Load-bias free four row roller bearing for rolling mill

A cylindrical roller bearing and cylindrical roller technology, applied in the direction of roller bearings, bearing components, shafts and bearings, can solve the problems of bearing fatigue damage, short life of spherical roller bearings, and high maintenance costs, and achieve radial The effect of increasing the load bearing capacity, increasing the contact area of the raceway, and improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation manner of the present invention will be further described below in conjunction with the accompanying drawings.

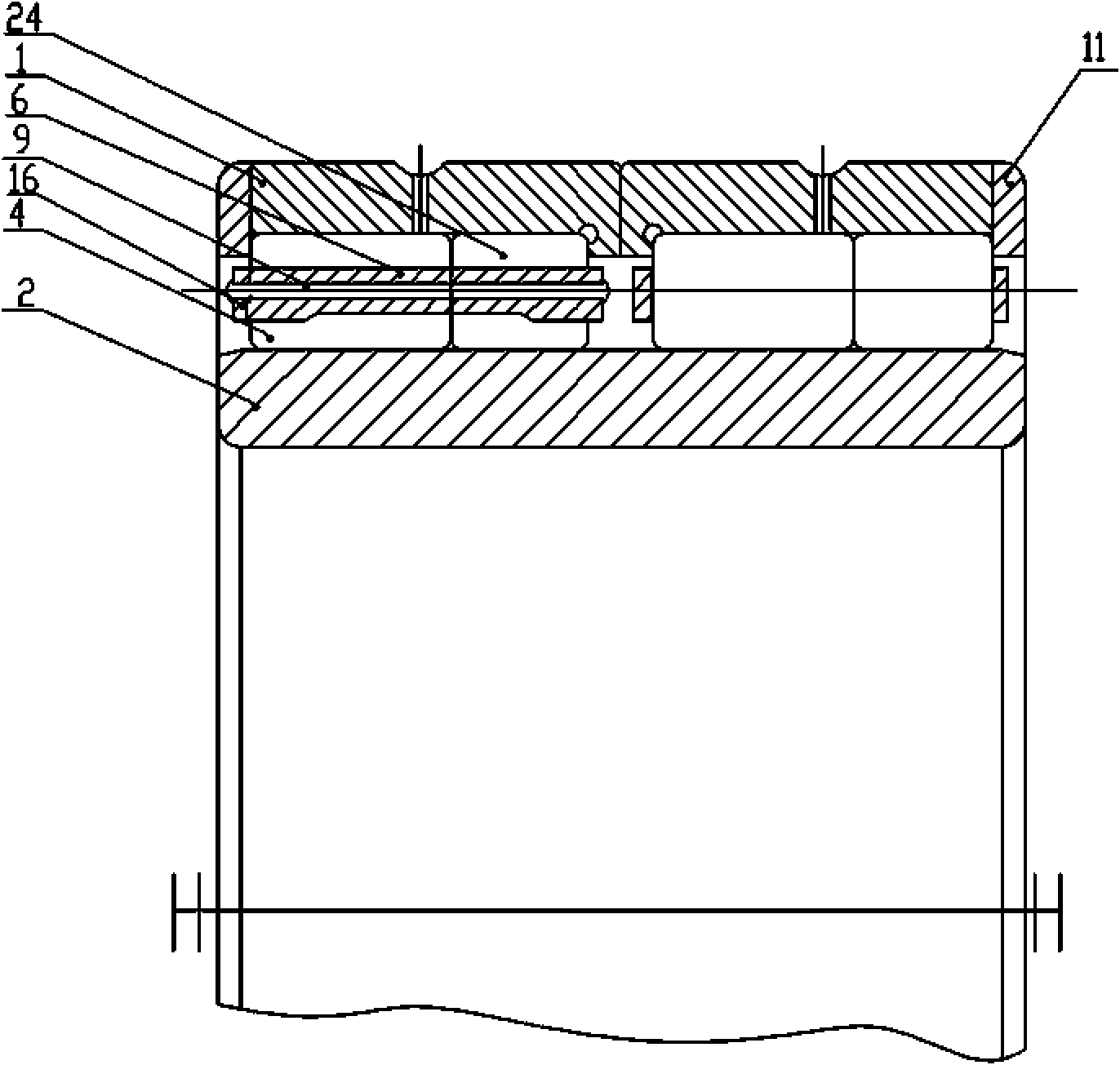

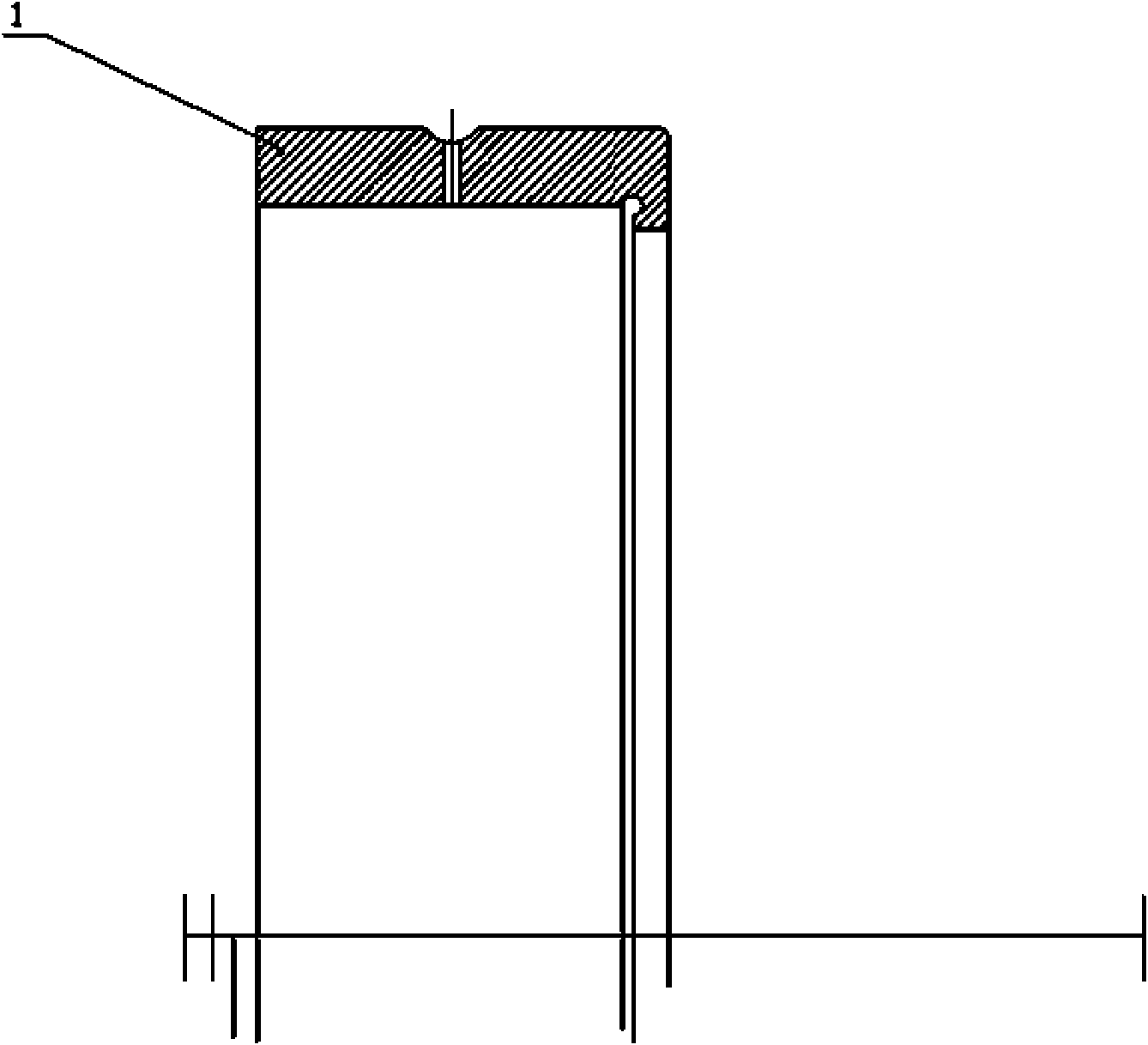

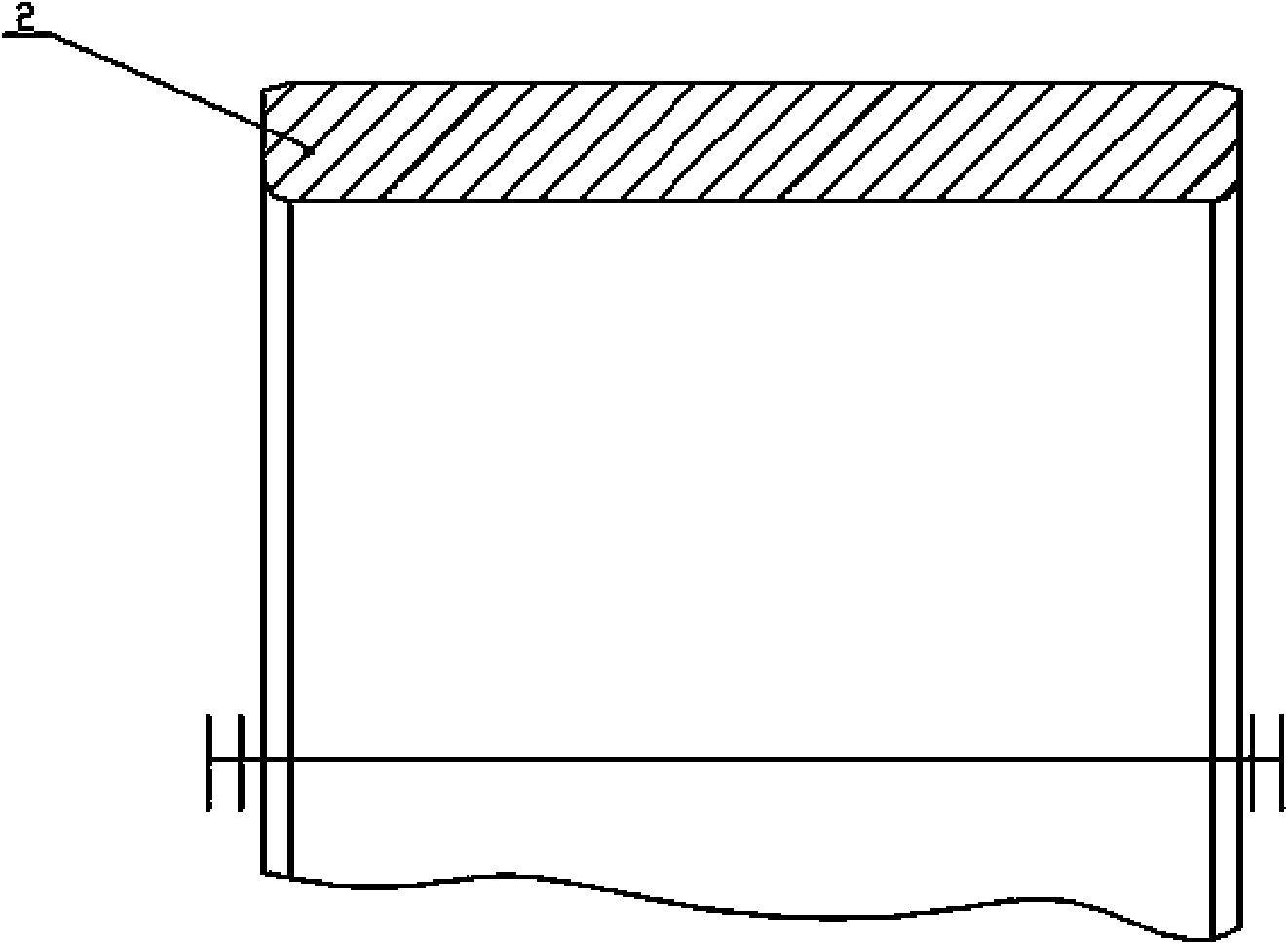

[0012] Such as Figure 1~4 As shown, a four-row cylindrical roller bearing for rolling mills with unbiased loads is provided with double outer rings 1 and inner rings 2 , and edge retaining rings 11 are provided on both ends of the outer ring 1 . There are two sets of cages 6 between the outer ring 1 and the inner ring 2, and the cage cover 16 is connected with the cage 6 through rivets 9. Two rows of cylindrical rollers are evenly distributed on each cage 6 along the circumferential direction. The length of one row of cylindrical rollers 4 in the first cage 6 is 1 / 4-1 / 2 longer than the length of the other row of cylindrical rollers 24.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap