Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

27 results about "Oil tank" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

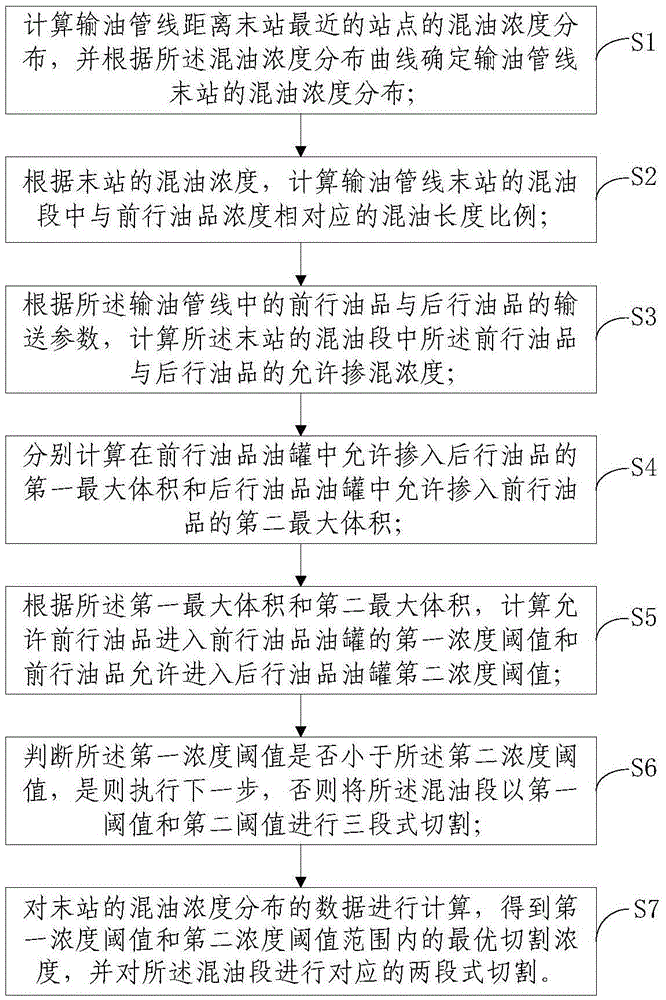

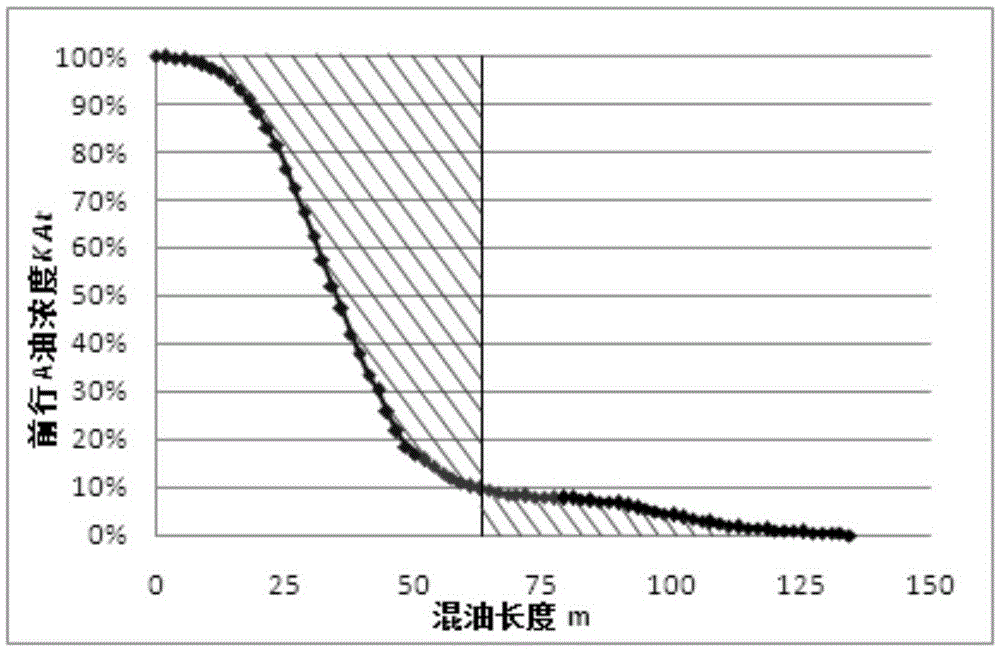

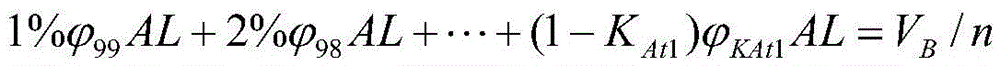

Cutting method for mixed-oil section in refined oil product batch transportation

Owner:CHINA PETROLEUM & CHEM CORP +1

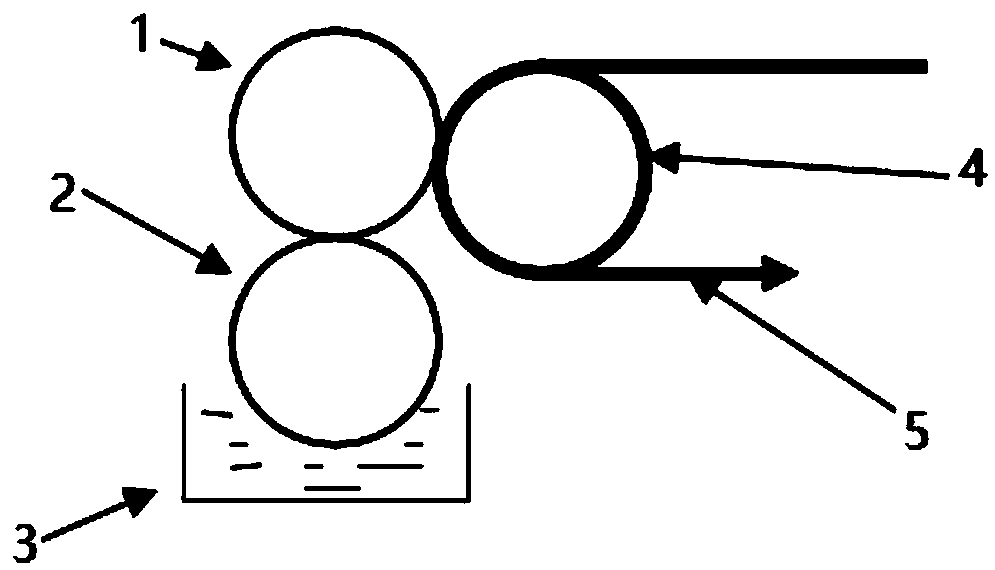

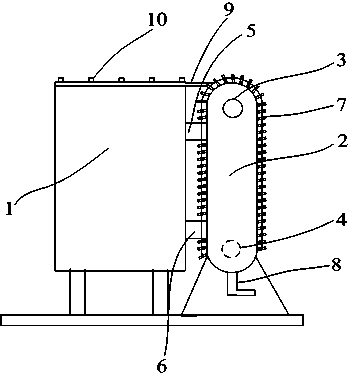

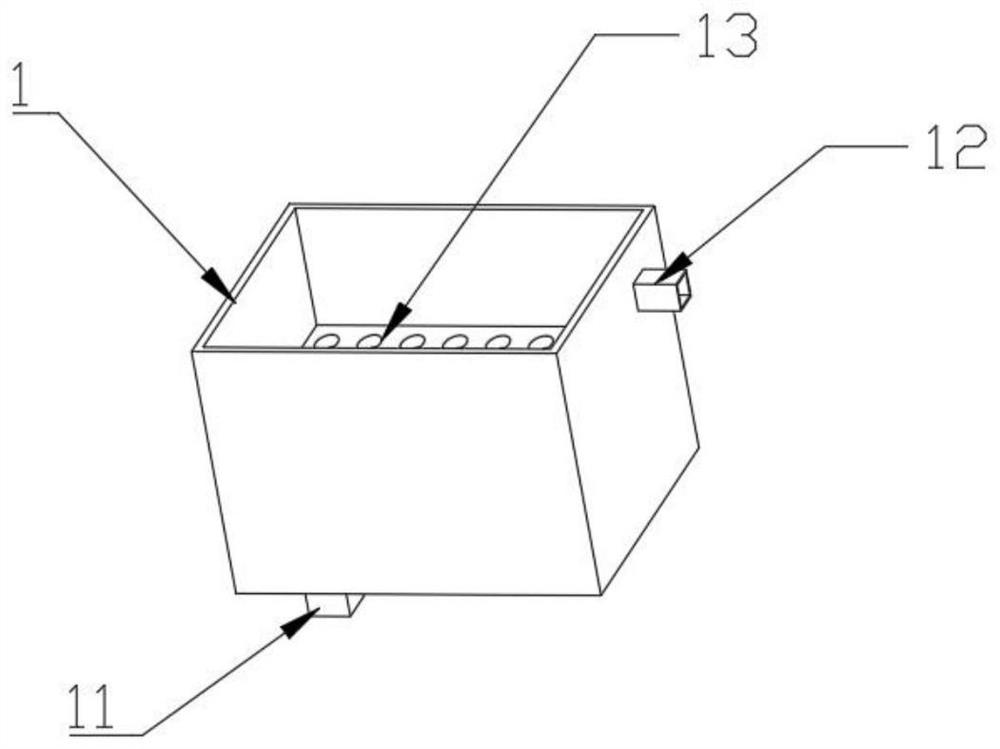

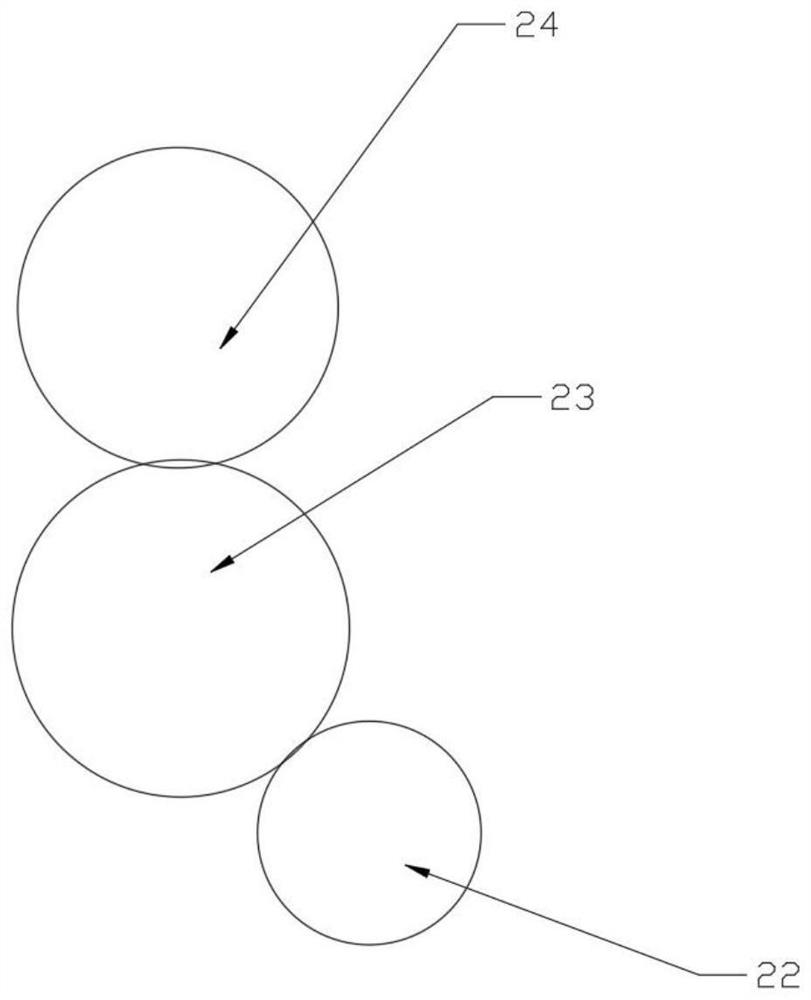

Steel bending equipment for steel machining

InactiveCN112139303AAvoid scratchesAvoid damageShaping toolsMetal-working feeding devicesStructural engineeringContact position

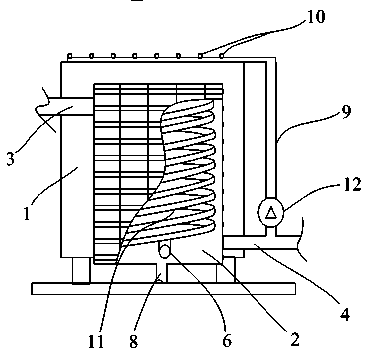

The invention discloses steel bending equipment for steel machining, and belongs to the technical field of steel machining. The steel bending equipment comprises a machine body, lubricating oil tanks,a base, roll shafts, an oil storage box, a positioning mechanism and a mounting seat, wherein the machine body is fixedly installed on the base through a side connecting plate, hydraulic machines arefixedly installed at the top of the machine body, and one ends of hydraulic rods installed at the output ends of the hydraulic machines penetrate through and extend to the outer side of the machine body to be fixedly provided with a bending plate. According to the steel bending equipment, the roller shafts are installed on the equipment, when steel is bent and pressure is applied to the bent position of the steel, the roll shafts replace a bent face to make contact with the steel, and when pressure is applied for bending, the steel can be bent along the smooth surfaces of the roll shafts, compared with traditional bending treatment, the situation that the surface of the steel is scratched and damaged is avoided, and meanwhile, the lubricating oil tanks are installed on the outer side of the equipment in a matched mode, the contact positions between the roll shafts and the steel can be effectively lubricated, and the bending smoothness is further improved.

Owner:赵桂荣

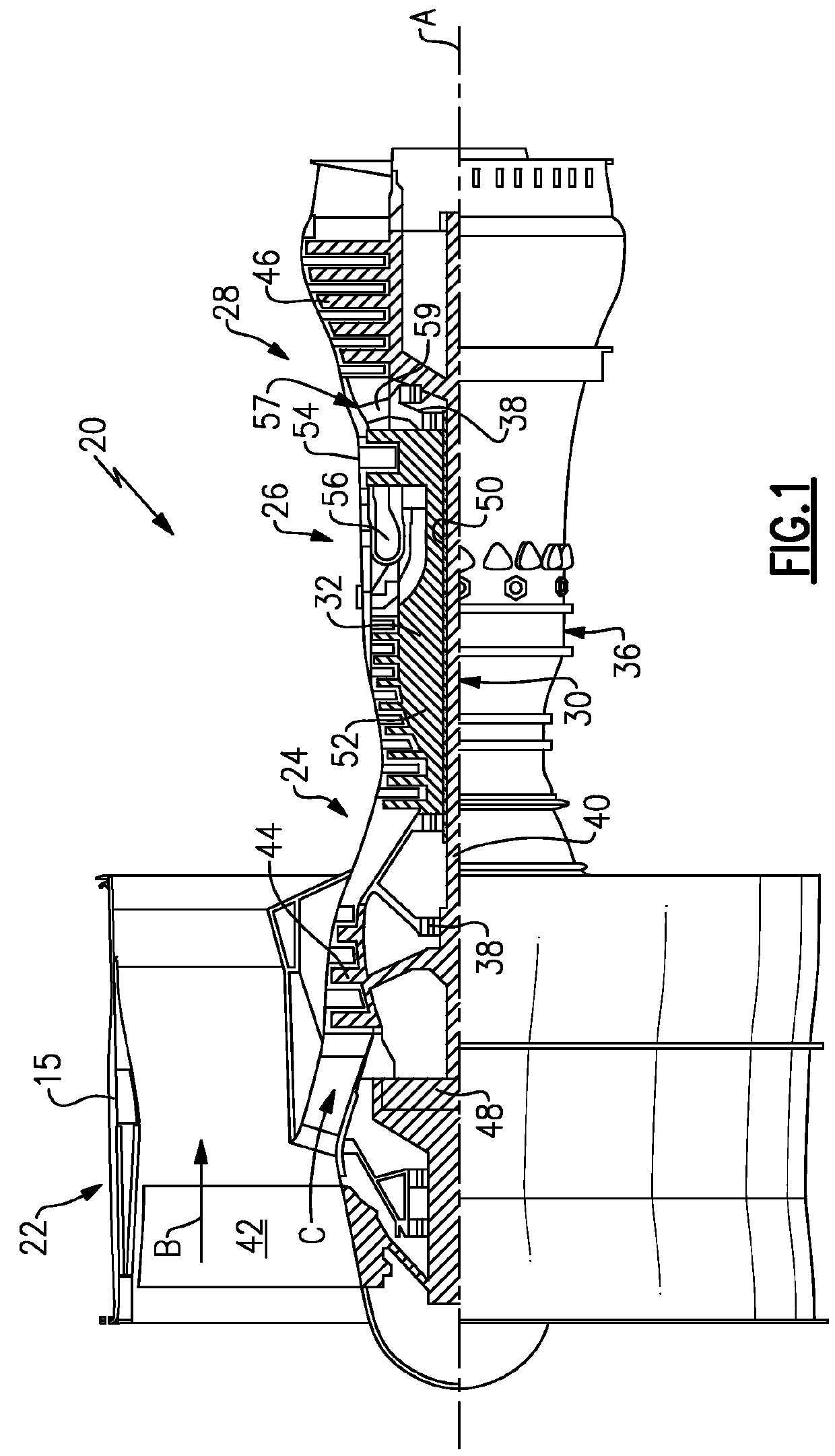

Geared gas turbine engine with oil deaerator and air removal

Owner:RAYTHEON TECH CORP

Static-conducting and anti-corrosive coating on inner wall of oil tank, and preparation method of static-conducting and anti-corrosive coating

InactiveCN104098989ALight colorEasy for visual inspectionAnti-corrosive paintsEpoxy resin coatingsPetrochemicalReactive diluent

The invention discloses a static-conducting and anti-corrosive coating and a preparation method thereof. The static-conducting and anti-corrosive coating comprises bisphenol A epoxy resin, a reactive diluent, rutile titanium dioxide, conductive mica powder, a coupling agent and a flexibilizer. The bisphenol A epoxy resin is ground; the reactive diluent, the flexibilizer, the coupling agent and a light-colored static-conducting material are added; and the coating free of an inertial and volatile solvent is prepared. The coating has the characteristics of high cohesion, good closure and stable static conductivity, is suitable for internal anti-corrosive and static-conducting protection of oil storage and transport equipment such as an oil storage tank, an oil transport pipeline and an oil transport tank in the petrochemical industry, and is also suitable for anti-corrosive and anti-static protection of a gas tank, a water gate and an underground pipeline.

Owner:SHAANXI RES DESIGN INST OF PETROLEUM CHEM IND

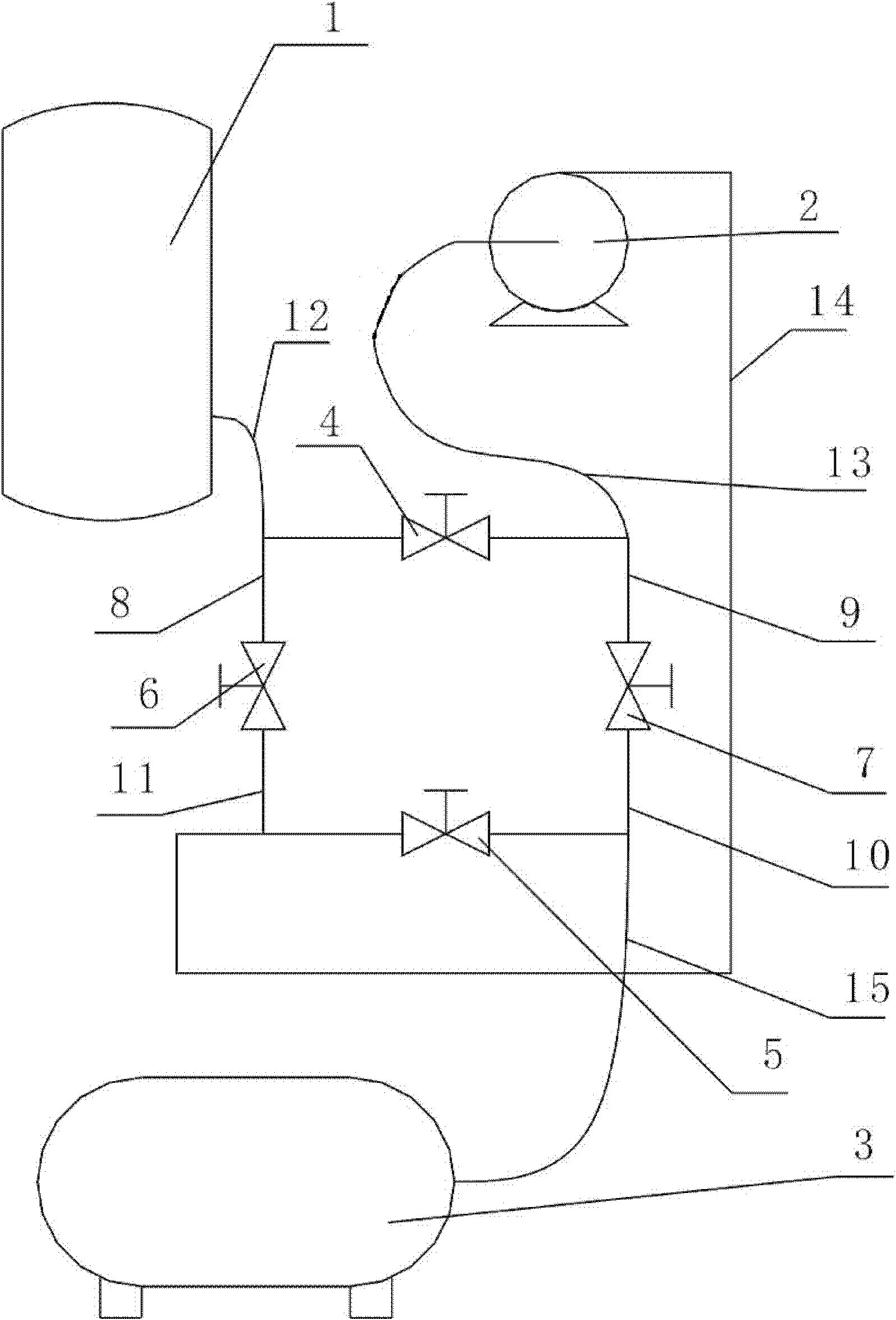

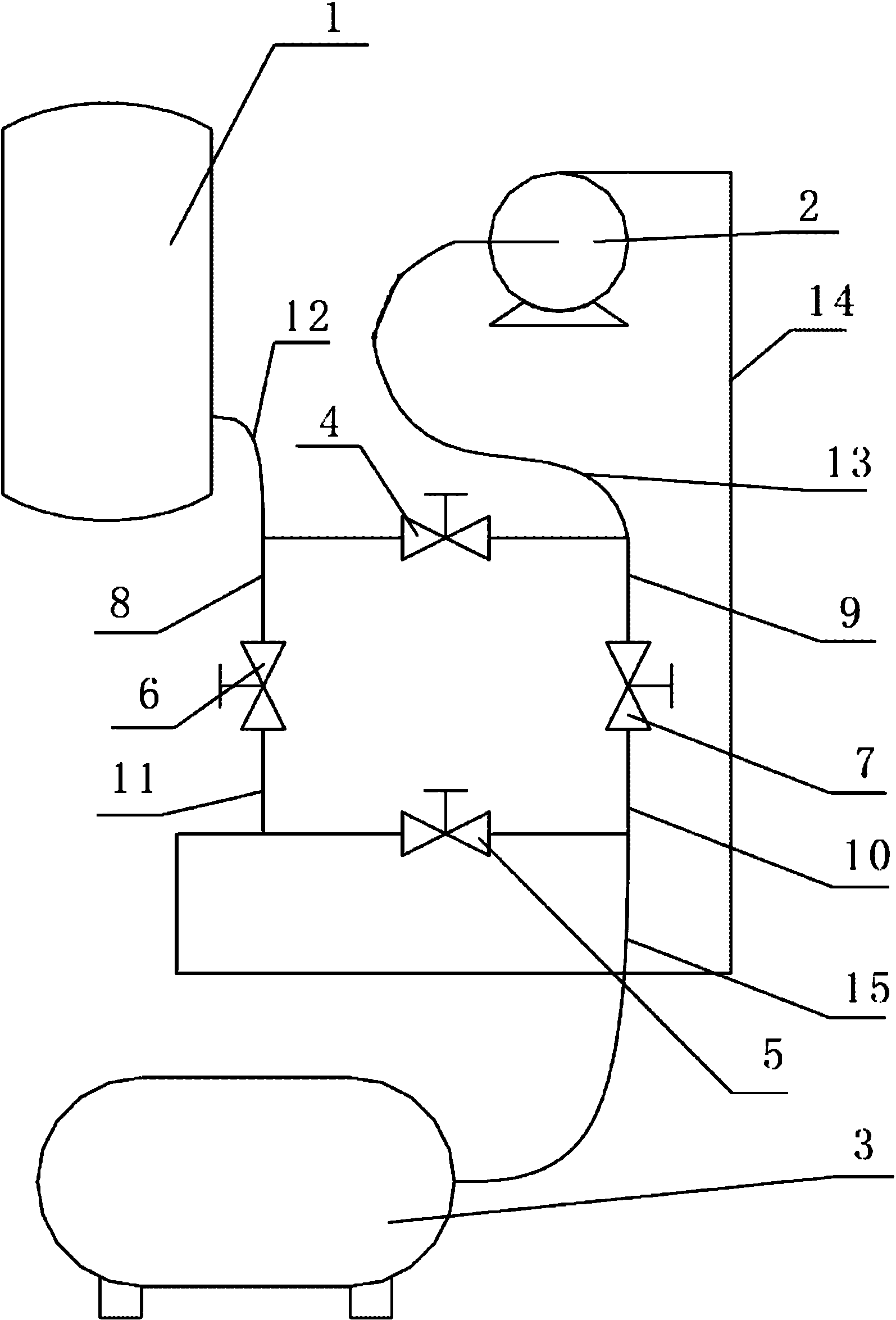

Filtering method for transformer oil

InactiveCN102426903AAvoid frequent openingSave energyTransformers/inductances coolingFiltration separationWork periodTransformer oil

Owner:CHINA FIRST METALLURGICAL GROUP

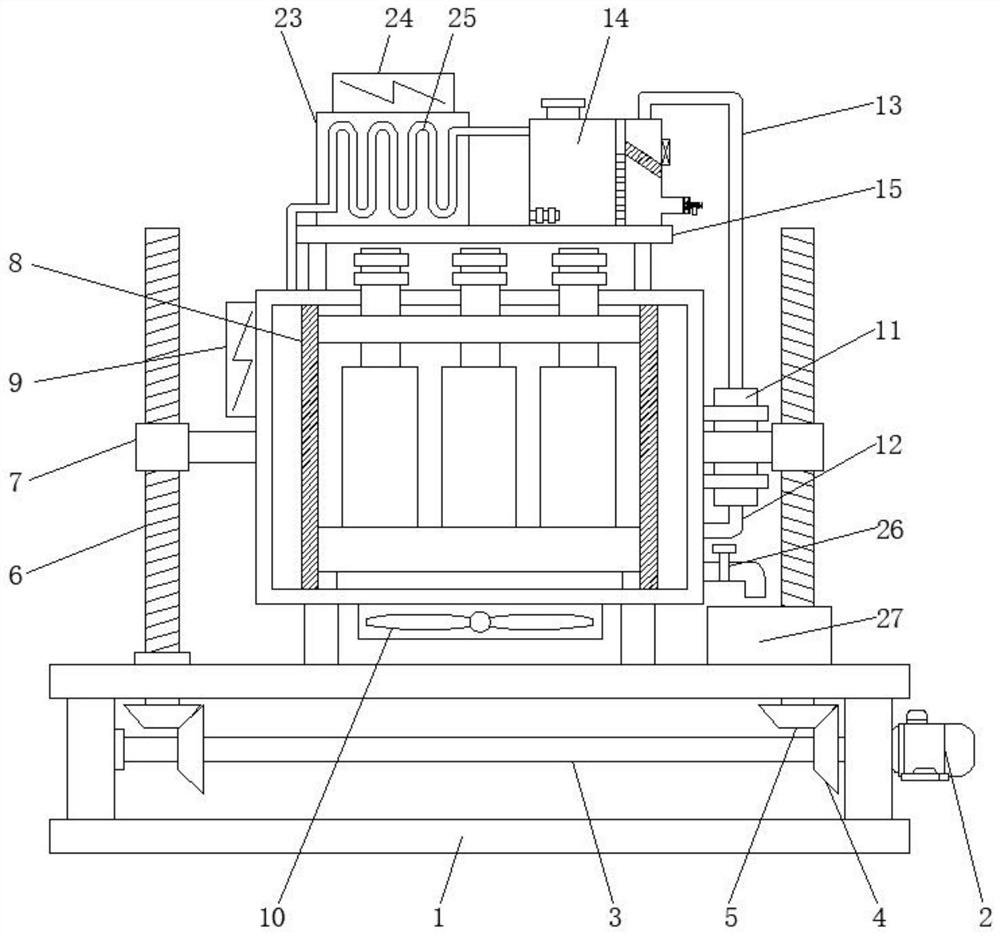

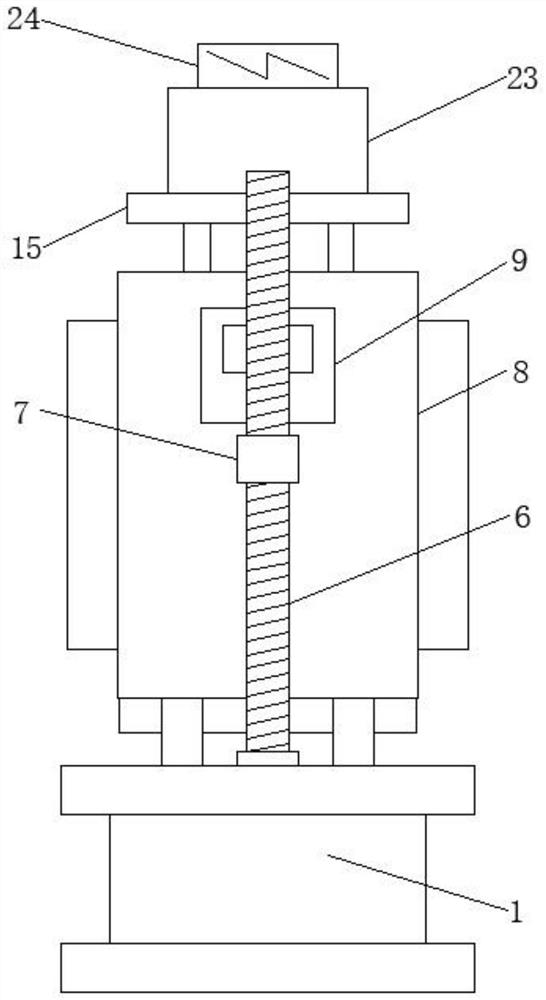

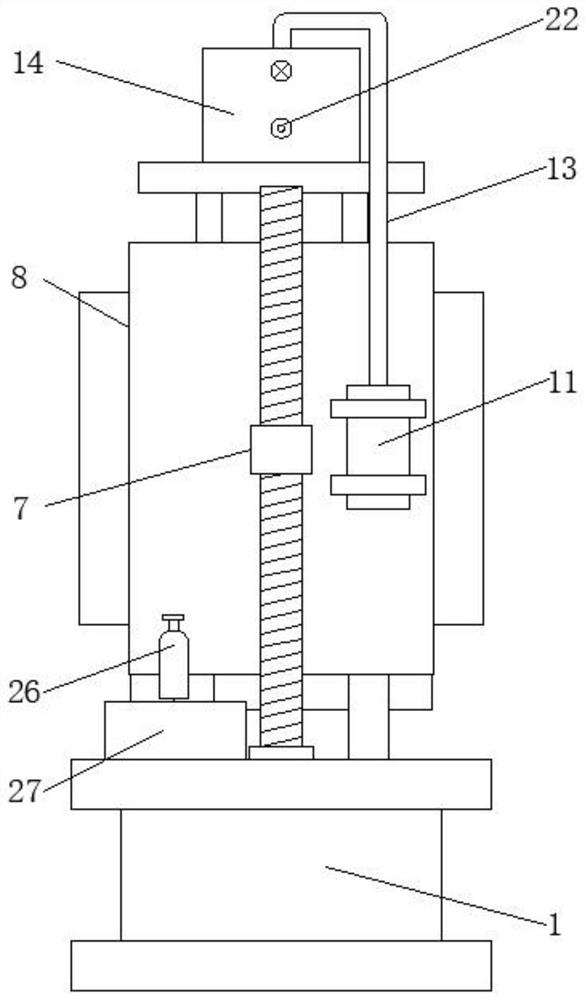

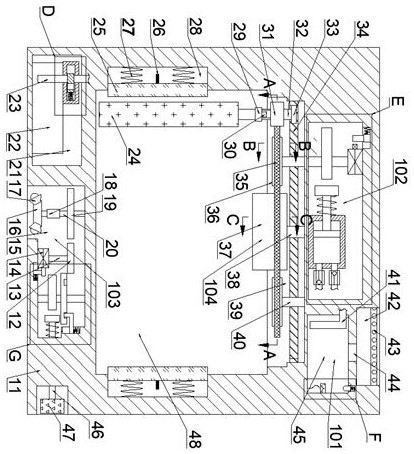

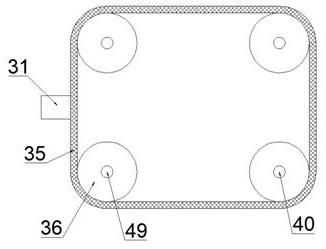

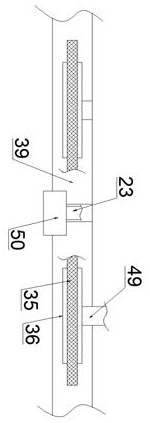

Cutting device with deformation protective structure and for hydraulic power oil tank processing

ActiveCN111702250ASolve the problem of untidyImprove stabilityMetal sawing devicesMetal sawing accessoriesStructural engineeringProcess engineering

The invention discloses a cutting device with a deformation protective structure and for hydraulic power oil tank processing. The cutting device comprises a device main body, the device main body comprises a supporting column, a supporting plate is fixedly connected to the top end of the supporting column, side plates are correspondingly connected to the left and right sides of the supporting plate, a top plate is fixedly connected between the two groups of side plates, a hydraulic push rod is fixedly connected to the bottom end of the top plate, a cutting machine is fixedly connected to the bottom end of the hydraulic push rod, a trolley is movably connected to the right side of the supporting column, a transmission mechanism is arranged on the left side of the hydraulic push rod, a clamping mechanism is arranged on the upper part of the supporting plate, an extruding mechanism is arranged in the supporting plate, a pushing mechanism is arranged in the supporting plate, and a transport mechanism is arranged on the right side of the supporting plate. According to the cutting device, the stability during cutting and the accuracy of cutting of the device are improved, a metal plate after cutting can be directly dropped into the trolley, and convenience is provided for manual collection.

Owner:HUNAN YONGSHENG HYDRAULIC TECH CO LTD

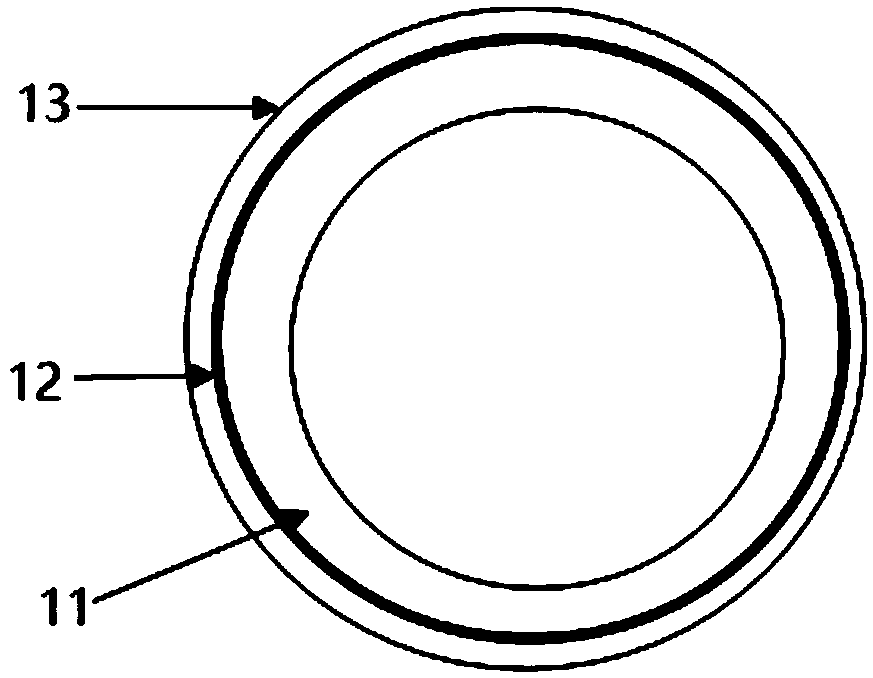

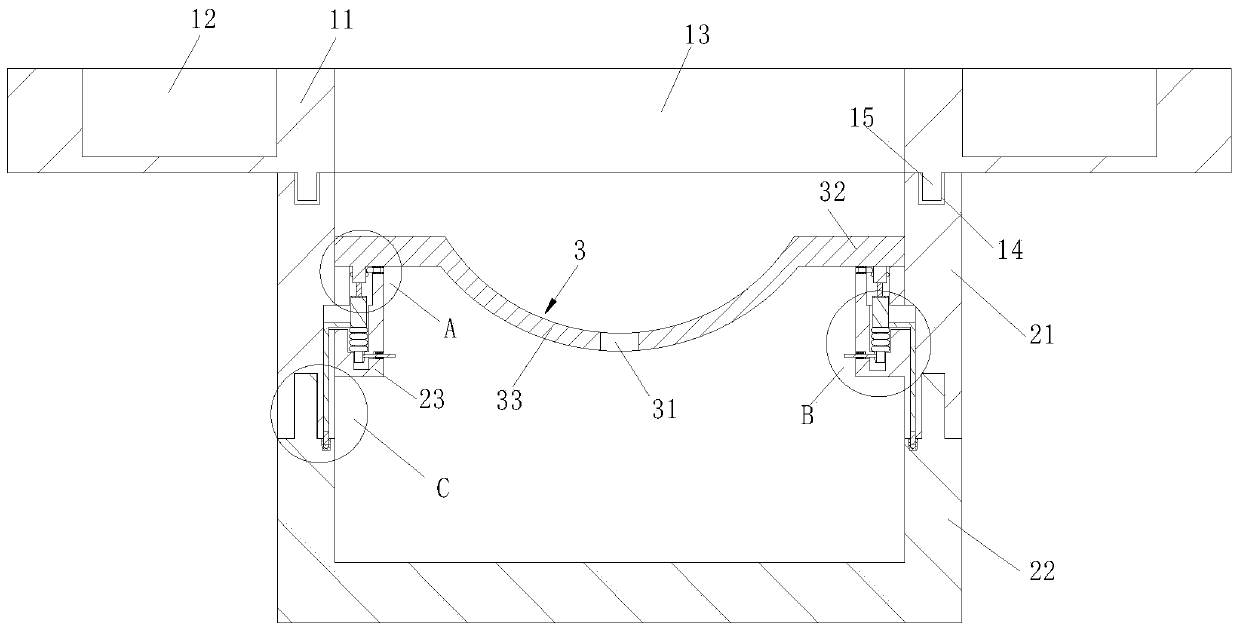

Seamless rubber printing plate and printing device with seamless rubber printing plate

InactiveCN108995353AWon't breakNo emissionsRotary letterpress machinesRelief printingAdhesiveEngineering

Owner:SHANGHAI YUNCHENG PLATE MAKING

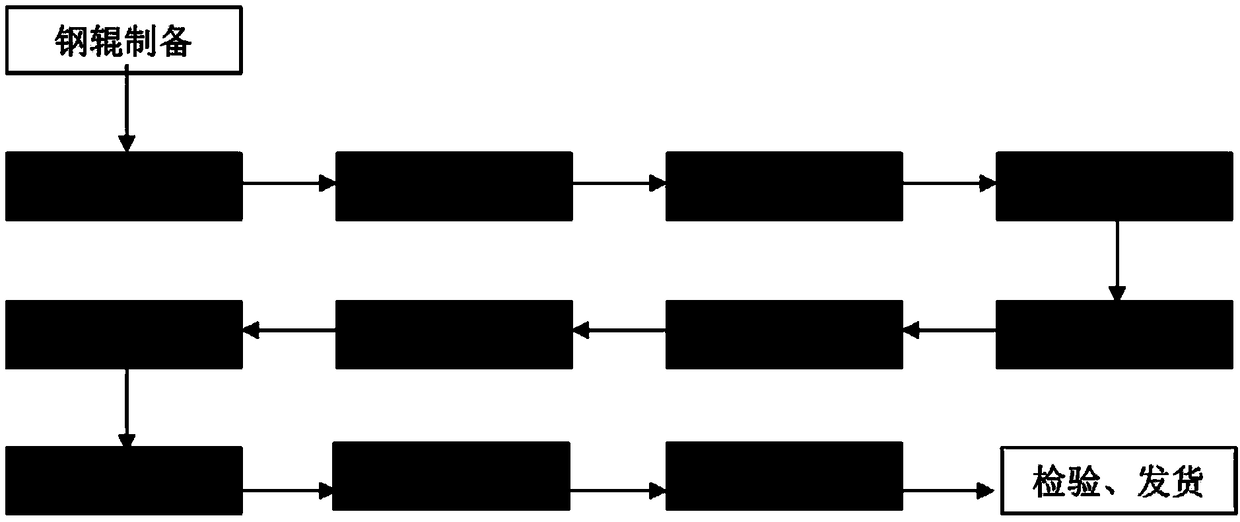

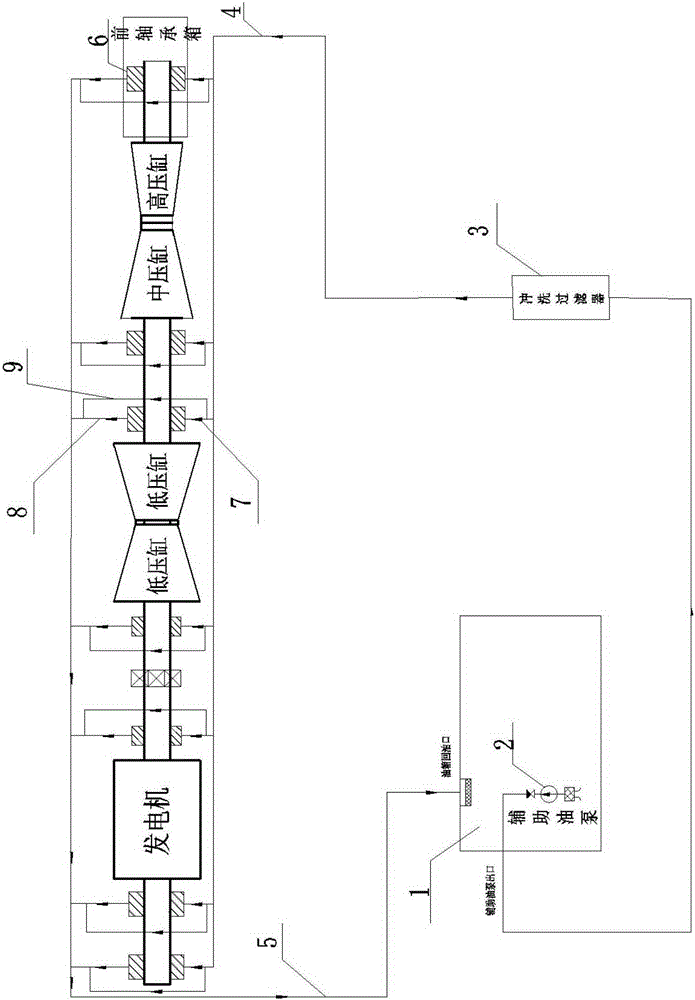

Lubricating oil filtering system for turbine body

InactiveCN105317478ASmall amount of installation workShorten cycle timeMachines/enginesEngine componentsElectricityTurbine

Owner:CHINA ENERGY ENG GRP TIANJIN ELECTRIC POWER CONSTR CO LTD

Oil-immersed transformer capable of cleaning impurities

InactiveCN112466616AEasy to check and maintainIncrease heightTransformers/reacts mounting/support/suspensionTransformers/inductances coolingElectric machineTransformer oil

Owner:江苏永刚电力设备有限公司

Bidirectional braking hydraulic machine and working method thereof

PendingCN113459558AImprove work efficiencyImprove working precisionPress ramHydraulic cylinderFour-way valve

The invention discloses a bidirectional braking hydraulic machine and a working method thereof. An oil outlet of an oil tank is connected with the input end of an oil pump; a hydraulic directional valve and a first electromagnetic directional valve are both three-position four-way valves, when the first electromagnetic directional valve is in the middle position, a first oil port and a second oil port of the first electromagnetic directional valve are connected with the hydraulic directional valve, a third oil port of the first electromagnetic directional valve is connected with the oil tank, and a fourth oil port of the first electromagnetic directional valve is connected with the output end of the oil pump; when the hydraulic reversing valve is in the middle position, a first oil port of the hydraulic reversing valve is connected with the oil tank, a second oil port is connected with an oil inlet of an overflow valve, a third oil port is connected with the output end of the oil pump, a fourth oil port is connected with rodless cavities of two hydraulic cylinders, a fifth oil port is divided into two paths, one path is sequentially connected with a throttling valve and rod cavities of the two hydraulic cylinders, the throttling valve is connected with a second electromagnetic reversing valve in parallel, and the other path is connected with an overflow valve; and an oil outlet of the overflow valve is respectively connected with an oil inlet of a third electromagnetic directional valve and the oil tank; and an oil outlet of the third electromagnetic directional valve is connected with the oil tank. Bidirectional pressing forming is achieved, the quality of formed parts and the production efficiency are improved, and the production cost is greatly reduced.

Owner:SHAANXI UNIV OF SCI & TECH

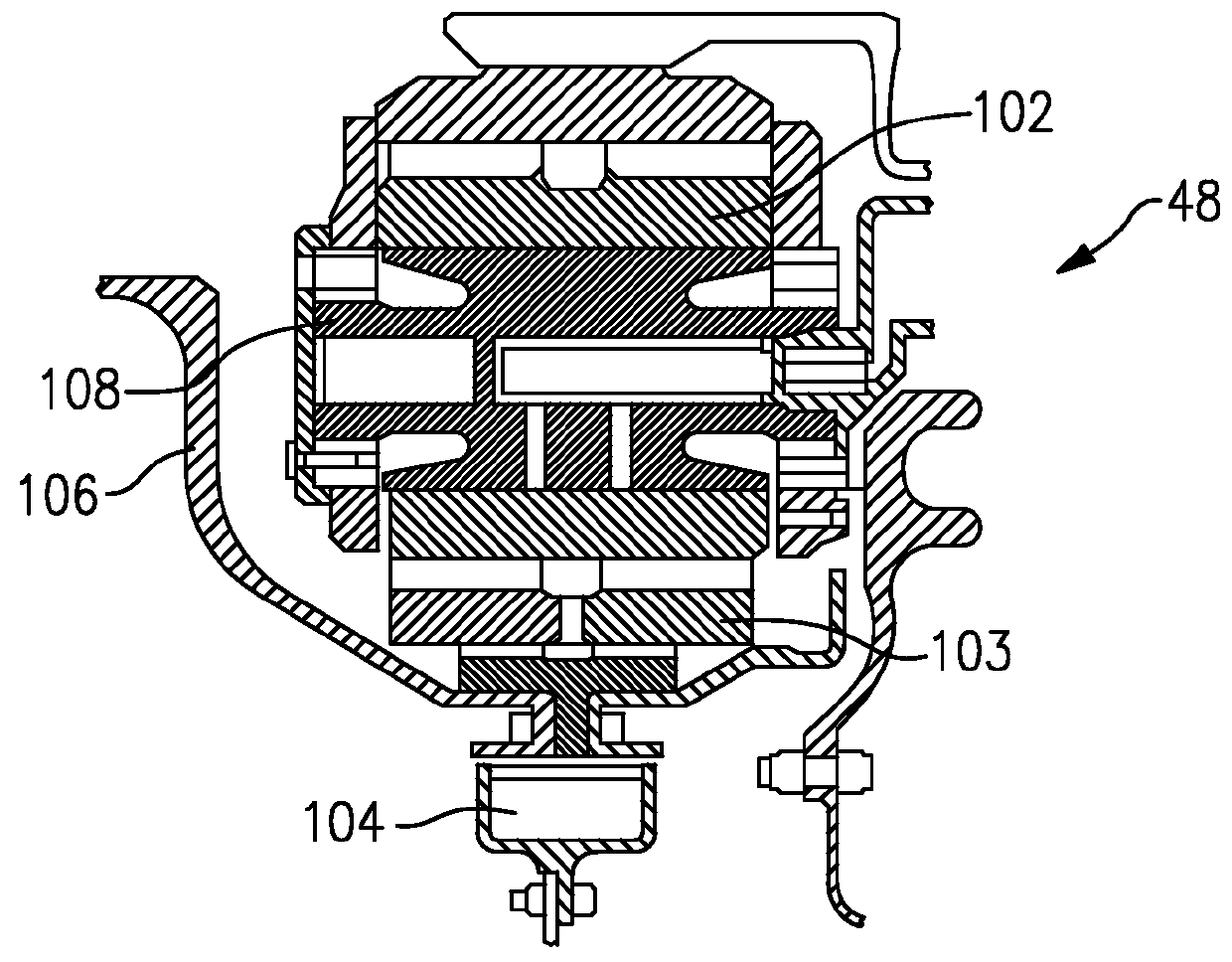

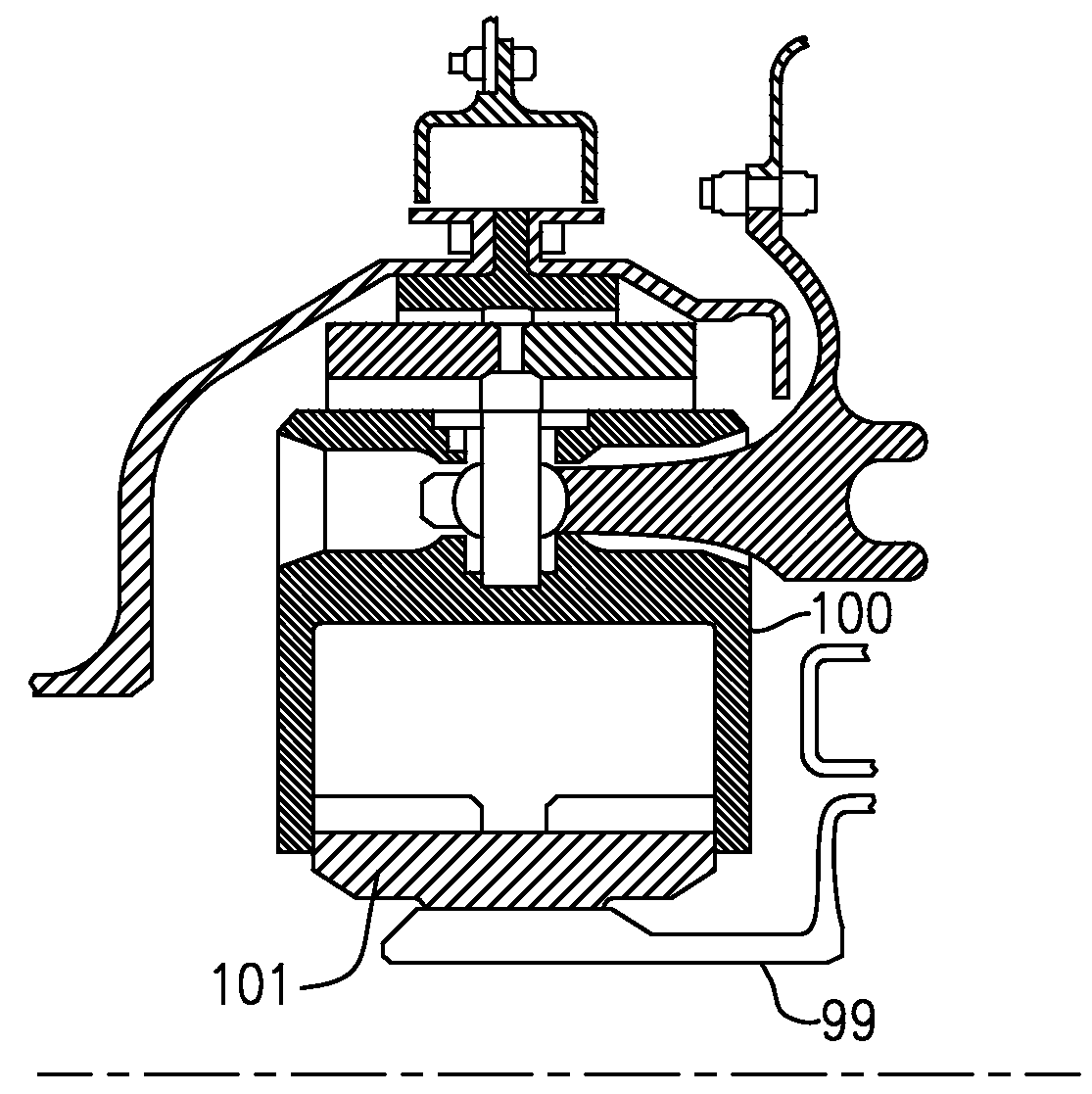

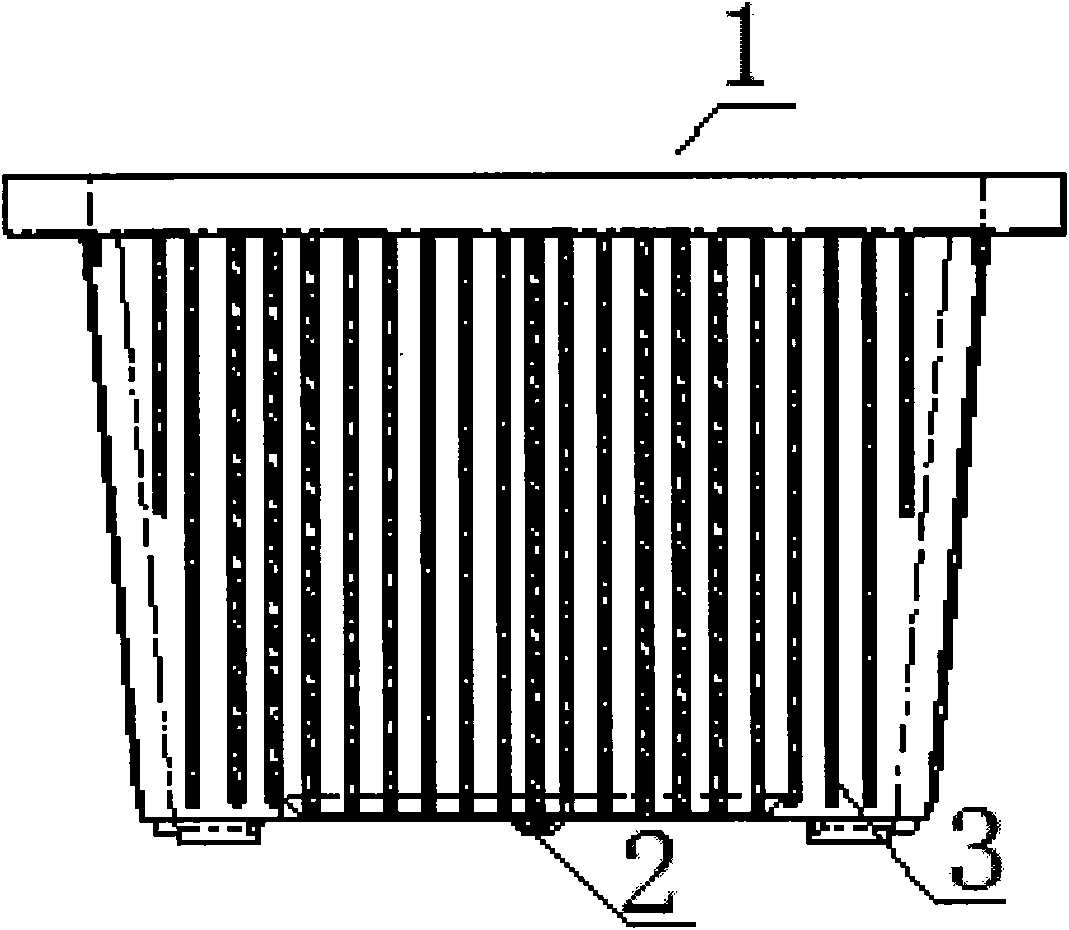

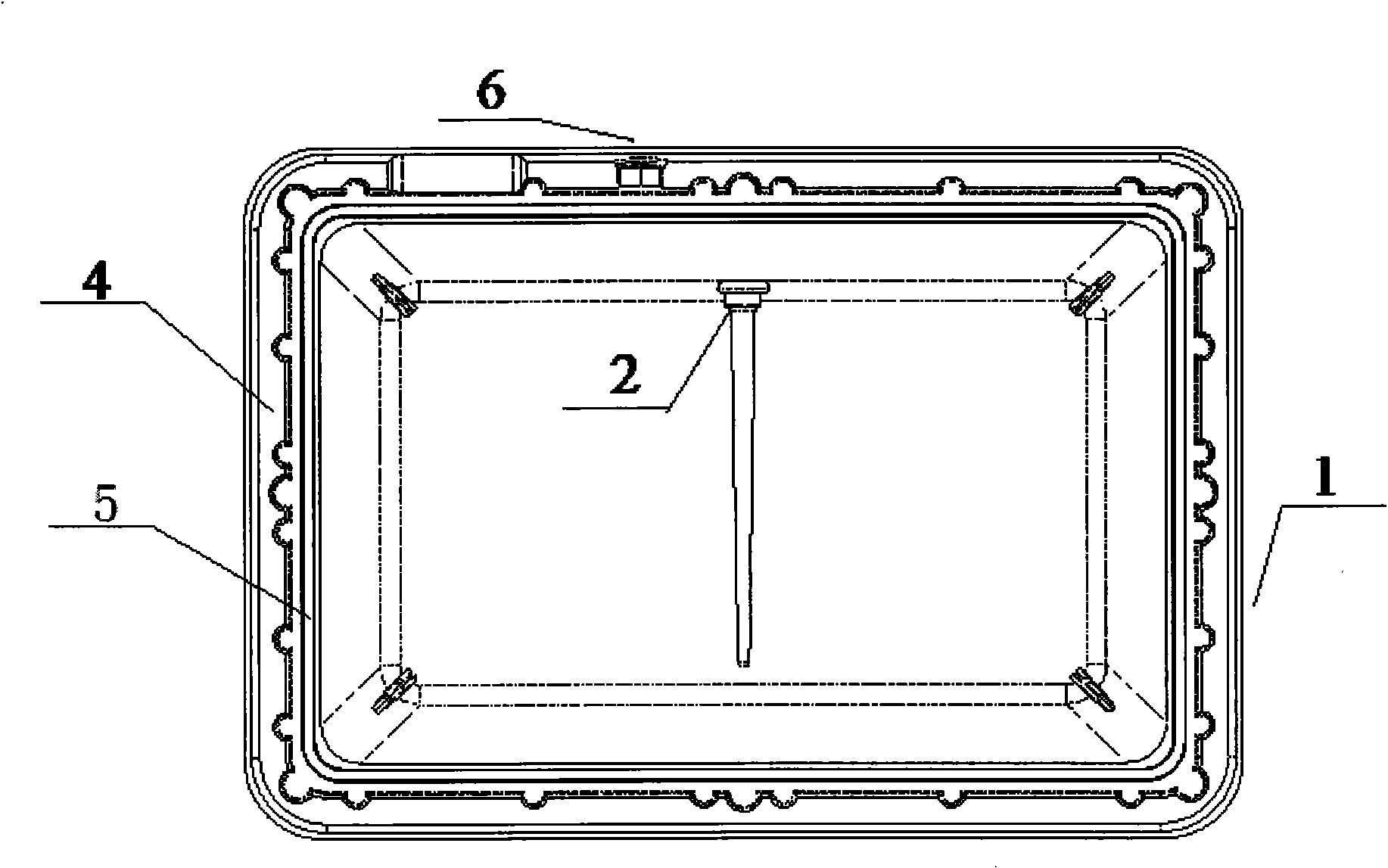

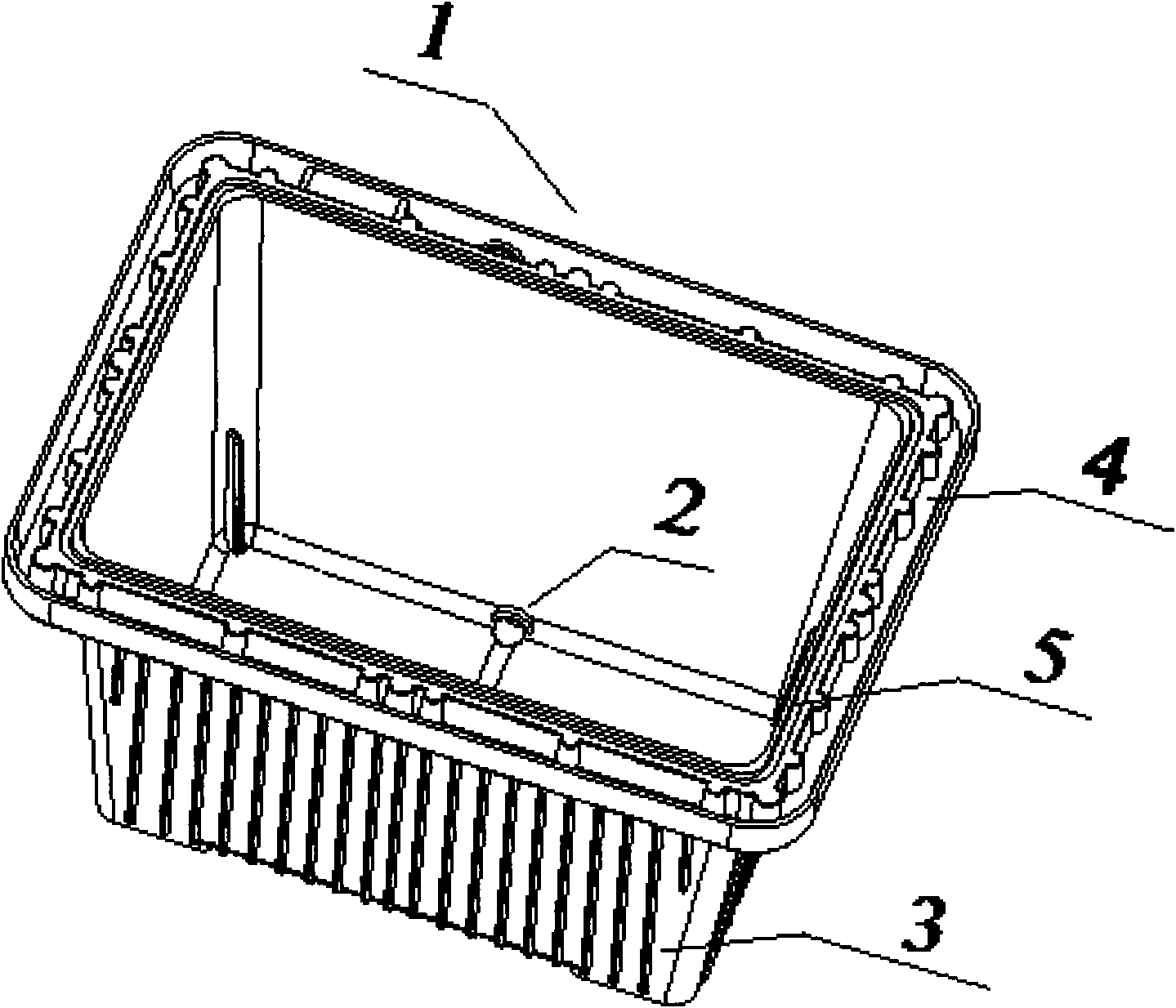

One-time molded oil tank

InactiveCN101852221AImprove cooling effectExtended service lifePump assembliesSafe operationHeat transfer

Owner:太仓成铭液压机械有限公司

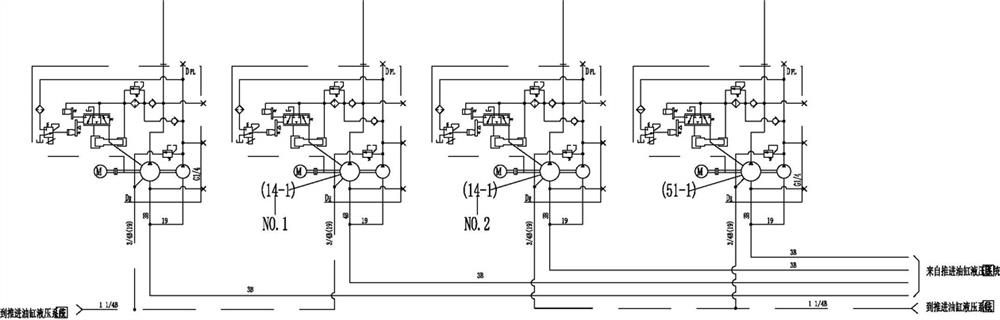

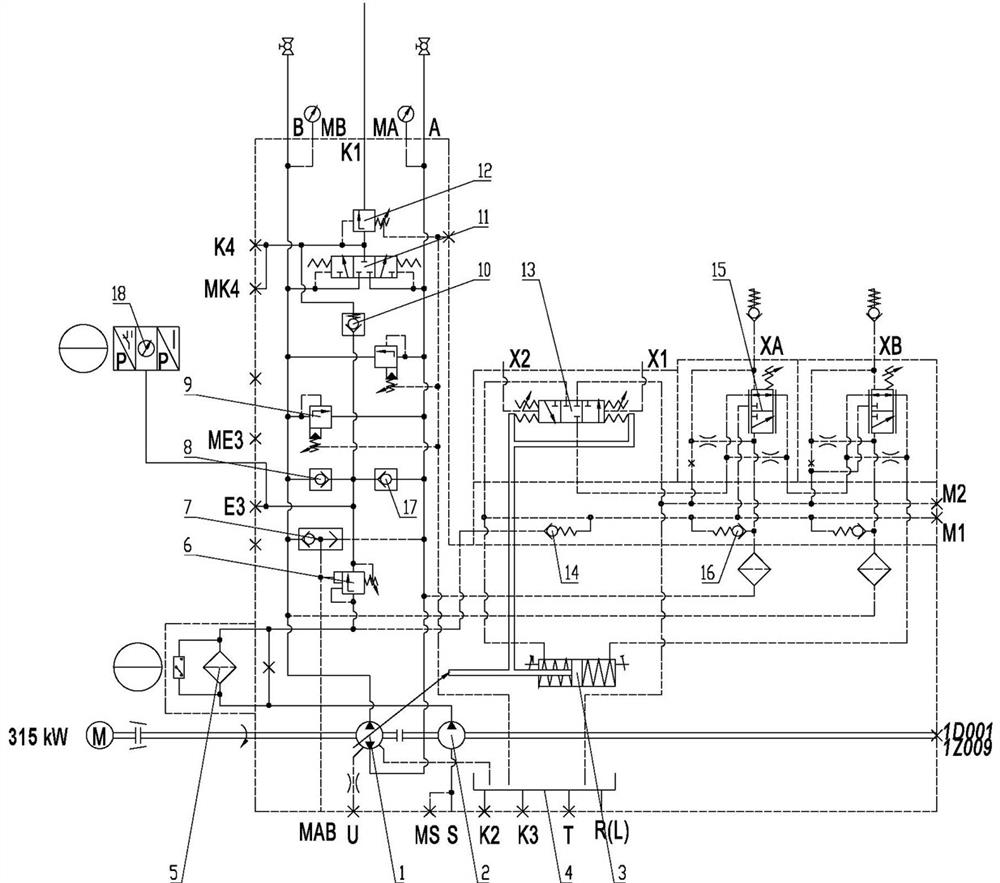

Screw machine closed hydraulic system for shield machine and shield machine

PendingCN112610547ASo as not to damageAvoid damageFluid-pressure actuator safetyServomotorsEngineeringMachine

Owner:JIANGSU KAIGONG TUNNEL MACHINERY

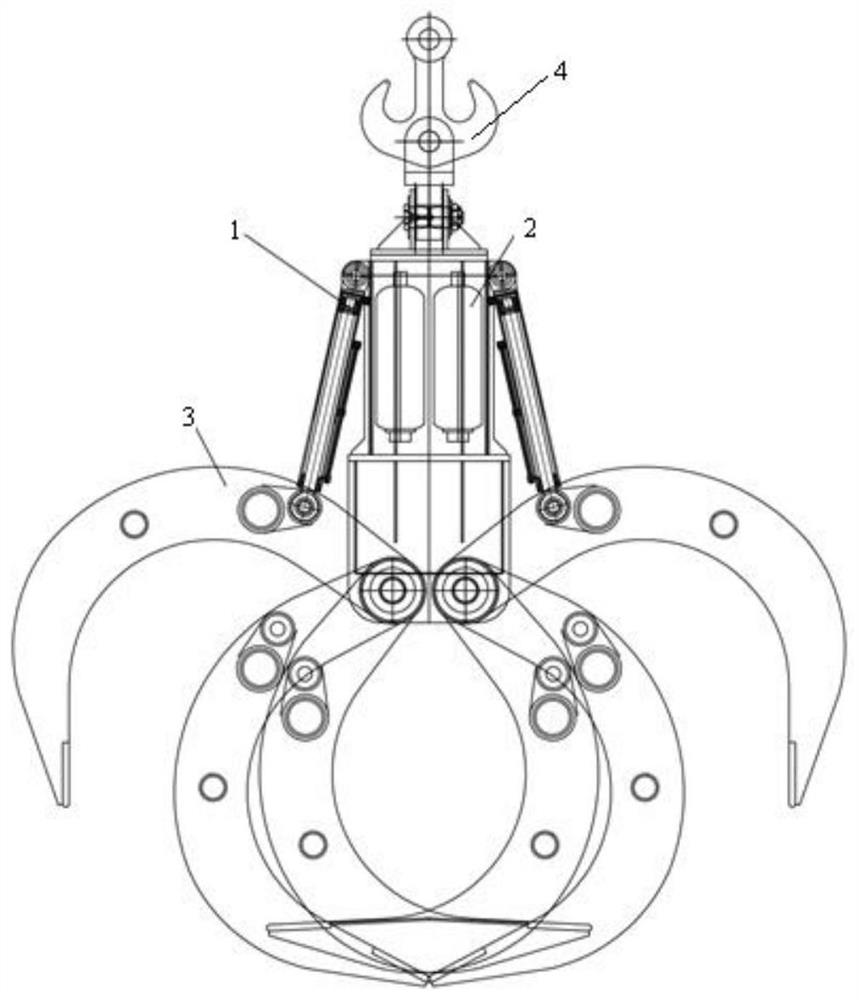

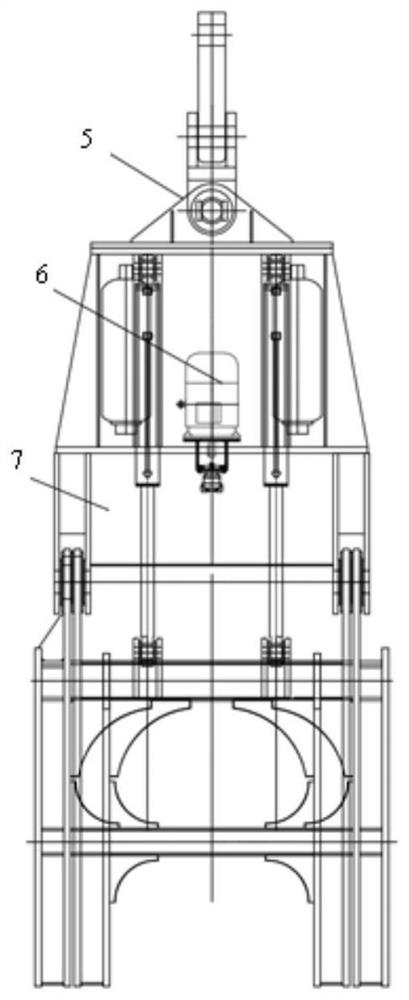

Operating system and method of electric hydraulic gripping apparatus in container loading and unloading equipment

PendingCN112897330AEasy to operateFast clamping speedServomotor componentsServomotorsPower efficientControl system

Owner:ENBEILI KUNSHAN MACHINERY

Equipment capable of cleaning transformer and protecting detection

InactiveCN112530674AAchieve cleanupReduce security risksTransformers/inductances coolingFire rescueWater sourceProcess engineering

Owner:义乌市怡裳电子商务有限公司

Transformer heat dissipation tube

InactiveCN104319074AAvoid damageImprove heat transfer efficiencyTransformers/inductances coolingThermodynamicsTap water

Owner:CHONGQING WANGBIAN ELECTRIC GRP CORP

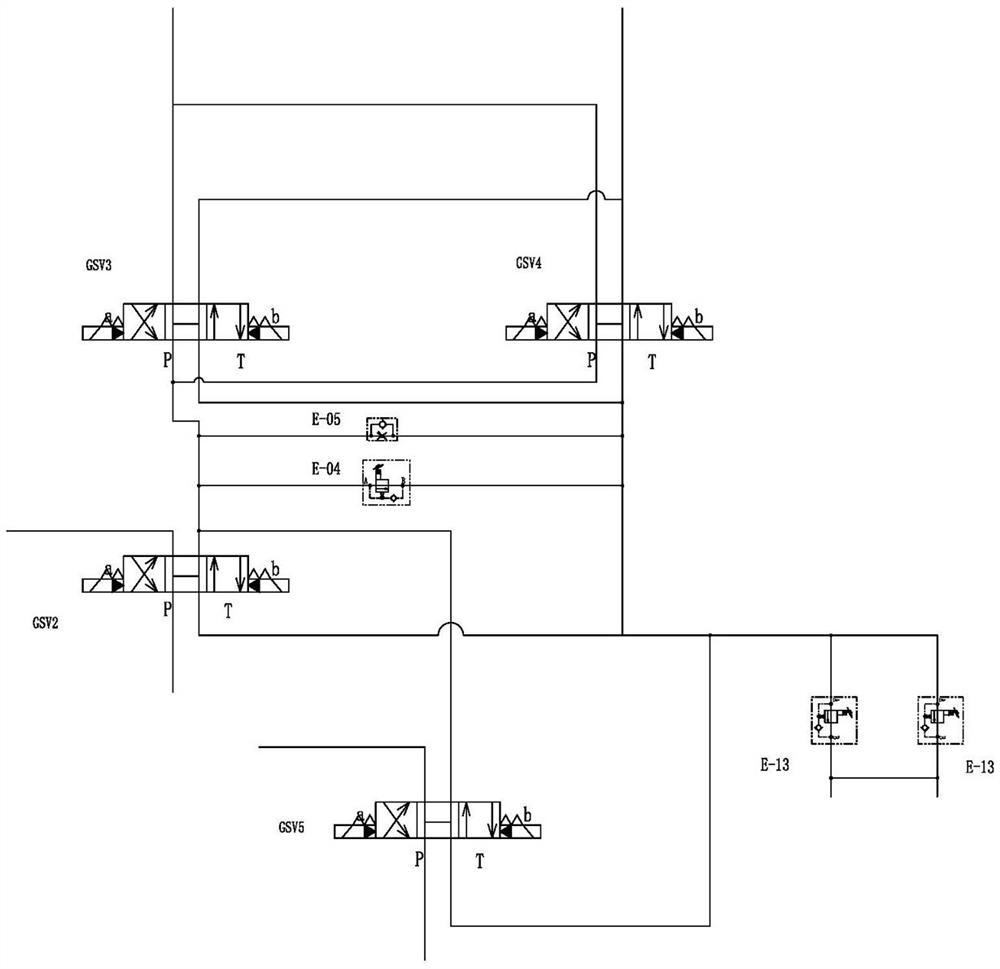

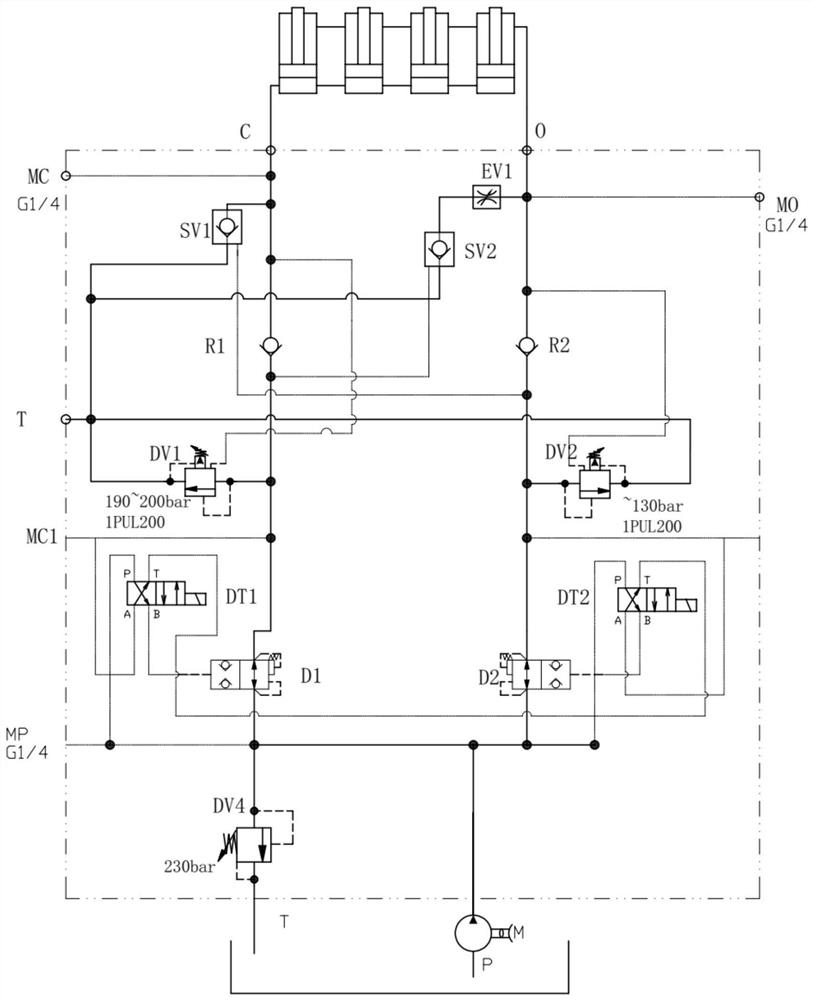

Double-oil-inlet type hydraulic integrated valve group and double-oil-pump type hydraulic station for large filter press

PendingCN114412870APressurize fastPressurization simplifiedFluid-pressure actuator testingServomotor componentsFilter pressOil pump

According to the double-oil-inlet type hydraulic pile-up valve group and the double-oil-pump type hydraulic station for the large filter press, the key points of the innovative scheme are that the hydraulic pile-up valve group comprises a hydraulic pile-up valve, an electro-hydraulic directional control valve, a hydraulic control one-way valve and an electromagnetic relief valve; the double-oil-inlet hydraulic pile-up valve is mainly characterized in that an existing single-oil-inlet hydraulic pile-up valve is improved into a double-oil-inlet hydraulic pile-up valve, so that double large electric oil pump sets and the hydraulic pile-up valve can be directly connected through double hydraulic oil pipes, and a three-way connector is omitted; the functions of hydraulic oil reversing, overflow pressure stabilizing and non-return pressure maintaining are achieved. The double-oil-pump type hydraulic station uses the hydraulic pile-up valve group, and solves the problems that a single-oil-inlet type hydraulic pile-up valve needs to be indirectly connected with a double-large electric oil pump group and the hydraulic pile-up valve by means of a three-way joint, the structure is complex, the number of oil pipe joints is large, the failure rate is high, and certain pressure loss exists after hydraulic oil is converged through the three-way joint; an oil inlet hole of the hydraulic pile-up valve is close to an oil tank cover, the installation space is limited, and the three-way connector is difficult to install and detach.

Owner:JINGJIN ENVIRONMENTAL PROTECTION INC

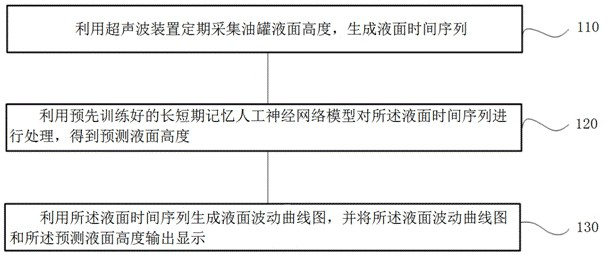

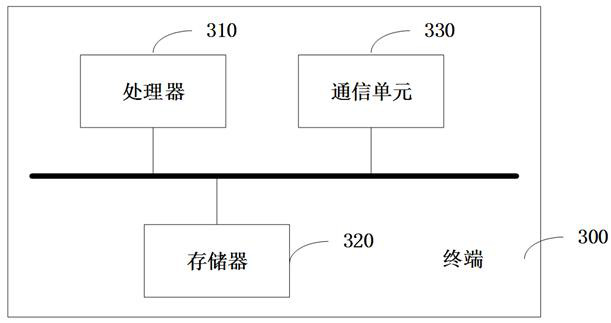

Oil tank liquid level ultrasonic measurement method and system based on LSTM, terminal and storage medium

InactiveCN113566929AImprove accuracyReliable design principleMachines/enginesLevel indicatorsEngineeringComputational physics

Owner:SHANDONG XIWANG FOOD

Mechanical arm and control method thereof

ActiveCN105625956AEasy to operateImprove securityDrilling rodsDrilling casingsPush pullControl valves

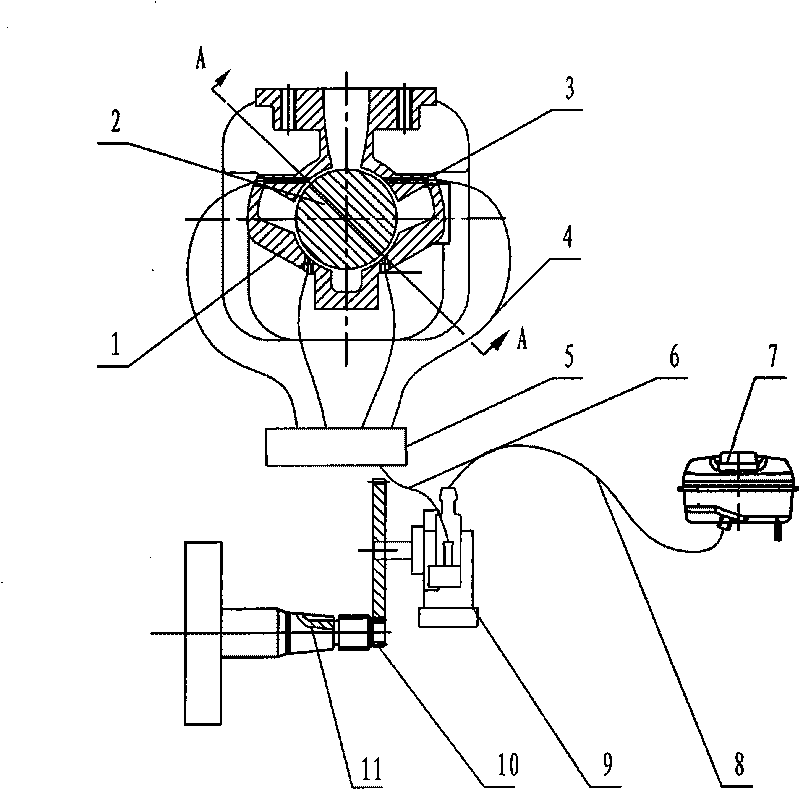

The invention discloses a mechanical arm and a control method thereof and belongs to the field of petroleum machinery. The mechanical arm comprises a mechanical arm assembly, a single-oil-way control valve, a dual-oil-way control valve and a controller, wherein the mechanical arm assembly comprises a servo cylinder and a displacement sensor, a servo cylinder front oil way and a servo cylinder back oil way are arranged on the servo cylinder, and the servo cylinder is connected with a push-pull manipulator; the servo cylinder front oil way and the servo cylinder back oil way are connected with a hydraulic oil tank respectively, the single-oil-way control valve is arranged on the servo cylinder back oil way, and the dual-oil-way control valve is arranged on the servo cylinder front oil way and the servo cylinder back oil way; the controller is connected with the displacement sensor and the single-oil-way control valve. According to the mechanical arm and the control method thereof, problems that operation processes are complex and operation safety is lower during operations related to pulling and running of oil tubes at wellheads of oil and water wells are solved, the operation processes are simplified, and the operation safety is improved; the mechanical arm and the control method thereof are used for pulling and running of the oil tubes for the oil and water wells.

Owner:PETROCHINA CO LTD

Lubricating system for double-stroke gasoline engine

InactiveCN101737115AGuaranteed emission standardsIncrease powerPressure lubrication with lubrication pumpDiaphragm pumpGasoline

Owner:JIANGSU NONGHUA WISDOM AGRICULTURAL SCIENCE AND TECHNOLOGY CO LTD

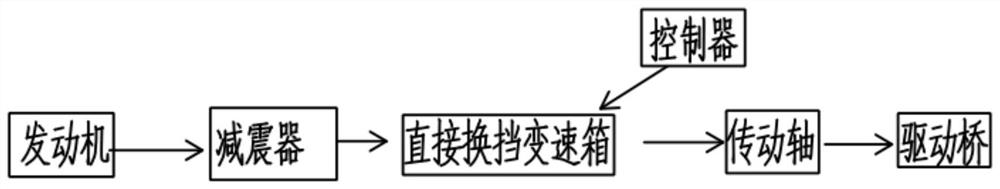

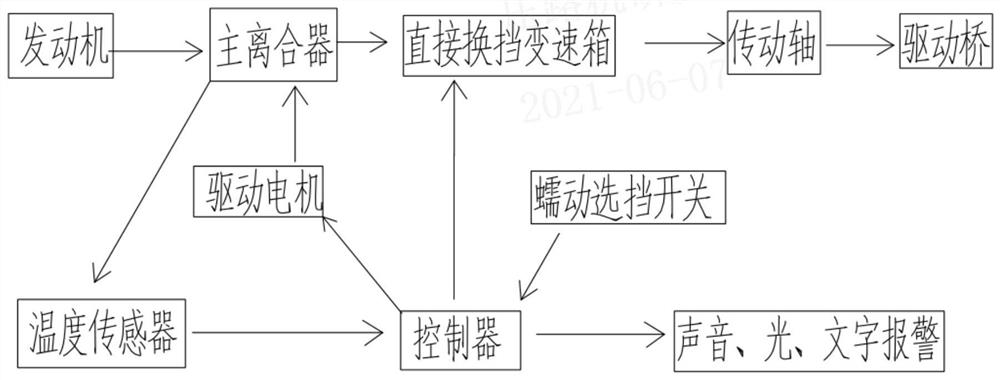

Direct gear shifting system and method with peristaltic walking function

ActiveCN113404855AIncrease speedRealize low speed driving stateHybrid vehiclesClutchesDrivetrainDrive shaft

Owner:XCMG CONSTR MACHINERY

Engine oil oil-way system of gasoline engine

Owner:YONGKANG LINGHANG MACHINE POWER

Novel internal circulation engine

Owner:艾士成

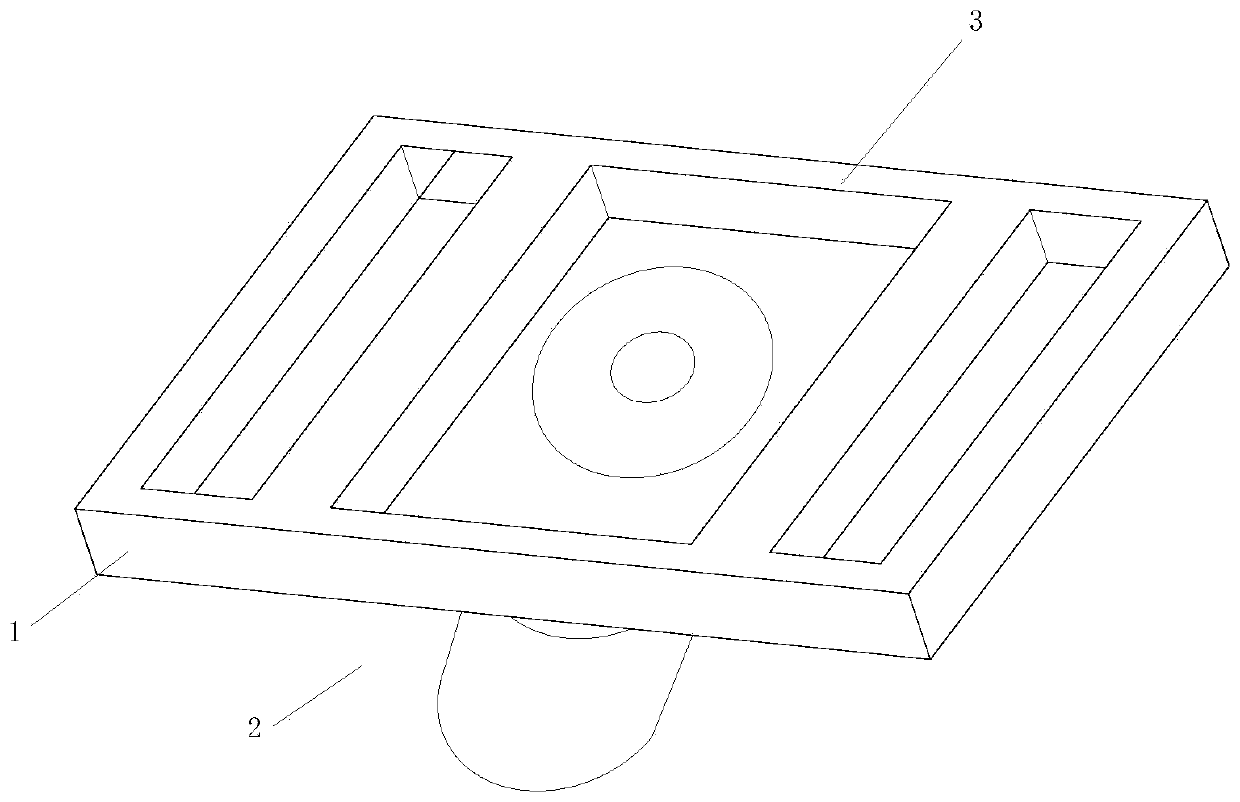

Protective oil tank for oil field maintenance field-acquisition site and manufacturing method for protective oil tank

ActiveCN111547390AFirmly connectedEasy to operateSewerage structuresLarge containersOil fieldOil tank

Owner:潍坊金浩包装制品有限公司

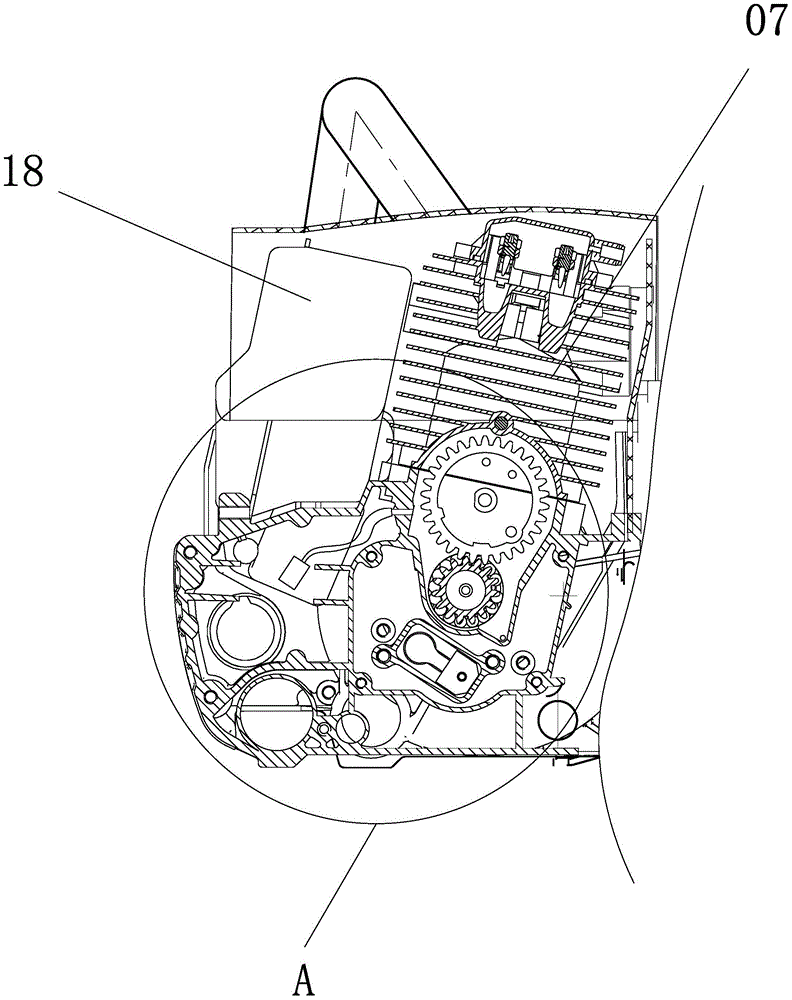

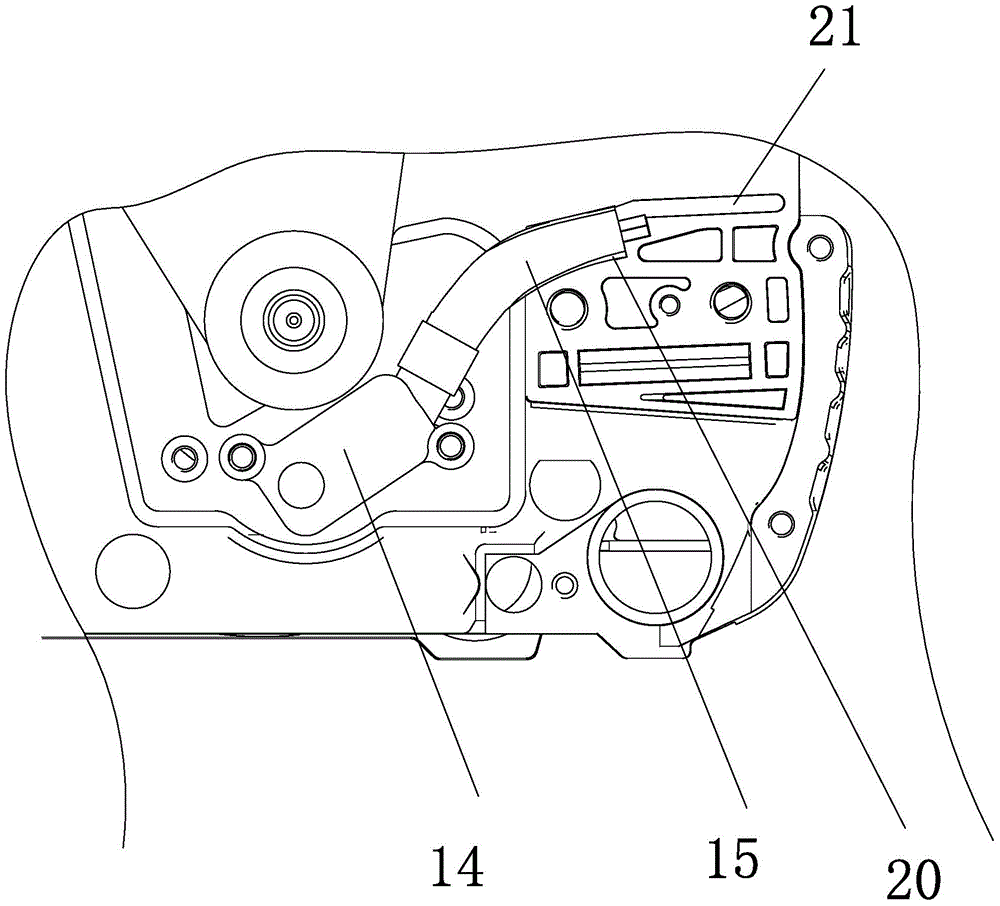

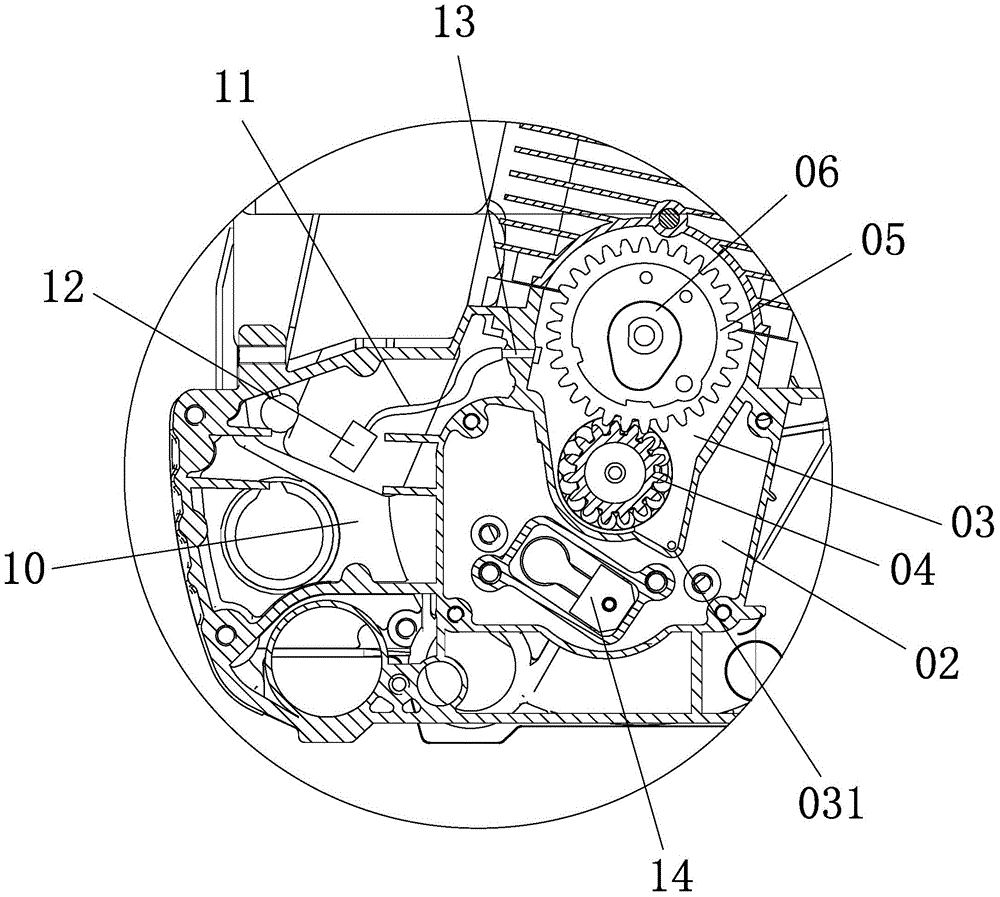

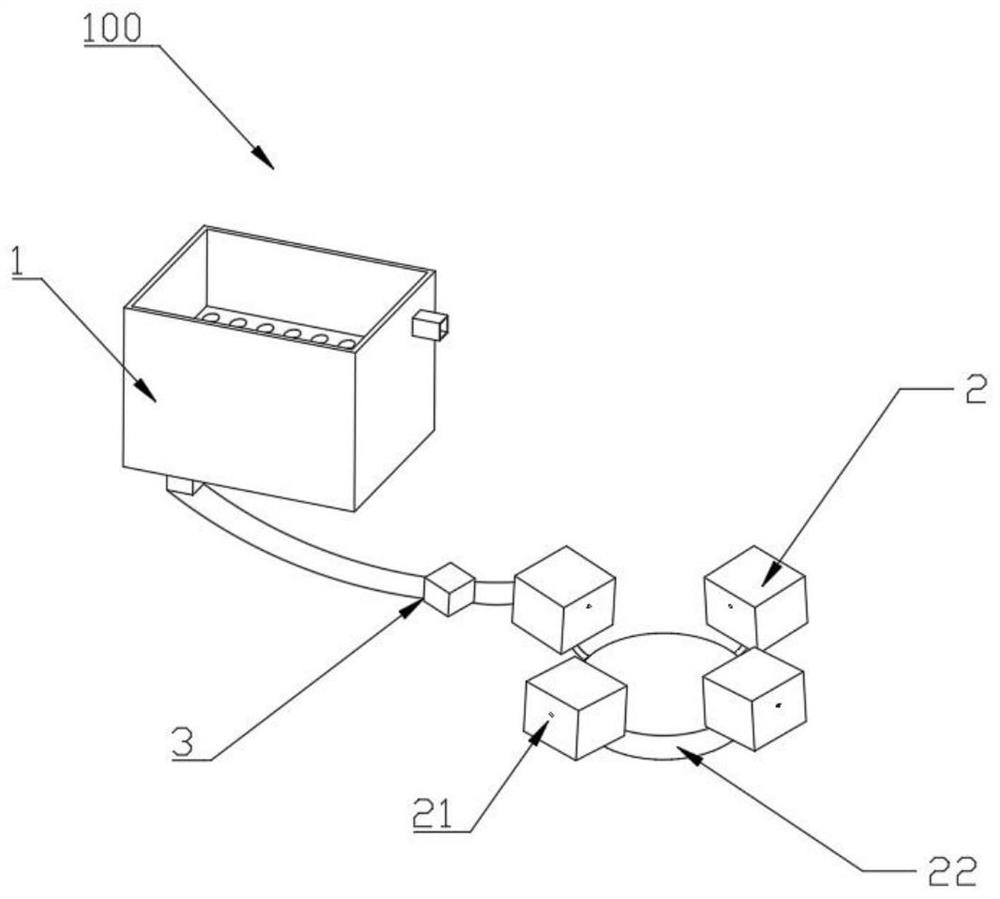

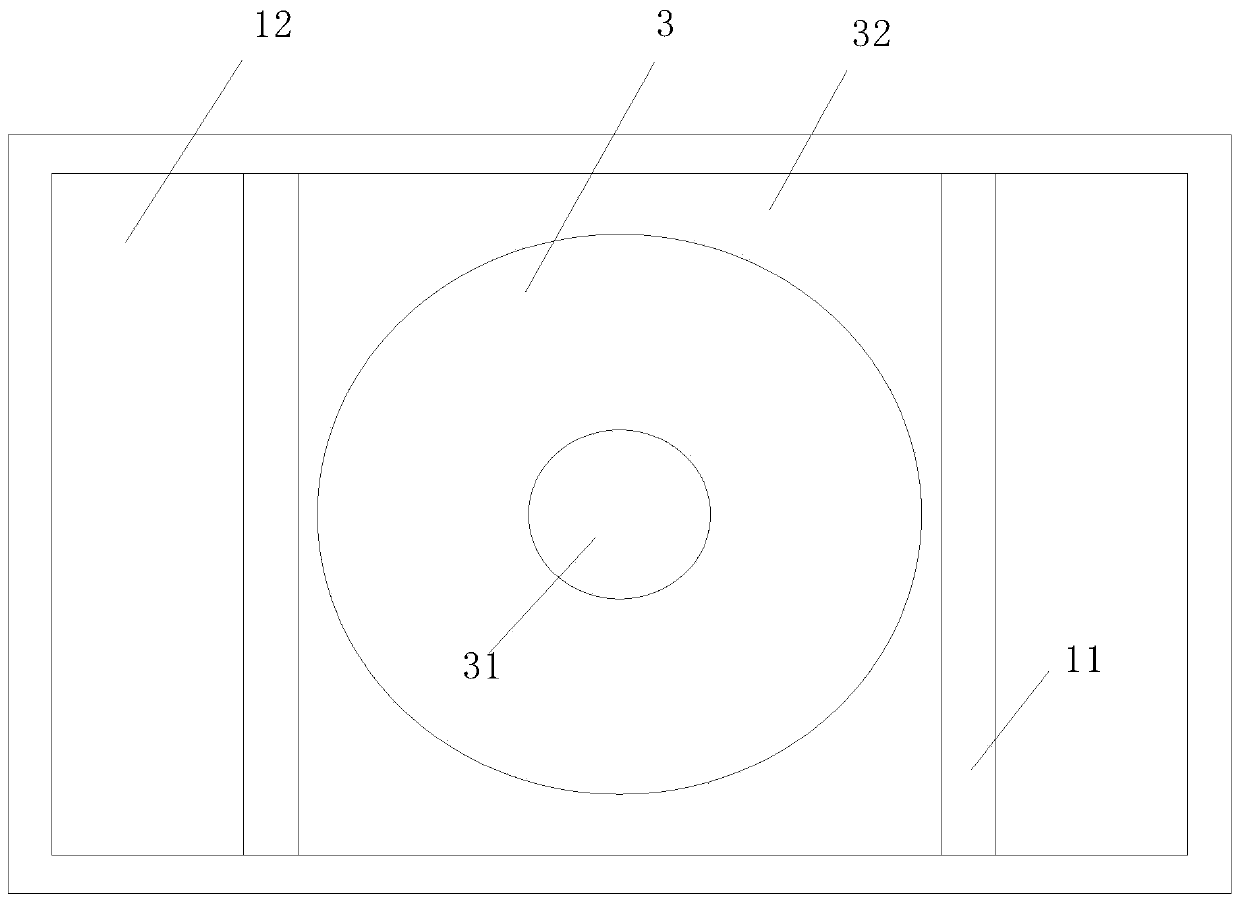

Oil tank installation structure and engine

InactiveCN109026469AAvoid the influence of layoutEasy to installMachines/enginesLiquid fuel feedersCrankcaseOil tank

The invention relates to the technical field of engine parts and aims at providing an oil tank installation structure and an engine. The oil tank installation structure comprises a crank case, a fan cover, an oil tank and a fixing part. The oil tank comprises an oil tank body, an installation supporting lug and a clamping connection protrusion. A connecting through hole is formed in the installation supporting lug and fixedly connected, penetrates the installation supporting lug and is then fixedly connected with the crank case, and therefore the oil tank and the crank case can be fixedly connected. A clamping connection opening is formed in the fan cover, the clamping connection protrusion is connected in the clamping connection opening in a clamping manner, and therefore the oil tank andthe fan cover can be fixedly connected together. By means of the oil tank installation structure, supporting lugs on the left side and the right side of the oil tank are eliminated, and due to the fact that the installation supporting lug is arranged at the lower end of the oil tank and is connected with the crank case, the influences on the arrangement of the rest of parts are avoided after theoil tank is installed on the crank case; and the clamping connection protrusion is arranged at the upper end of the oil tank, the oil tank is connected with the fan cover in a clamping connection manner, and installation is convenient and fast.

Owner:LONCIN MOTOR

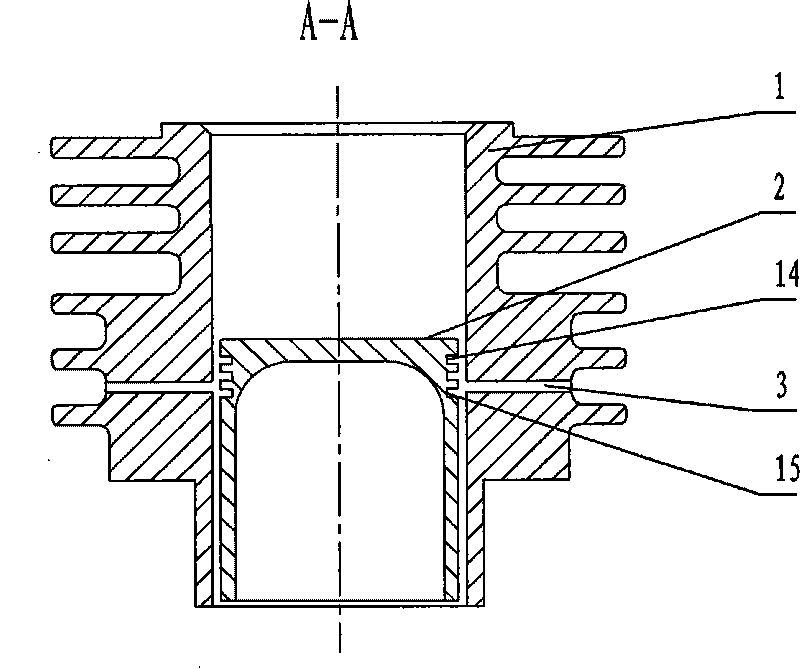

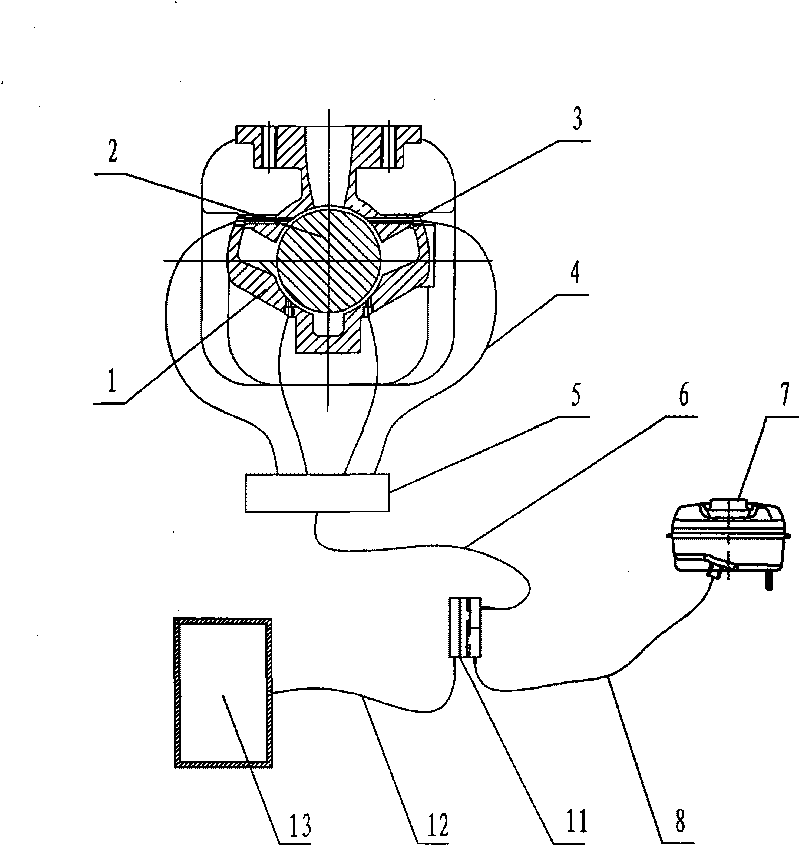

Molded self-lubricating joint bearing and use method thereof

Owner:福建省德源智能科技有限公司

Device for detecting influence of outgoing line mode of vehicle-mounted transformer on short-circuit resisting capability

PendingCN114325471AImprove short circuit resistanceTransformers/inductances coolingTransformers/inductances coils/windings/connectionsIn vehicleTransformer

The invention relates to a device for detecting the influence of the outgoing line mode on the short-circuit resistance of a vehicle-mounted transformer, which is characterized in that a winding is arranged in an oil tank, an incoming line terminal is arranged at the upper part of the oil tank, an outgoing line device comprising an outgoing line terminal is arranged on the side surface of the oil tank, and the incoming line terminal and the outgoing line terminal are connected with the winding; the wire inlet terminal and the wire outlet terminal are connected with an external current applying unit to form a closed loop, an upper end camera is arranged on the upper portion of the oil tank, a side face camera is arranged on the side of the wire outlet device, and a plurality of vibration sensors are arranged in the wire outlet device and on the outer side face of the wire outlet device. The vibration sensors are installed at the positions of an outgoing line, a paperboard and an outgoing line clamp of the outgoing line device, the vibration sensors are connected into the signal collecting and processing device through shielding signal lines, and according to a calculated test data result, if the outgoing line, the paperboard and the outgoing line clamp deform seriously, the outgoing line mode of the vehicle-mounted transformer is adjusted. According to the invention, data and basis can be provided for improving the anti-short-circuit capability of the vehicle-mounted transformer in the future.

Owner:SHANDONG POWER EQUIP

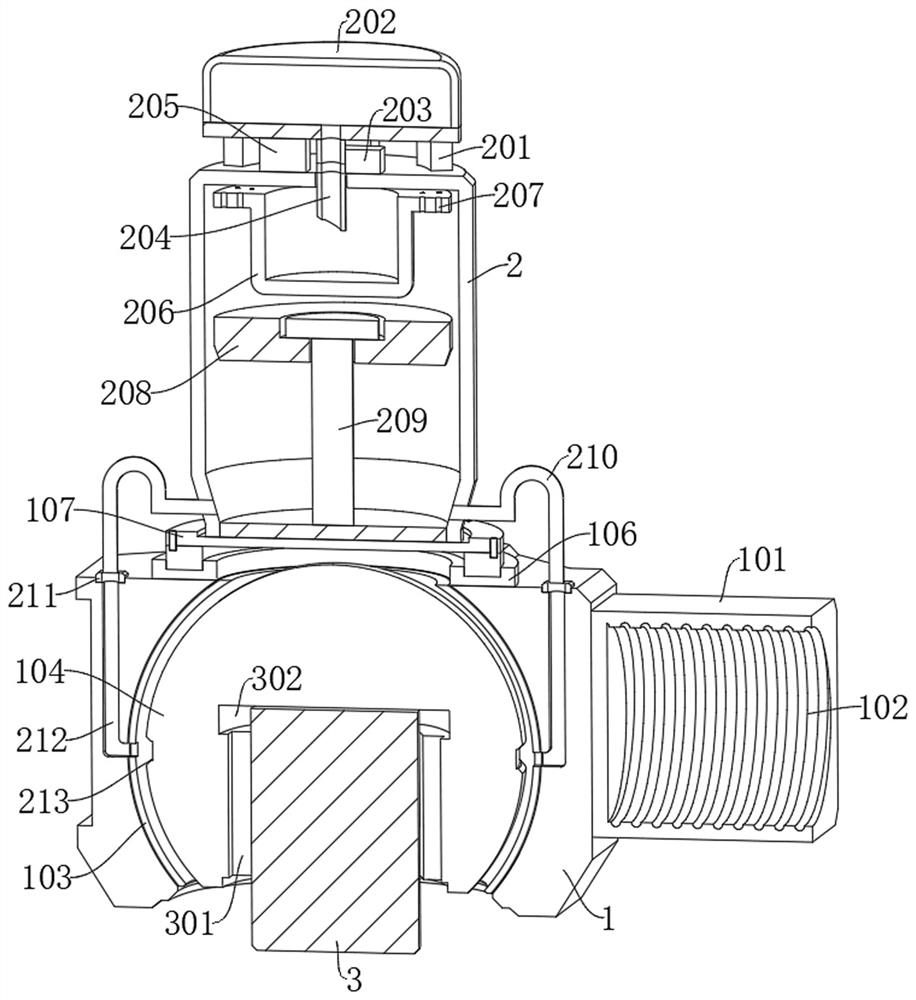

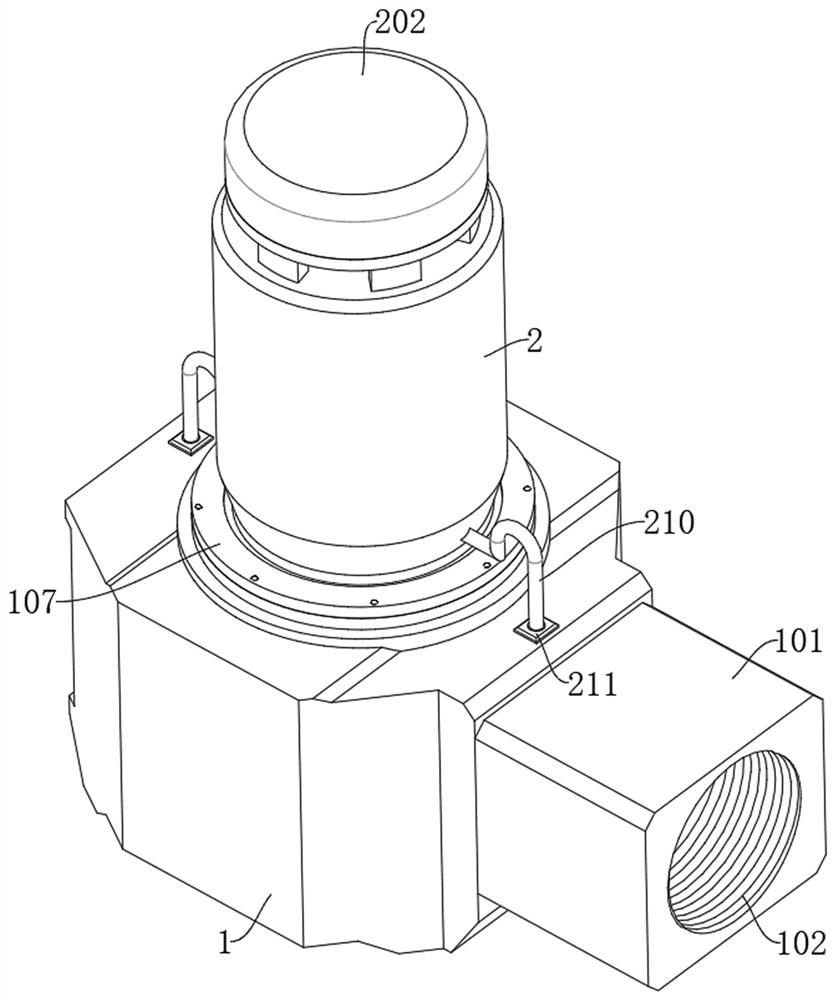

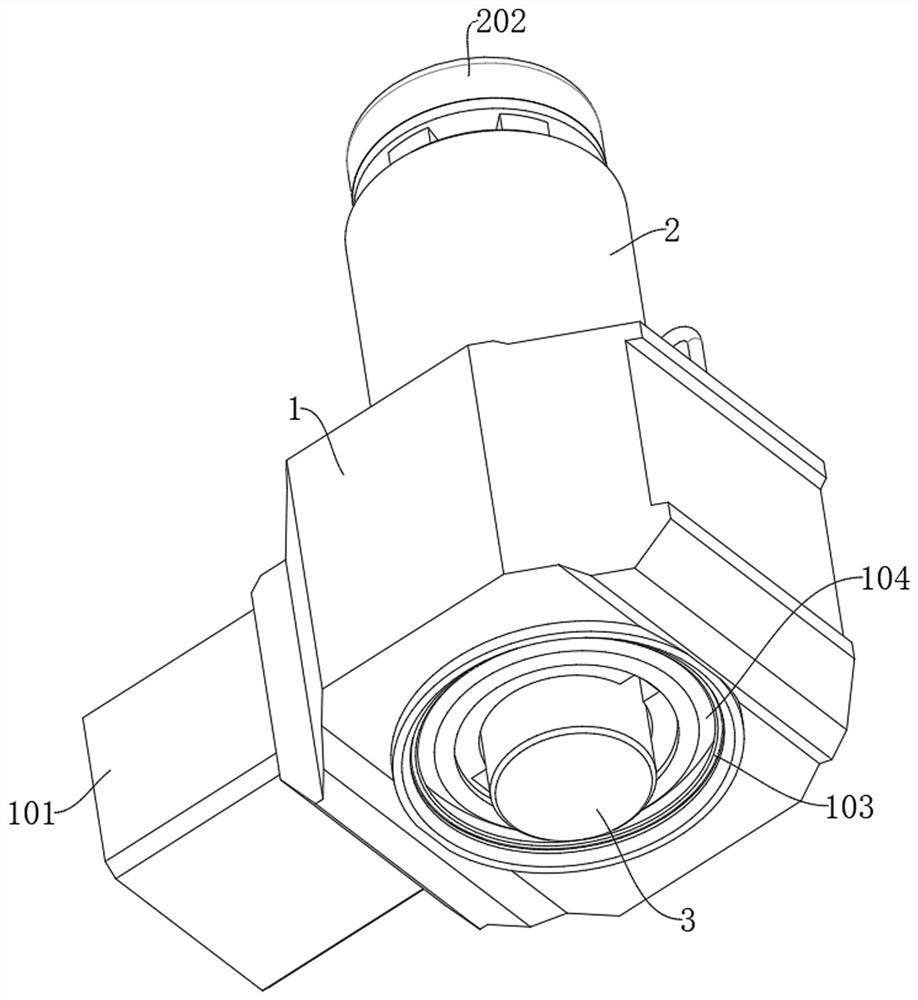

Efficient oil-water separation device

ActiveCN114212904AImprove stabilityRealize automatic impurity removalFatty/oily/floating substances removal devicesTreatment involving filtrationSeparation technologyOil water

The invention relates to an efficient oil-water separation device, and relates to the field of oil-water separation technologies. The oil-water separation device comprises a separation device body, an oil storage tank arranged below the separation device body, a supporting frame connected to the upper portion of the oil storage tank in a sliding mode, a storage bin fixedly arranged on the supporting frame, an oil outlet pipe arranged below the storage bin, a control valve arranged on the oil outlet pipe and a filter screen arranged at a feeding port of the separation device body. The impurity removing mechanism is arranged between the filter screen and the separation device body and used for removing impurities on the filter screen, and the moving mechanism is arranged between the supporting frame and the oil storage tank and used for driving the supporting frame to slide towards the side away from or close to the separation device body. The oil-water separator has the beneficial effects that a worker can conveniently remove impurities in the oil-water separator, the operation stability of the oil-water separator is improved, the labor intensity of the worker is relieved, and the treatment efficiency of the oil-water separator is improved.

Owner:SHENZHEN HENGXINGSHENG KITCHENWARE CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap