Tin soldering equipment for wiring terminal and enameled aluminum wire on straight stator

A technology for connecting terminals and arranging stators, applied in the field of machinery, can solve the problems of waste of manpower, low efficiency of manual soldering, and inability to guarantee welding quality, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with the accompanying drawings.

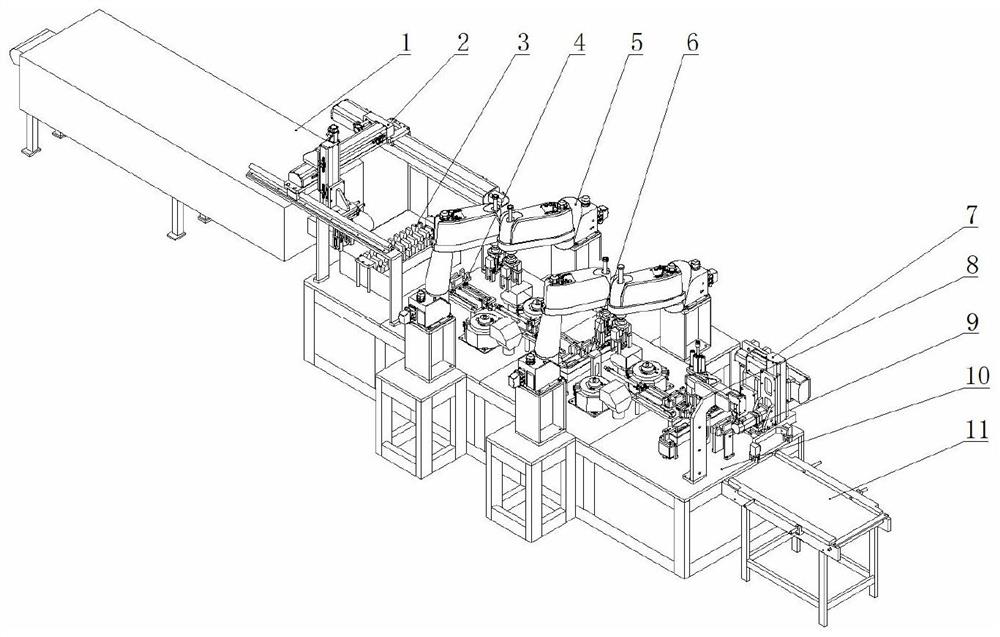

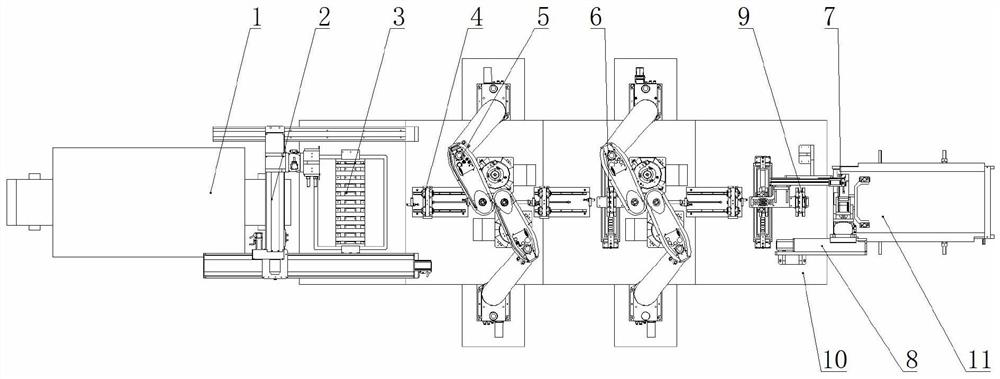

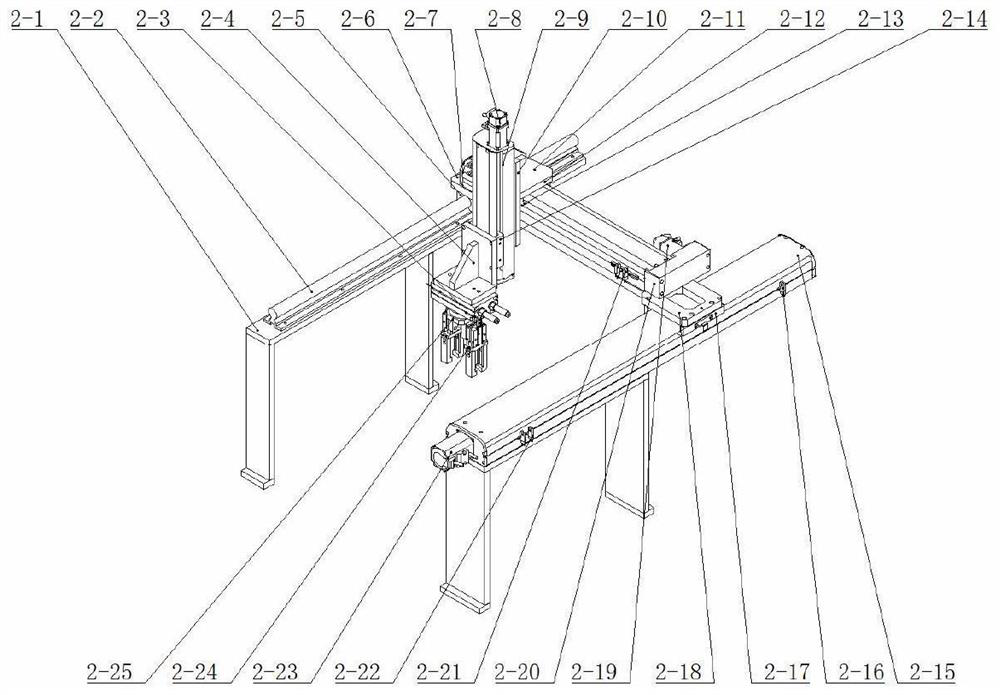

[0032] Such as figure 1 and 2 As shown in the figure, a soldering equipment for connecting terminals on the stator and enamelled aluminum wires in a straight row includes a drying channel belt transmission mechanism 1, a drying channel, a cleaning and feeding mechanism 2, an ultrasonic cleaning box assembly 3, a transfer transition mechanism 1, and a transfer mechanism Transition mechanism 2, transfer transition mechanism 3 4, paint stripping mechanism, soldering mechanism 5, paint remover reagent tank assembly, flux reagent tank assembly 6, flip feeding mechanism 7, handling mechanism 8, feeding tooling 9, base 10 and feeding belt transmission mechanism 11. The transmission belt of the feeding belt transmission mechanism 11 is fixed with multiple vertical partitions arranged equidistantly along the ring of the transmission belt; the feeding tooling 9 is located at the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap