Manufacture of RFID tags and intermediate products therefor

a technology of radio frequency identification and intermediate products, which is applied in the direction of casings/cabinets/drawers, instruments, casings/cabinets/drawers, etc., can solve problems such as mechanical connections failing, and achieve the effect of facilitating manufacture and high effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

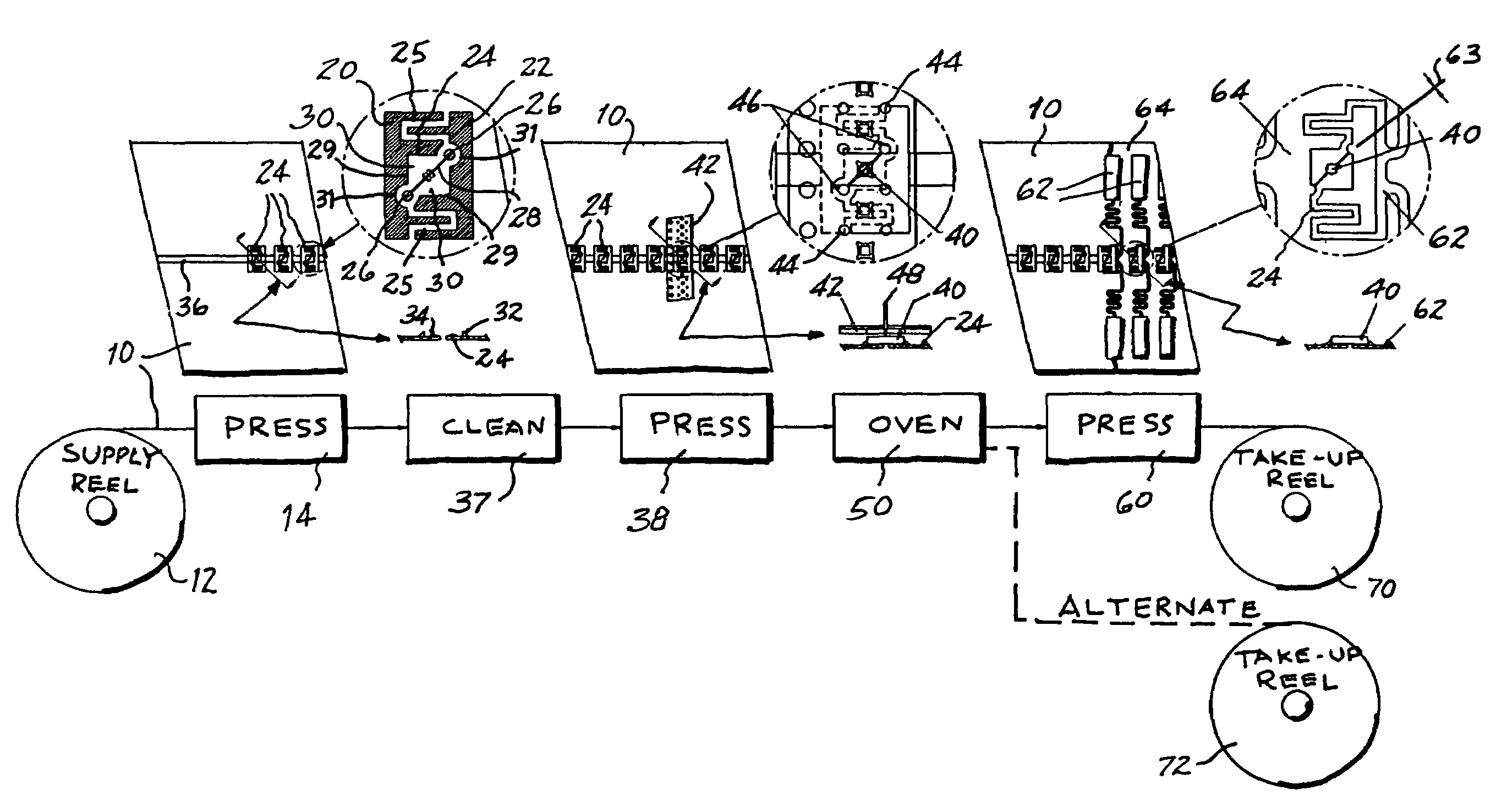

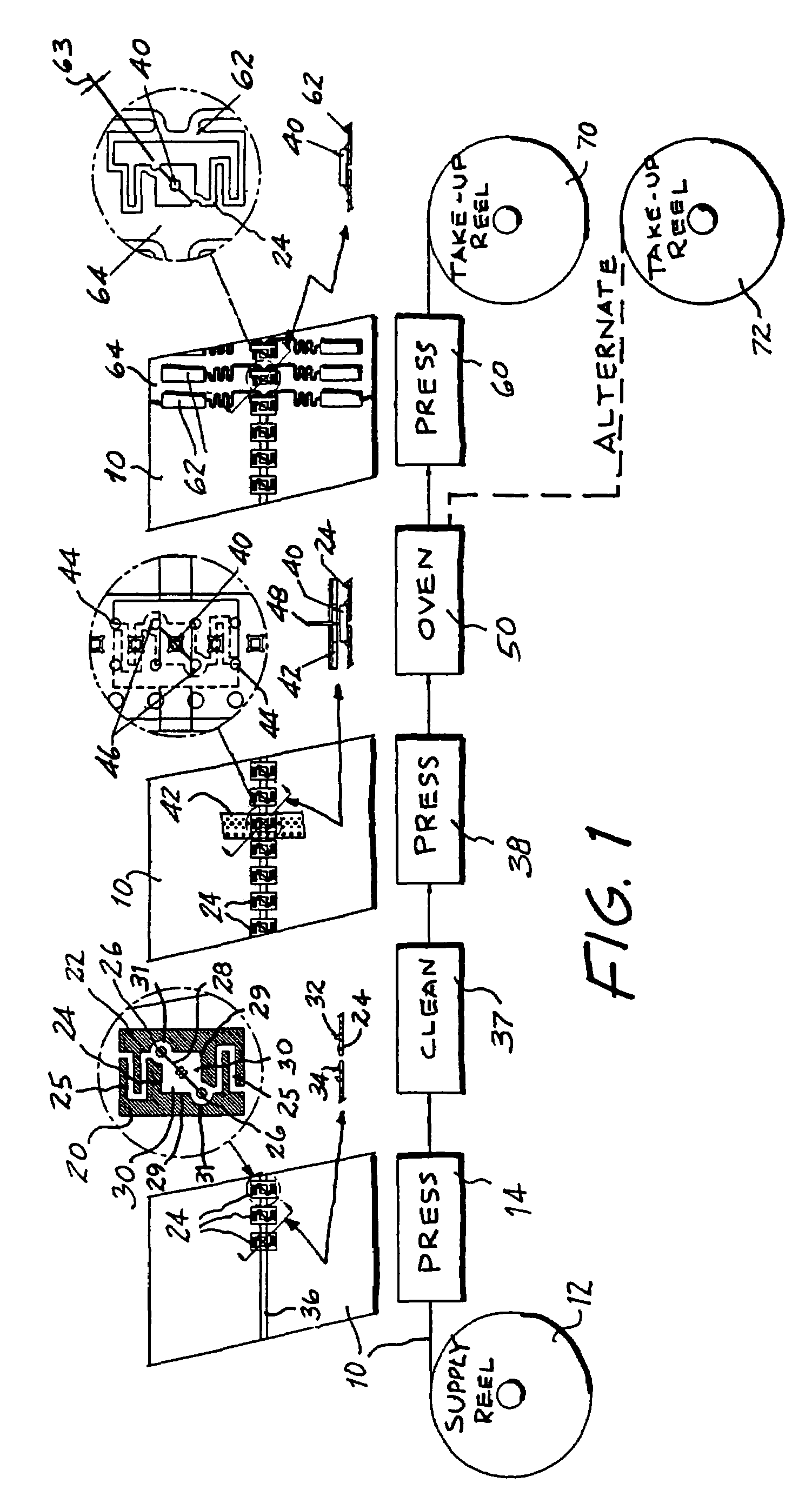

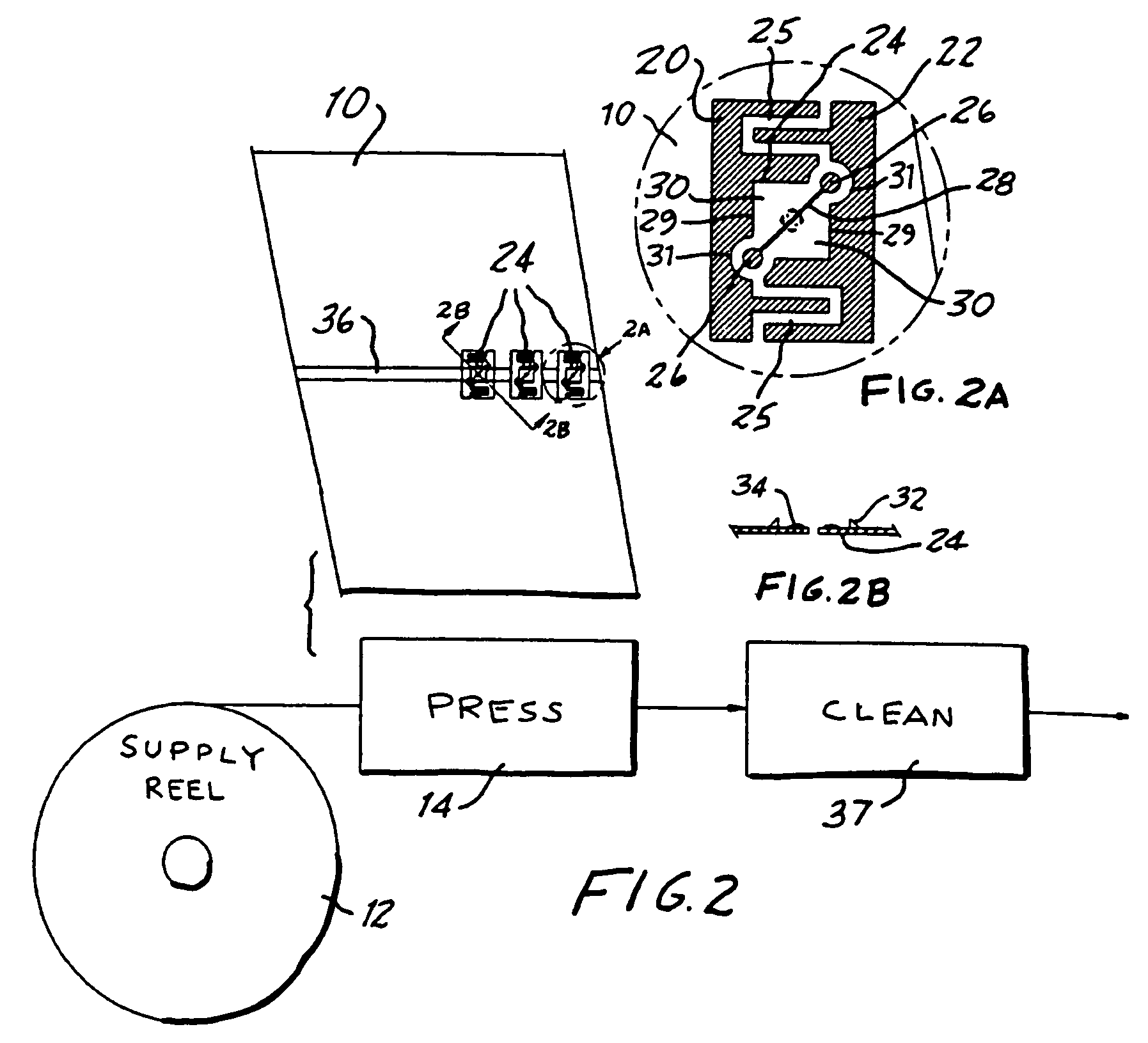

[0029]Referring now to the drawing, and especially to FIG. 1 thereof, a sequential line is illustrated in which an aluminum strip 10 is supplied from a supply reel 12 and advanced along a longitudinal direction to a first press 14 where portions of the strip 10 are punched from the strip 10, as represented by shaded areas 20 and 22, to establish a series of contact members 24 integrated with and carried by the remainder of the strip 10, spaced longitudinally from one another along the strip 10, each contact member 24 remaining coupled with the strip 10 by a compliant coupling arrangement shown in the form of undulant arms 25 connecting each contact member 24 with the strip 10.

[0030]Locators in the form of pilot holes 26 are placed at the opposite ends of a slot 28 which separates each contact member 24 into two contact elements 29 such that the overall area of each contact member 24 is divided into two separate contact areas 30. The pilot holes 26 extend altitudinally through ears 31 f

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Electrical conductivity | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap