Lubricating system for double-stroke gasoline engine

A lubrication system and gasoline engine technology, applied in the field of lubrication systems, can solve the problems affecting gasoline engine power and poor effect, achieve the effects of improving power and service life, ensuring up-to-standard emissions, and overcoming poor emission effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

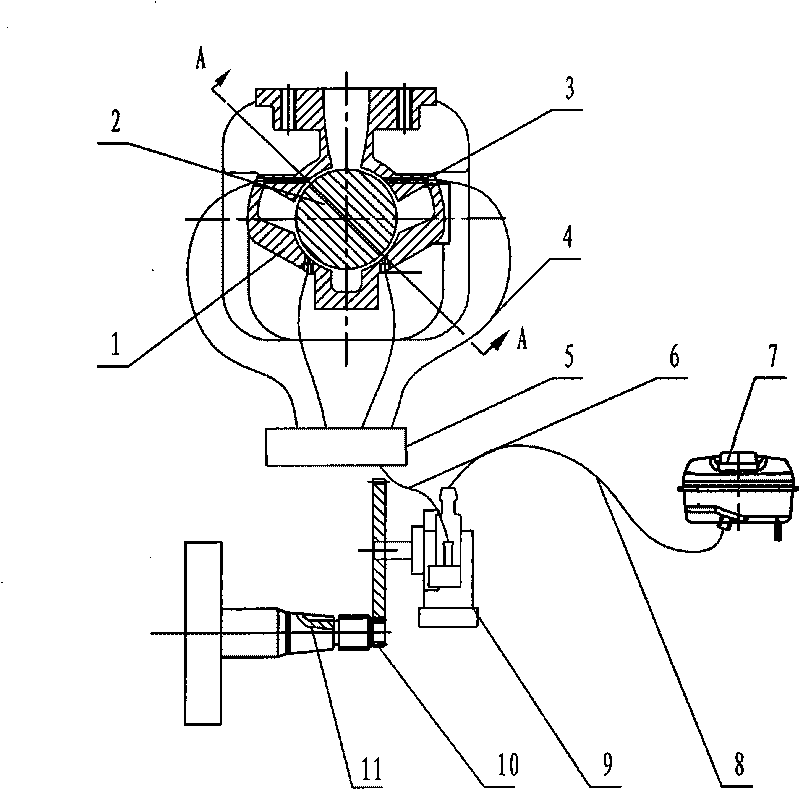

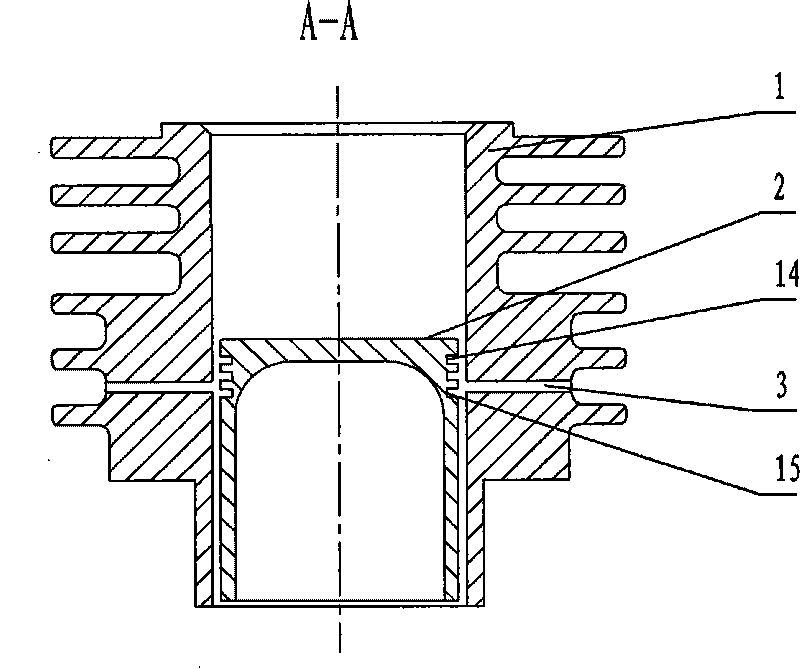

[0014] Embodiment one, such as figure 1 with figure 2 shown. The lubrication system of the two-stroke gasoline engine described in the present embodiment comprises a cylinder 1, an oil pump 9, an oil tank 7, a gear pair 10 and an oil distribution box 5, and the oil pump 9 communicates with the oil tank 7 through an oil pipe 8; the oil pump 9 The gear pair 10 is connected to the crankshaft 11 of the two-stroke gasoline engine; the oil pump 9 communicates with the oil distribution box 5 through the oil delivery pipe 6; the oil distribution box 5 is provided with four oil holes 3 on the cylinder 1 through four oil supply pipes 4, respectively Connected. The piston 2 placed in the cylinder 1 is provided with an oil ring 15 below the two gas rings 14 on its peripheral surface. When working, the crankshaft 11 of the two-stroke gasoline engine provides power to the oil pump 9 through the gear pair 10, and the oil pump 9 pumps the oil in the oil tank 7 into the oil distribution box 5

Embodiment 2

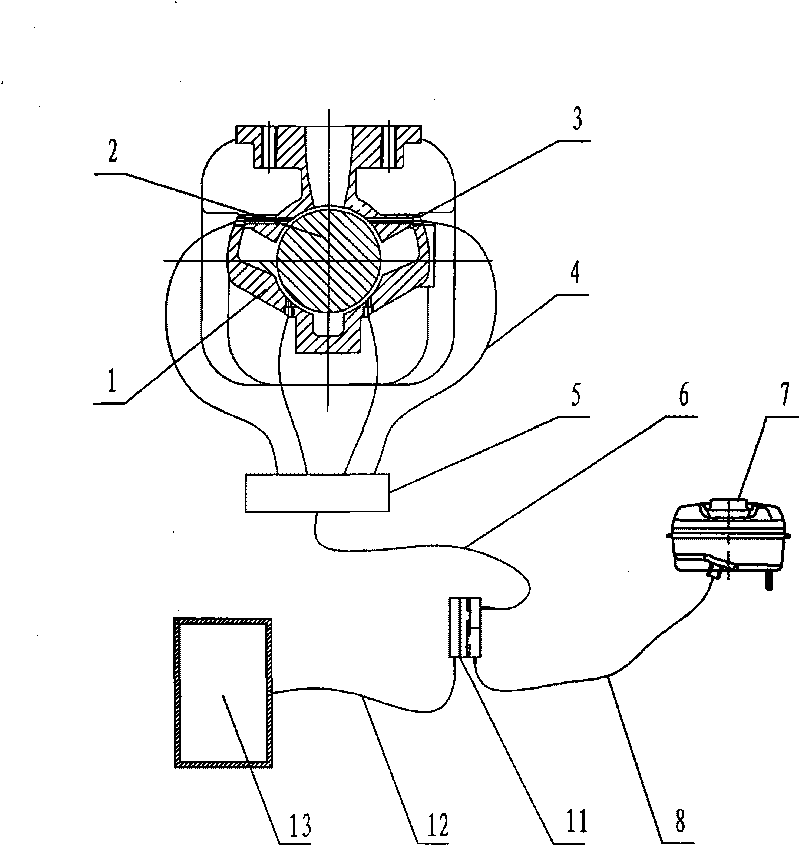

[0015] Embodiment two, such as image 3 shown. In this embodiment, the oil pump 9 and the gear pair 10 in the first embodiment are replaced by a diaphragm pump 11 . The air inlet of the diaphragm pump 11 communicates with the crankcase 13 of the two-stroke gasoline engine through the air pipe 12; 6 communicates with the oil distribution box 5. During work, the constantly changing air flow in the crankcase 13 of the two-stroke gasoline engine provides power to the diaphragm pump 11, and the diaphragm pump 11 pumps the oil in the oil tank 7 into the oil distribution box 5.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap