Socket connector

a socket connector and connector technology, applied in the direction of multi-conductor cable end pieces, fixed connections, coupling device connections, etc., can solve the problems of difficult to ensure the coplanarity of the soldering parts, and the problem may even be worse, and achieve good coplanarity performan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

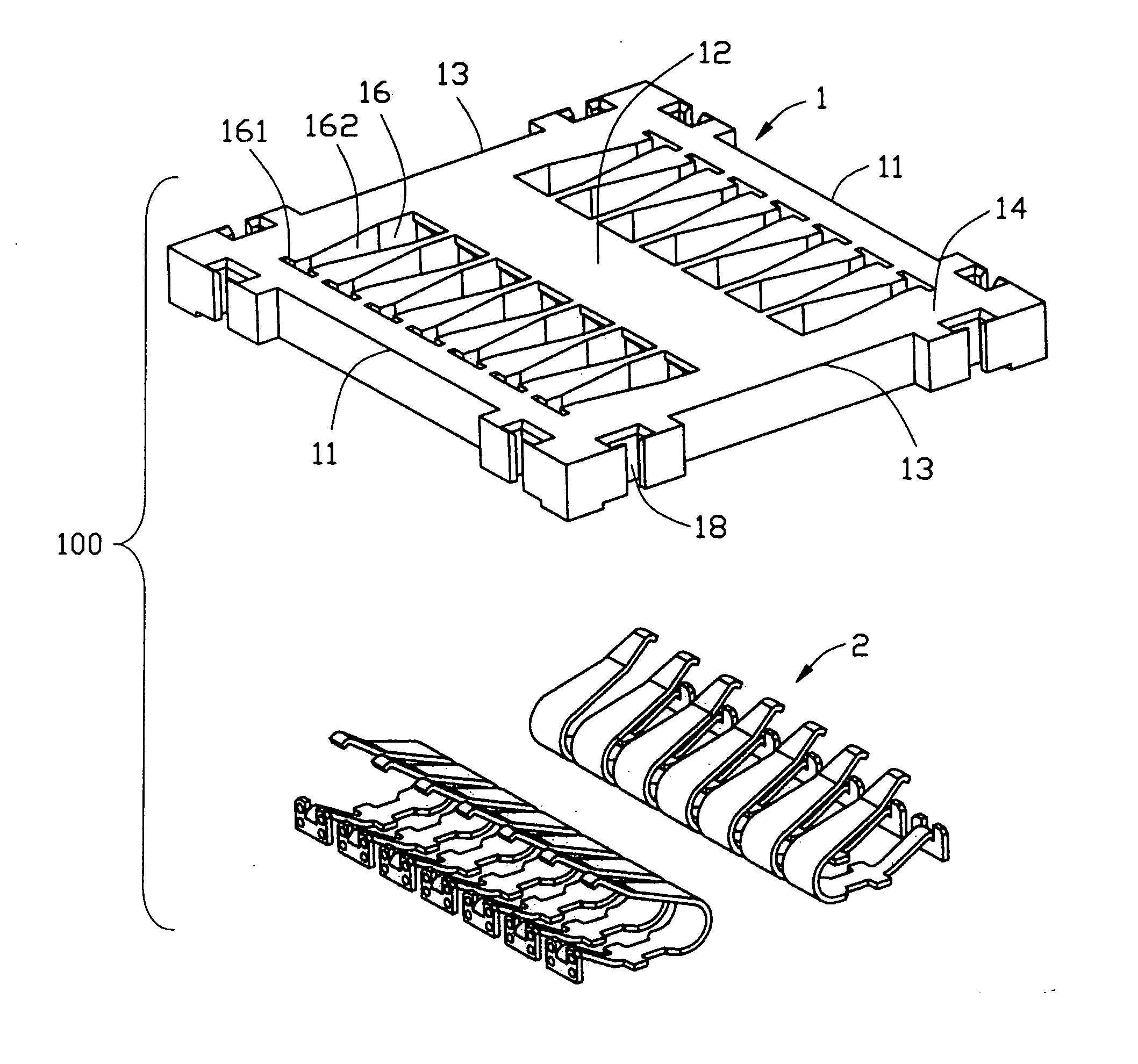

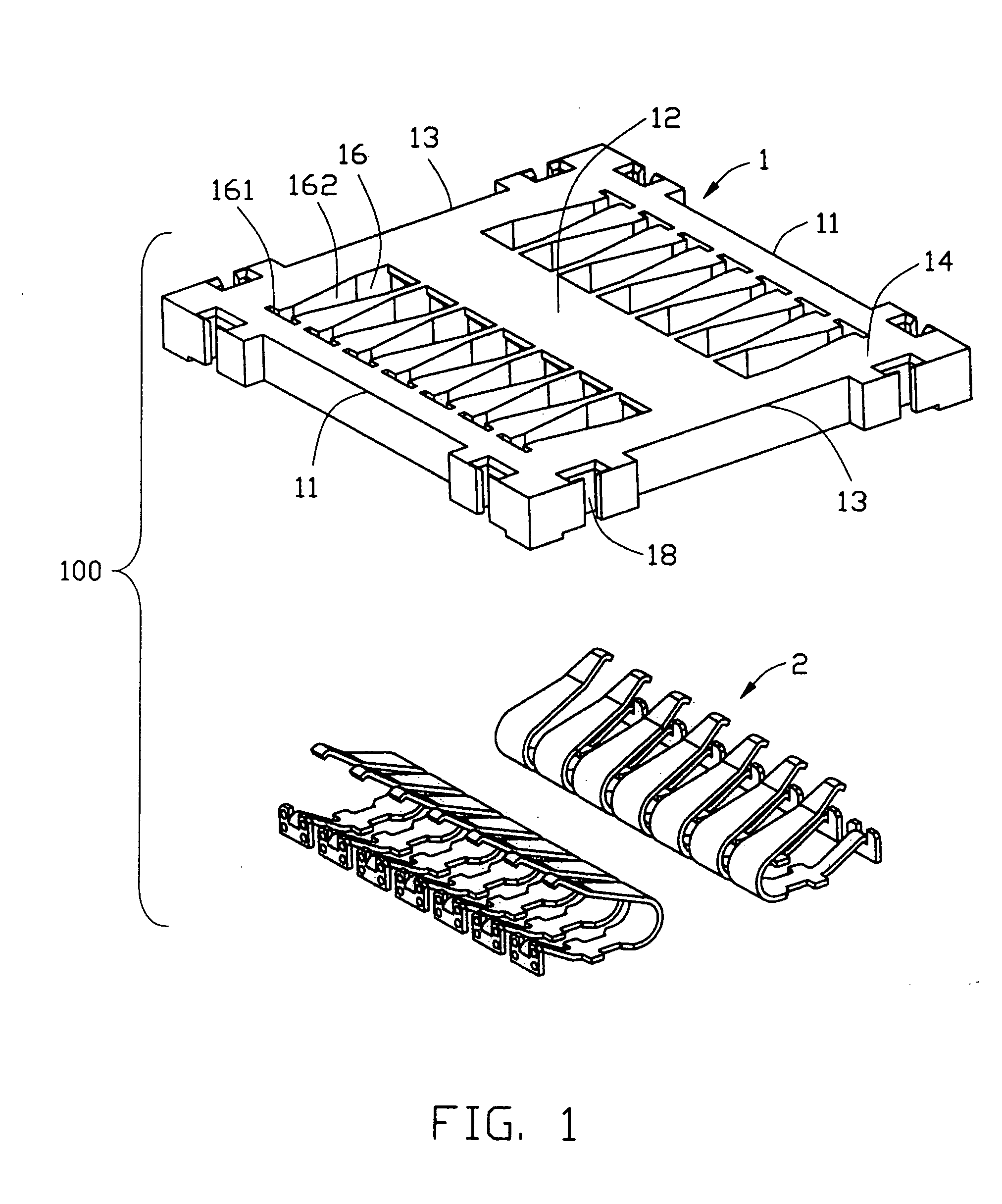

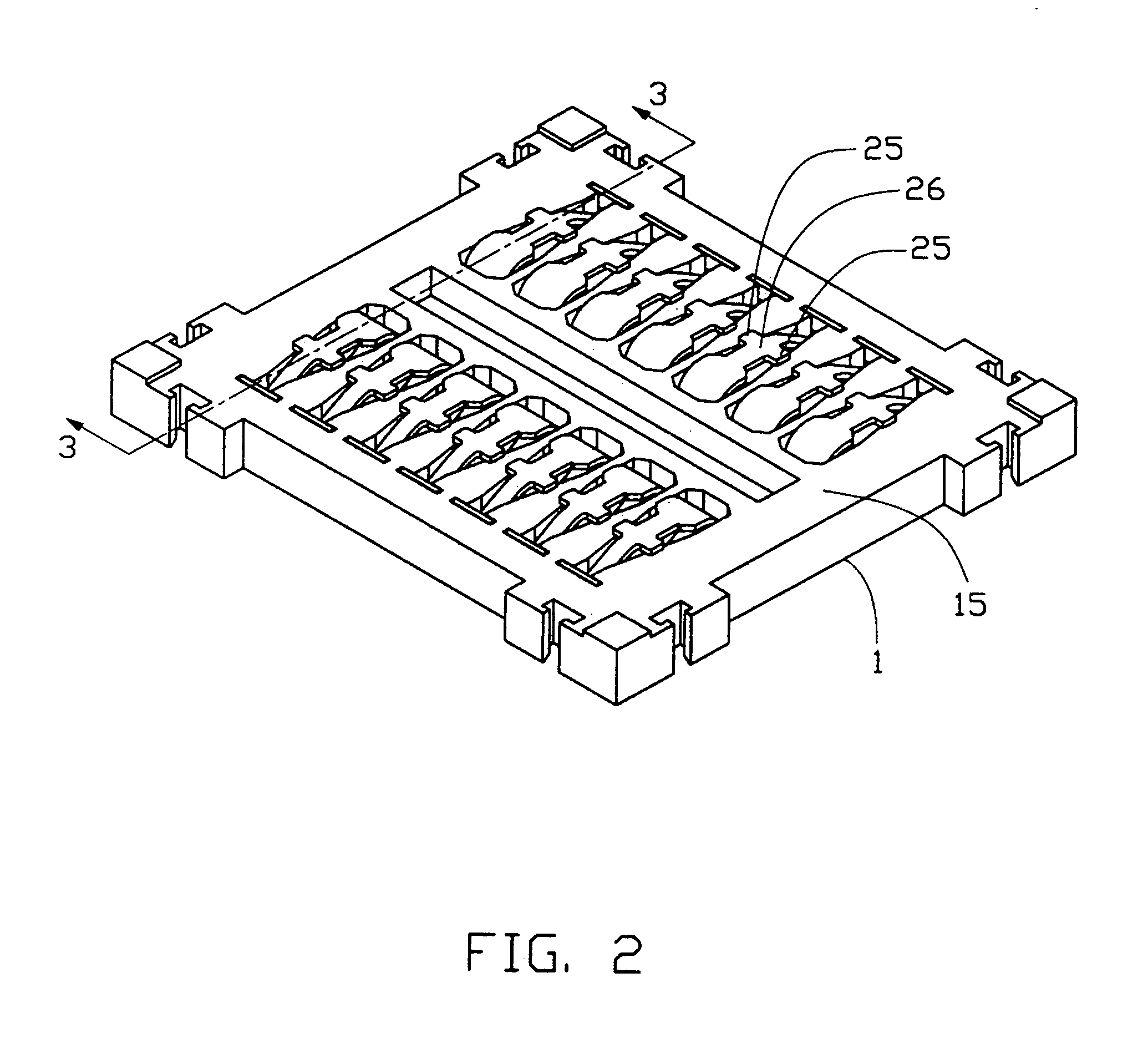

[0018] Referring to FIGS. 1 and 2, a socket connector 100 in accordance with the present invention comprises an insulative housing 1 and a plurality of contacts 2.

[0019] The insulative housing 1 comprises opposite side walls 11, opposite end walls 13 respectively perpendicular to the side walls 11 and a central wall 12 parallel to the side walls 11 and connecting with central portions of the end walls 13. The insulative housing 1 is symmetrical with the central wall 12. The insulative housing 1 has a top surface 14 and a bottom surface 15. A plurality of passageways 16 is defined through the top surface 14 and the bottom surface 15 in the insulative housing 1. The passageways 16 are arranged in two rows and are symmetrical with the central wall 12. Each passageway 16 has a slit 161 located adjacent to a corresponding side wall 11, and a receiving groove 162 extending in a direction perpendicular to the slit 161 and towards the central wall 12. The insulative housing 1 has a plurality

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap