Safety shoe with external steel toe and production process of safety shoe

An external, safety shoe technology, applied in the direction of shoe uppers, footwear, heel pads, etc., can solve the problems of uncomfortable wearing, steel toe exposure, worn toes, etc., to achieve a broad market space, novel steel toe, structure simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

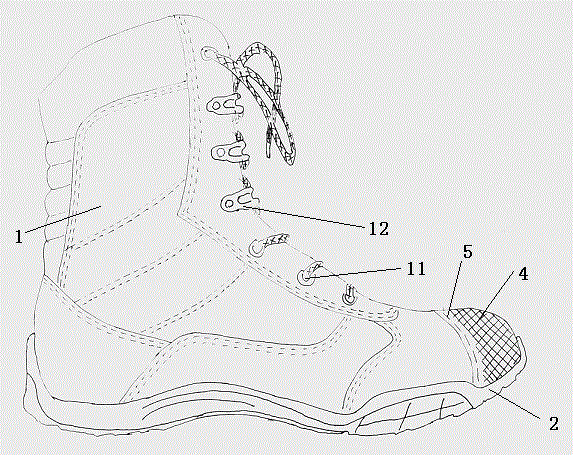

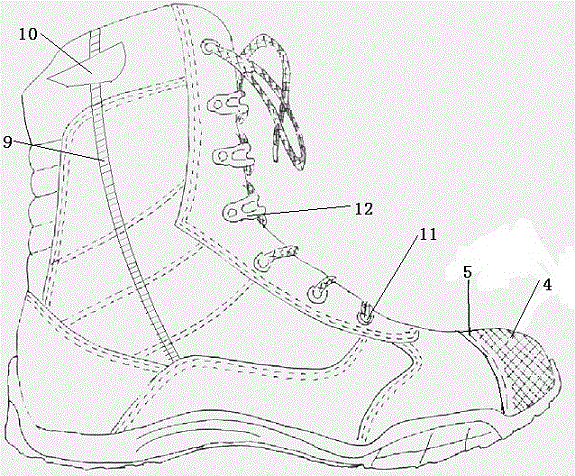

[0036] An external steel toe safety shoe includes an upper 1 , a sole 2 , a tongue 3 and a steel toe 4 . The steel head is placed on the outer skin layer of the upper head, the inner side of the steel head is glued to the upper skin surface layer, and the bottom end of the steel head is attached to the bottom edge of the upper at the corresponding position, and is connected and fixed with the sole.

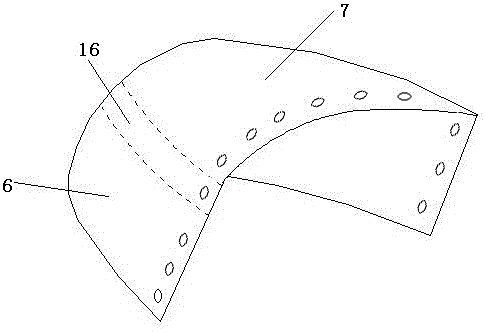

[0037] The top edge and the side edge of the steel toe are evenly provided with some fixing holes, and the upper skin of the shoe is provided with connecting holes at positions corresponding to the fixing holes, and the upper of a shoe and the steel toe are connected and fixed by using the mark line 5 to pass through the fixing holes and the connecting holes. The fixing holes are elliptical, the major axis of the fixing holes is 3-5 mm, the minor axis is 1.5-3.5 mm, and the distance between the fixing holes is 6-10 mm.

[0038] The steel head is formed by connecting arc-shaped sid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap