Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6 results about "Oil temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A quality conventional motor oil will tolerate oil sump temperatures of up to 250 degrees, but starts breaking down over 275 degrees. The traditional approach is to try to hold oil temperatures between 230 and 260 degrees.

Double-oil-tank oil supply system

InactiveCN108397320ANot easy to crystallizeGuaranteed normal startupMachines/enginesThermal treatment of fuelFuel tankOil temperature

The invention provides a double-oil-tank oil supply system. The double-oil-tank oil supply system comprises a first oil tank, a second oil tank, a fuel conversion valve and a heating device; the gradeof diesel oil in the first oil tank is higher than the grade of diesel oil in the second oil tank; the heating device is used for heating the oil in the first oil tank; when a vehicle is cold startedin a cold region, the fuel conversion valve controls a fuel pipeline of the second oil tank to communicate with an engine oil way, and the heating device starts to heat the oil in the first oil tank;and after the temperature of the oil in the first oil tank is increased to reach a set oil temperature, the fuel conversion valve controls a fuel pipeline of the second oil tank to cut off from the engine oil way, and the fuel conversion valve controls communication between the fuel pipeline of the first oil tank and the engine oil way. The double-oil-tank oil supply system can guarantee normal cold start of the vehicle in the cold region, meanwhile, needs no mode of baking the oil tanks by fire to heat the oil, prevents the time and vigor wastes, improves the safety, and saves more costs.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

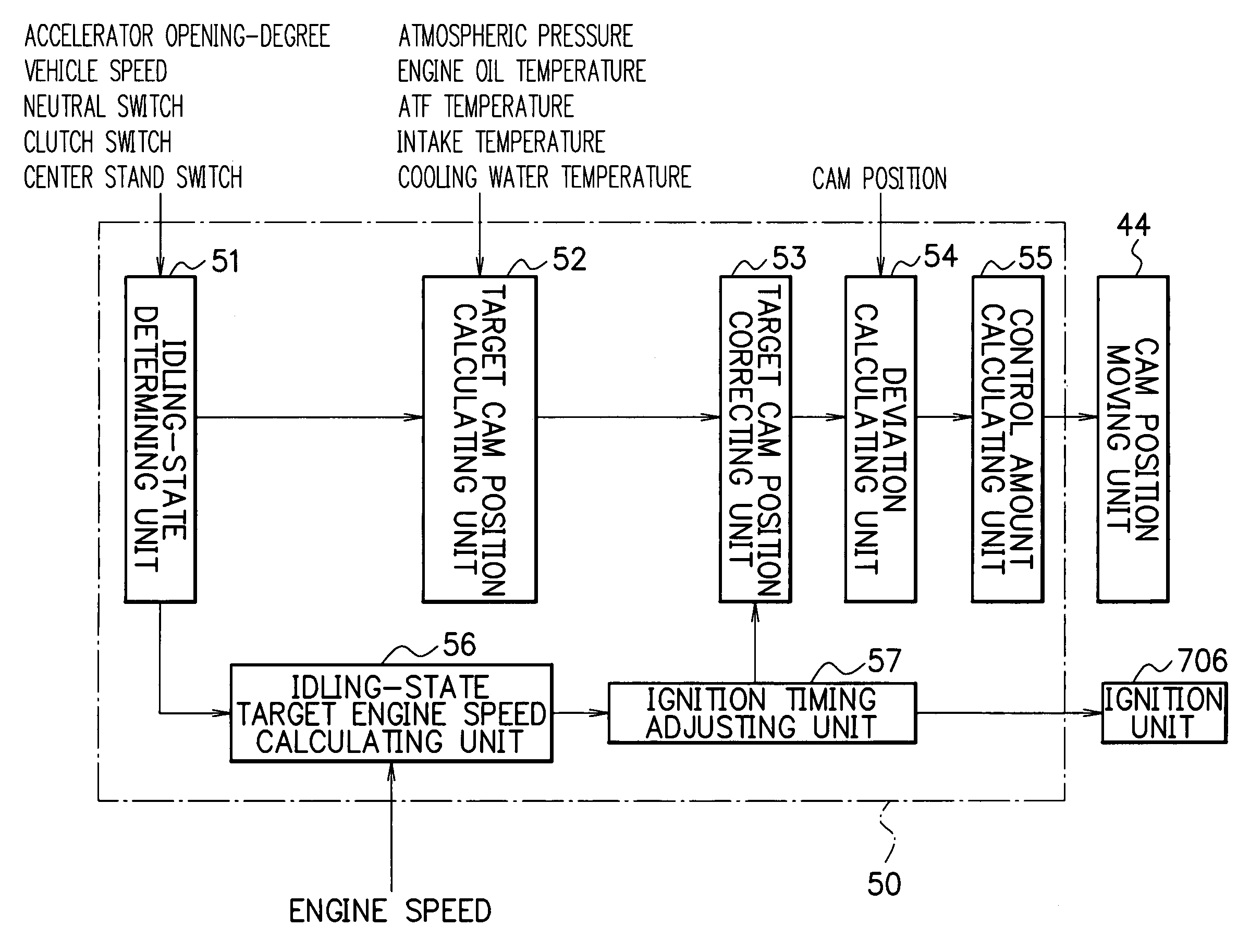

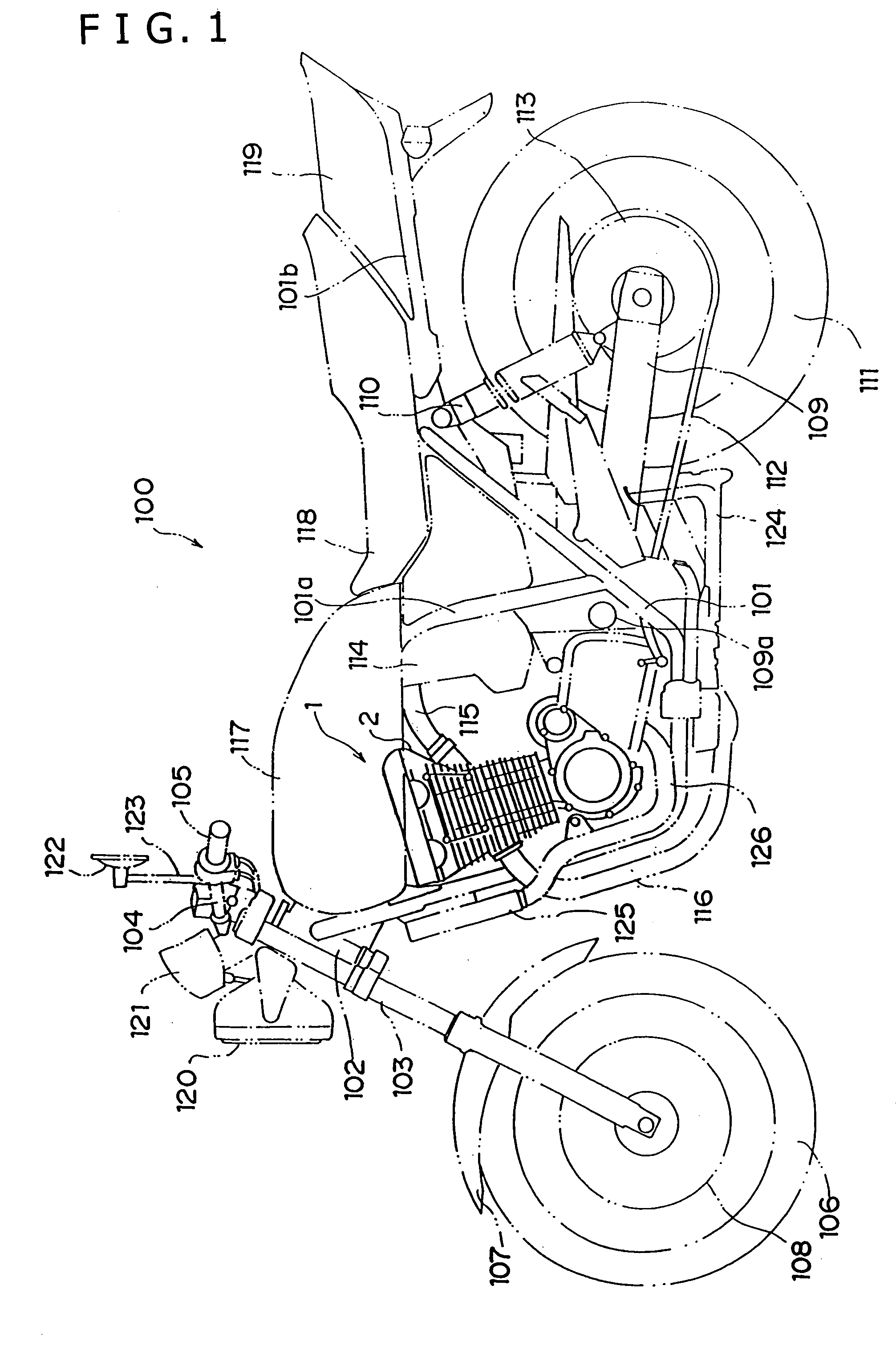

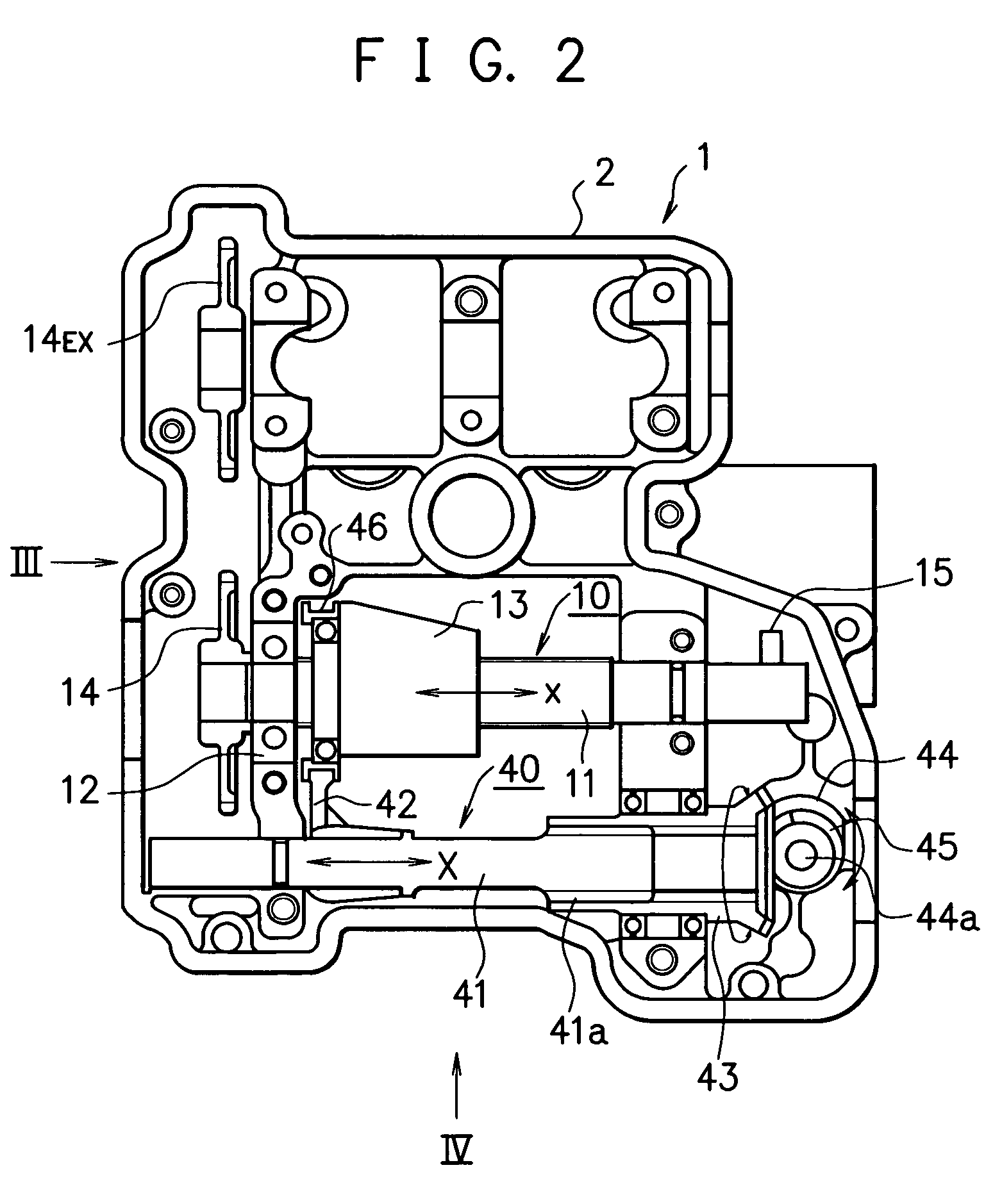

Control device and control program product for engine

Owner:SUZUKI MOTOR CORP

Peanut kernels mixed with sesames and processing method thereof

The invention discloses peanut kernels mixed with sesames and a processing method thereof. The processing method specifically includes the following steps that (1) paste is made, namely whole eggs are put into corn starch, low-speed stirring is performed by using a stirring machine for 1.5-2.5 minutes; (2) coating is performed, namely peanut kernels are transferred to the paste and are mixed evenly for standby application; (3) deep frying is performed: initial frying is performed, namely corn germ oil is transferred to a deep frying pan to perform deep frying for 3.5-4.0 minutes, coated and initially-fried peanut kernels are taken out; refrying is performed, namely after the oil temperature rises to 135-145 DEG C, the initially-fried sample is transferred to the deep frying pan, is processed for 4 minutes and then is taken out. (4) stir-frying is performed, 0.3-0.4 part of corn germ oil is put into the frying pan, white granulated sugar is added to fry the peanut kernels to be light brown, the coated and fried peanut kernels are put into the pan and are stirred evenly, then the sesames are scattered into the peanut kernels, and the mixture is continuously and evenly stirred. The peanut kernels mixed with the sesames is simple to make, good in taste and easy to preserve. On the premise that the taste is guaranteed, the nutrients in the raw materials are retained to the greatest degree. The made finished product is rich in nutrition.

Owner:HENAN INST OF SCI & TECH

Multifunction Vehicle Display Monitor With Video Capability

InactiveUS20130107047A1Remove restrictionsInstrument arrangements/adaptationsColor television detailsPower modeDisplay device

A multifunction monitor display system capable of showing vital vehicle information, such as available fuel, engine oil temperature and vehicle power mode in a first format on a primary display area of a display screen in a first mode and showing video images from a video camera in the primary display area and the vital vehicle information in a second format on a secondary display area of the display screen in a second mode. The secondary display area is an area that may be separate and discrete from, as well as smaller than, the primary display area

Owner:DEERE & CO

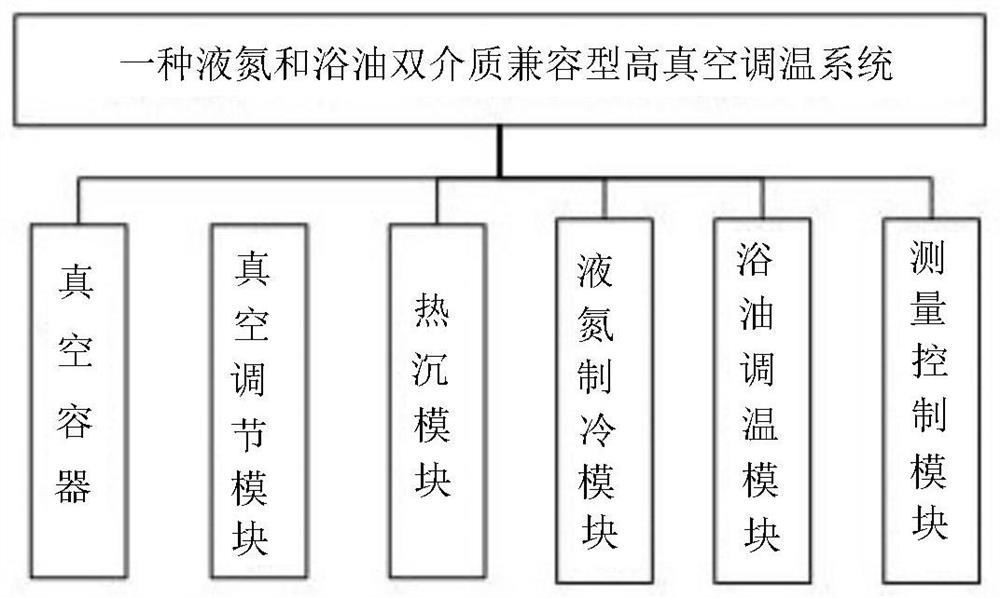

Liquid nitrogen-bath oil double-medium compatible high-vacuum temperature adjusting system and temperature adjusting method

InactiveCN112295630AExpand the test temperature zoneReduce testing costsHeating or cooling apparatusEngineeringHeat sink

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

Parallel off-line crude oil preheater

PendingCN111102595ASmall temperature fluctuationsReduce dosageLiquid fuel feeder/distributionTemperature controlSteam pressure

The invention provides a parallel off-line crude oil preheater, which comprises an on-line crude oil preheater, wherein one end of the on-line crude oil preheater is connected with a crude oil inlet pipe and a hot oil outlet pipe correspondingly, and the other end of the on-line crude oil preheater is connected with a heat exchanger; and a water gun is arranged at an inlet of the on-line crude oilpreheater. The parallel off-line crude oil preheater is mainly technically characterized in that the crude oil inlet pipe of the on-line crude oil preheater is connected with the off-line crude oil preheater in parallel. In order to solve the problem of unstable oil temperature at present, the off-line crude oil preheater is connected in parallel on the basis of the original on-line crude oil preheater, and crude oil is shunted, passes through residual steam in advance to heat part of raw oil, and then enters the on-line crude oil preheater together with the other part of the crude oil, so that the requirement of oil temperature control is met; and because the steam pressure is stable, the temperature fluctuation of the crude oil is small and can be controlled within + / -3 DEG C, and the temperature of the crude oil is controlled in a better control range, so that the aims of improving the yield, reducing the consumption and reducing the using amount of screen residues and additives are achieved.

Owner:HANGZHOU FUCHUNJIANG IND

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap