Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7 results about "Steam pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

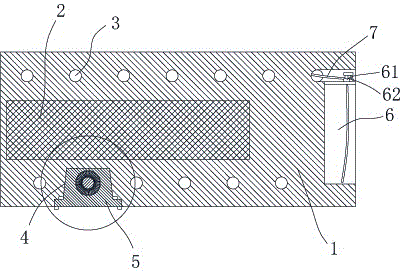

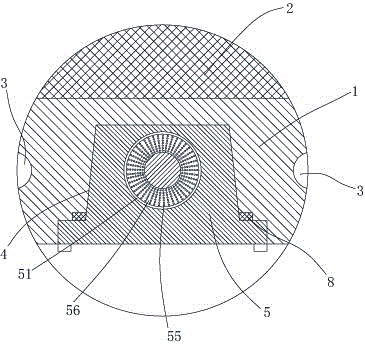

Vamp automatic steaming setting machine and vamp steaming setting method

The invention relates to a vamp automatic steaming setting machine and a vamp steaming setting method. The machine comprises a steaming setting box body, a steam generating device, a pressure detecting device for detecting the steam pressure, a steam recycling machine, a vacuumizing device and an air inlet device. The output end of the steam generating device is connected with the steam chamber ofthe steaming setting box body, the steam injection pressure of the steam chamber is 0.1 MPa-0.5 MPa, the steam recycling machine and the vacuumizing device are communicated with the steam chamber, and a workbench for placing shoe trees is arranged in the steaming setting box body. After the technical scheme of the vamp automatic steaming setting machine and the vamp steaming setting method is adopted, the steam generating device generates a steam injection pressure of 0.1 MPa-0.5 MPa in the steam chamber in the steaming setting process, so that the steam rapidly permeates vamps and accelerates the melting and bonding of hot melt yarns; meanwhile, the internal stress of the vamps is eliminated, and the machine has the advantages of short working hours, high efficiency and good effect.

Owner:BLACK SWAN INTELLIGENT TECH (FUJIAN) CO LTD

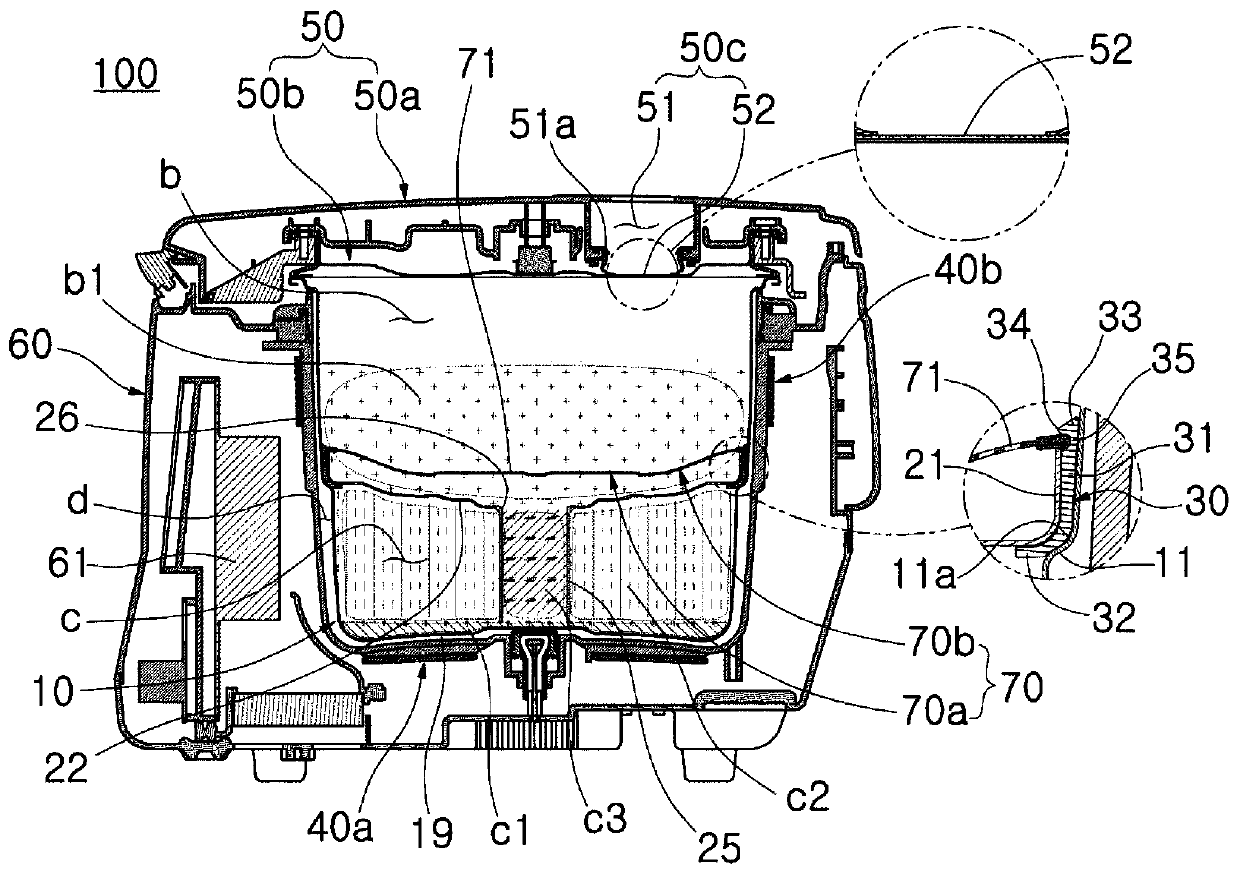

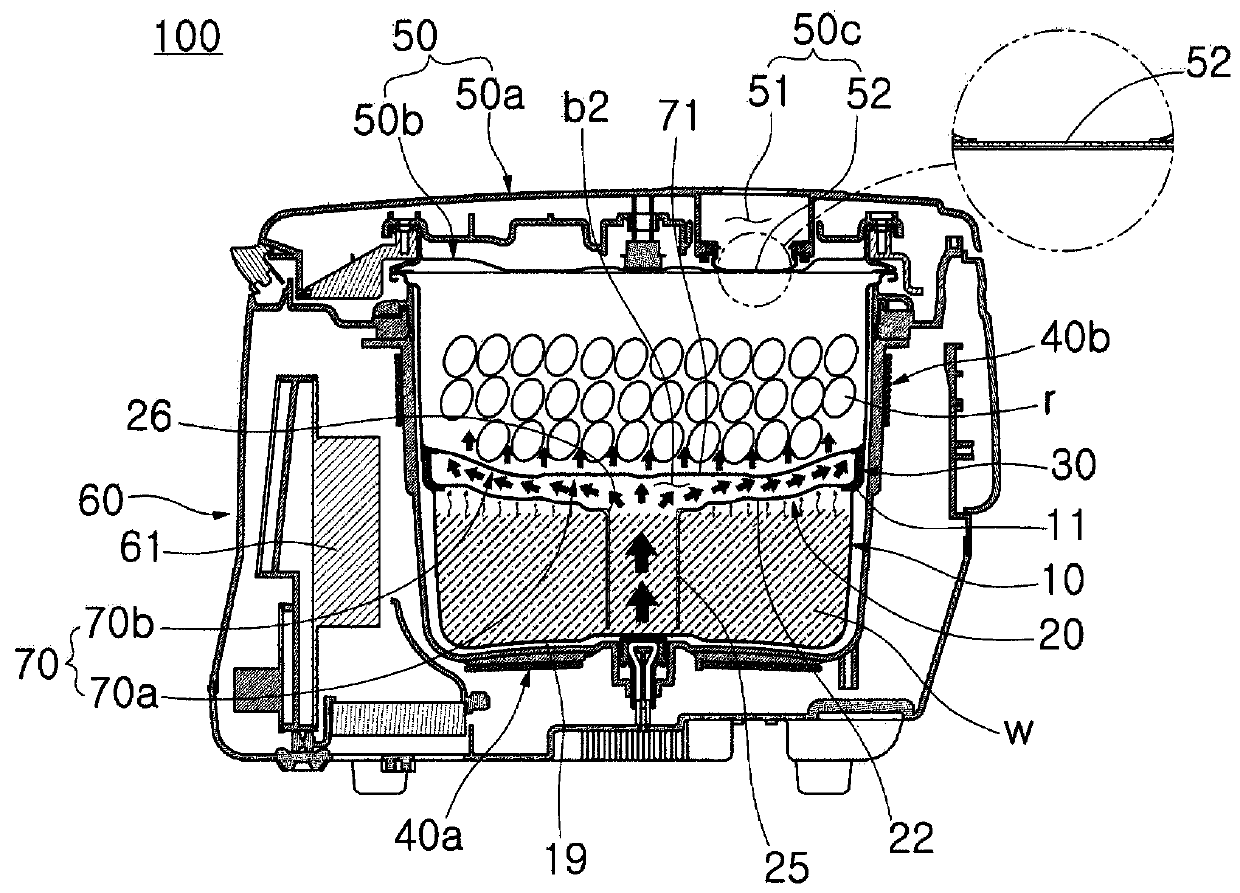

Electric cooker

ActiveCN110811294AImprove cooking qualityImprove separation efficiencyRefuse receptaclesPressure-cookersSiphonWater storage

Owner:CUCKOO ELECTRONICS CO LTD

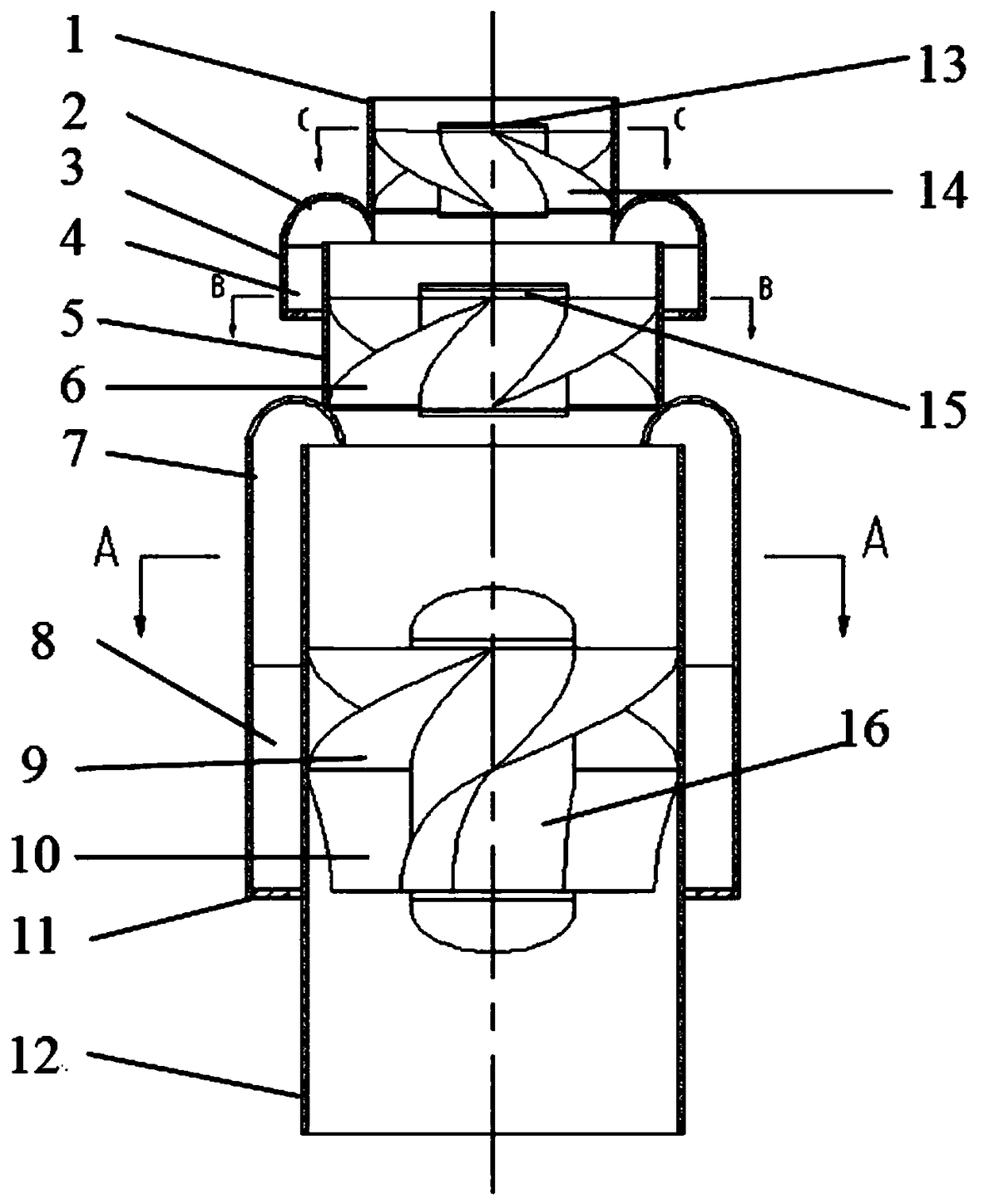

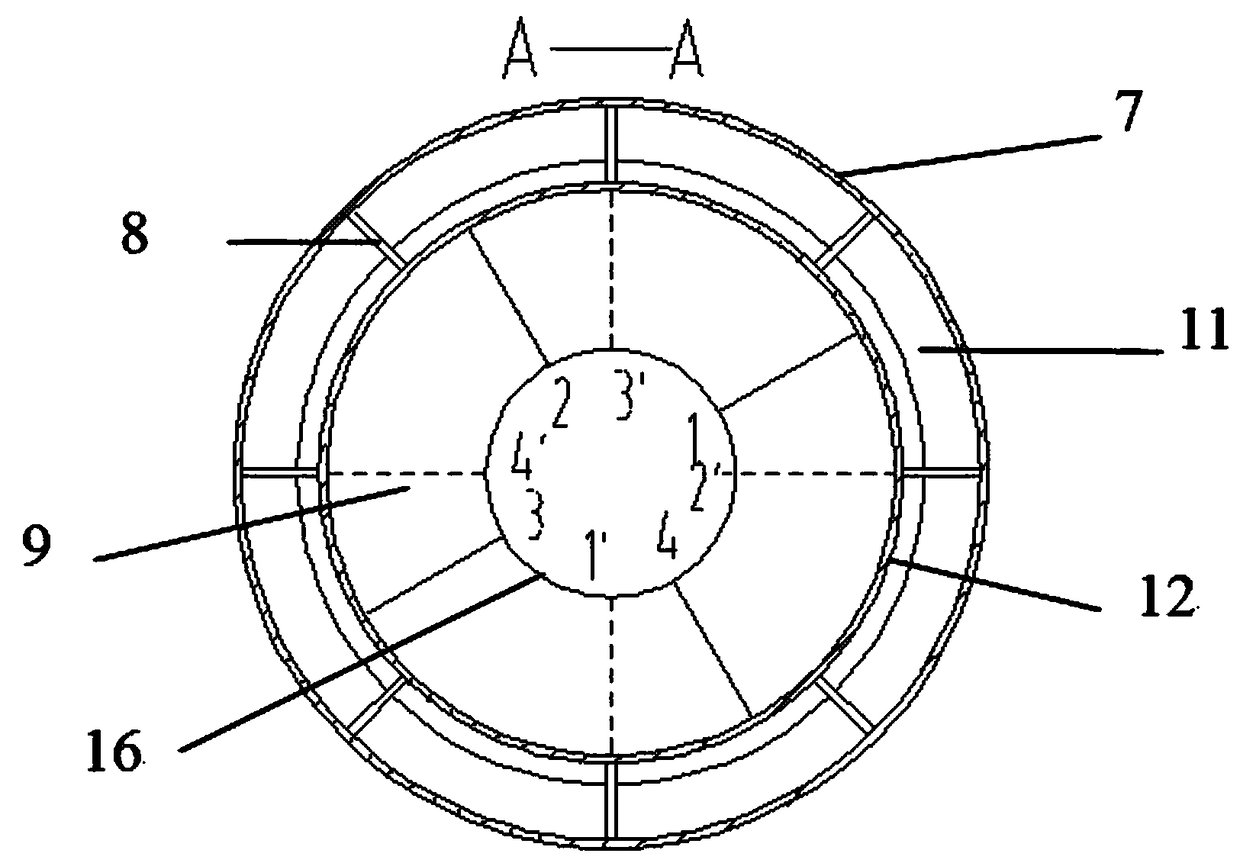

Steam-water separator with pressure recovery stage

Owner:RES INST OF NUCLEAR POWER OPERATION +1

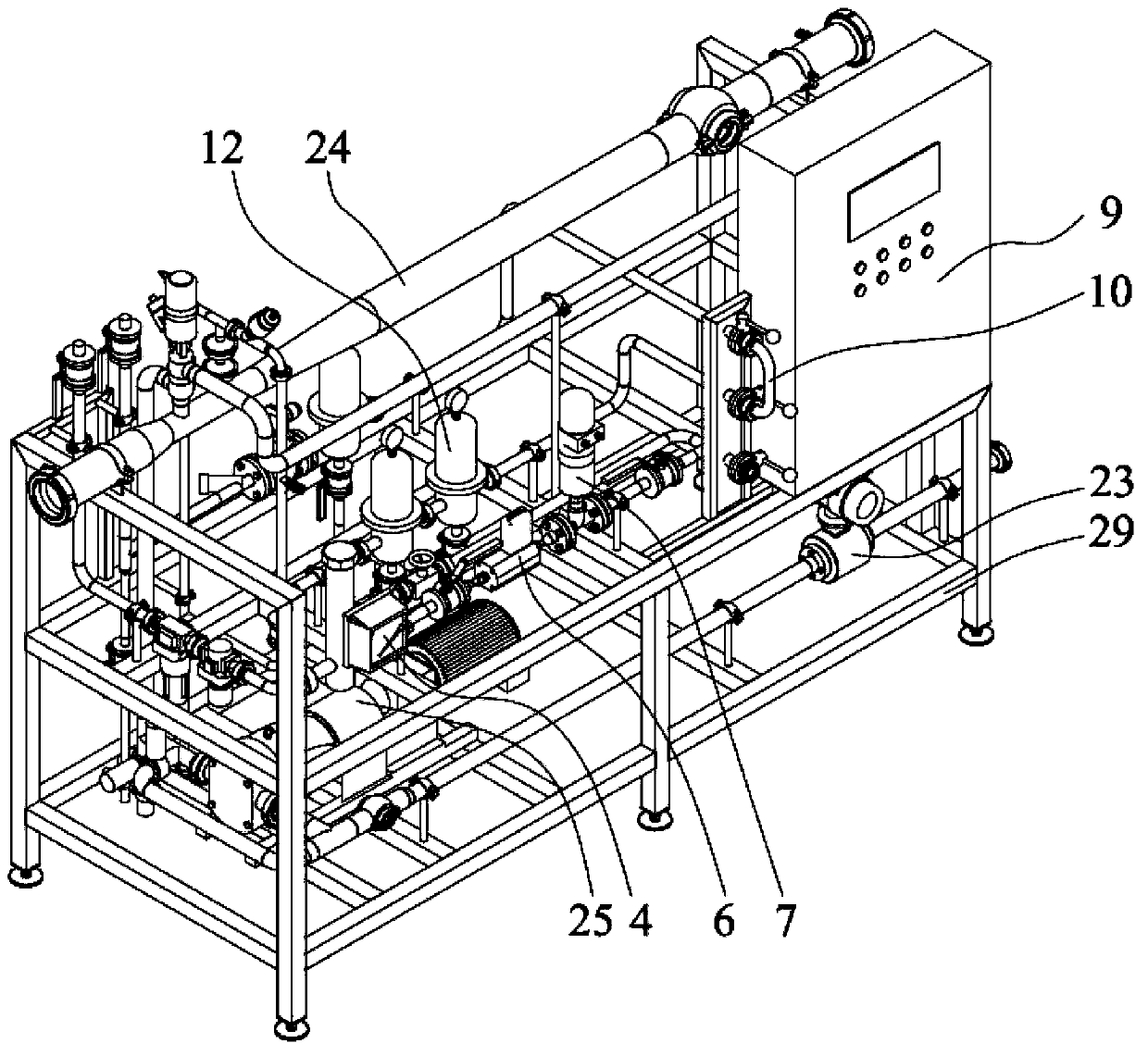

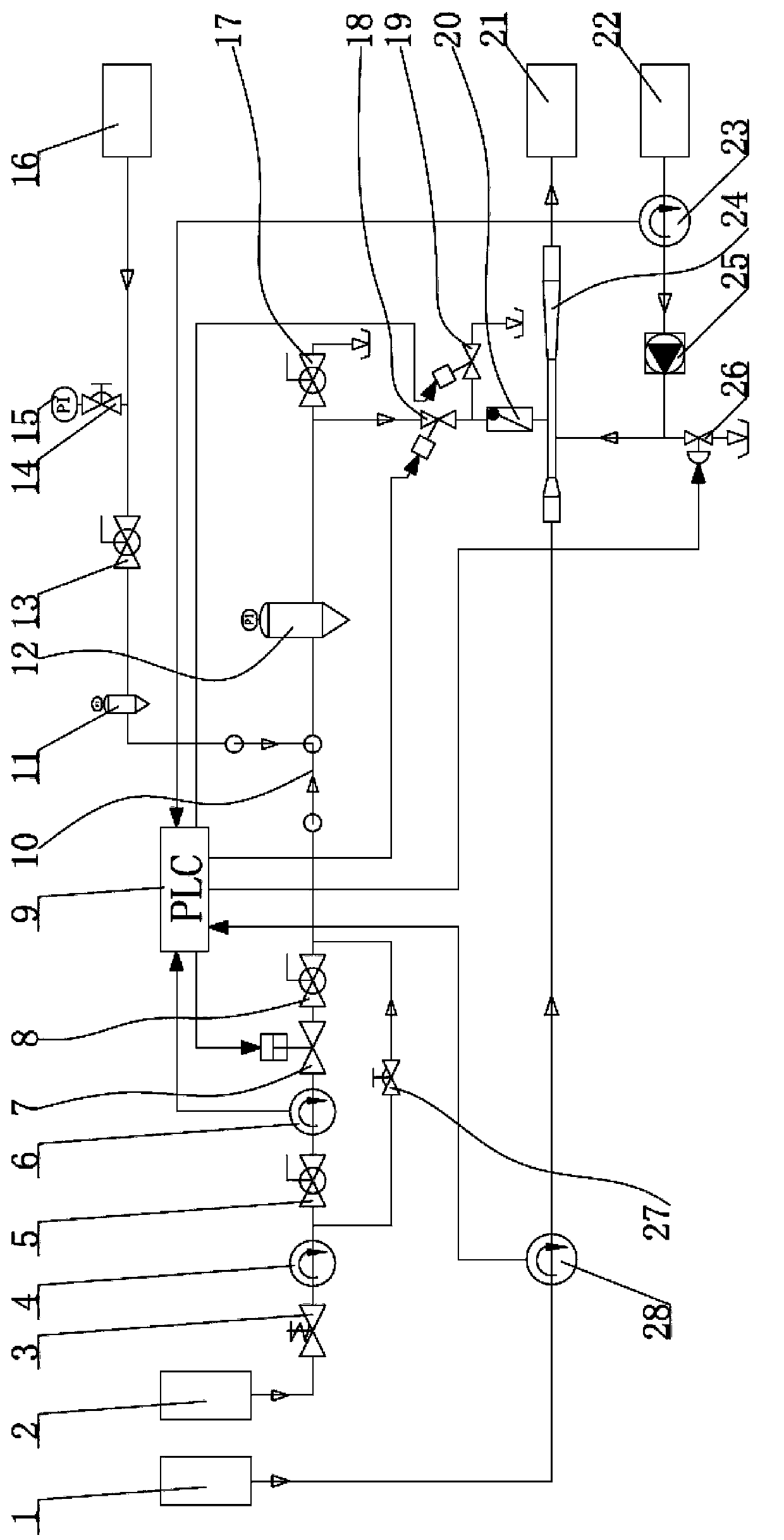

Full-automatic wort oxygenated yeast adding machine and wort oxygenated yeast adding method

InactiveCN102816662BAvoiding problems with feedback regulation hysteresisMethod is feasibleWort preparationHuman error probabilityLoop control

Owner:ANHUI HUAYI BIOLOGICAL EQUIP TECH

Parallel off-line crude oil preheater

PendingCN111102595ASmall temperature fluctuationsReduce dosageLiquid fuel feeder/distributionTemperature controlSteam pressure

The invention provides a parallel off-line crude oil preheater, which comprises an on-line crude oil preheater, wherein one end of the on-line crude oil preheater is connected with a crude oil inlet pipe and a hot oil outlet pipe correspondingly, and the other end of the on-line crude oil preheater is connected with a heat exchanger; and a water gun is arranged at an inlet of the on-line crude oilpreheater. The parallel off-line crude oil preheater is mainly technically characterized in that the crude oil inlet pipe of the on-line crude oil preheater is connected with the off-line crude oil preheater in parallel. In order to solve the problem of unstable oil temperature at present, the off-line crude oil preheater is connected in parallel on the basis of the original on-line crude oil preheater, and crude oil is shunted, passes through residual steam in advance to heat part of raw oil, and then enters the on-line crude oil preheater together with the other part of the crude oil, so that the requirement of oil temperature control is met; and because the steam pressure is stable, the temperature fluctuation of the crude oil is small and can be controlled within + / -3 DEG C, and the temperature of the crude oil is controlled in a better control range, so that the aims of improving the yield, reducing the consumption and reducing the using amount of screen residues and additives are achieved.

Owner:HANGZHOU FUCHUNJIANG IND

Safe steam pressure sterilizer

Owner:NINGBO RUNYES MEDICAL INSTR

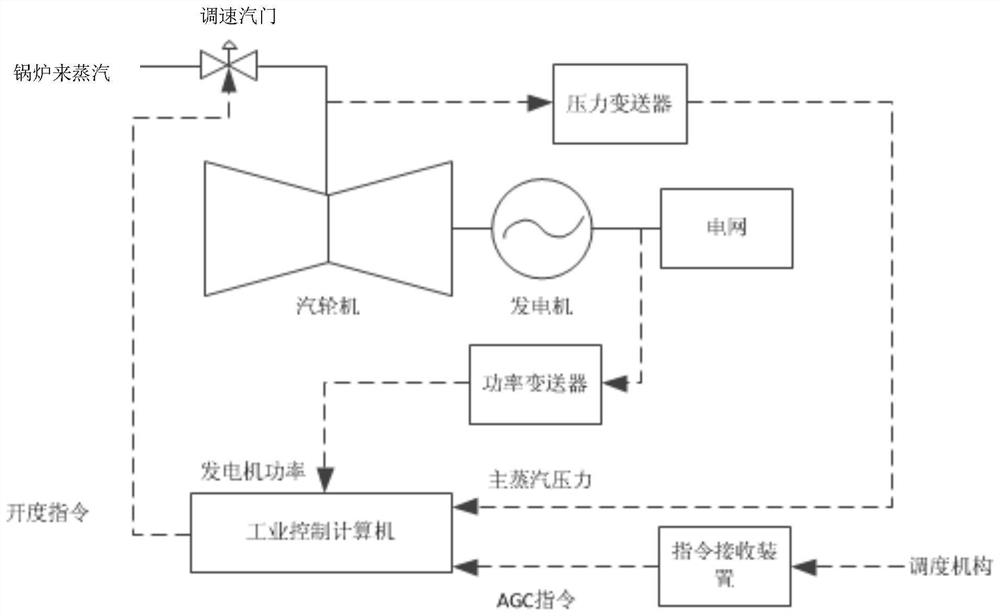

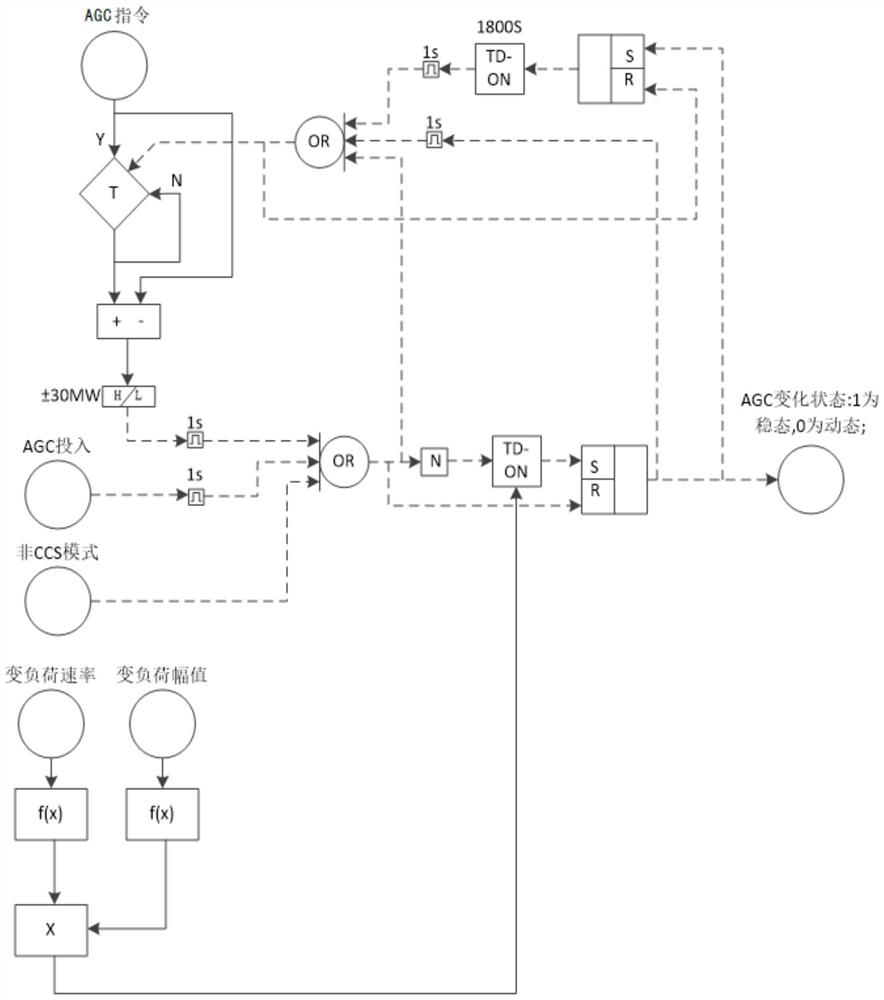

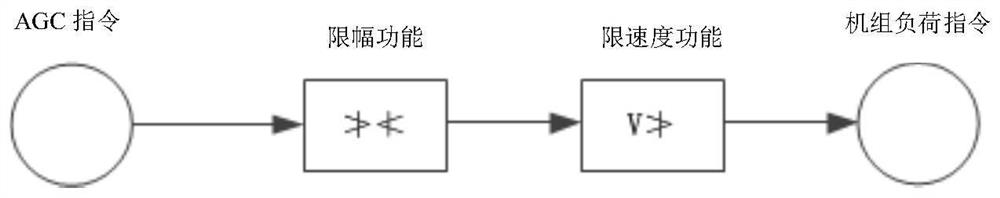

Coal-fired unit variable-rate load control method and device based on AGC instruction state change judgment

PendingCN114609902AImprove responsivenessImprove load regulation performance indicatorsSingle network parallel feeding arrangementsMachines/enginesSteam pressureLoad instruction

Owner:浙江浙能温州发电有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap