Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

23 results about "Soldering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soldering (AmE: /ˈsɒdərɪŋ/, BrE: /ˈsoʊldərɪŋ/) is a process in which two or more items are joined together by melting and putting a filler metal (solder) into the joint, the filler metal having a lower melting point than the adjoining metal. Unlike welding, soldering does not involve melting the work pieces. In brazing, the work piece metal also does not melt, but the filler metal is one that melts at a higher temperature than in soldering. In the past, nearly all solders contained lead, but environmental and health concerns have increasingly dictated use of lead-free alloys for electronics and plumbing purposes.

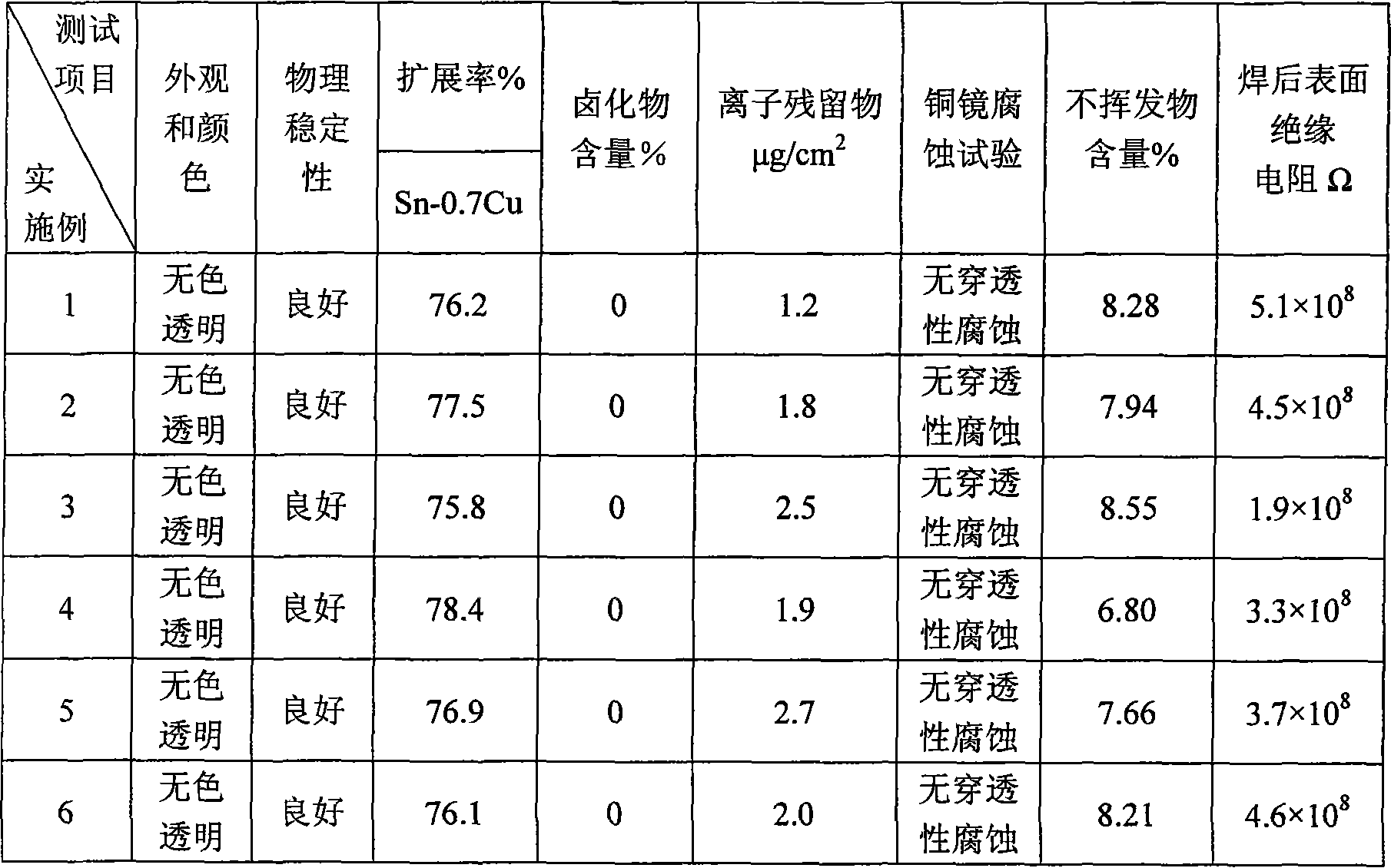

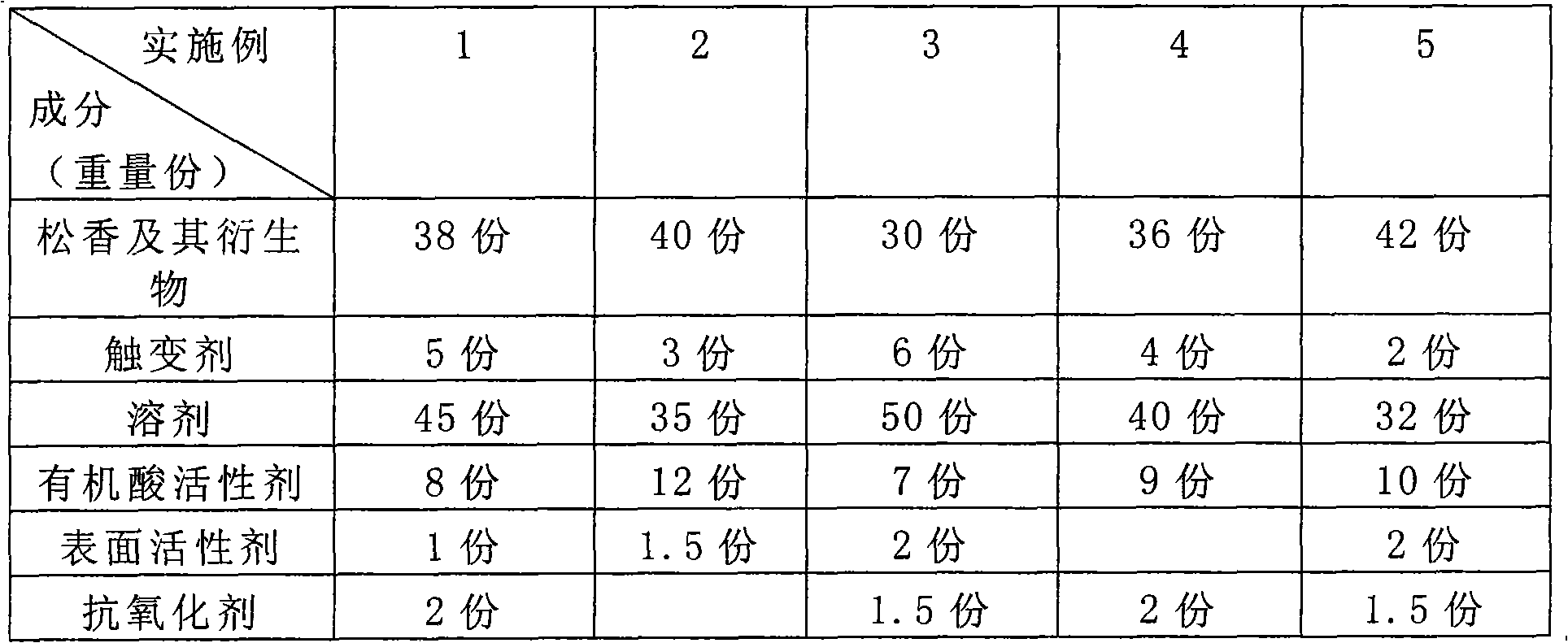

Free from cleaning soldering flux without halogen and rosin in use for solder without lead

InactiveCN101049661AImprove solderabilitySolderability is sufficientWelding/cutting media/materialsSoldering mediaHalogenSoldering

Owner:BEIJING UNIV OF TECH

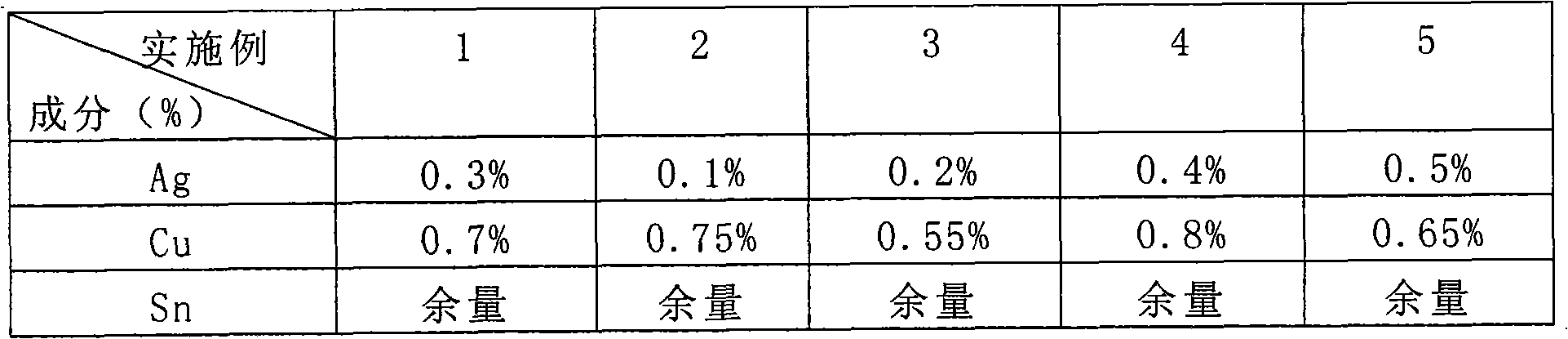

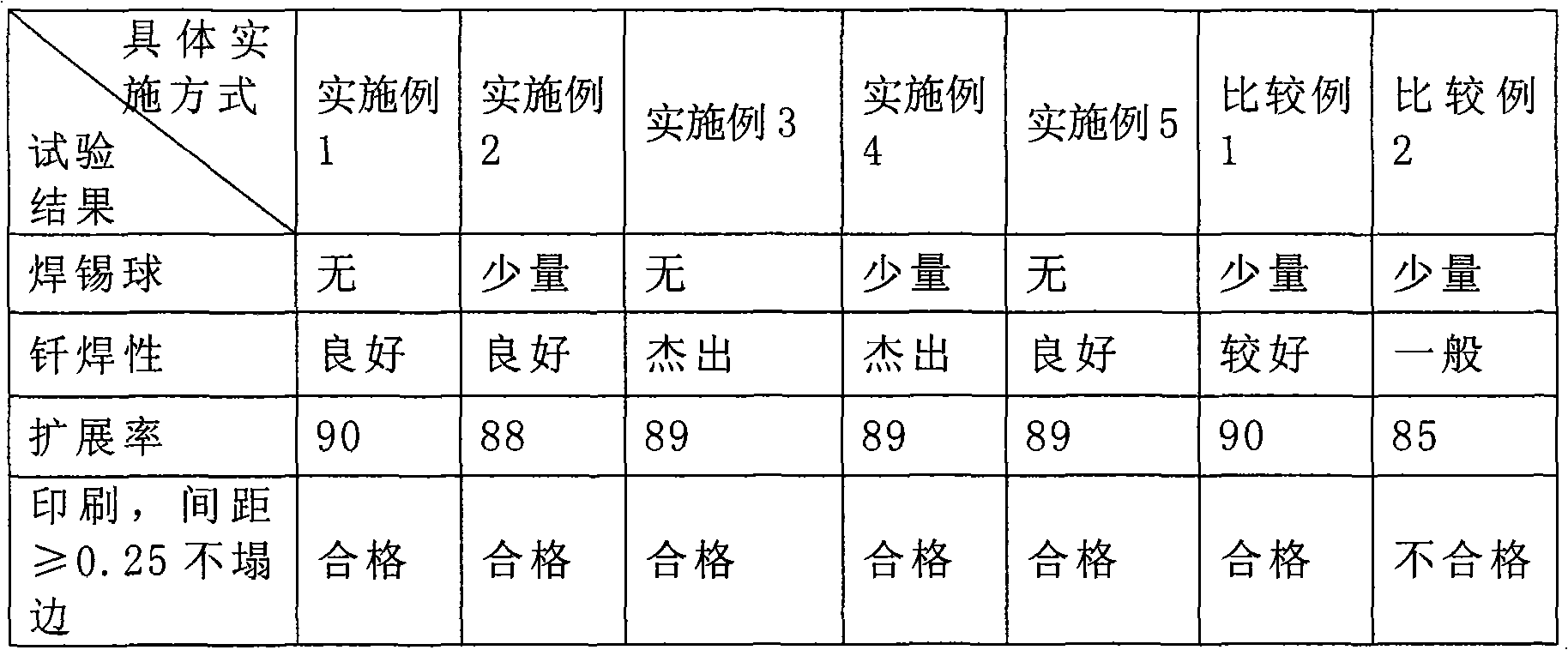

Low-silver halogen free soldering paste

Owner:上海一远电子科技有限公司

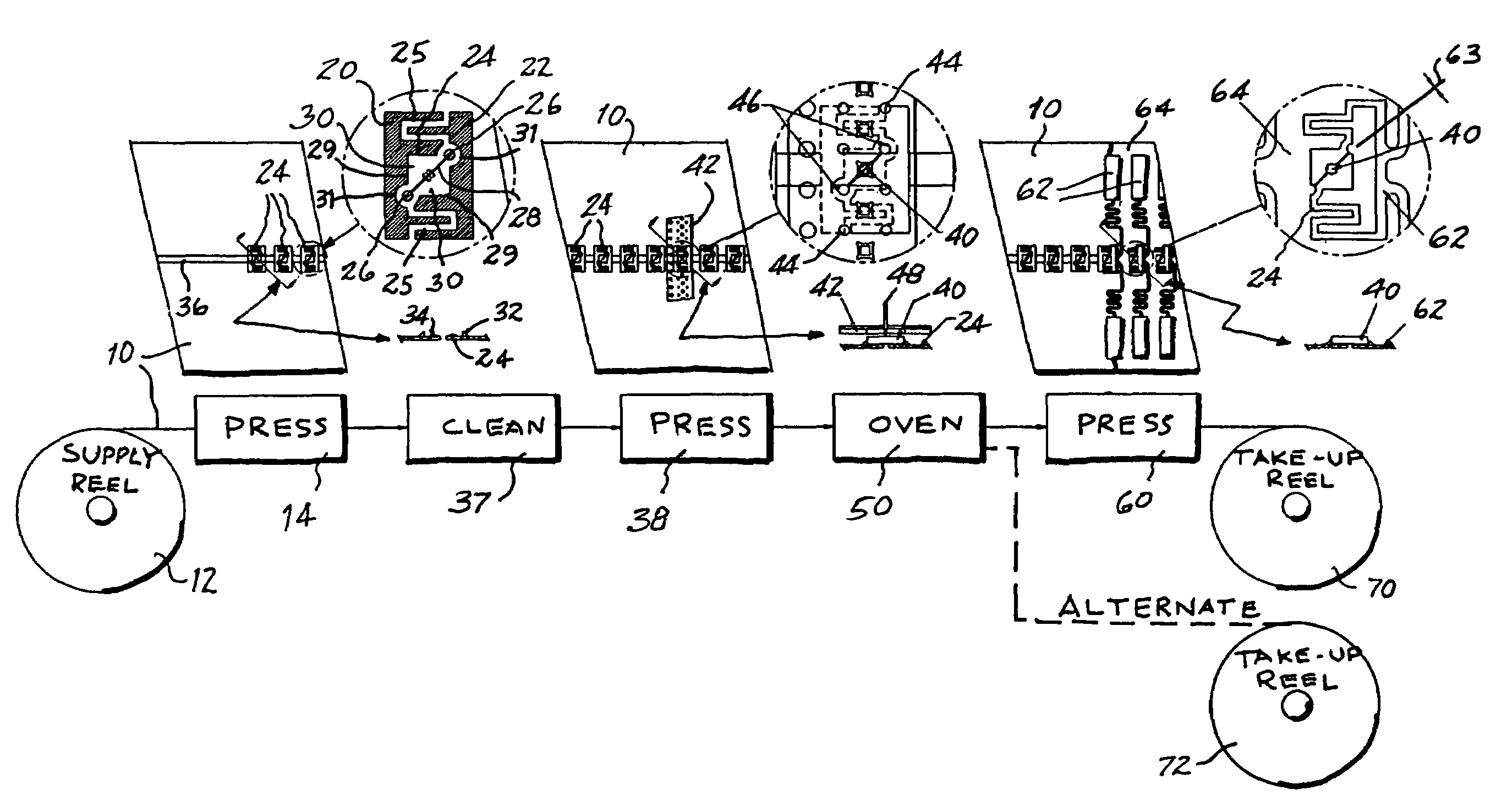

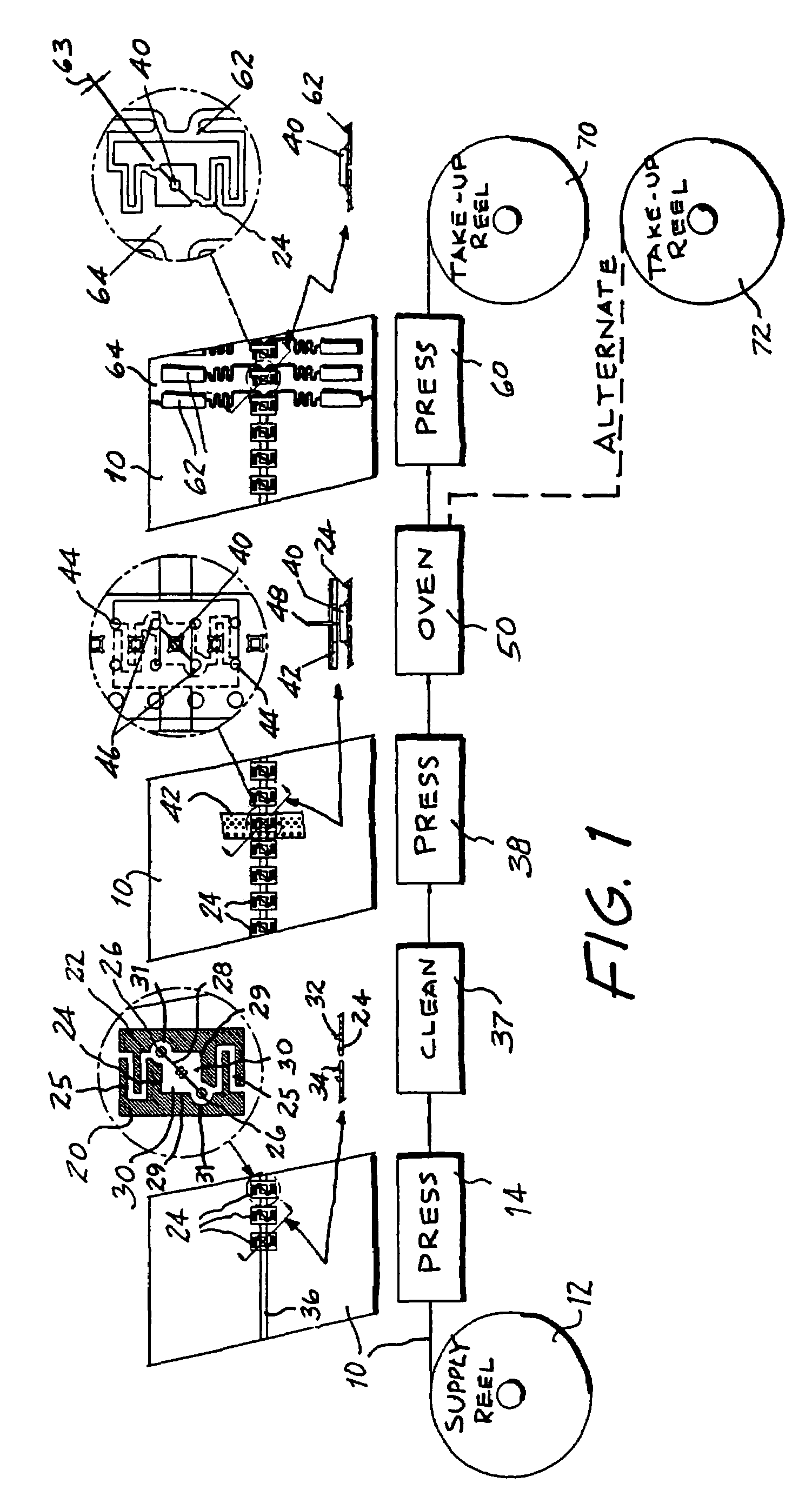

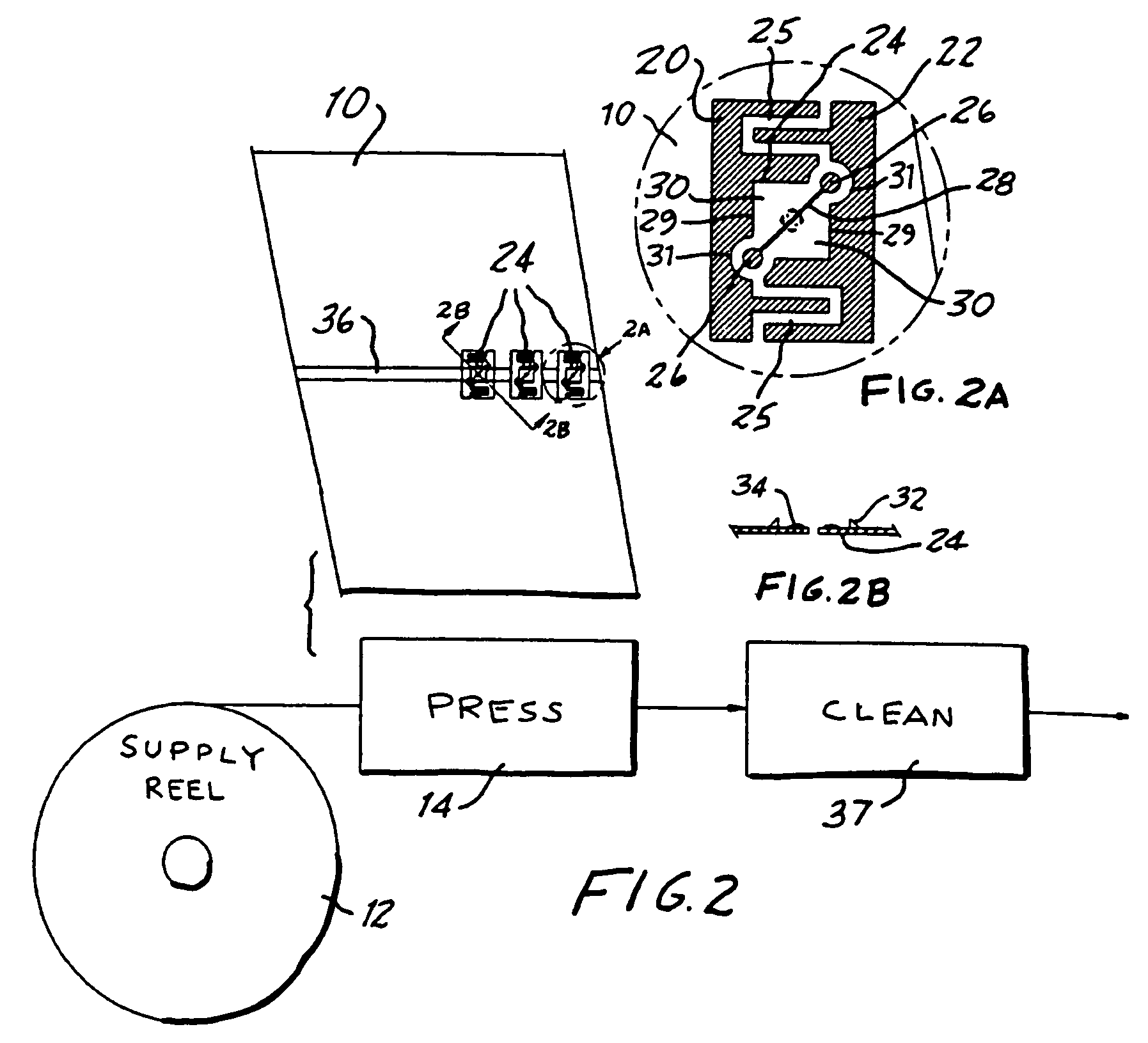

Manufacture of RFID tags and intermediate products therefor

InactiveUS7229018B2Easy to manufactureHighly effectiveLine/current collector detailsElectronic circuit testingCouplingEngineering

Owner:A K STAMPING

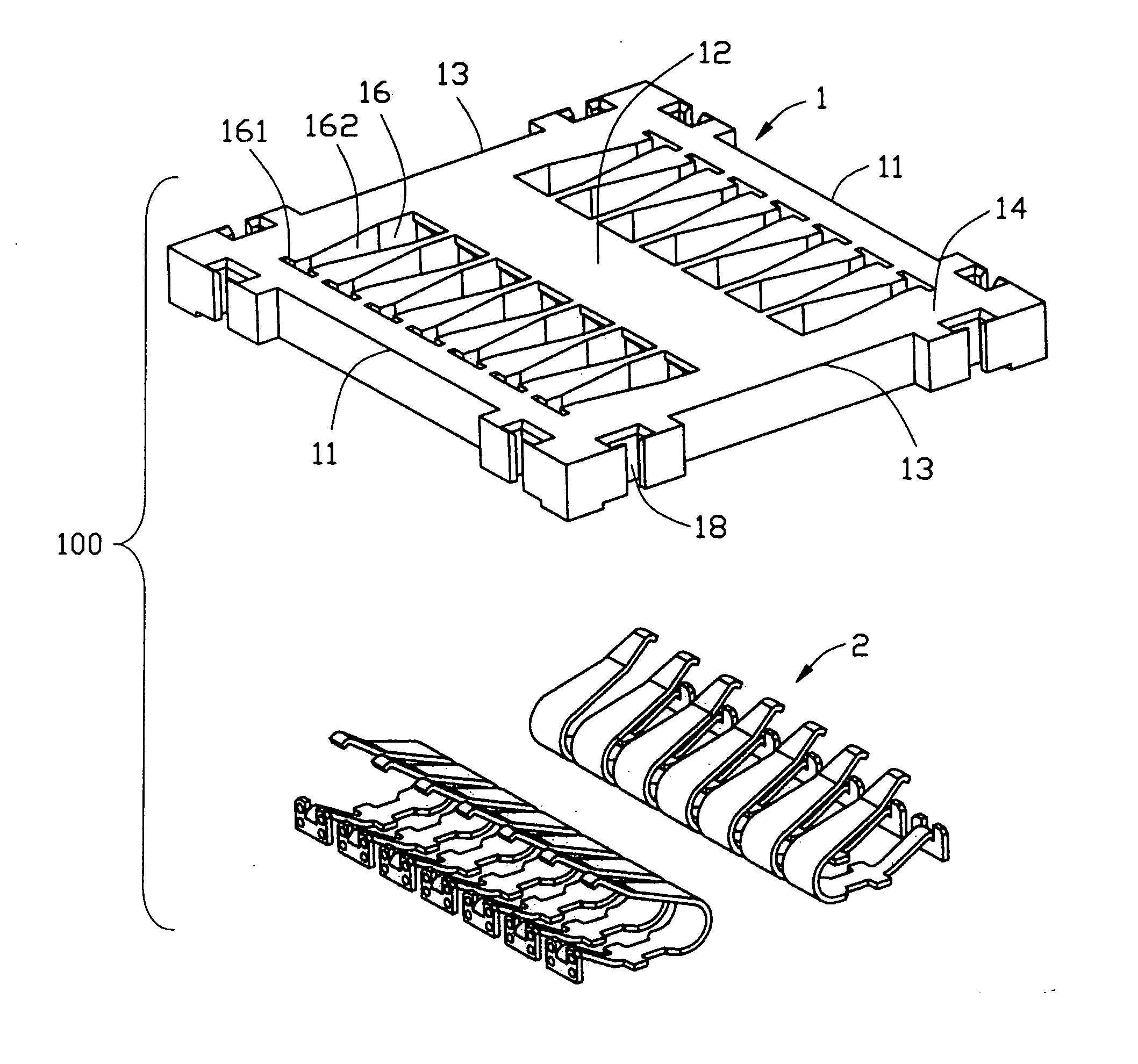

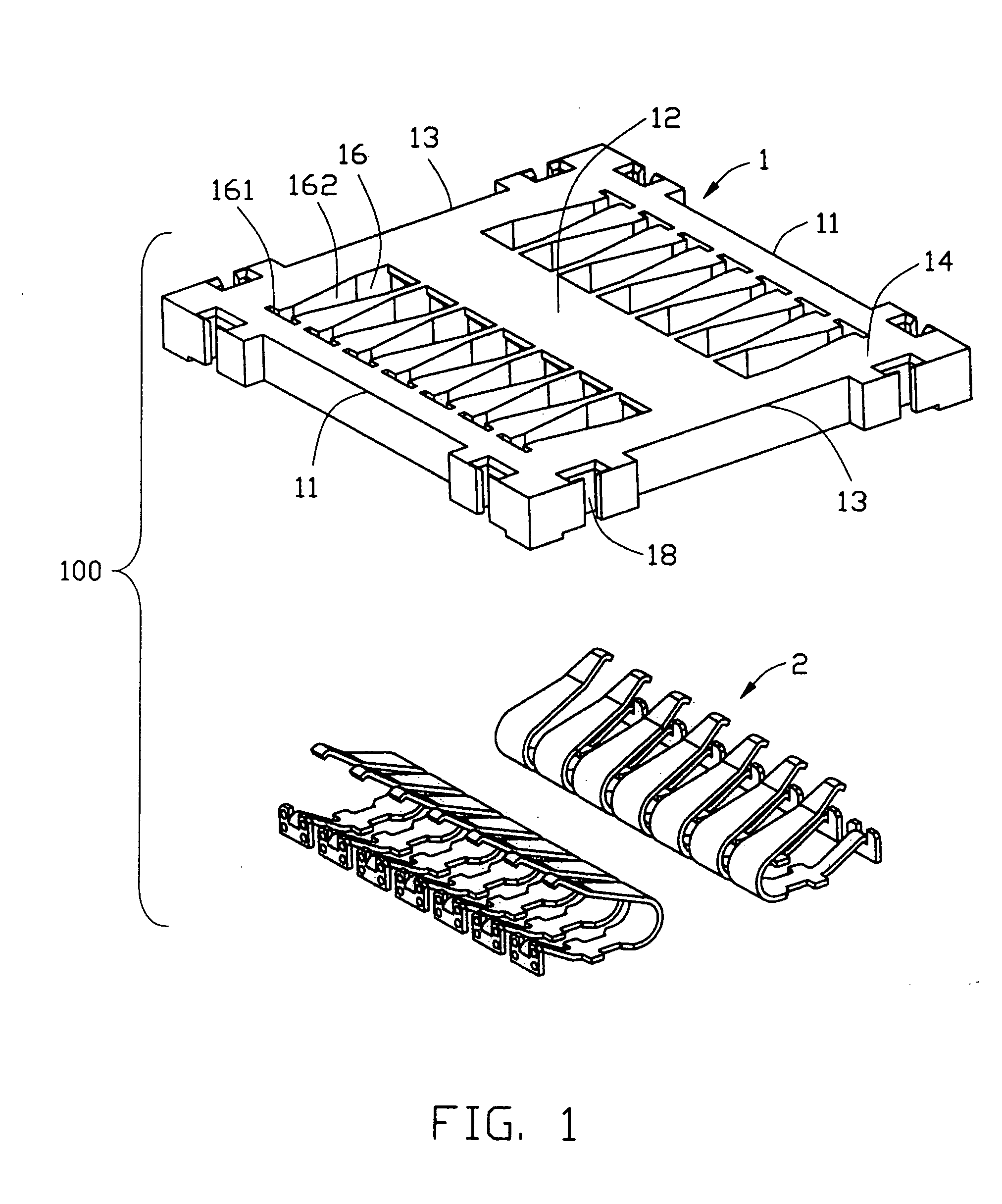

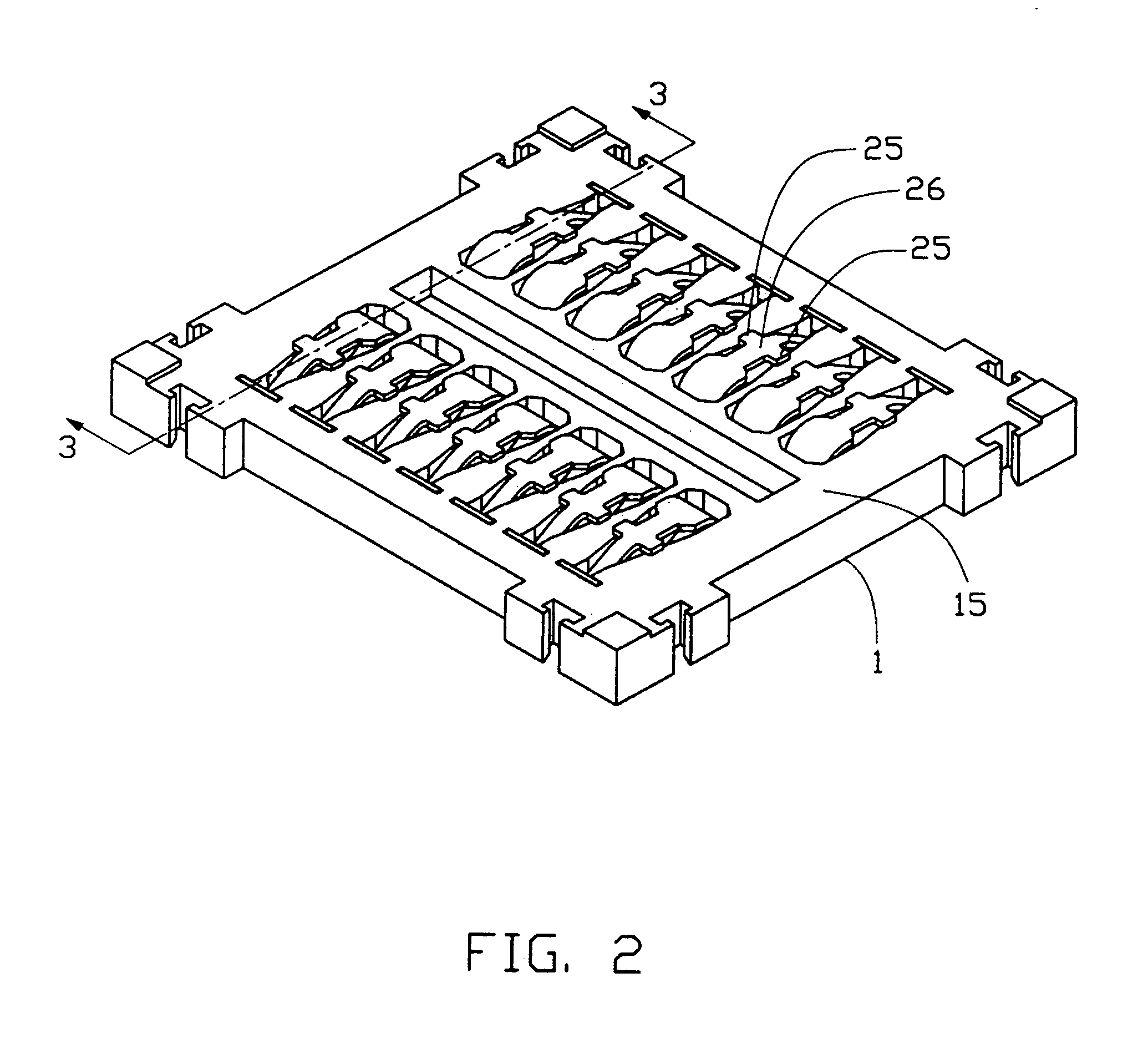

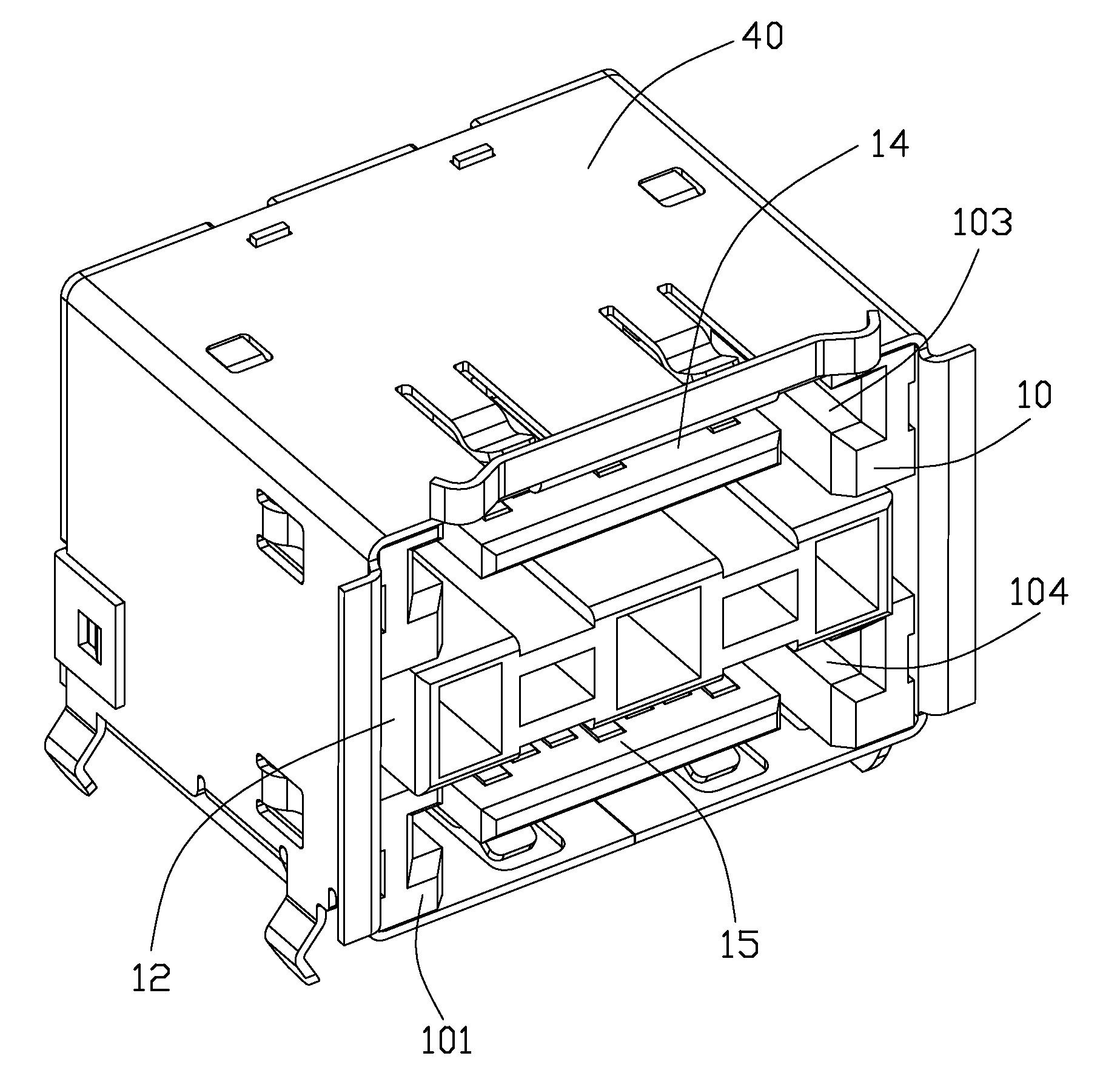

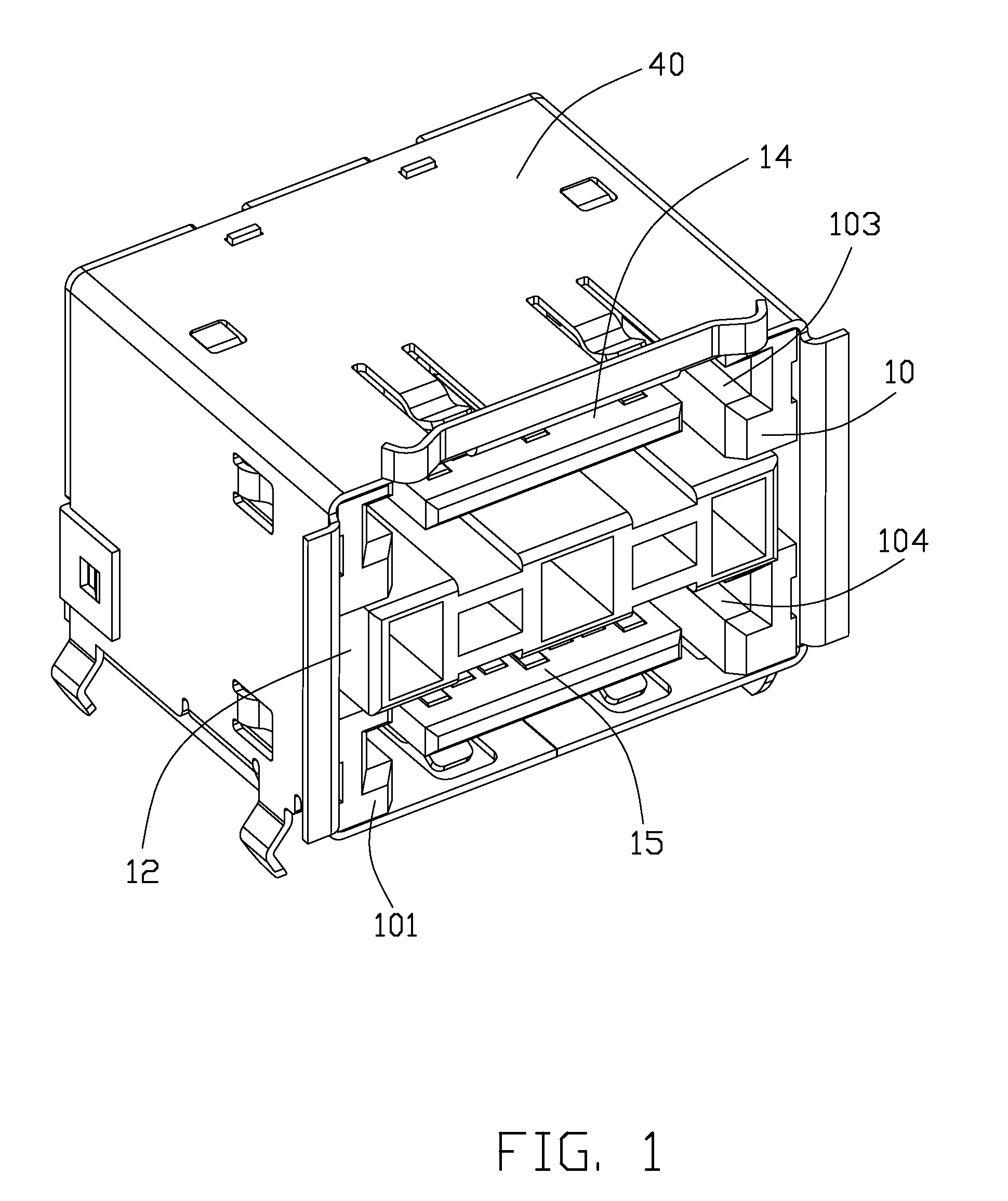

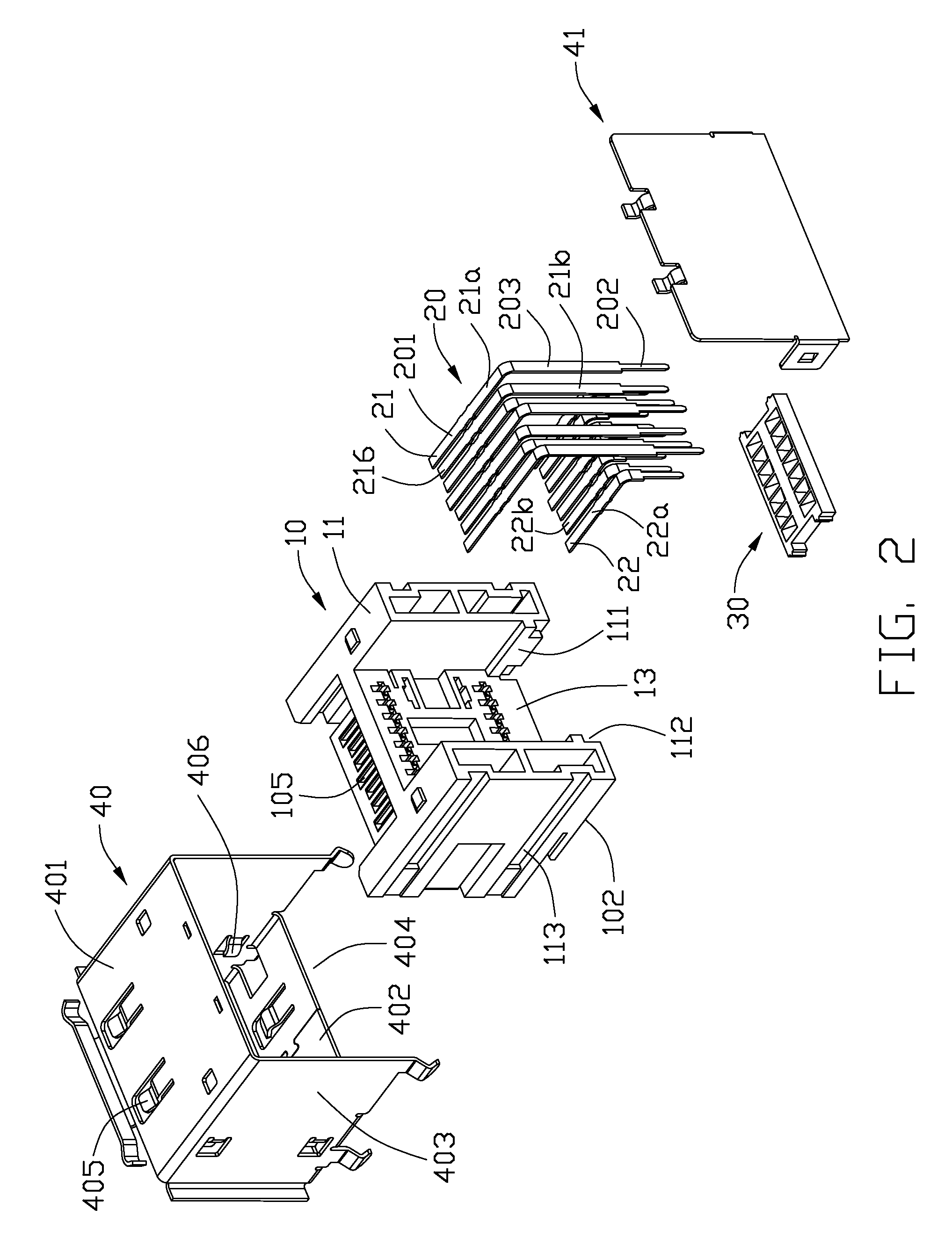

Socket connector

InactiveUS20050170674A1Good coplanaritySoldered/welded conductive connectionsCoupling contact membersEngineeringSoldering

Owner:HON HAI PRECISION IND CO LTD

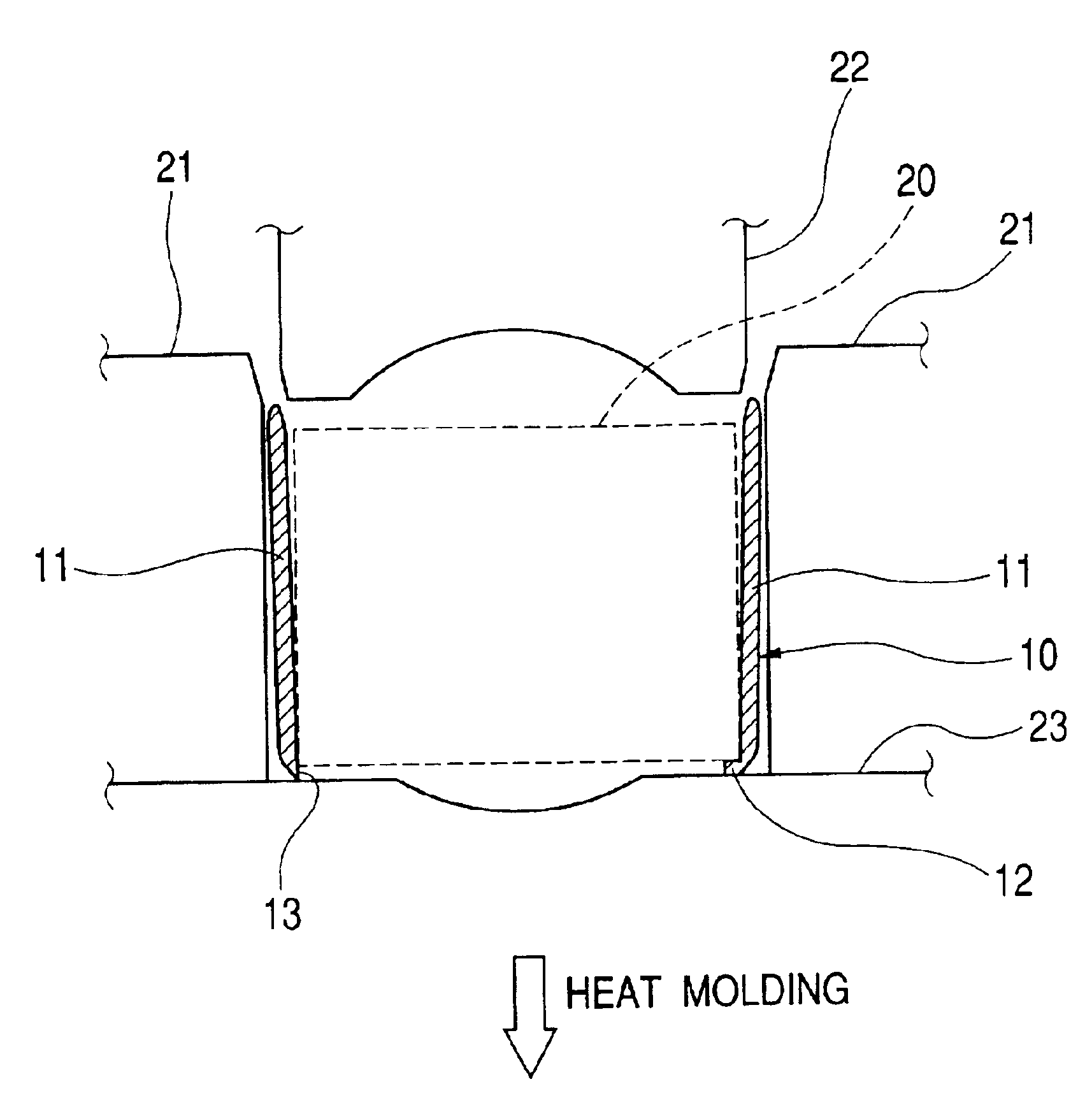

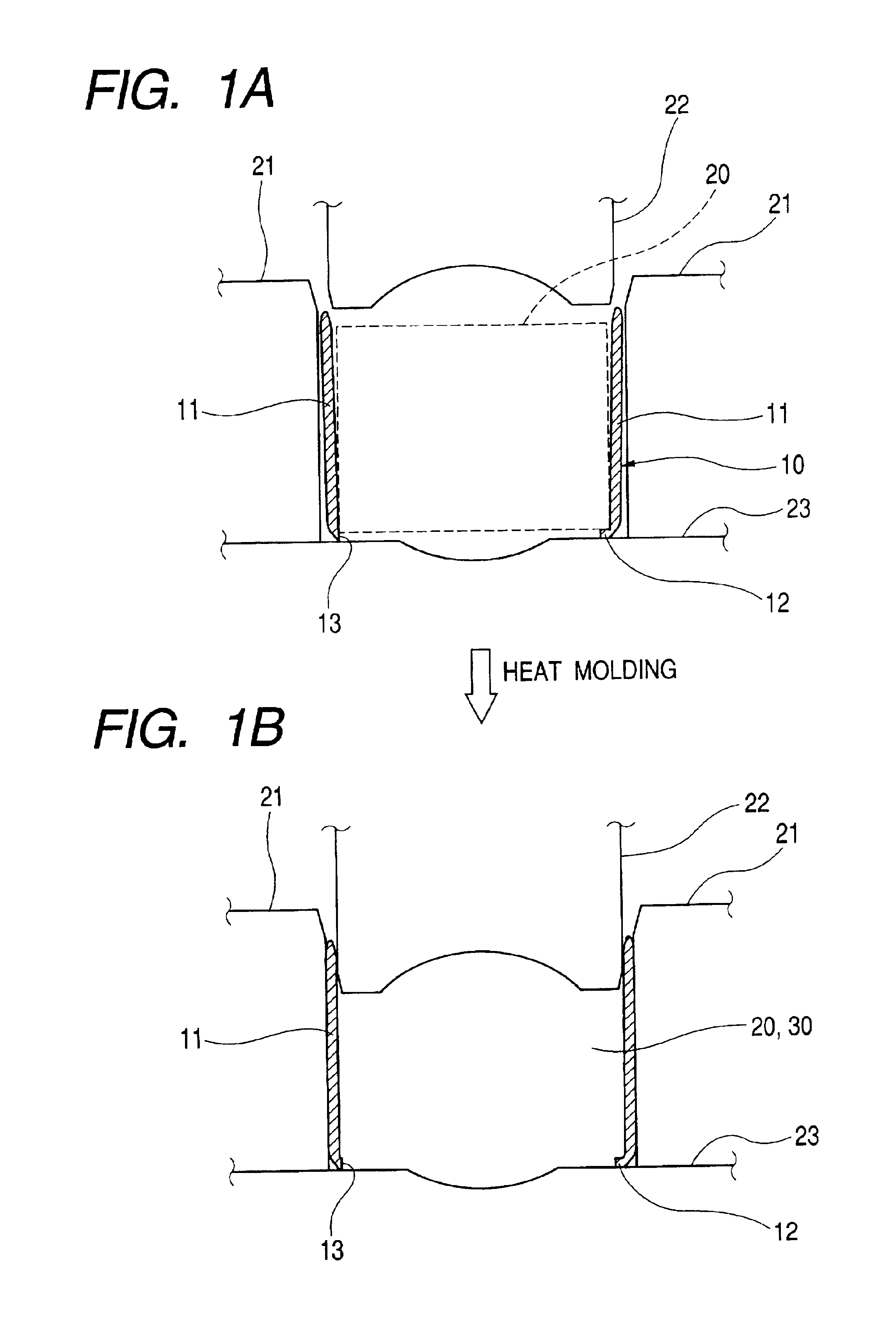

Method for conductively connecting a component on a transparent substrate

InactiveUS20120266461A1Avoid cleaningFast solderingPrinted circuit assemblingLight absorption dielectricsEnergy supplyLength wave

The invention relates to a method to conductively connect an electrical component with at least one conductive layer, whereby the conductive layer is applied to a substrate which is essentially transparent in the visible wavelength zone of light, comprising the following steps: the electrical component or the conductive layer is provided with a soldering material in the area where the component is to be connected to the conductive layer; the soldering material is provided with energy supplied by an energy source, such that the soldering material melts and a non-detachable, material-bonded conductive connection between the electrical component and the conductive layer is established.

Owner:SCHOTT AG

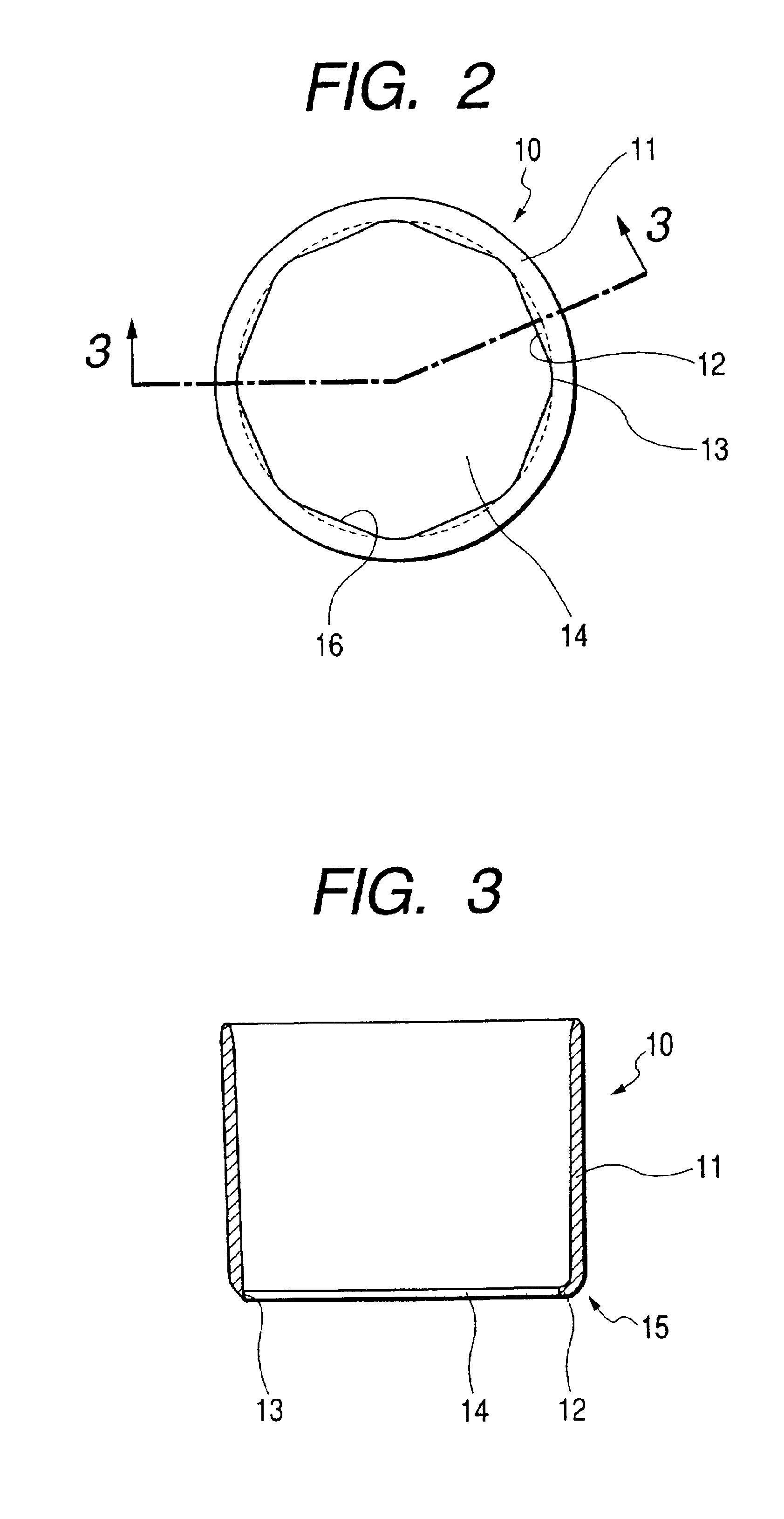

Method for fabrication of optical element having metal ring

InactiveUS6935136B2Increase in sizeHigh precisionGlass drawing apparatusGlass forming apparatusThin walledSoldering

Owner:ALPS ALPINE CO LTD

Cable joint connecting structure and connecting method

ActiveCN109786987AEasy to operateImprove connection reliabilityLine/current collector detailsSoldered/welded conductive connectionsStructural engineeringSoldering

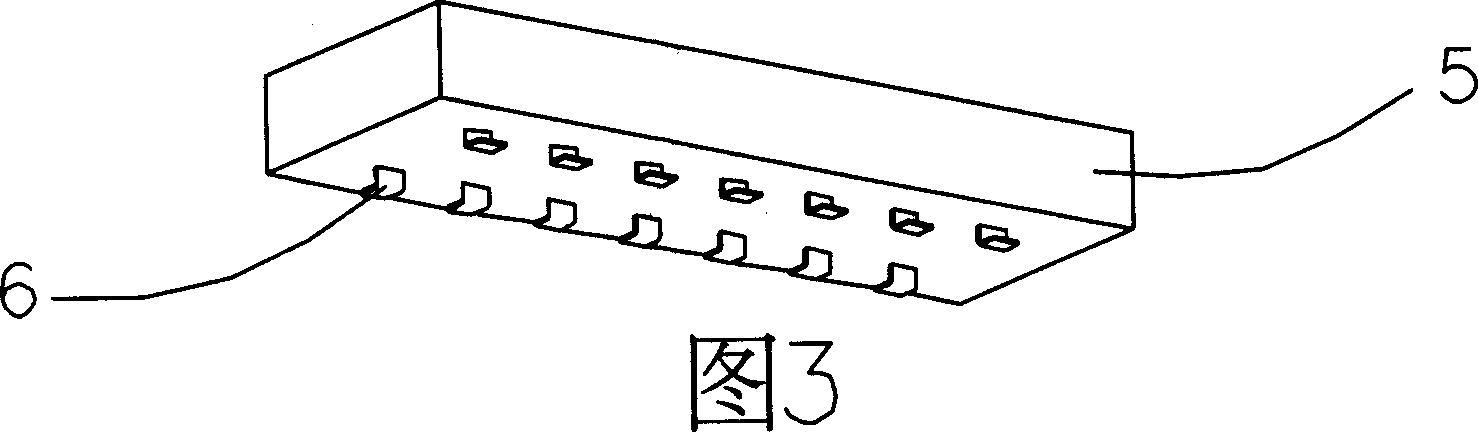

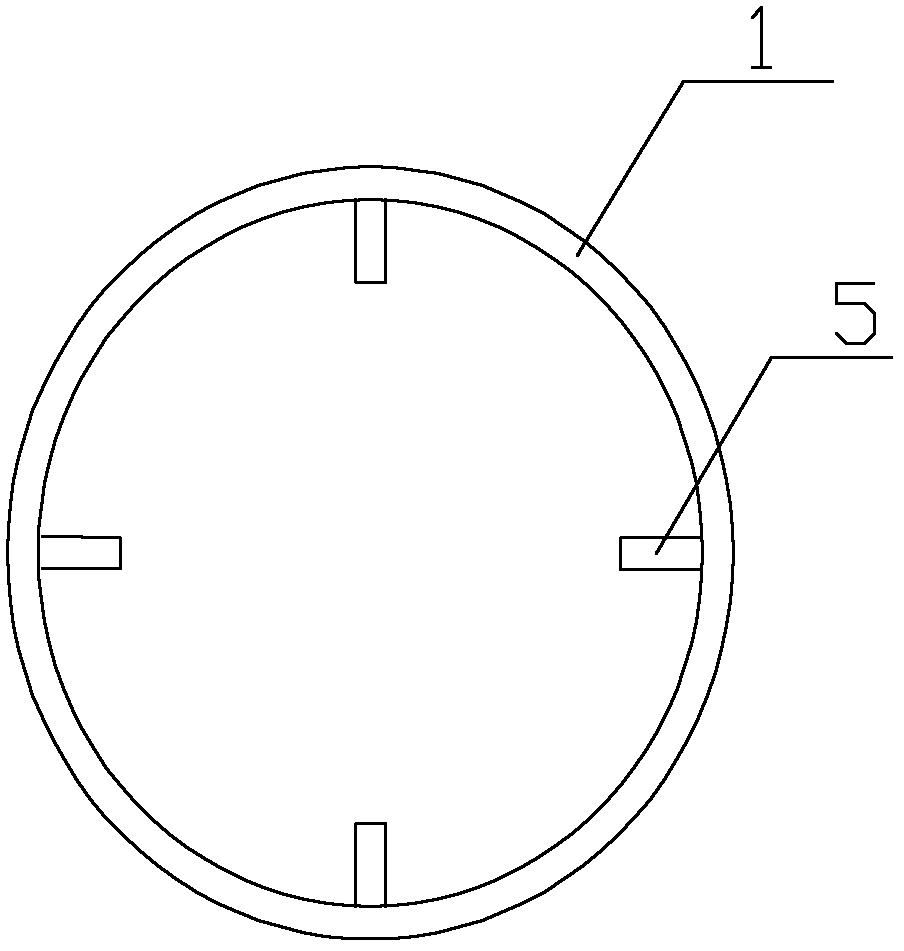

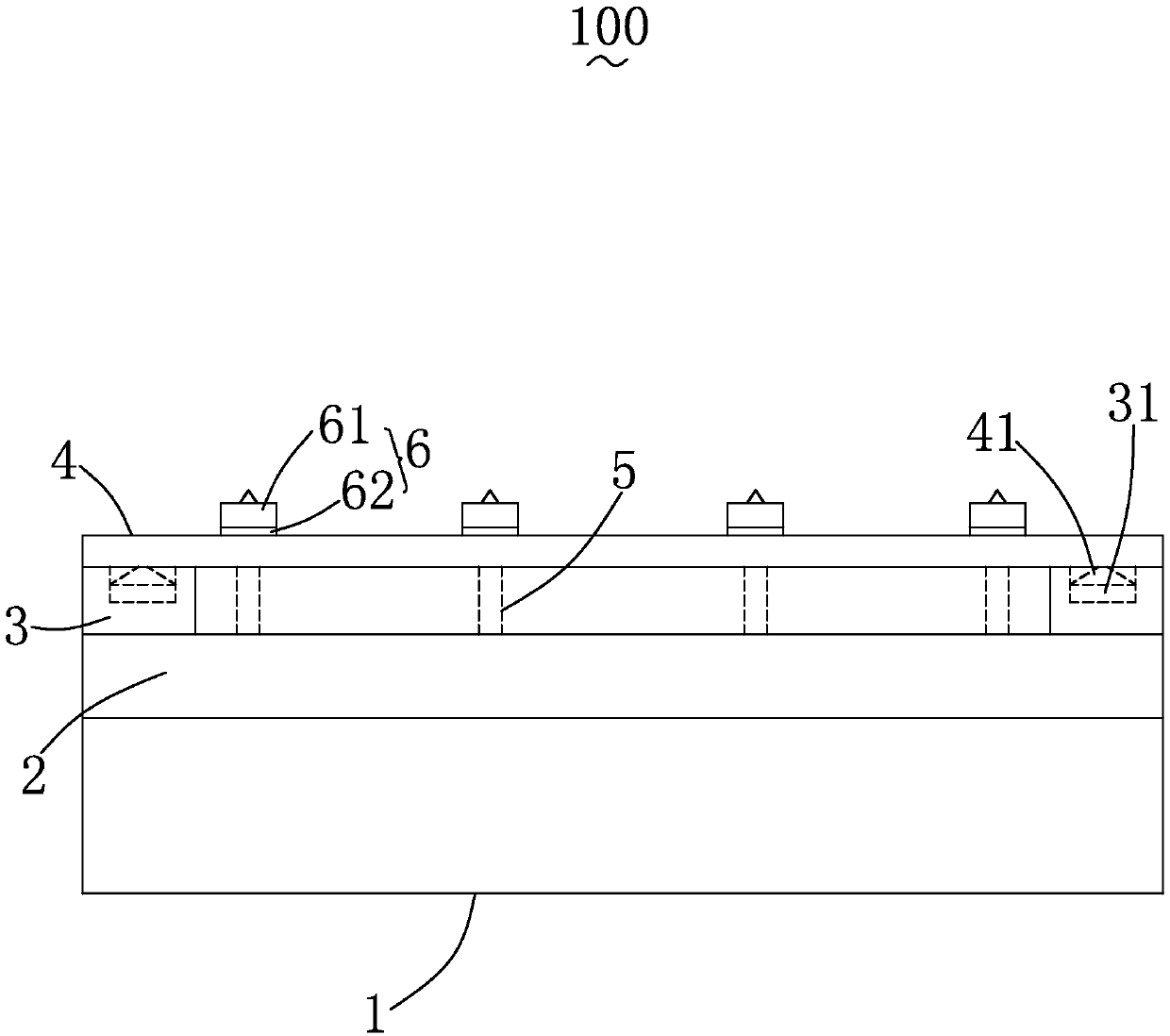

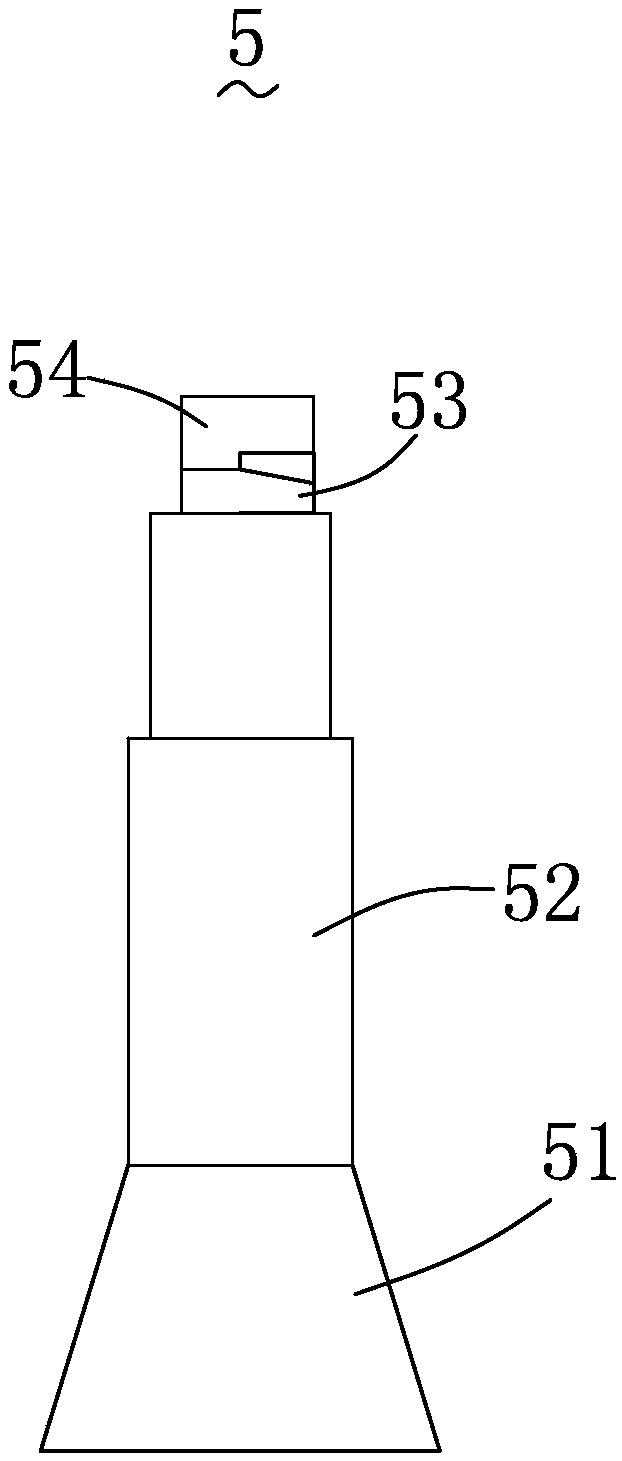

The invention discloses a cable joint connecting structure and a connecting method. The disadvantages that a cable joint and a cable conductor are inconvenient for connecting operation, the connectionreliability is bad, and the loose risk is existent are solved. The connecting structure comprises the joint body and the cable conductor; a large-diameter cylinder, a small-diameter cylinder and lugplates are arranged on the joint body; a soldering frame is arranged in the small-diameter cylinder, the soldering frame comprises a base, a plurality of support strips connected to the base; a plurality of axially arranged slots are correspondingly arranged on the inner wall of the small-diameter cylinder and the support strips one by one; the support strips are inserted into the slots in an adapting manner; a plurality of small-diameter soldering slots communicating with the slots are arranged on the outer wall of the small-diameter cylinder, and small-diameter soldering blocks are arrangedin the small-diameter soldering slots; a plurality of inward arched clamping shrapnel is uniformly arranged on the inner wall of the large-diameter cylinder, one end of each inward arched clamping shrapnel is tightly connected with the inner wall of the large-diameter cylinder, the other end movably fits with the inner wall of the large-diameter cylinder; the plurality of large-diameter solderingslots are arranged on an outer wall of the large-diameter cylinder, the large-diameter soldering blocks are arranged in the large-diameter soldering slots, and the cable conductors are inserted into the large-diameter cylinder and the small-diameter cylinder.

Owner:HANGZHOU SHIBANG ELECTRIC TECH CO LTD

Moisture-proof lead-free soldering nylon 46 composite material and preparation method thereof

InactiveCN102942785AImprove high temperature resistanceHigh tensile strengthGlass fiberMixed materials

The invention relates to a moisture-proof lead-free soldering nylon 46 composite material and a preparation method thereof. The nylon 46 composite material comprises the following components by weight: 40.4-89.2% of PA46 resin, 5-15% of PPO resin, 0-5% of a compatibilizer, 0-45% of glass fiber and 1-2% of other assistants. The preparation method of the composite material is as follows: weighing each component according to the above weight, and drying the components; adding the dried PA46 resin, PPO resin, compatibilizer and assistants into a high-speed mixer for mixing; and adding the mixed materials into a double-screw extruder, adding glass fiber for reinforcement, and extruding for granulation. The composite material provided by the invention has excellent wet proof lead-free soldering performance and good mechanical properties, and can be applied to the preparation of connector of electronic and electrical products requiring lead-free soldering and preparation of high-temperature resistant automotive plastic parts, etc.

Owner:HUIZHOU HUAJU PLASTIC TECH CO LTD +1

Alloying technology for high voltage diode chip

ActiveCN102945810AReduce usageReduce security risksSemiconductor/solid-state device manufacturingCyanidePotassium

Owner:RUGAO DACHANG ELECTRONICS

Welding method between electronic components

Owner:DEYI PRECISION ELECTRONIC IND CO LTD PANYU

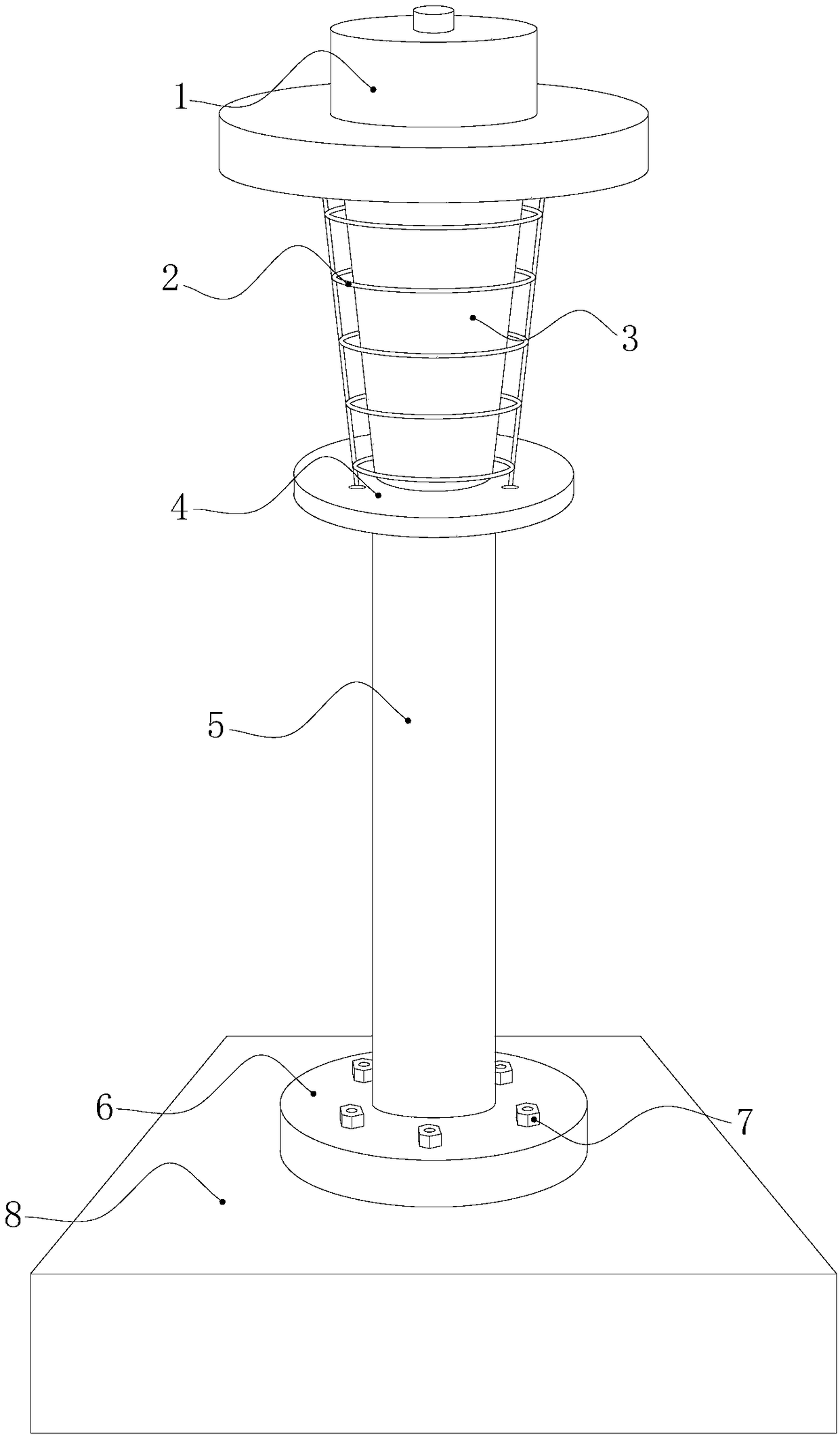

Quick heat-radiation light emitting diode (LED) garden lamp

InactiveCN102367928AFast heat dissipationImprove cooling effectPoint-like light sourceLighting heating/cooling arrangementsInterference fitInsulation layer

The invention relates to the field of an illumination lamp, in particular to a quick heat-radiation light emitting diode (LED) garden lamp having a good heat radiation effect, which aims to solve the heat radiation difficulty of the present LED lamp, and has fast heat radiation speed and large amount of heat radiation. The invention adopts a technical scheme that: the quick heat radiation LED garden lamp consists of a lamp holder, a heat radiator and a lamp adapter, which are sequentially connected with each other from top to bottom, wherein an axial through hole is arranged in the middle of the heat radiator, the periphery of the through hole is provided with heat radiation sheets, the upper end of a heat conducting bar is embedded inside the through hole, the lower end surface of the heat conducting bar is sequentially provided with a binding layer, an insulation layer substrate, a copper-clad layer and an insulation layer, and LED lamp beads are welded on the heat conducting bar through a tin soldering layer. 95 percent of the heat is radiated from the inside of each lamp bead through a central point of the LED lamp beads, and good heat conduction performance of the heat conducting bar and a mechanical-connection-free interference fit way between the heat conducting bar and the heat radiator are utilized to quickly transfer the heat received by the heat conducting bar to the heat radiator.

Owner:张向阳

Steel plate type circular thin-walled quenching roller

InactiveCN103184328ANo deformationGuaranteed aestheticsQuenching devicesInterference fitSoldering

Owner:刘平祥

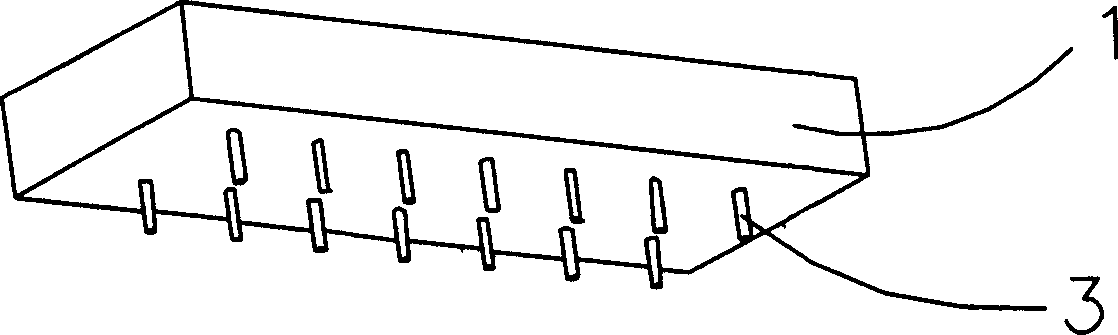

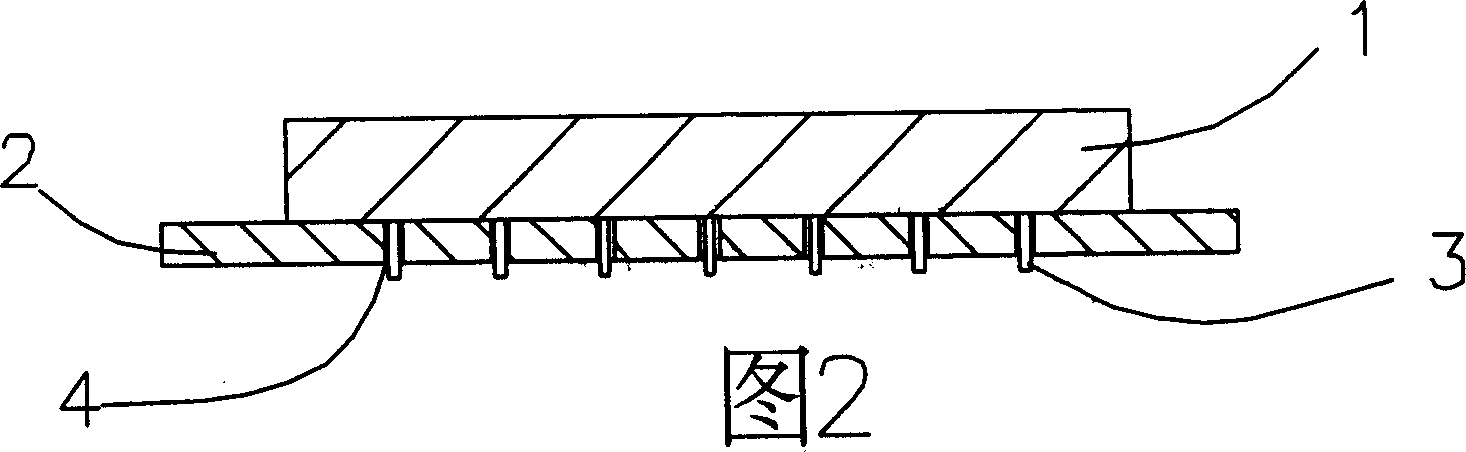

Printed circuit board soldering protection nail bed and manufacturing method thereof

ActiveCN107708324AFast preparationLow costScreen printersNon-metallic protective coating applicationEngineeringSoldering

Owner:广东喜珍电路科技有限公司

Stacked electrical connector with a new type of spacer

Owner:HON HAI PRECISION IND CO LTD

Wave generator belt wheel

Owner:苏州明杰自动化科技有限公司

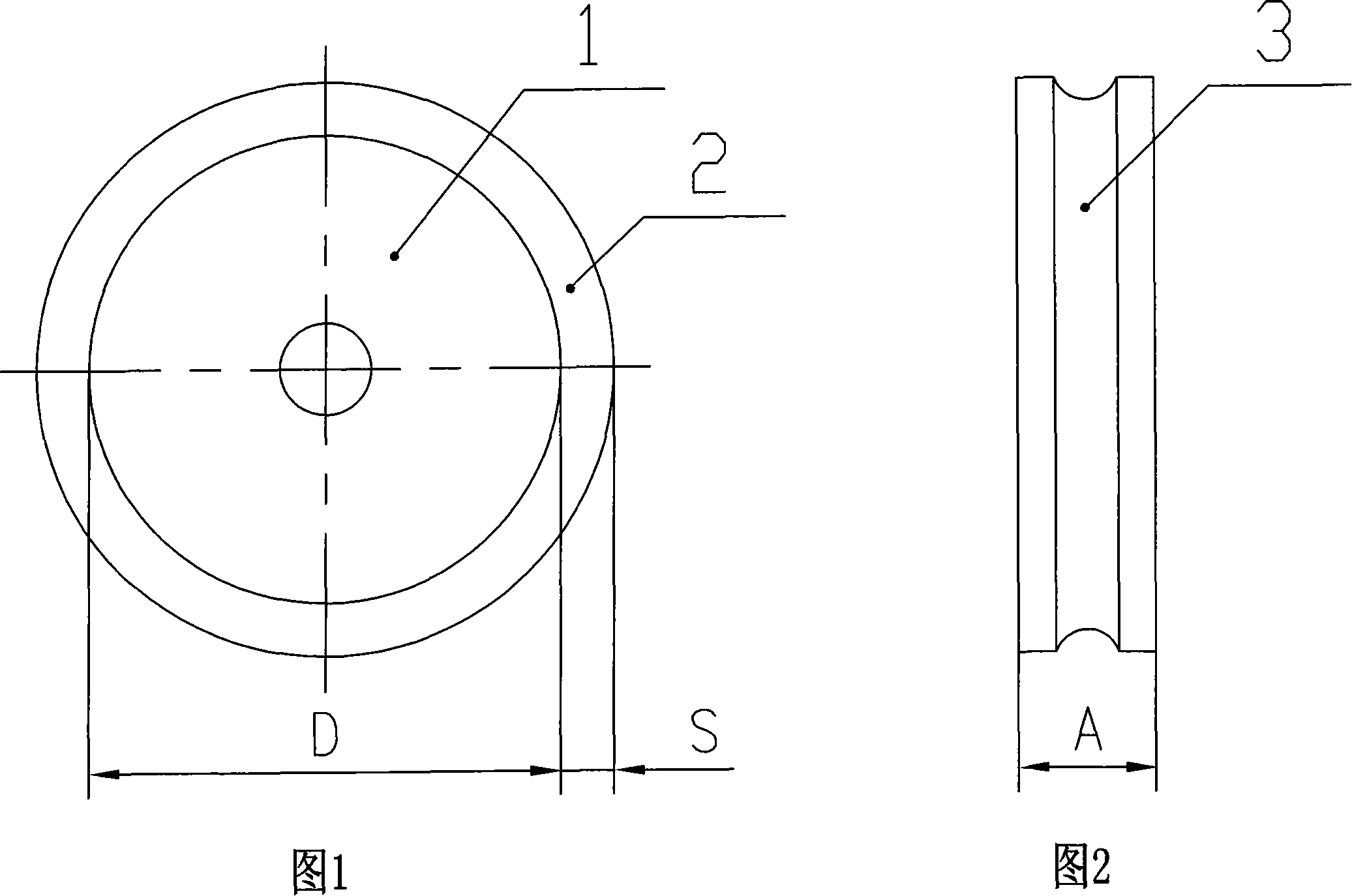

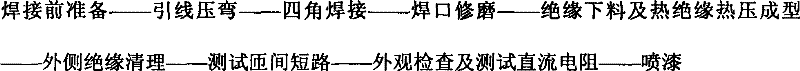

Machining method for magnetic pole winding of four-angle welding motor

InactiveCN101388583BConsistent shapeNeat surfaceApplying solid insulationHot stampingMagnetic poles

Owner:TIANJIN TIRNFR HEAVY HYDROELECTRIC FRCILITY CO LTD

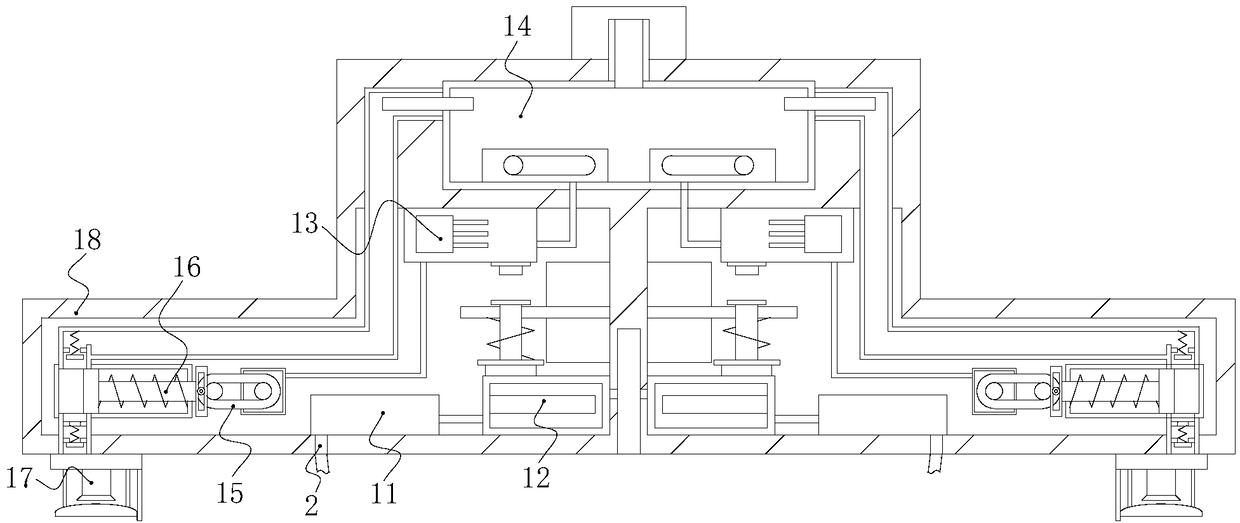

Circuit board wave crest soldering carrier cleaning device

ActiveCN108526113AAvoid breakingSmooth rotationGas treatmentDispersed particle filtrationEngineeringSoldering

The invention discloses a circuit board wave crest soldering carrier cleaning device. The cleaning device comprises a case; a lead rail is mounted on a side of the case; a bracket is slidably connected with the lead rail; a lower end of the bracket is located in a groove in the middle of the case; support plates are mounted on the bottom of the bracket; support rods are connected with the side edge of the case; a displacement device is arranged in the middle of the support rods; a motor is mounted in the middle of the displacement device; the lower end of the displacement device is connected with a roll shaft which is connected with the motor through a belt in a transmission manner; and the roll shaft is evenly covered with fur brushes corresponding to the support plates. According to theinvention, the roll shaft equipped with the fur brushes is driven to rotate by the motor through the belt, so that the manual brushing is replaced; the cleaning device is high in cleaning efficiency,uniform in cleaning force, not easy to destroy a carrier, no need to manually move the carrier, and can adapt to the cleaning work of carriers of different thickness; a filter is used to absorb the odor of a cleaning liquid, thereby reducing the pollution to the outside air, and lowering the impact on the staff body.

Owner:ZHONG SHAN SHI BAO YUE JIA DIAN ZI YOU XIAN GONG SI

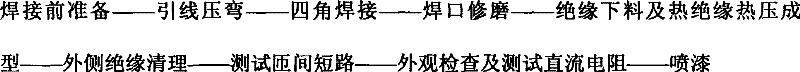

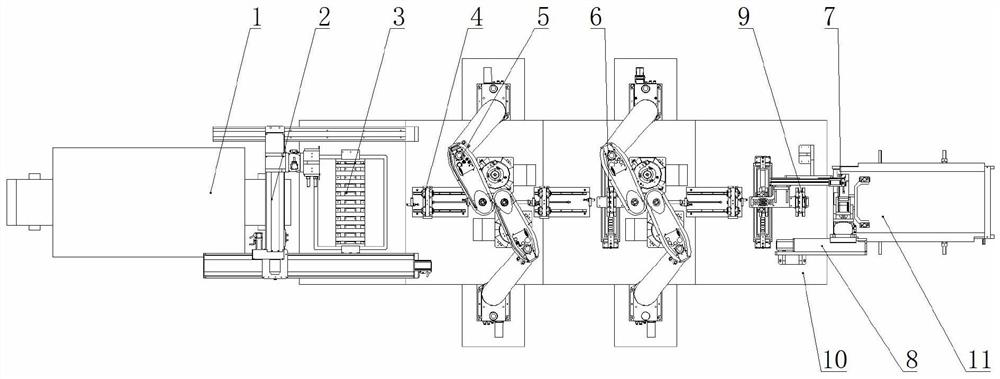

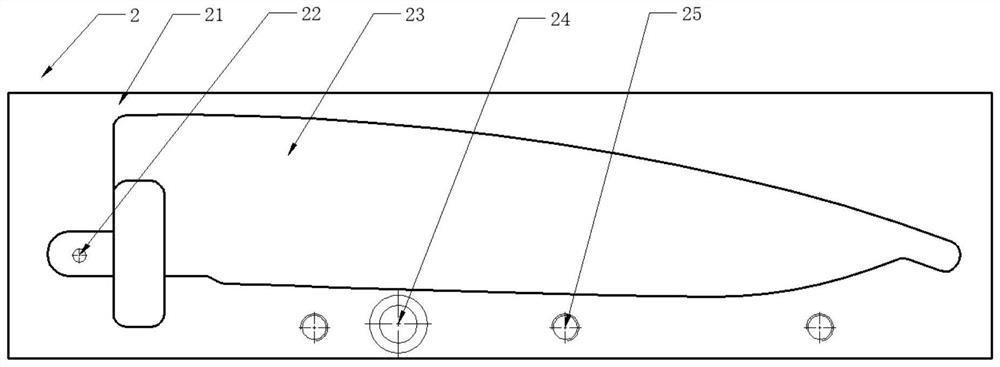

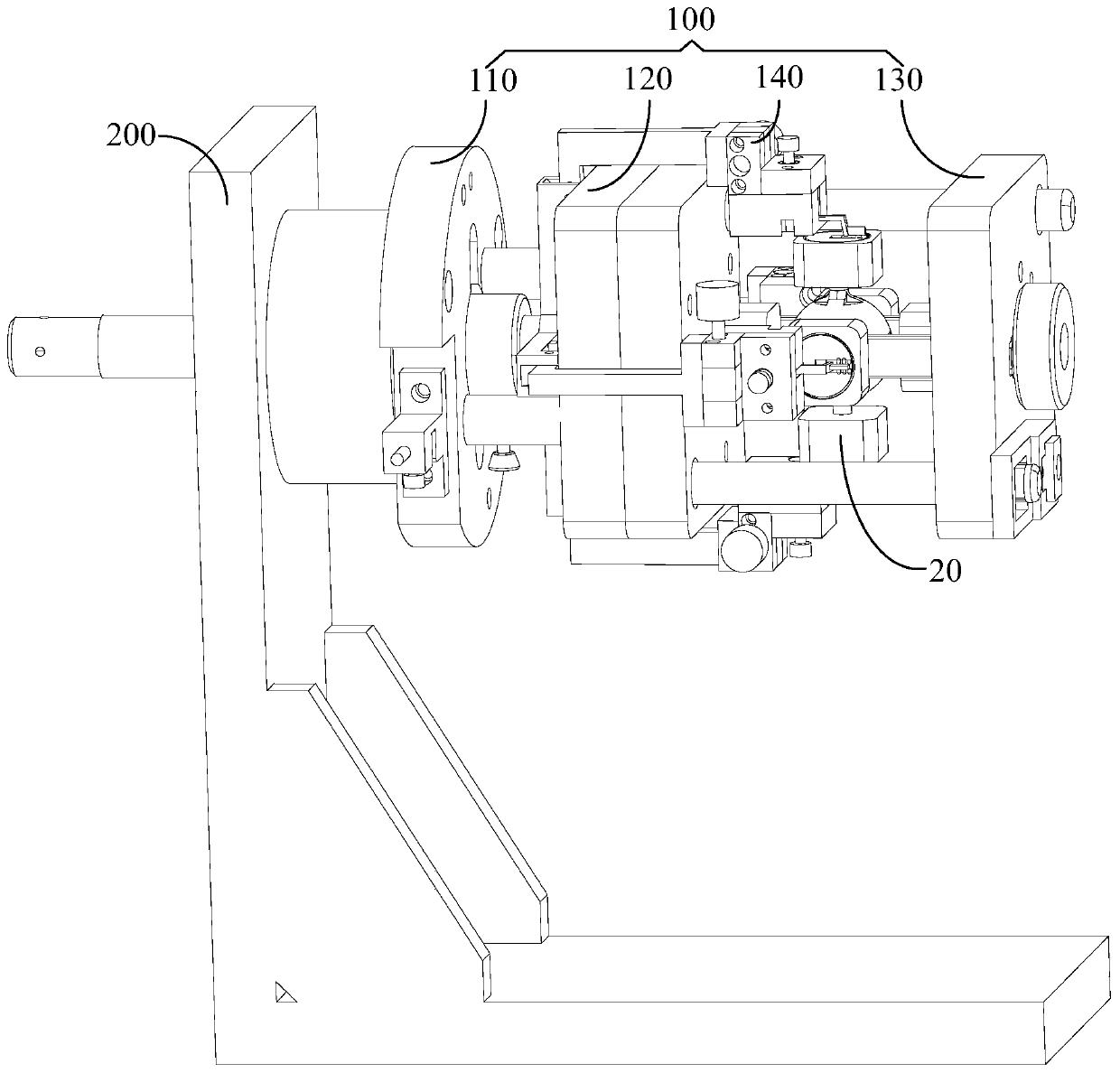

Tin soldering equipment for wiring terminal and enameled aluminum wire on straight stator

PendingCN113708179AIncrease productivityDip fully and evenlyLine/current collector detailsMegasonic cleaningStructural engineering

Owner:浙江理工大学上虞工业技术研究院有限公司 +2

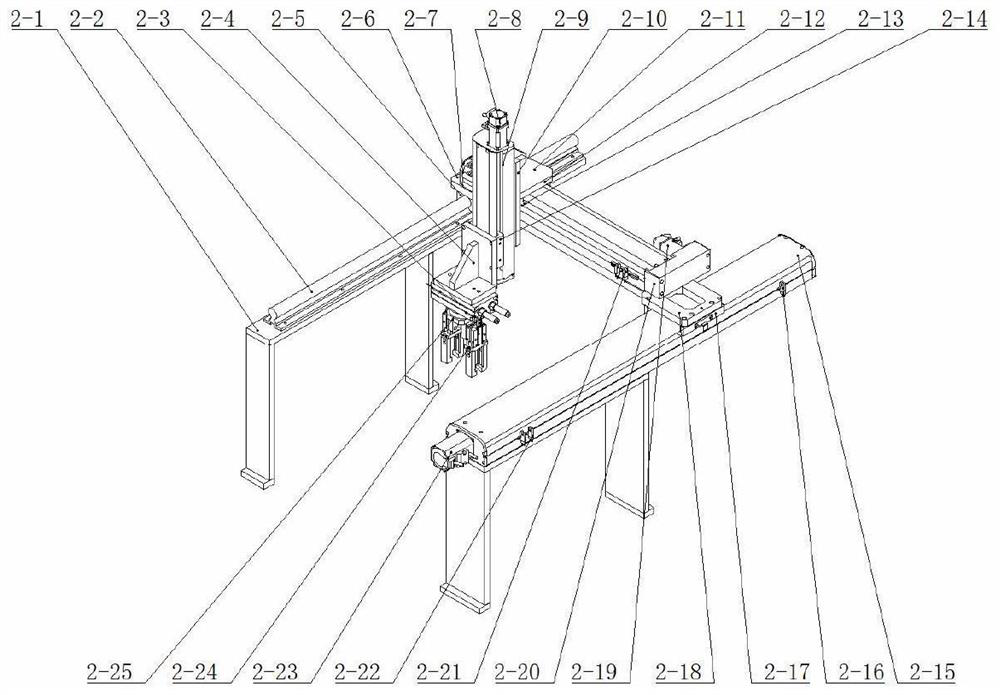

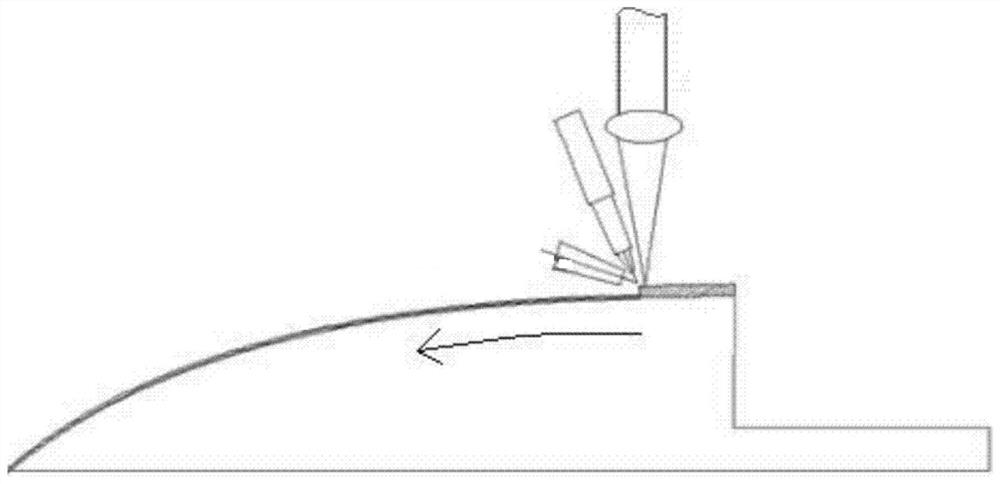

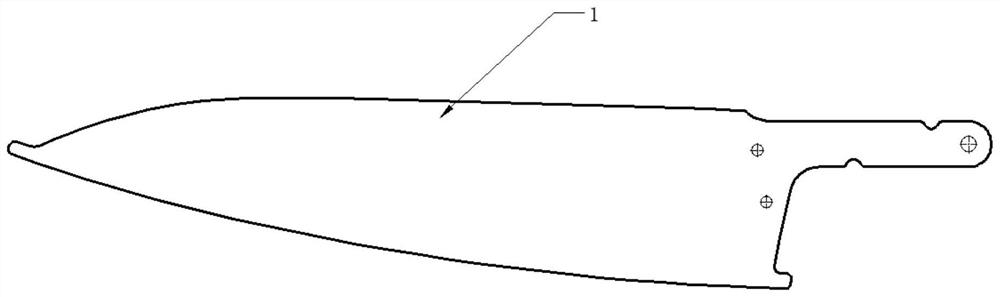

Method of hardening tool edge through soldering wire and tool edge fixture

PendingCN111822827AWelding accessoriesMachining toolpathSoldering

Owner:BMAN MFG ZHE JIANG

High-performance 7/16 welding joint type RF coaxial connector

InactiveCN104332785APlay a protective effectImprove retentionCoupling contact membersTwo-part coupling devicesElectrical conductorStructural engineering

The invention discloses a high-performance 7 / 16 welding joint type RF coaxial connector. The connector comprises a connecting nut and two conductors; the two conductors include an inner conductor and an outer conductor, wherein the inner conductor is welded onto an inner core of a cable, and while the outer conductor is mounted on the surface of the inner conductor through a medium. The connector also comprises screwing cable corrugation which is mounted at in the side edge of the outer conductor and connected with a silver soldering filling part, wherein the silver soldering filling part is arranged between the outer conductor and a cable. With the adoption of the high-performance 7 / 16 welding joint type RF coaxial connector, soldering tin can be fully filled during welding, so that the requirement on high intermodulation can be met; the corrugation for screwing the cable is arranged in the tail part of a housing and can be used for protecting the cable; therefore, the stability of an assembly is improved; the retention of the cable is improved.

Owner:ZHENJIANG HUAHAO ELECTRONICS COMPONENT

Garden LED lamp convenient to install

InactiveCN109058875AAvoid lossSemiconductor devices for light sourcesInsect catchers and killersEngineeringSoldering

Owner:湖州致远互联软件有限公司

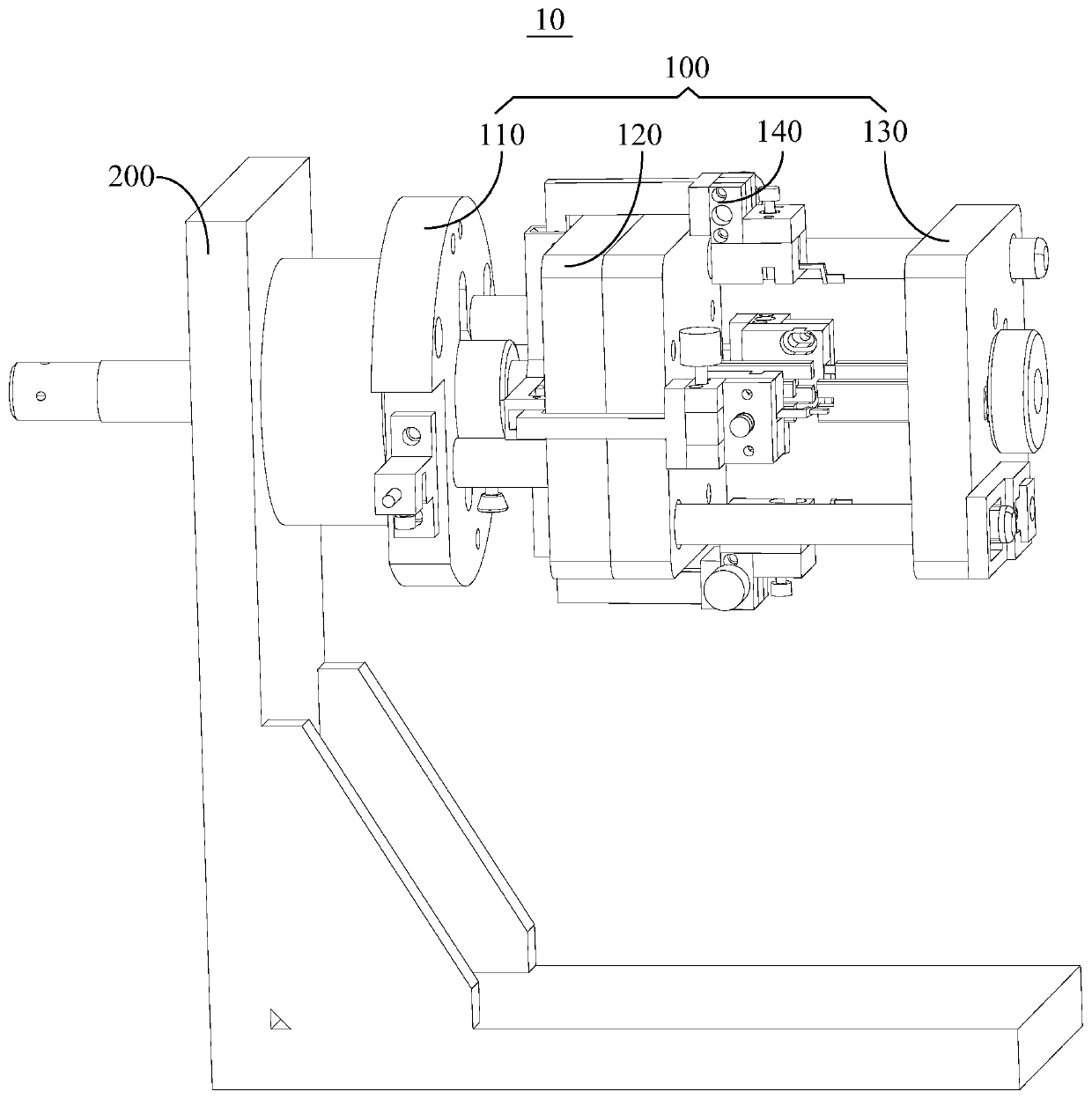

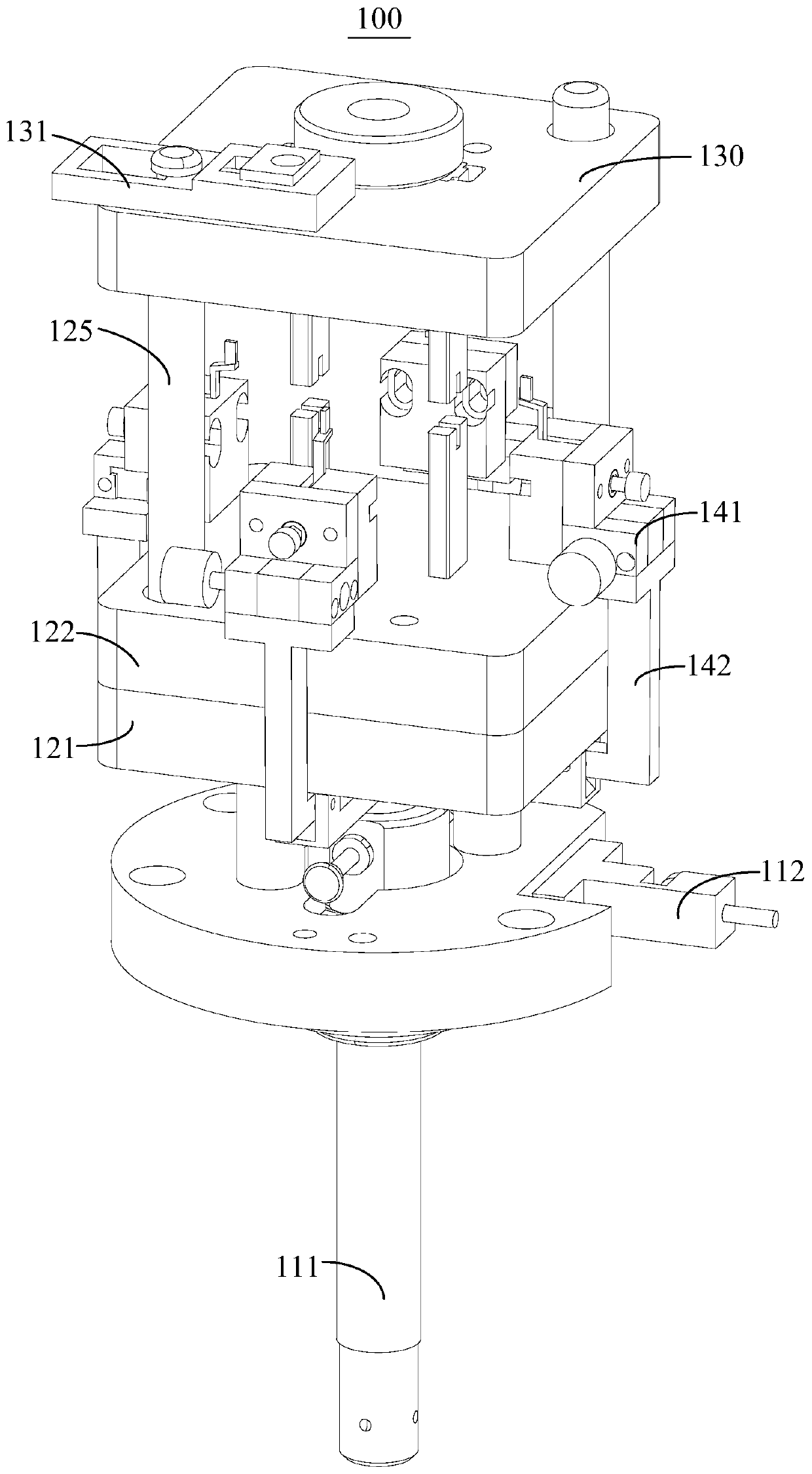

Welding jig for laser tin soldering of hexahedron

PendingCN110355442AIncrease productivityGuaranteed welding yieldWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSoldering

Owner:SHENZHEN TETELASER TECH CO LTD

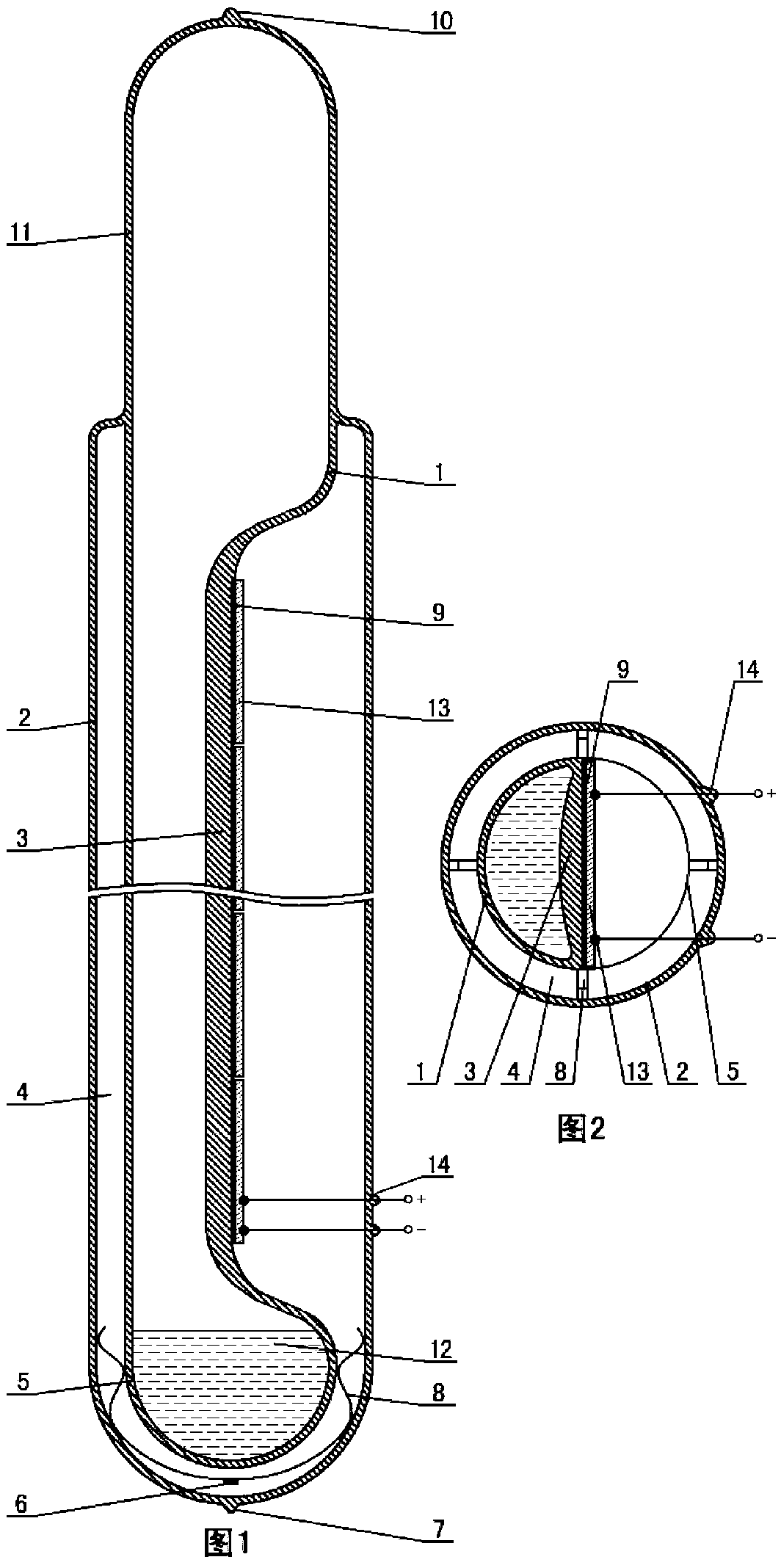

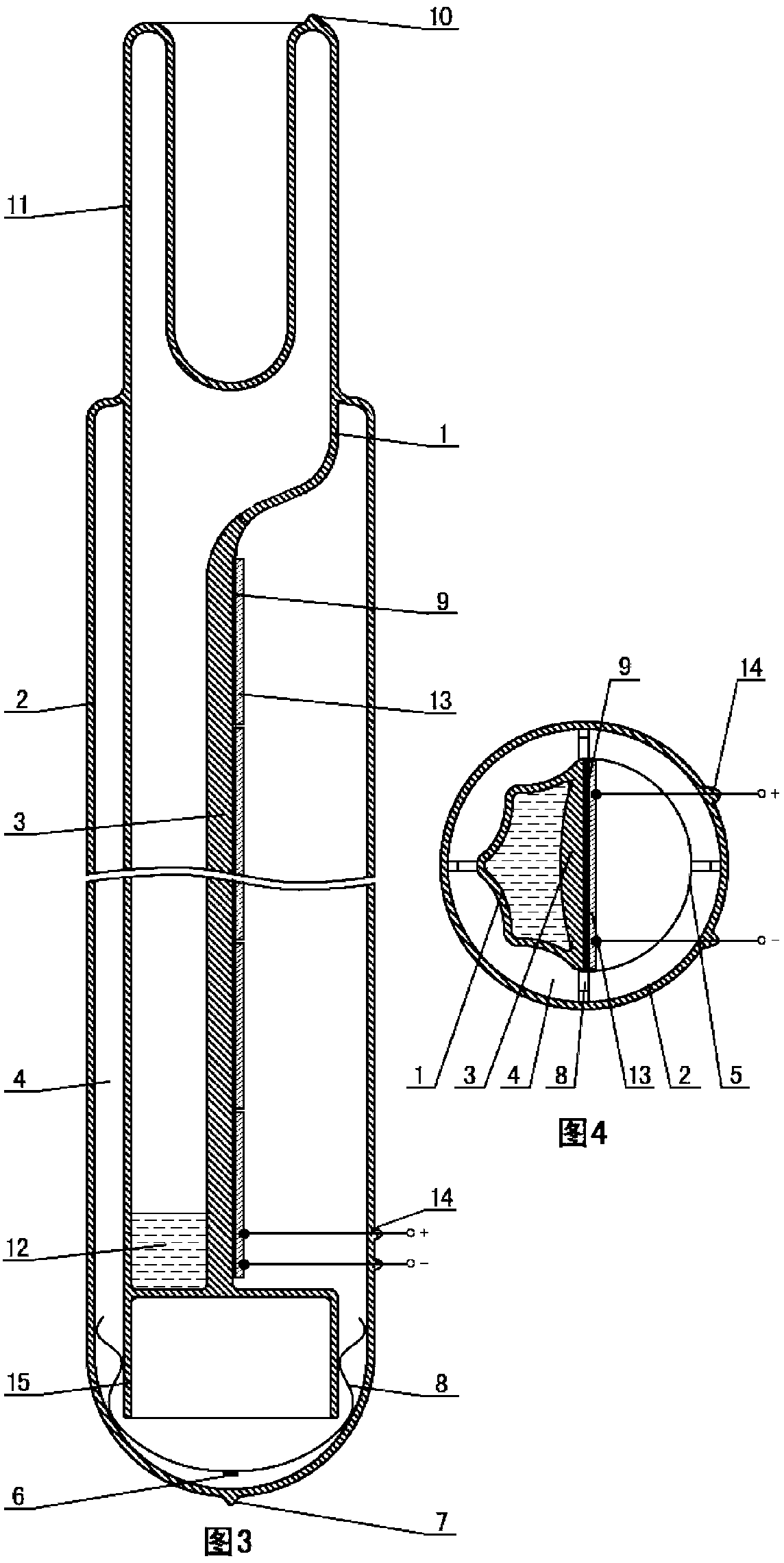

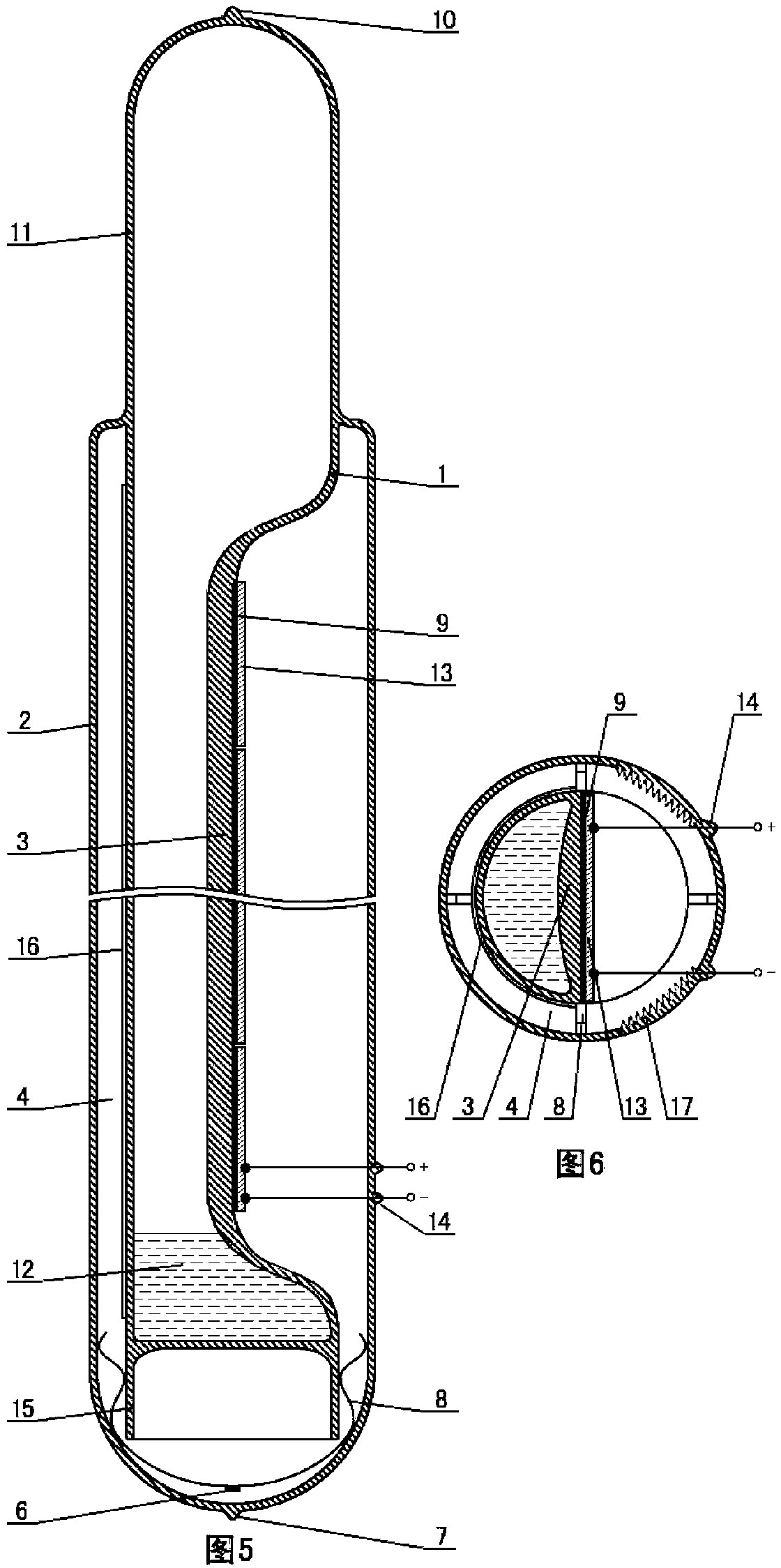

All-glass evacuated photovoltaic heat tube collector tube

InactiveCN101598463BImprove heat absorption efficiencyExtended service lifeSolar heating energySolar heat devicesCell layerEngineering

Owner:BEIJING HIKEEN TECH +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap