Steel rail production process with limited participation of universal mill

A universal rolling mill and production process technology, applied in the direction of rolling mill control devices, metal rolling stands, metal rolling mill stands, etc., can solve problems such as dimensional fluctuations in the height direction of the rail head, and solve the problems of dimensional fluctuations and high and low points, and improve The effect of rail finished pass rate and high-speed rail running smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

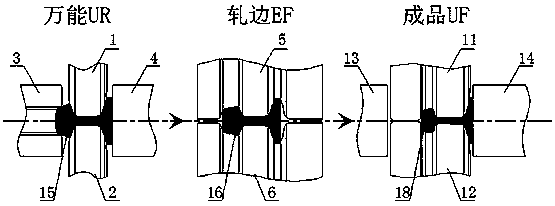

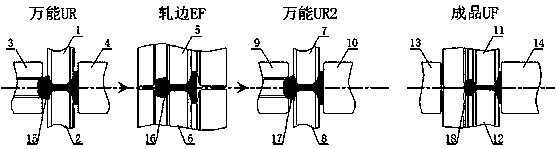

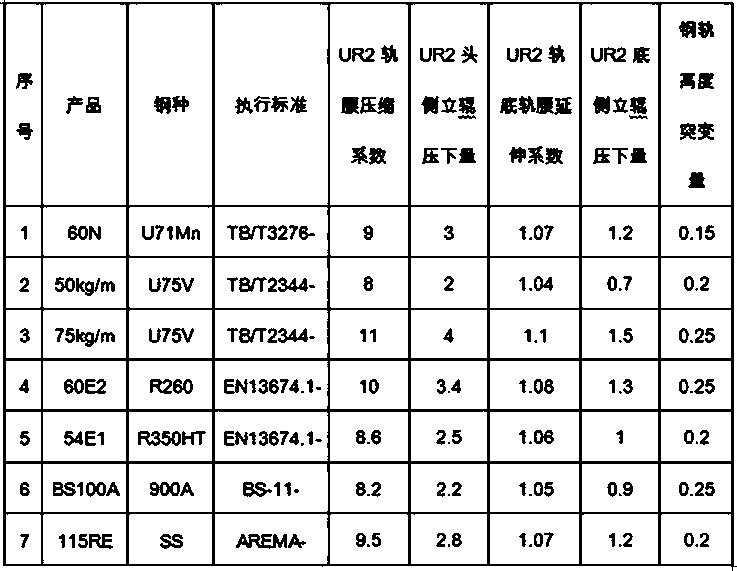

[0036] In TB / T3276-iron standard 60N rail, TB / T2344-iron standard 50kg / m and 75kg / m rail, EN13674.1-European standard 60E2 and 54E1 rail, BS-11-British standard BS100A rail, SS American standard 115RE rail In the process design and production, the rail production process with limited participation of the universal rolling mill was adopted. The last rolling process of the universal rolling mill is universal UR-edge rolling EF-universal UR2 rolling and forming a continuous rolling relationship. Universal UR and edge rolling EF adopt conventional design, universal UR2 adopts light reduction, limited participation rolling design scheme, universal UR2 The pass design parameters are shown in Table 1:

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap