Spherical magnesium hydroxide particle, spherical magnesium oxide particle, and method for producing same

A technology of magnesium oxide particles and magnesium hydroxide, applied in magnesium hydroxide, magnesium oxide and other directions, can solve problems such as insufficient resin dispersion and achieve the effect of easy production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

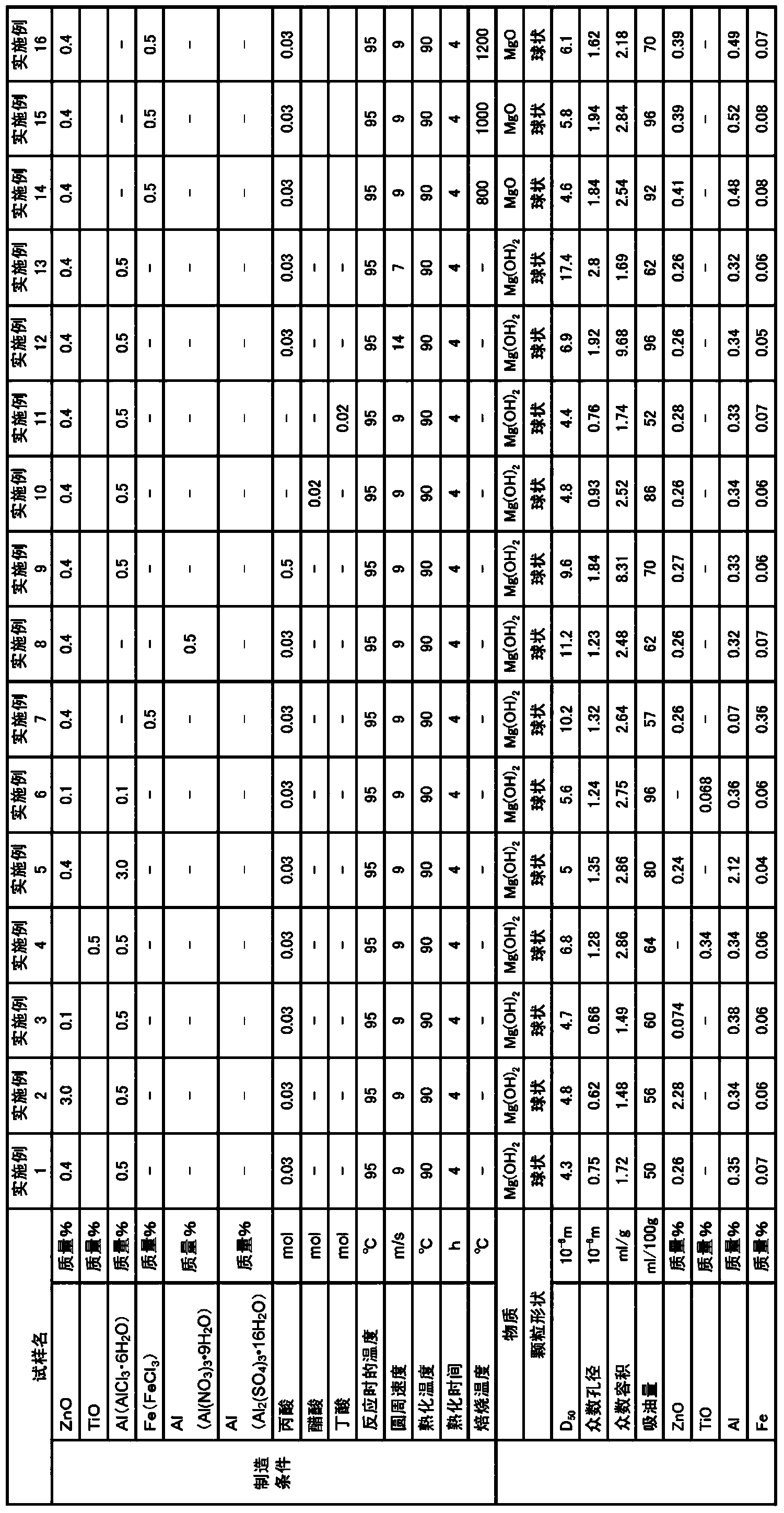

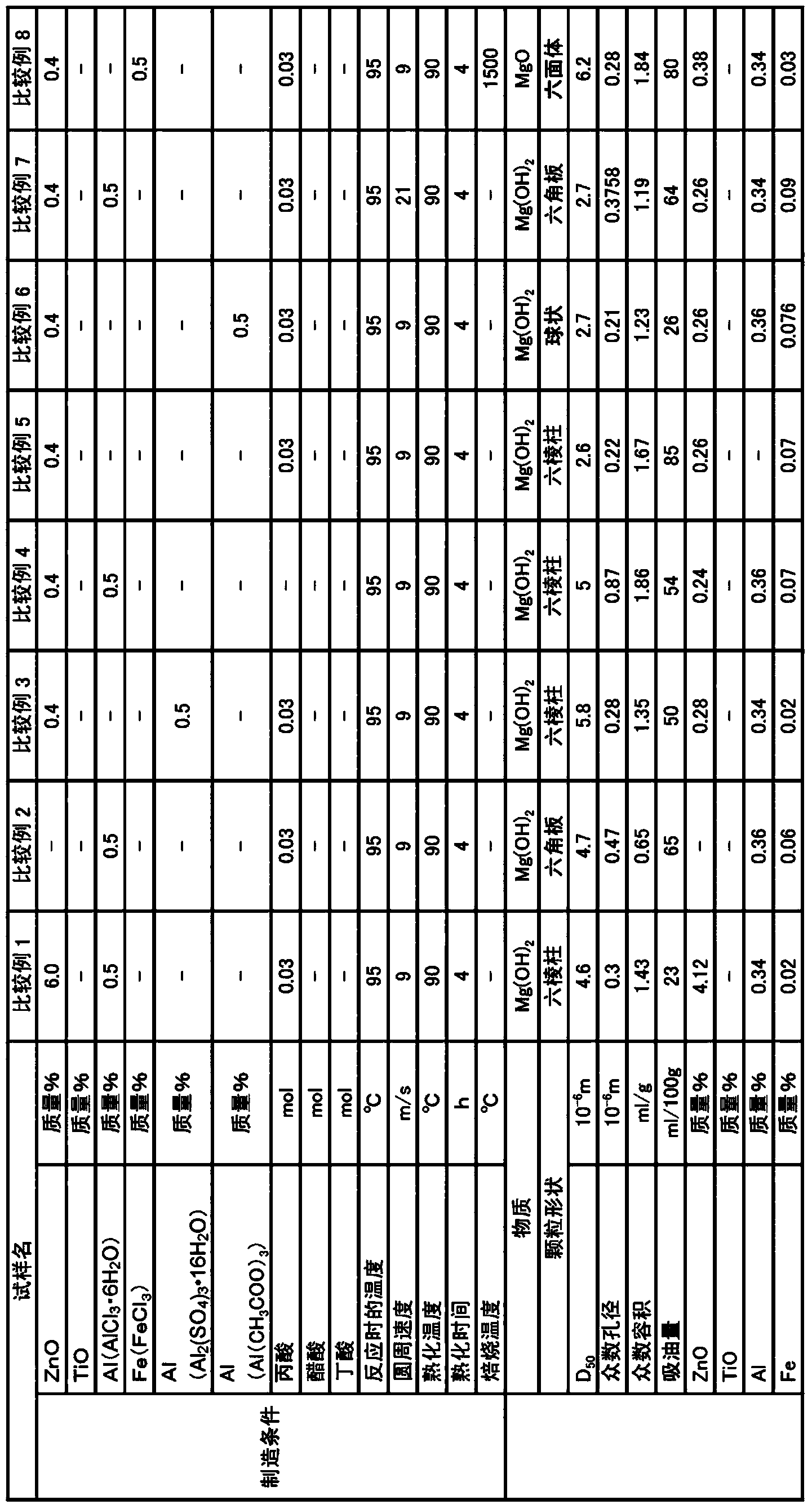

[0102] [Example 1]

[0103] In a solution containing 0.4% by mass of zinc oxide and 1 liter of ion-exchanged water with respect to the magnesium oxide used in the reaction, 0.5% by mass of aluminum chloride·hexahydrate and 0.03 mol of propionic acid relative to 100 g of magnesium oxide was used to prepare a reaction liquid.

[0104] The temperature of the prepared reaction liquid was raised to 60° C., and 100 g of magnesium oxide having an average particle diameter of 8.8 μm was introduced to obtain a mixed liquid. After adding magnesium oxide, the temperature of the reaction liquid was raised to 95° C., using a stirrer (T.K. HOMO DISPER manufactured by PRIMIX Corporation), the peripheral speed was adjusted to 9 m / s, and the reaction was performed for 1 hour.

[0105] After that, stirring was carried out at 90°C for 4 hours at a rotation speed sufficient to stir the slurry to prepare a magnesium hydroxide slurry. The prepared magnesium hydroxide slurry is filtered, washed with water

Example Embodiment

[0106] [Example 2]

[0107] Except the addition amount of zinc oxide being 3.0 mass %, it carried out similarly to Example 1.

Example Embodiment

[0108] [Example 3]

[0109] Except that the addition amount of zinc oxide was 0.1% by mass, the same procedure as in Example 1 was carried out.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap