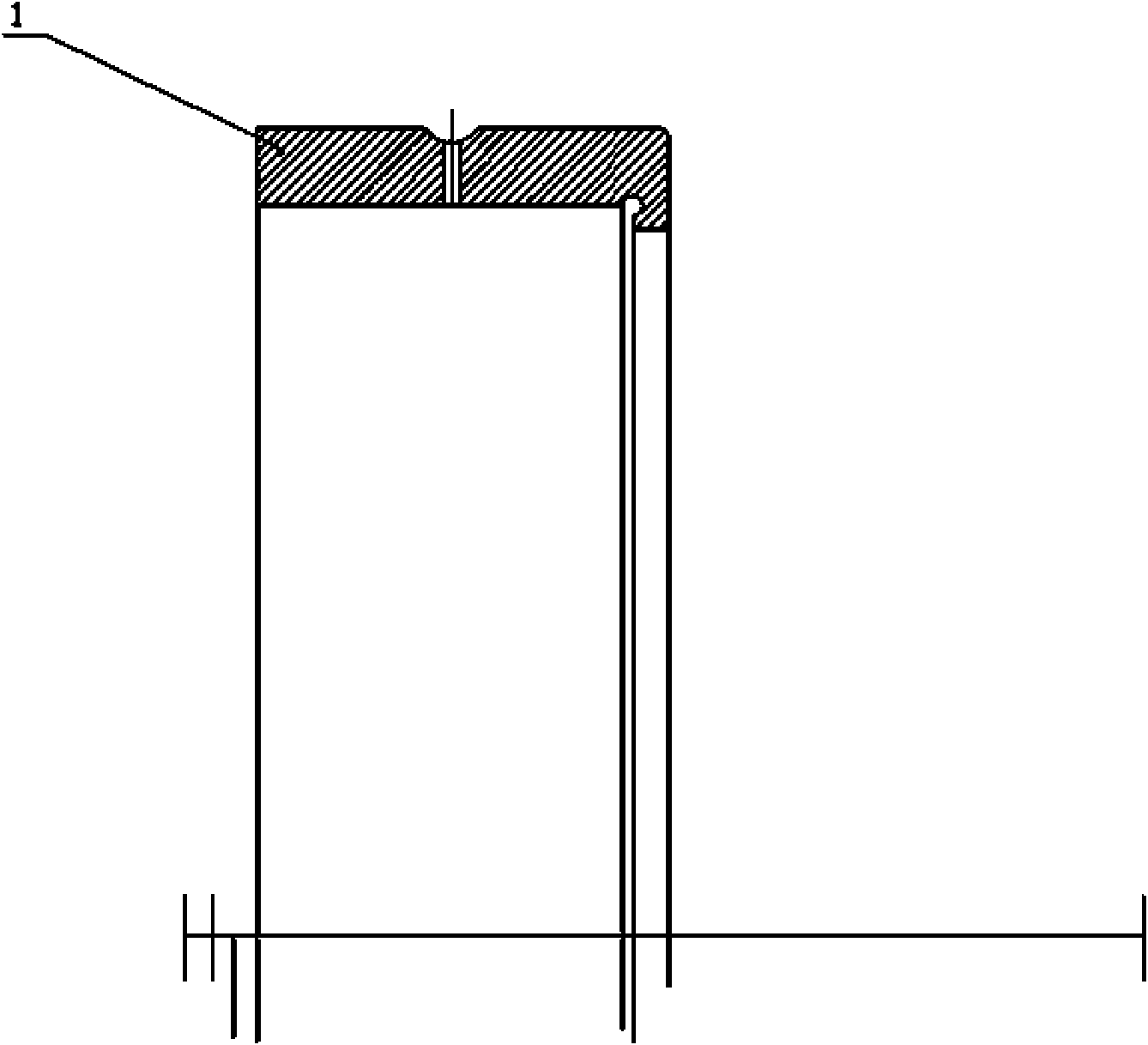

Four-row cylindrical roller bearing special for steel rolling mill

InactiveCN102454697AHigh strengthDoes not reduce lubrication functionRoller bearingsBearing componentsEngineeringRolling mill

Owner:WAFANGDIAN ZHENGDA METALLURGICAL MILL BEARING

Rolling process of 2 mm corrosion-resistant hot-rolled coiled plate

ActiveCN112474797AAccurate timingEasy to adjustMeasuring devicesMetal rolling arrangementsCorrosion resistantMetal

Owner:福建三宝特钢有限公司

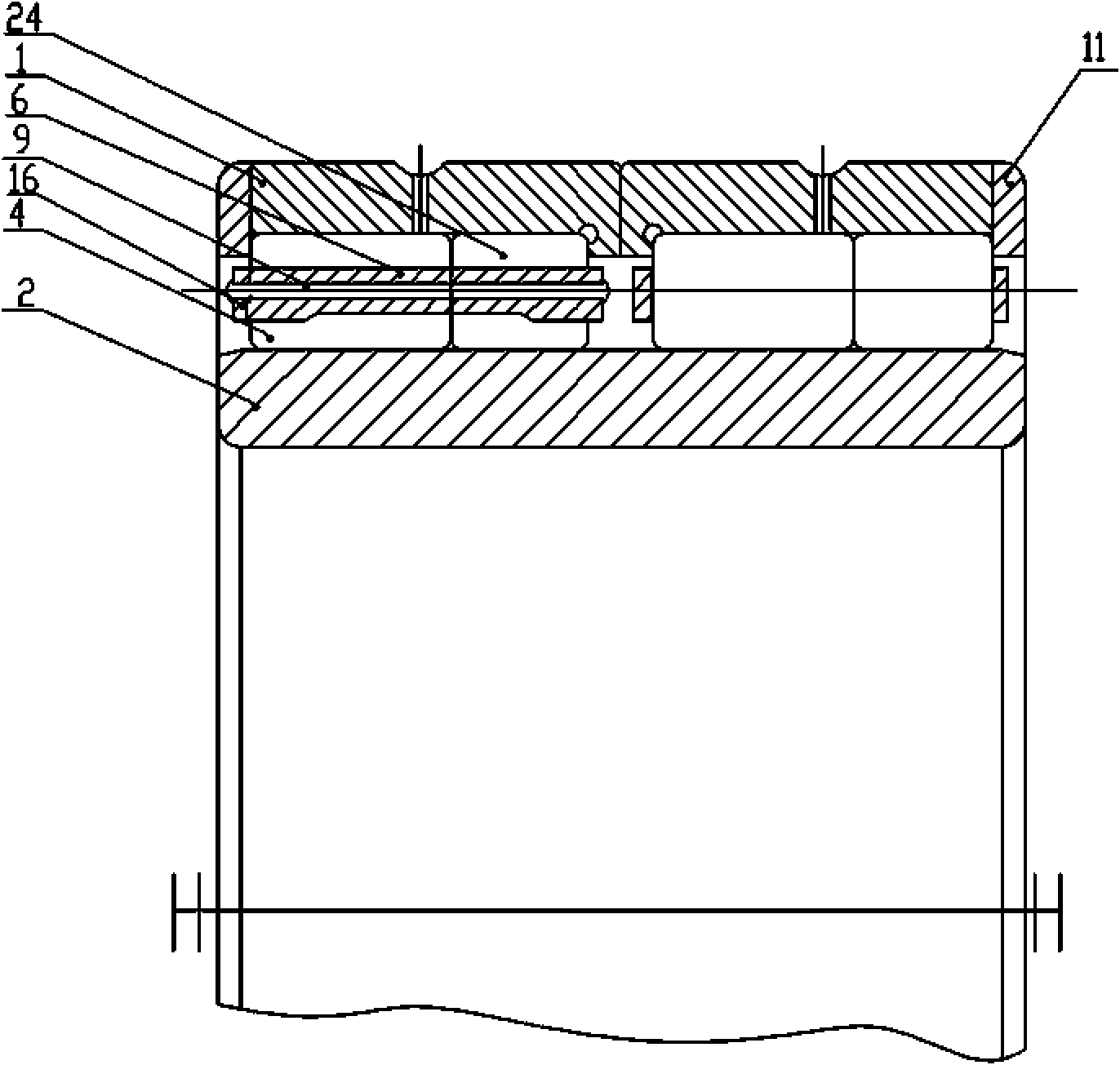

Load-bias free four row roller bearing for rolling mill

InactiveCN101586609AIncrease the lengthIncrease contact areaRoller bearingsBearing componentsStrip millEngineering

Owner:瓦房店第一轧机轴承制造有限公司

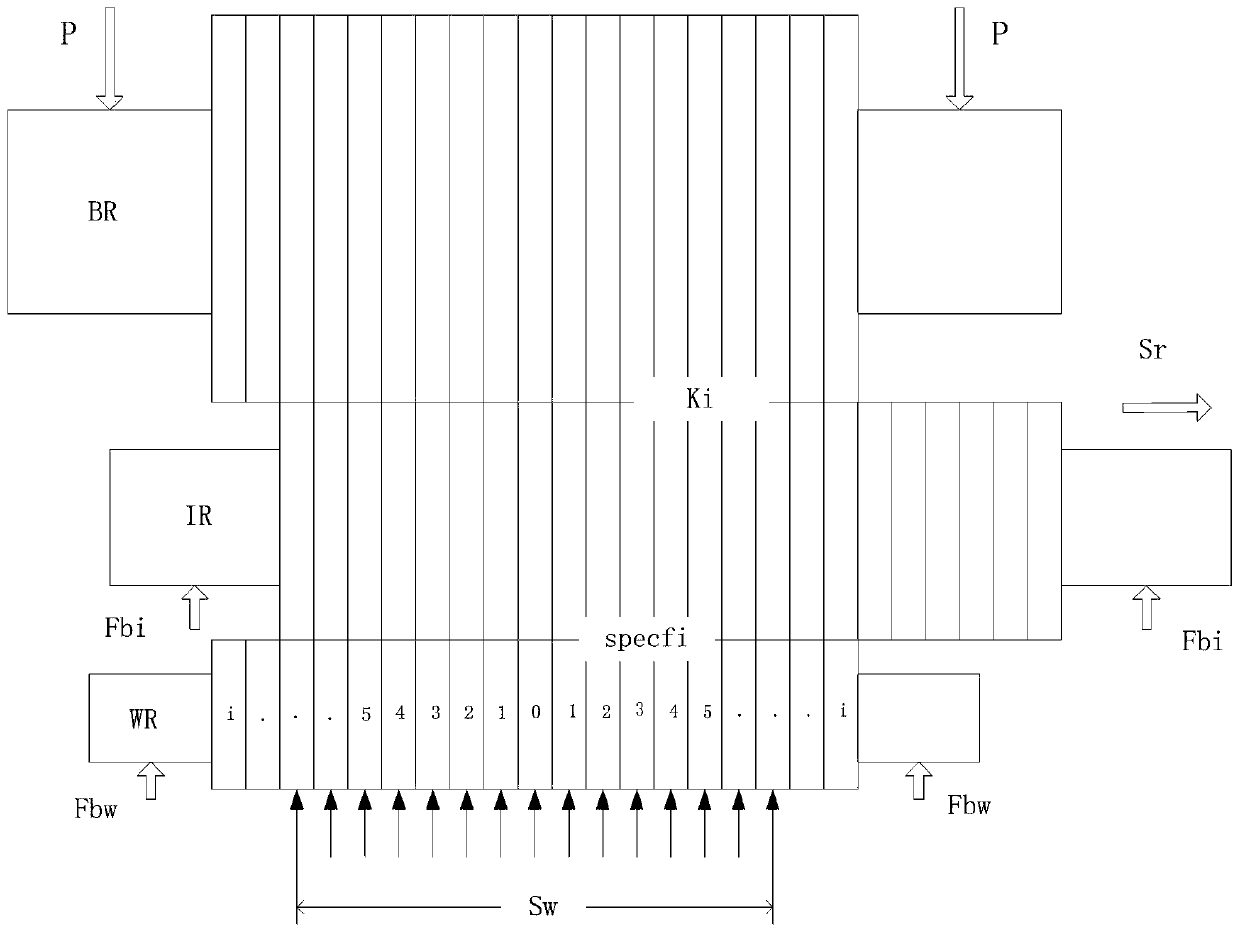

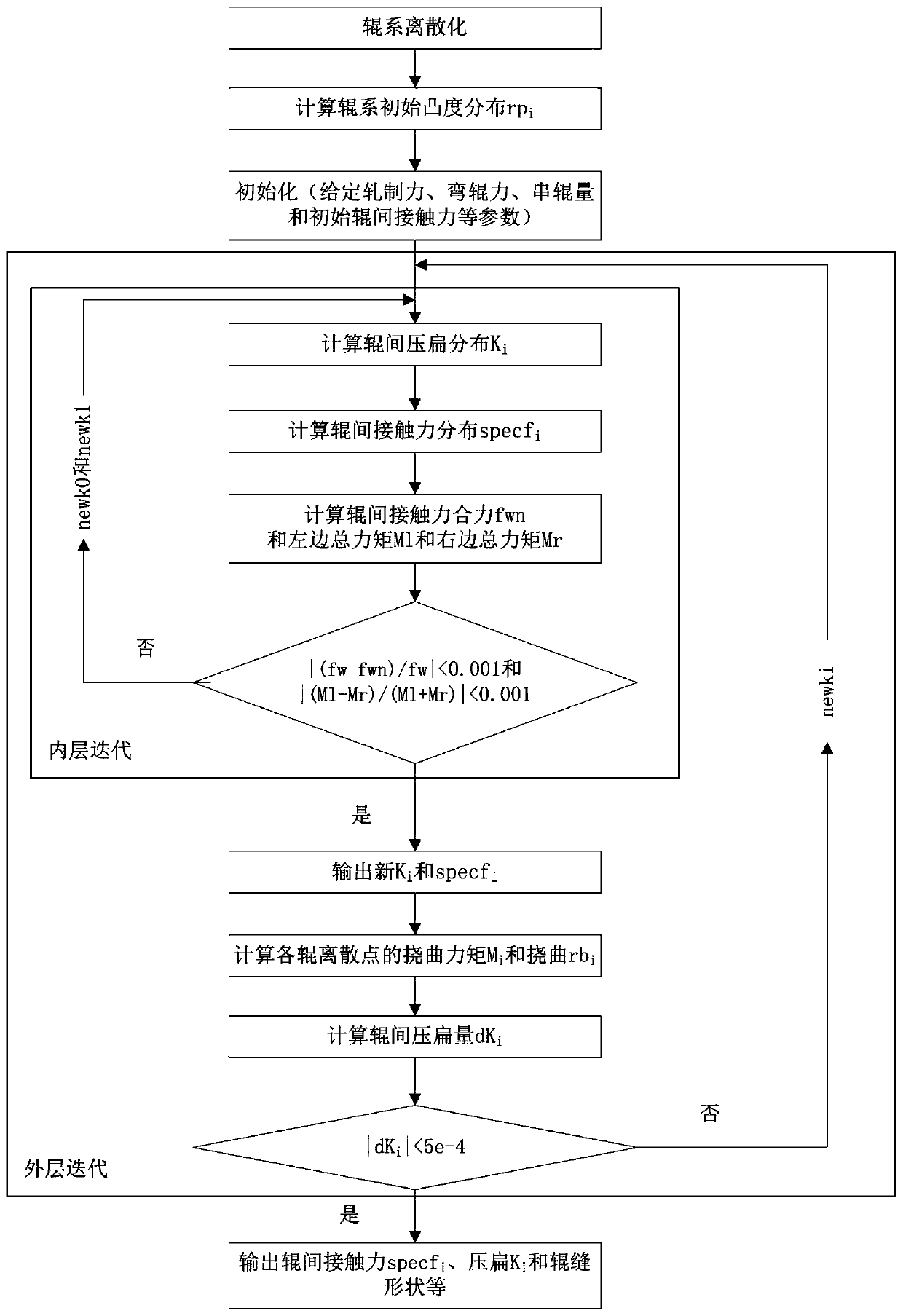

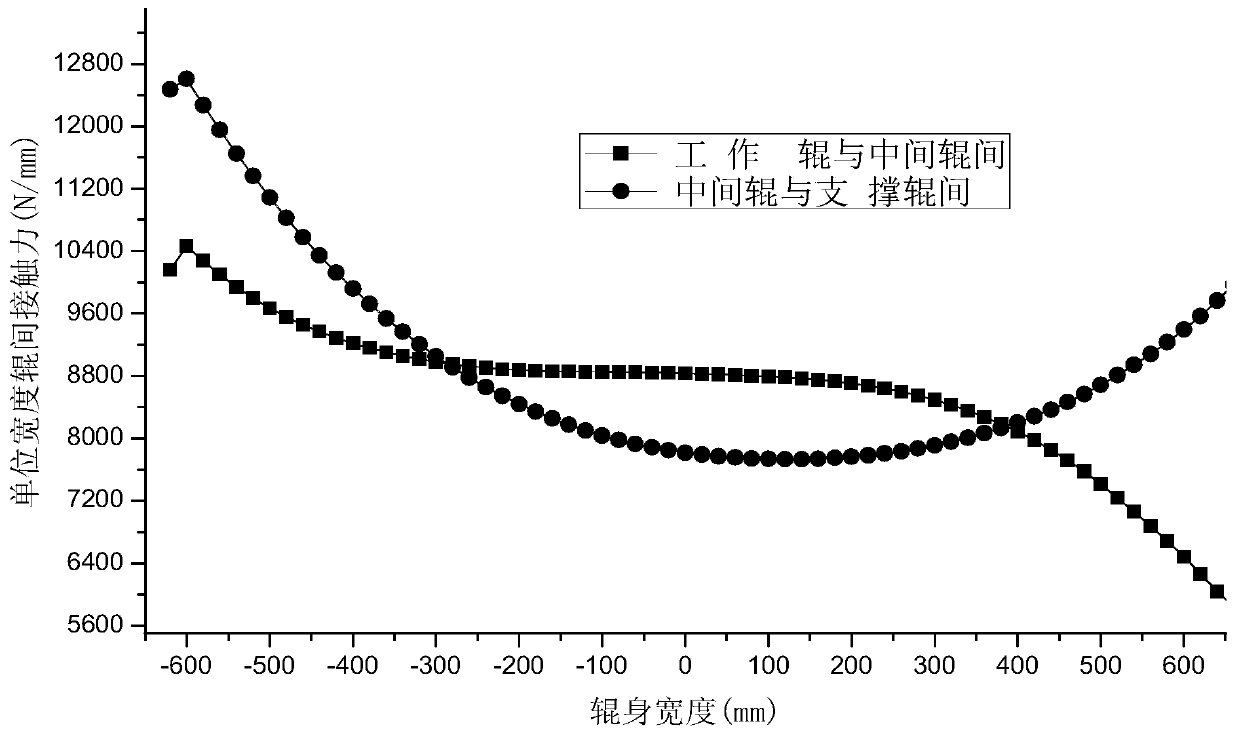

Method for calculating elastic deformation of roll syste of plate-strip rolling mill

PendingCN111310099AThe principle is simpleComplex mathematical operationsClassical mechanicsMechanics

Owner:WISDRI ENG & RES INC LTD

Spring rolling mill with breaking prior to milling

The invention discloses a spring rolling mill with breaking prior to milling, which comprises a mill body casing, a decelerator, a bearing pedestal, a high wear resistant sleeve loop, a cooling device, a spring, a drive wheel, a bearing, a driving shaft, a mill body end cover, a kickoff device, a pressurization bolt, a material-smashing device, a feed inlet and a discharging pipeline; the decelerator and the driving shaft are connected with the material-smashing device, the high wear resistant sleeve loop is connected to the inner wall of the mill body casing, the bearing pedestal is connected to the spring, and the spring is connected to the pressurization bolt.

Owner:安长海

Single-stand reversible rolling process for ultrathin wide red copper belt

InactiveCN113426831AReduce thicknessHigh tensile strengthFurnace typesMetal rolling arrangementsLiquid stateCopper

Owner:江阴艾力特机械制造有限公司

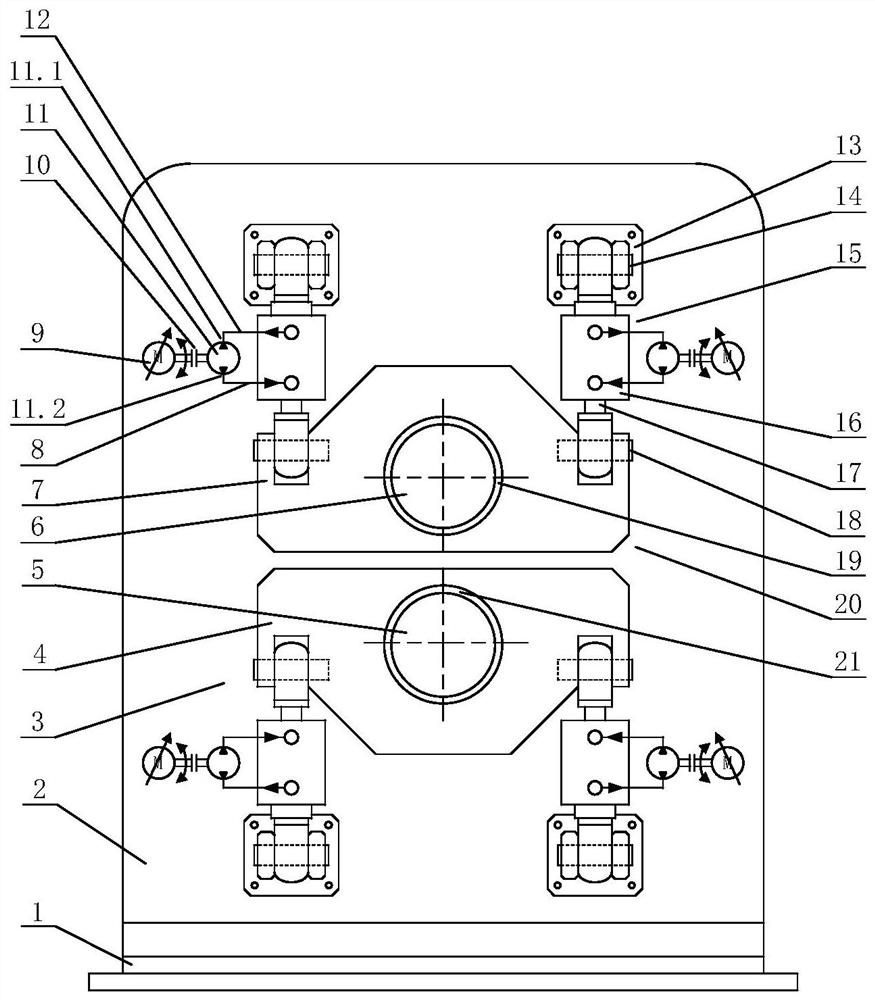

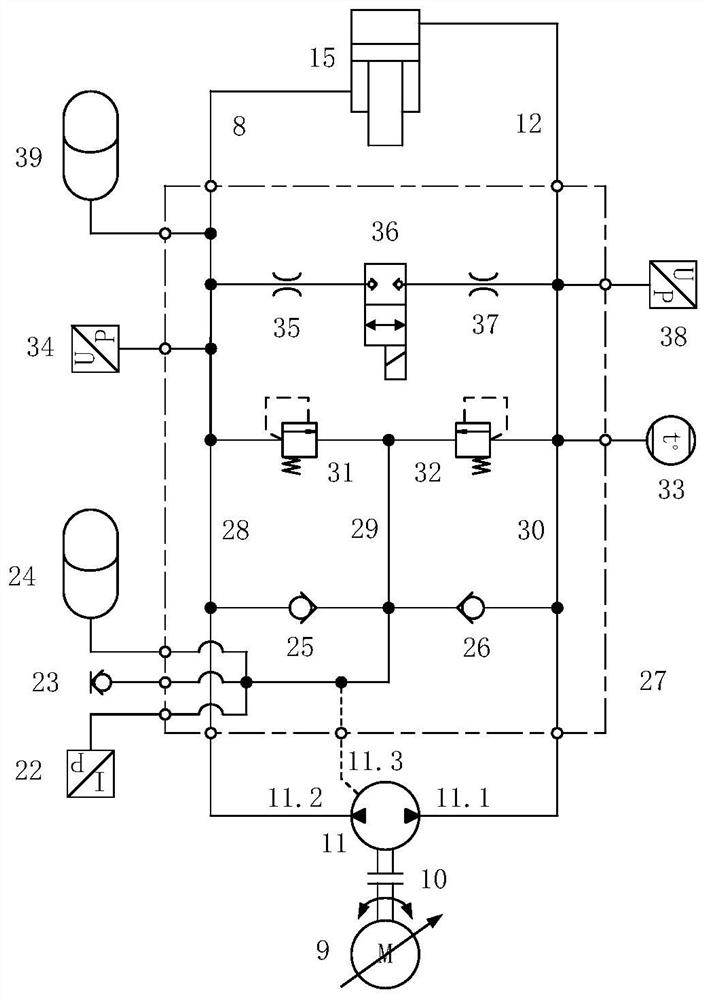

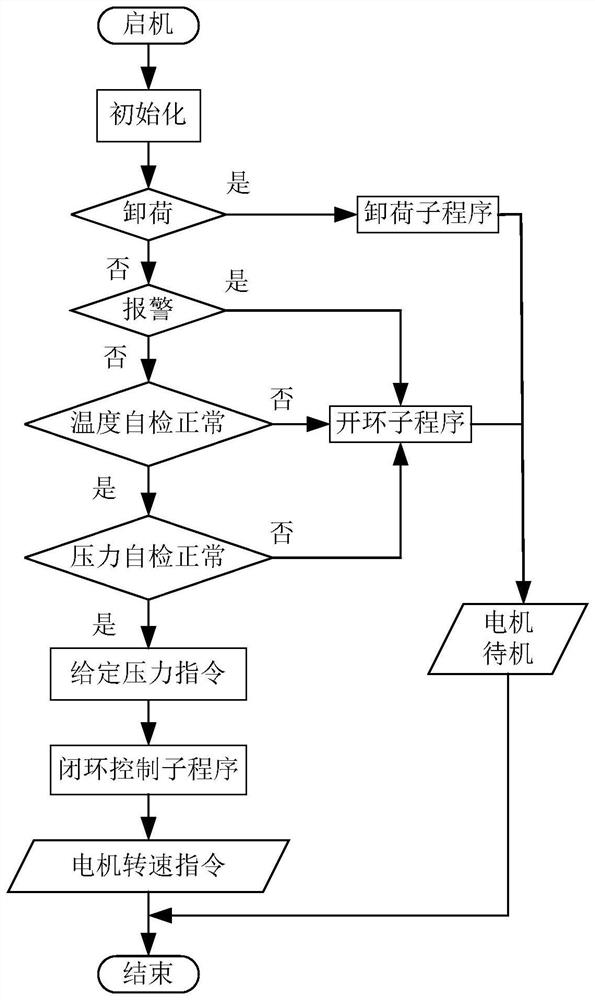

Lithium battery pole piece rolling mill pump control roll bending hydraulic system and roll bending device

PendingCN112253553ATroubleshootingAvoid throttling lossesFluid-pressure actuator safetyRoll force/gap control deviceEngineeringPole piece

Owner:秦皇岛海德科技有限公司

Online flushing device for hot rolling mill

PendingCN107020268AShort cleaning timeImprove cleaning efficiencyRolling equipment maintainenceCleaning using liquidsGear wheelRolling mill

Owner:GUANGXI LIUZHOU YINHAI ALUMINUM IND +1

High-speed steel bar cold-rolling mill

Owner:邯郸一三高研科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap