Printed circuit board soldering protection nail bed and manufacturing method thereof

A printed circuit board and nail bed technology, which is applied in the fields of printed circuit manufacturing, printed circuit, and printed circuit secondary processing, can solve the problems of difficult management, error-prone, high nail bed processing costs, etc., to reduce management difficulty and improve Work efficiency, material cost saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

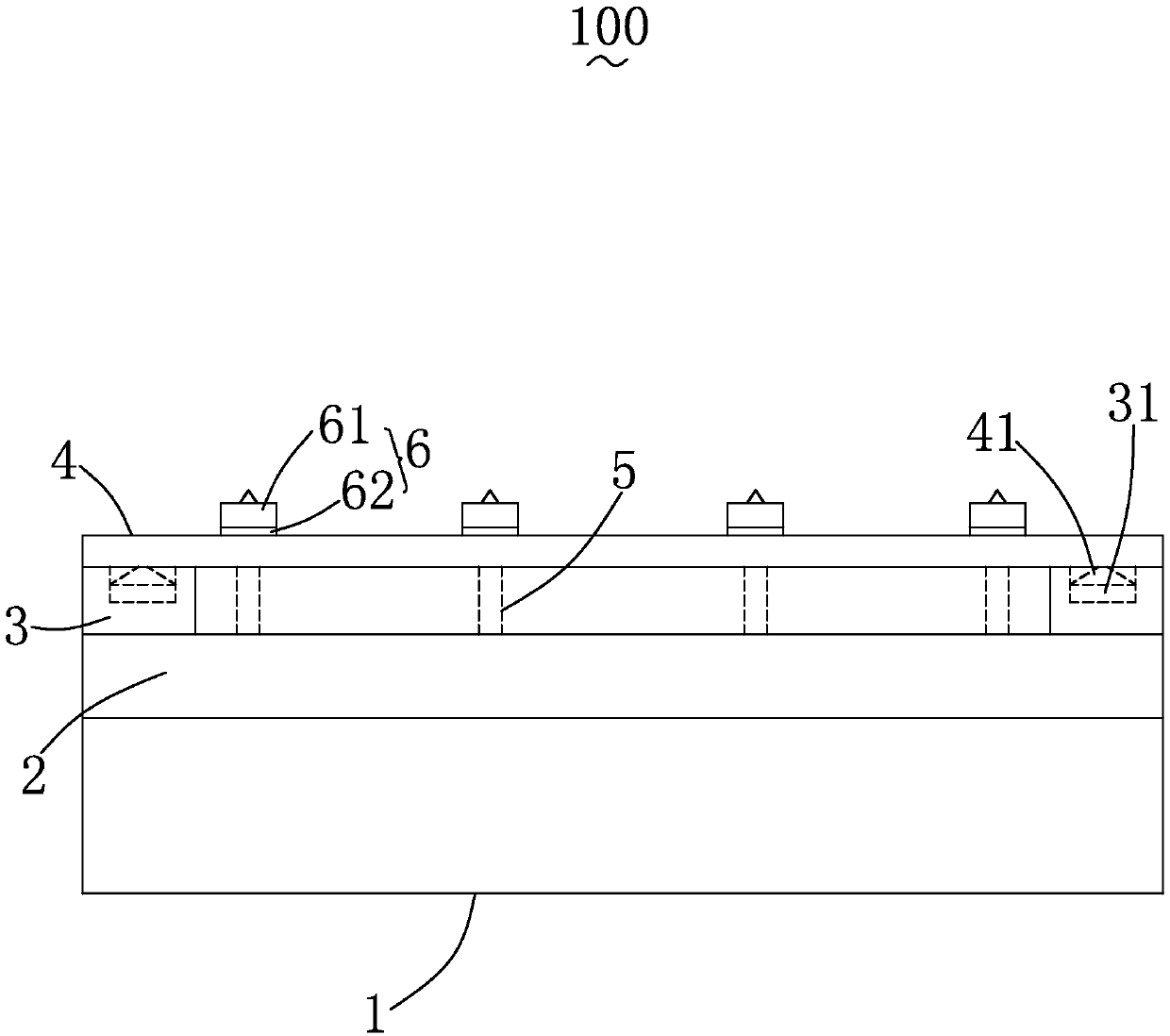

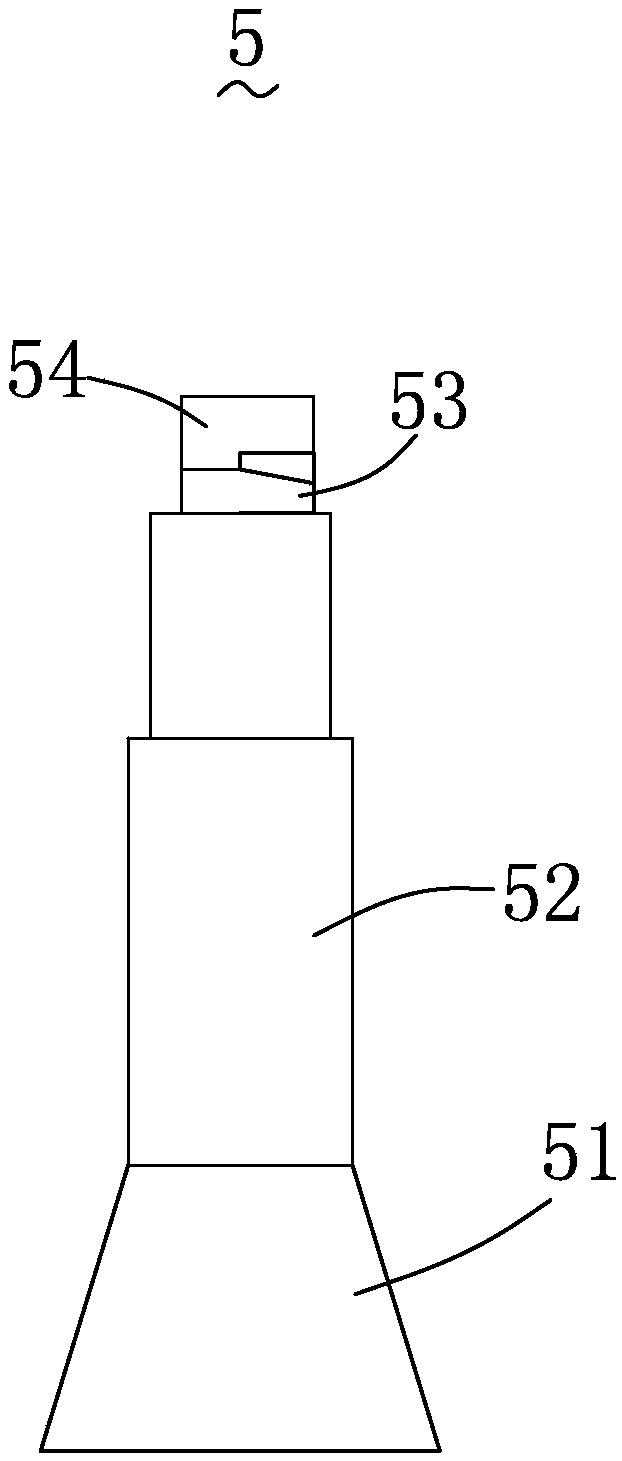

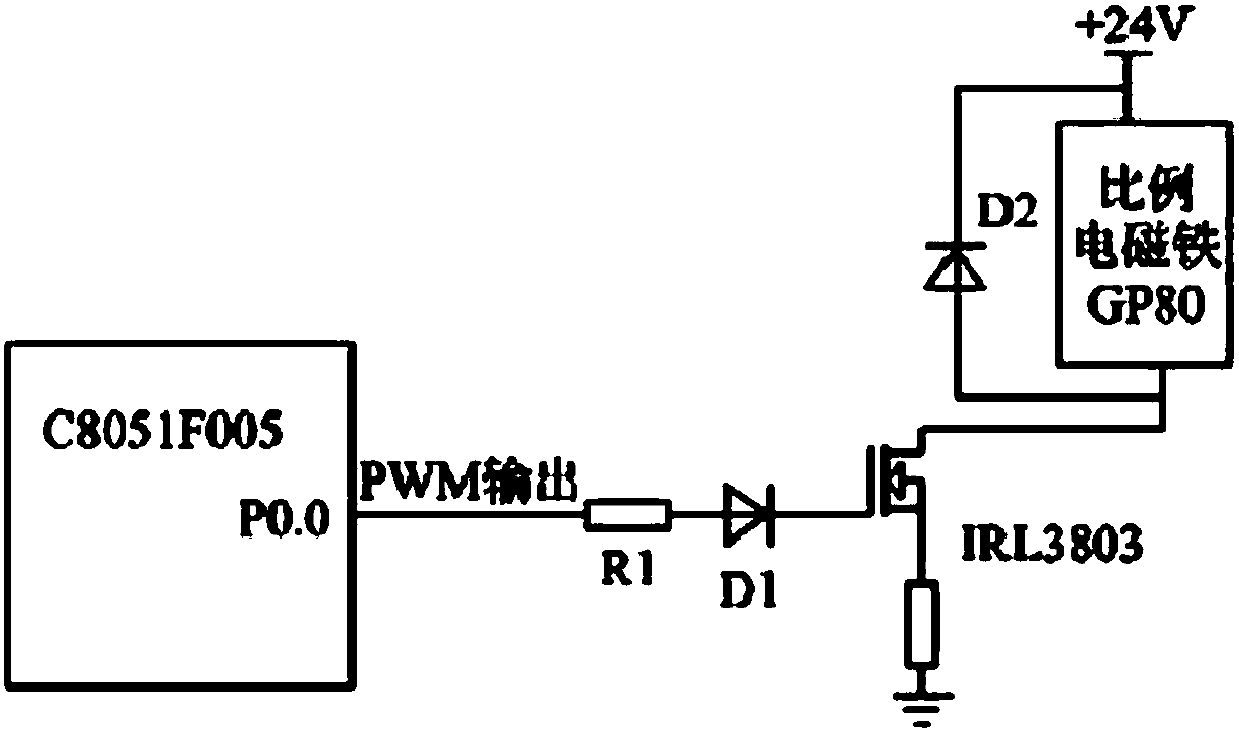

[0034] see figure 1 , is a structural schematic diagram of a preferred embodiment of a printed circuit board solder resist nail bed provided by the present invention. The printed circuit board anti-soldering nail bed 100 includes a support frame 1, a first nail bed bottom plate 2 carried by the support frame 1, and a support frame plate 3 ring-shaped on the top outer peripheral surface of the first nail bed bottom plate 2 , the second nail bed bottom plate 4 erected on the top of the support frame plate 3, the adsorption assembly 5 sandwiched between the first nail bed bottom plate 2 and the second nail bed bottom plate 4, and the second nail bed bottom plate 4 Several PIN nails 6 on the surface of the bed of nails bottom plate 4, the circuit system 7 and the LCD screen display electrically connected with the adsorption assembly 5.

[0035] The first nai

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap