Modified rubber additive production process, production system and rubber additive

A technology of modified rubber and production system, which is applied in the field of rubber additives production, and can solve problems such as inability to process rubber reinforcement additives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

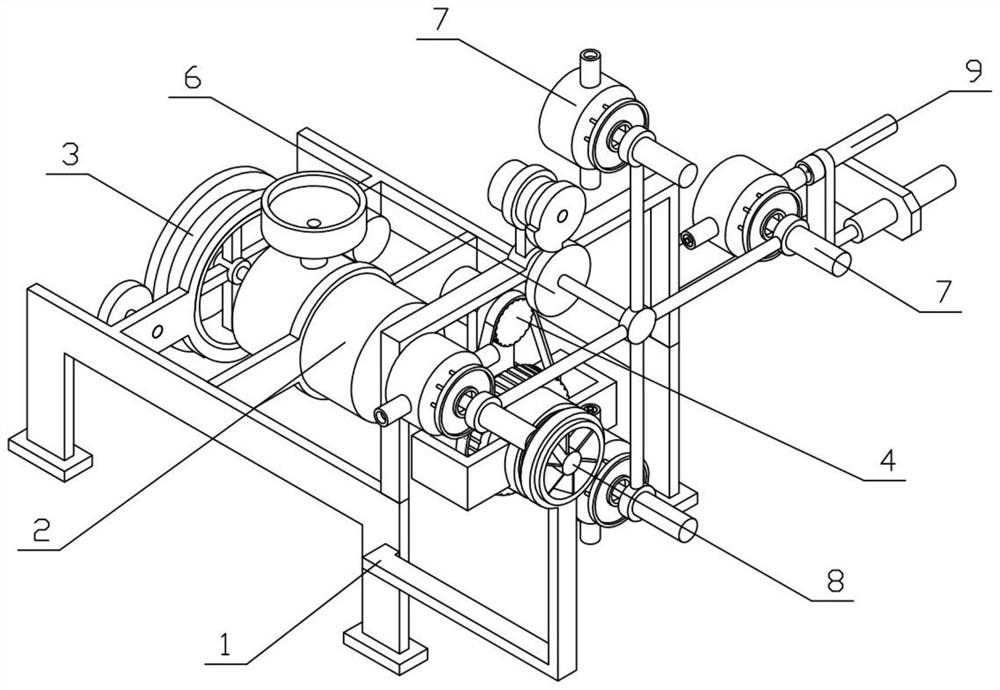

[0037] Combine below Figures 1 to 10Describe this embodiment, a production system for modified rubber additives, including a device support 1, an extrusion support 2, an extrusion mechanism 3, an injection molding mechanism 4, a closing mechanism 5, a replacement mechanism 6, a molding mechanism 7, a pushing fan 8 and Cooling mechanism 9, said device support 1 is fixedly connected with extruding support 2, is fixedly connected with extruding mechanism 3 on device support 1, and extruding mechanism 3 is rotatably connected on extruding support 2 again, and extruding support 2 is connected with Injection molding mechanism 4, the front end of extruding bracket 2 is fixedly connected with closing mechanism 5, and injection molding mechanism 4 is rotatably connected on closing mechanism 5, is connected with replacement mechanism 6 on device bracket 1, and is fixedly connected with four molding mechanisms 7 on replacement mechanism 6 , the left side of the device bracket 1 is rotat...

specific Embodiment approach 2

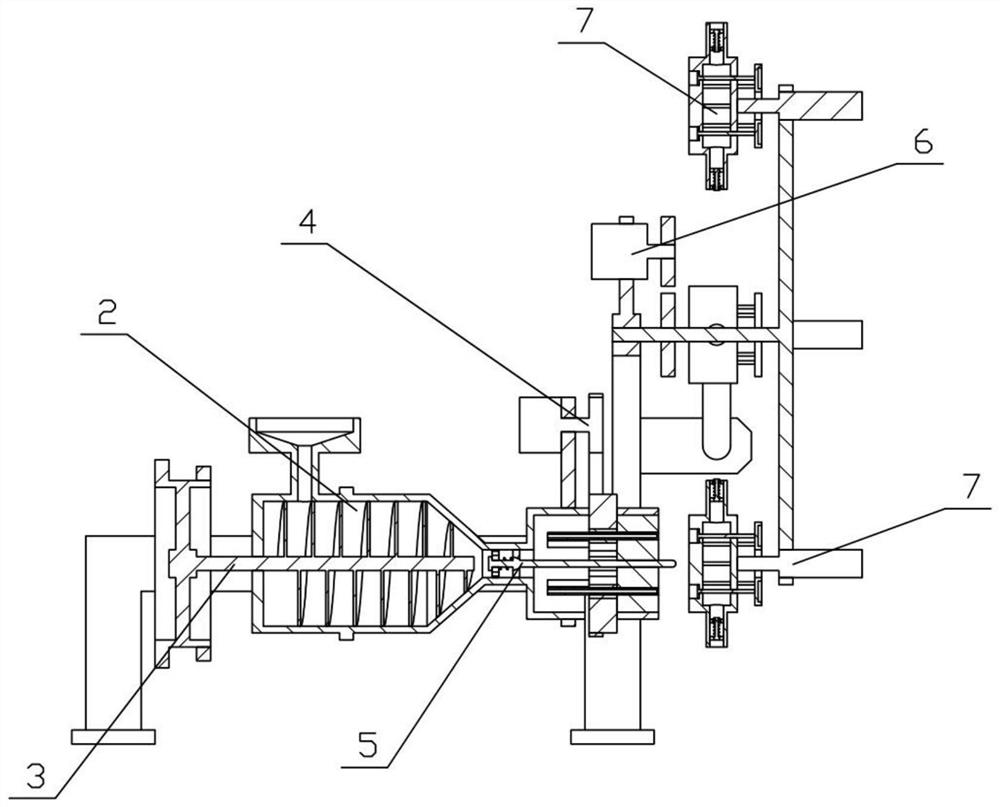

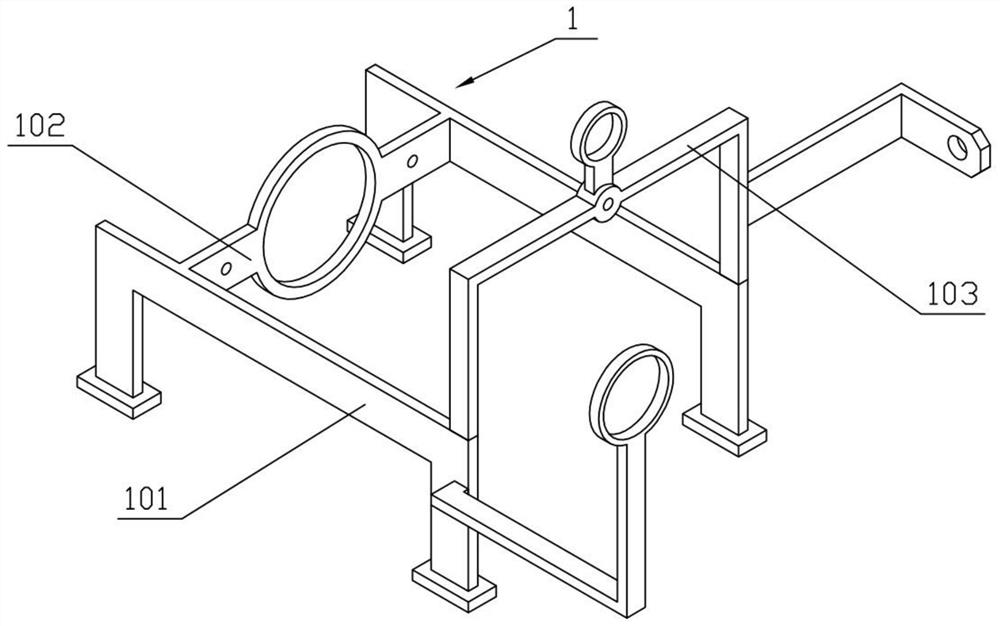

[0039] Combine below Figures 1 to 10 This embodiment will be described. This embodiment will further describe the first embodiment. The device bracket 1 includes a side bracket 101, a connecting bracket I 102 and a connecting bracket II 103. There are two side brackets 101. Between the rear ends of the two side brackets 101 A connecting bracket I102 is fixedly connected between them, and a connecting bracket II103 is fixedly connected between the front ends of the two side brackets 101. The extrusion bracket 2 includes an extrusion cylinder 201, a closing cylinder 202, a forming cylinder I203, a forming cylinder II204 and a feeding pipe 205 , the extruding cylinder 201 is fixedly connected to the connecting bracket I102, the front end of the extruding cylinder 201 is fixedly connected with the closing cylinder 202, the front end of the closing cylinder 202 is connected with the forming cylinder I203, and the front end of the forming cylinder I203 is fixedly connected with the ...

specific Embodiment approach 3

[0041] Combine below Figures 1 to 10 Describe this embodiment, this embodiment will further explain the second embodiment, the extrusion mechanism 3 includes an extrusion motor 301, an extrusion runner 302 and an extrusion screw 303, and the extrusion motor 301 is fixedly connected to the two side brackets Between 101, the extrusion runner 302 is rotatably connected to the connecting bracket I102, the extrusion runner 302 and the output shaft of the extrusion motor 301 are meshed for transmission, and the extrusion runner 302 is fixedly connected with an extrusion screw 303, and the extrusion screw 303 is rotatably connected in the extrusion cylinder 201.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap