Operating system and method of electric hydraulic gripping apparatus in container loading and unloading equipment

A technology for loading and unloading equipment and operating systems, which is applied in mechanical equipment, fluid pressure actuation devices, transportation and packaging, etc., to avoid waste of time and energy, improve clamping reliability, and speed up operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENTS The following examples are intended to illustrate the invention, but are not intended to limit the scope of the invention.

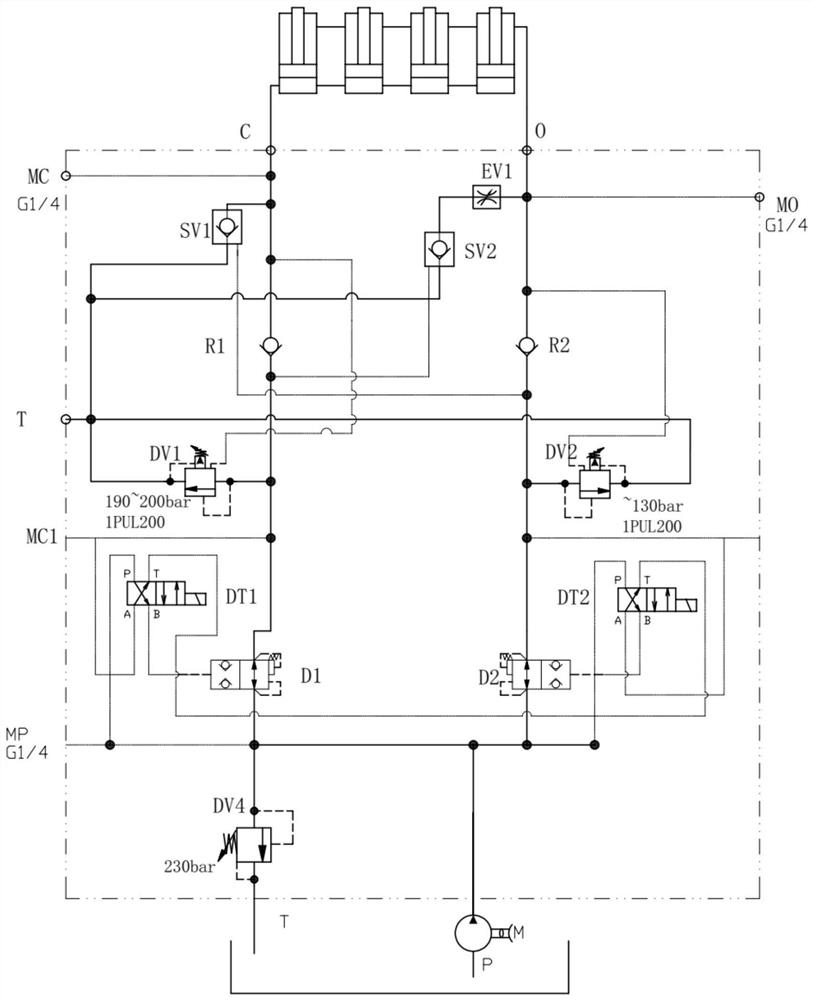

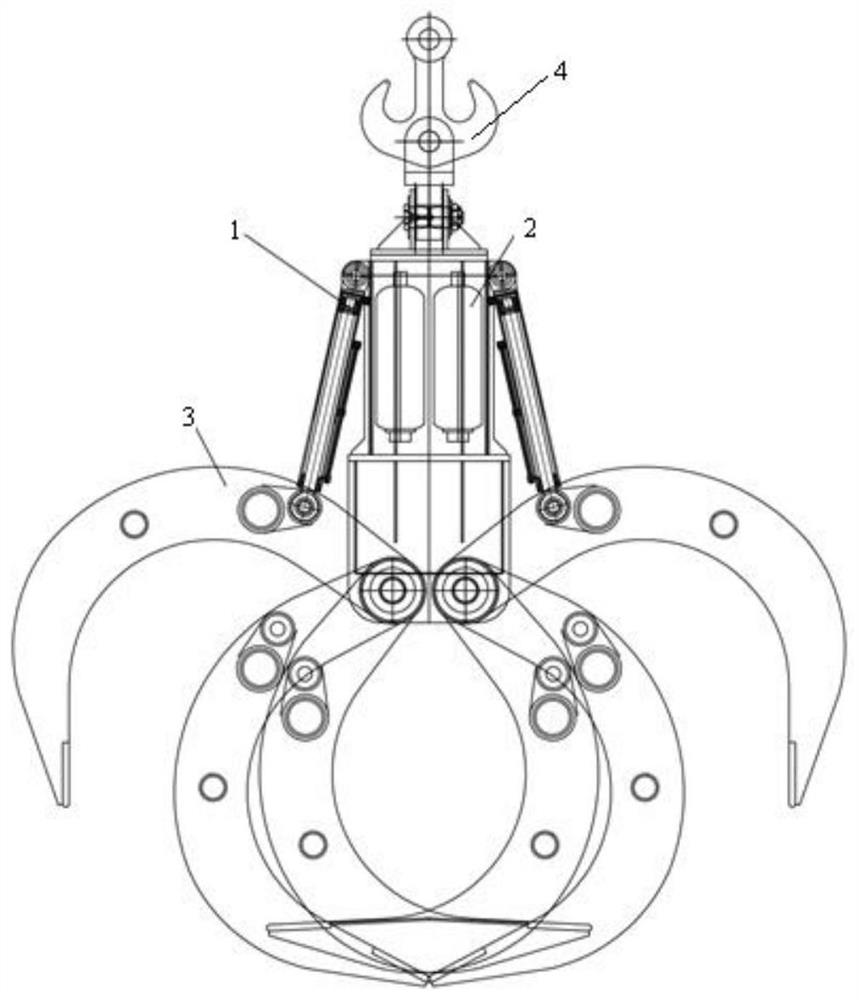

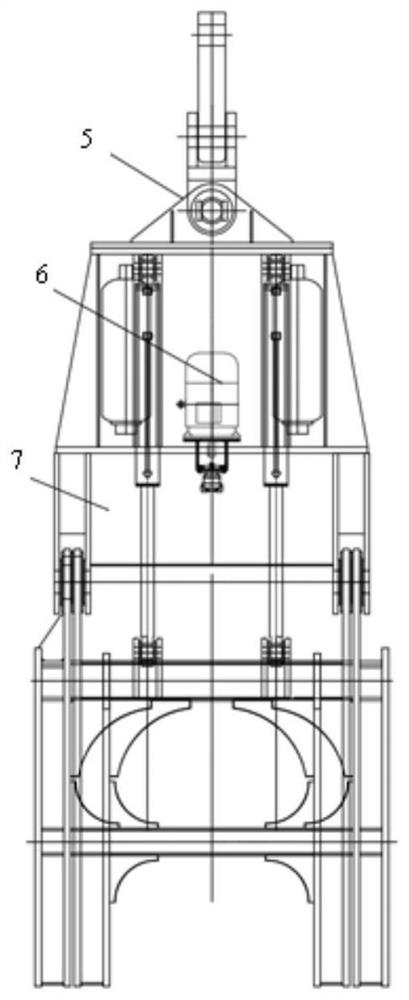

[0062] Figure 1 to 4 An electric hydraulic grip in the container handling device, the operating system includes an electric hydraulic power system, a loading and unloading operation control system, and a storage system, and the operating system is connected to the fuel tank through the return line and the oil pipe. The oil pump, regulator valve and one-way valve are sequentially provided on the oil pipeline, and the energy storage valve and the switching valve are sequentially provided on the accumulator line on the tubing path. The energy storage system includes several accumulators. .

[0063] The principles of the operating system provided in the container handling equipment provided by the present invention are as follows:

[0064] The operating system includes an electric hydraulic power system, a l

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap