Single-stand reversible rolling process for ultrathin wide red copper belt

A technology of copper strip and single stand, which is applied in the direction of manufacturing tools, metal rolling, furnace types, etc., can solve the problems of thick copper strip, rough copper strip, and poor tensile effect, so as to improve the scope of use and improve the tensile strength The effect of strength and smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

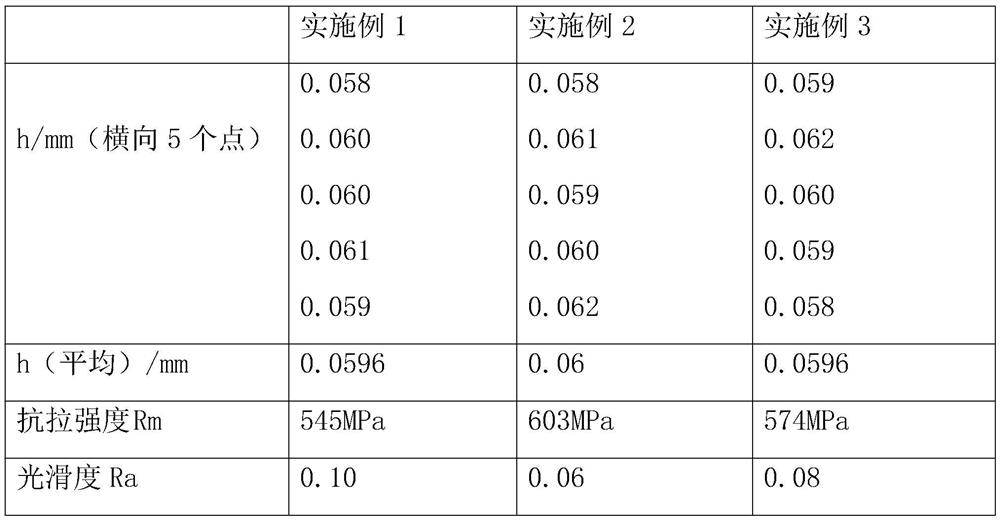

Embodiment 1

[0030] A single-stand reversible rolling process of an ultra-thin wide-width red copper strip provided by the invention comprises specific steps as follows:

[0031] S1, put the red copper raw material into the intermediate frequency furnace for melting until it reaches a liquid state, and the melting temperature is 1150°C;

[0032] S2, the obtained smelting liquid is formed into a slab with a certain cross-sectional shape and a certain size specification through the continuous casting machine, and is cooled by water until the slab drops to 20°C;

[0033] S3, putting the billet into the forging press for forging and pressing to obtain a red copper sheet, wherein the thickness of the red copper sheet is 2cm;

[0034] S4, putting the red copper sheet into water, and cleaning the red copper sheet, after cleaning, drying the red copper sheet by drying equipment;

[0035] S5, putting the red copper sheet into a vacuum annealing furnace for annealing, the annealing temperature is 510°

Embodiment 2

[0048] A single-stand reversible rolling process of an ultra-thin wide-width red copper strip provided by the invention comprises specific steps as follows:

[0049] S1, put the red copper raw material into an intermediate frequency furnace for melting until it reaches a liquid state, and the melting temperature is 1225°C;

[0050] S2, the obtained smelting liquid is formed into a slab with a certain cross-sectional shape and a certain size specification through the continuous casting machine, and is cooled by water until the slab drops to 25°C;

[0051] S3, putting the billet into the forging press for forging and pressing to obtain a red copper sheet, wherein the thickness of the red copper sheet is 3cm;

[0052] S4, putting the red copper sheet into water, and cleaning the red copper sheet, after cleaning, drying the red copper sheet by drying equipment;

[0053] S5, putting the red copper sheet into a vacuum annealing furnace for annealing, the annealing temperature is 545°C

Embodiment 3

[0066] A single-stand reversible rolling process of an ultra-thin wide-width red copper strip provided by the invention comprises specific steps as follows:

[0067] S1, put the copper raw material into the intermediate frequency furnace for melting until it reaches a liquid state, and the melting temperature is 1300°C;

[0068] S2, the obtained smelting liquid is formed into a slab with a certain cross-sectional shape and a certain size specification through the continuous casting machine, and is cooled by water until the slab drops to 30°C;

[0069] S3, putting the billet into the forging press for forging and pressing to obtain a red copper sheet, wherein the thickness of the red copper sheet is 4cm;

[0070] S4, putting the red copper sheet into water, and cleaning the red copper sheet, after cleaning, drying the red copper sheet by drying equipment;

[0071] S5, putting the red copper sheet into a vacuum annealing furnace for annealing, the annealing temperature is 580°C;

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap