Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6 results about "Wave crest" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

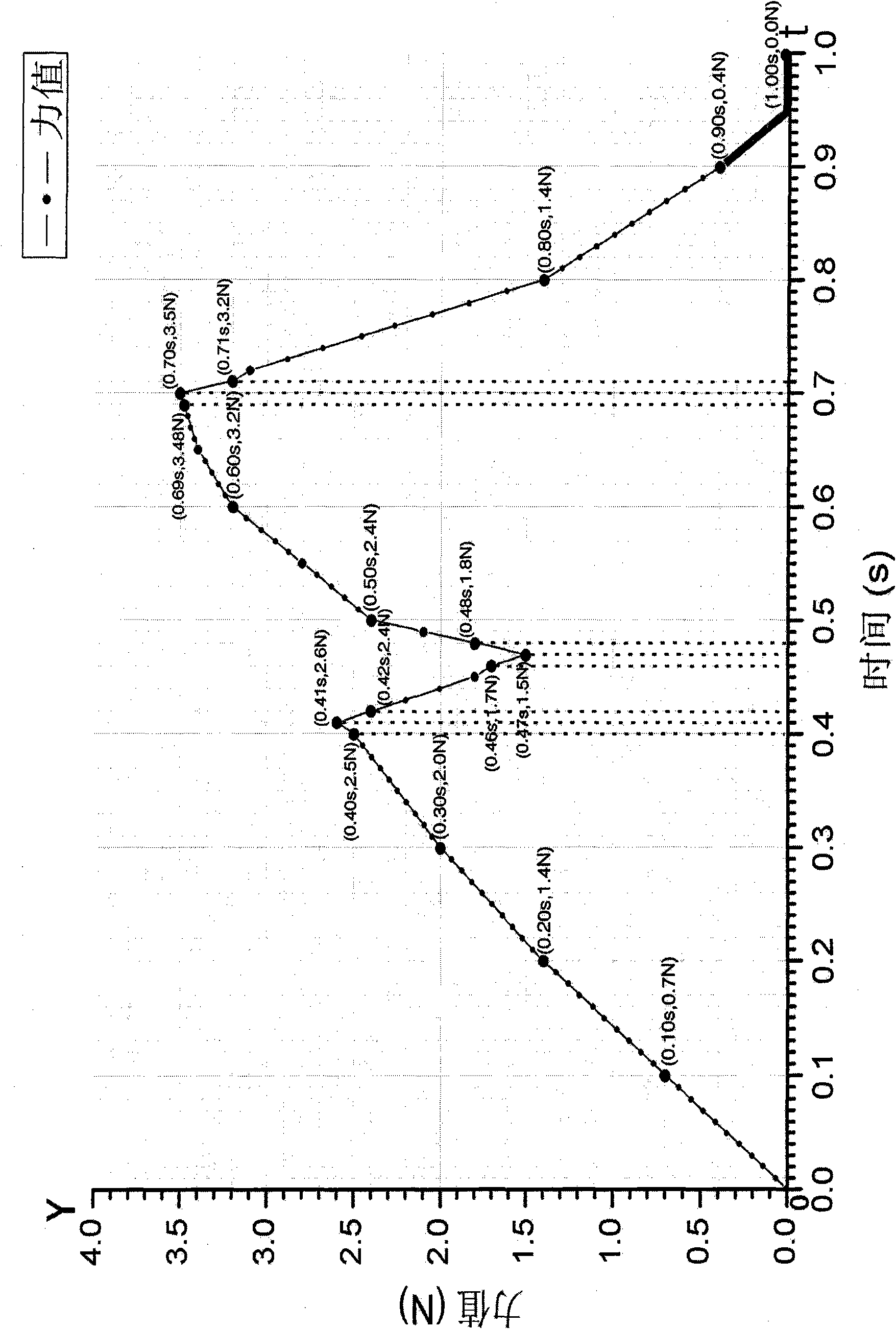

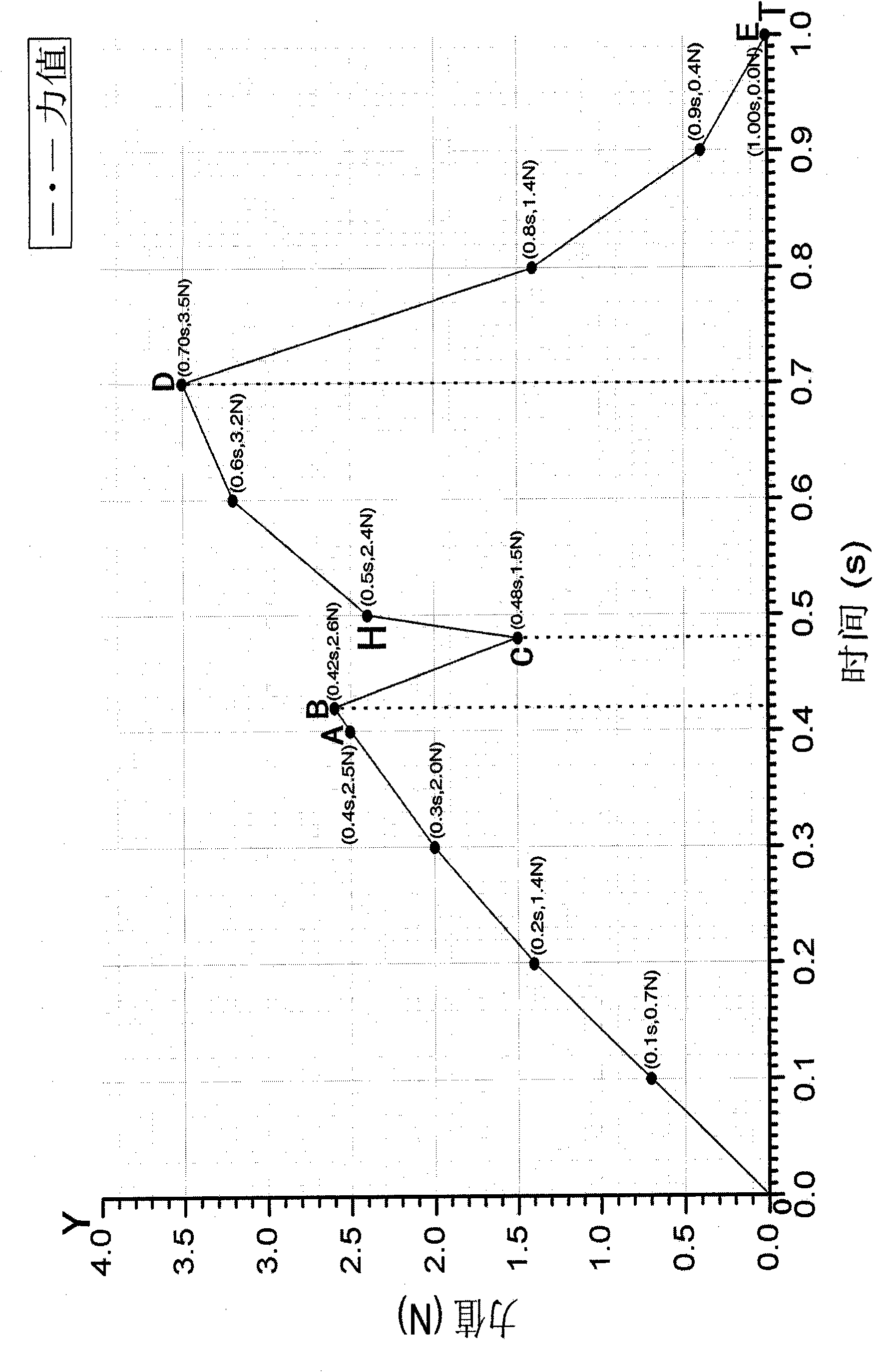

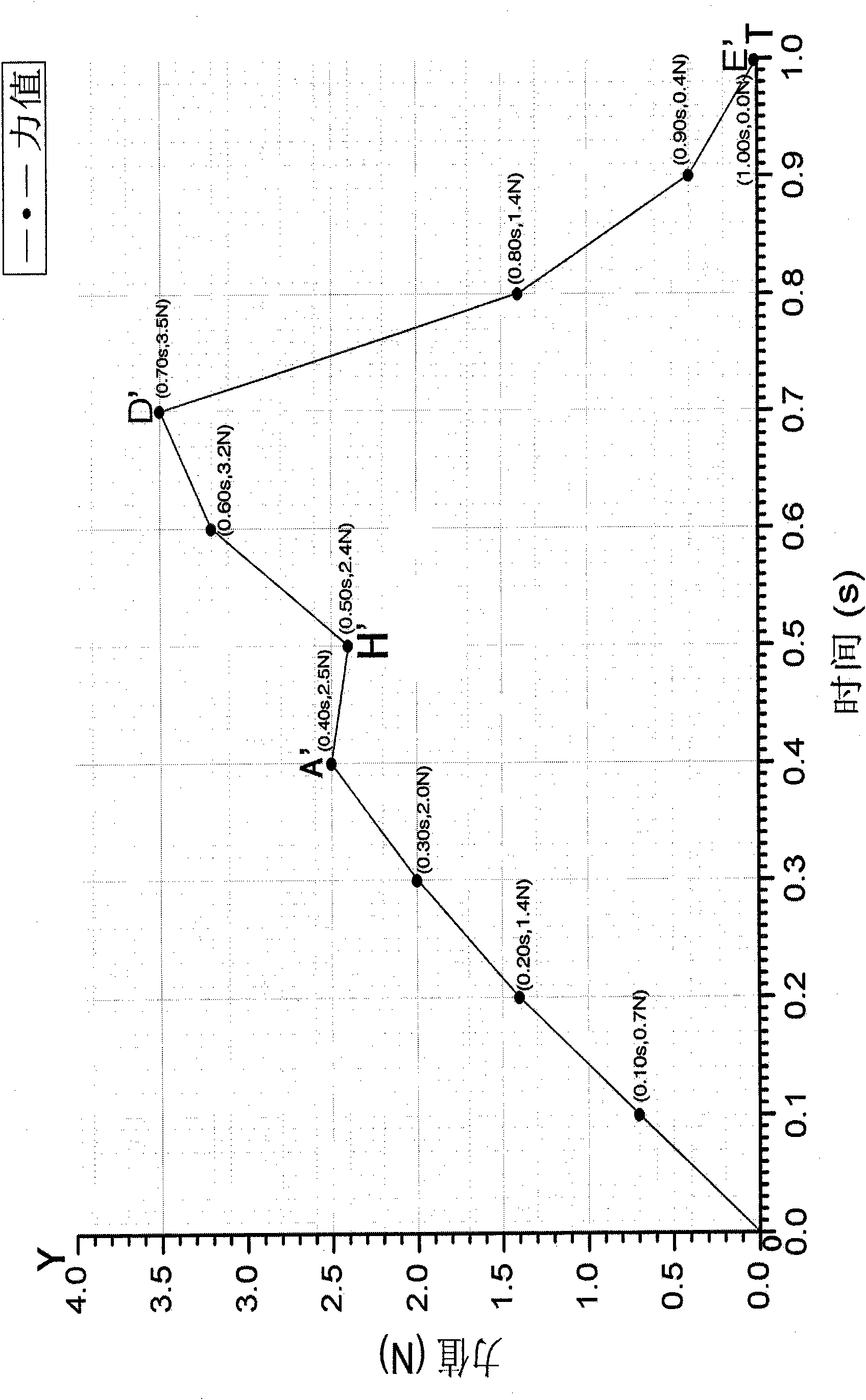

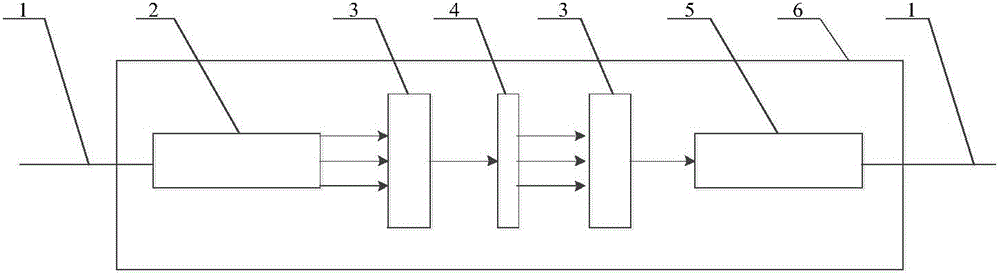

Graphical recording method for force value tests

InactiveCN101592534AAccurate responseUndisturbedForce measurementStructural/machines measurementComputer scienceWave crest

Owner:陈圣陶

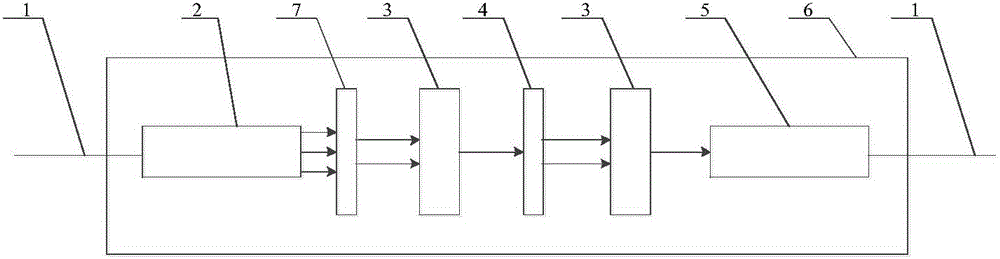

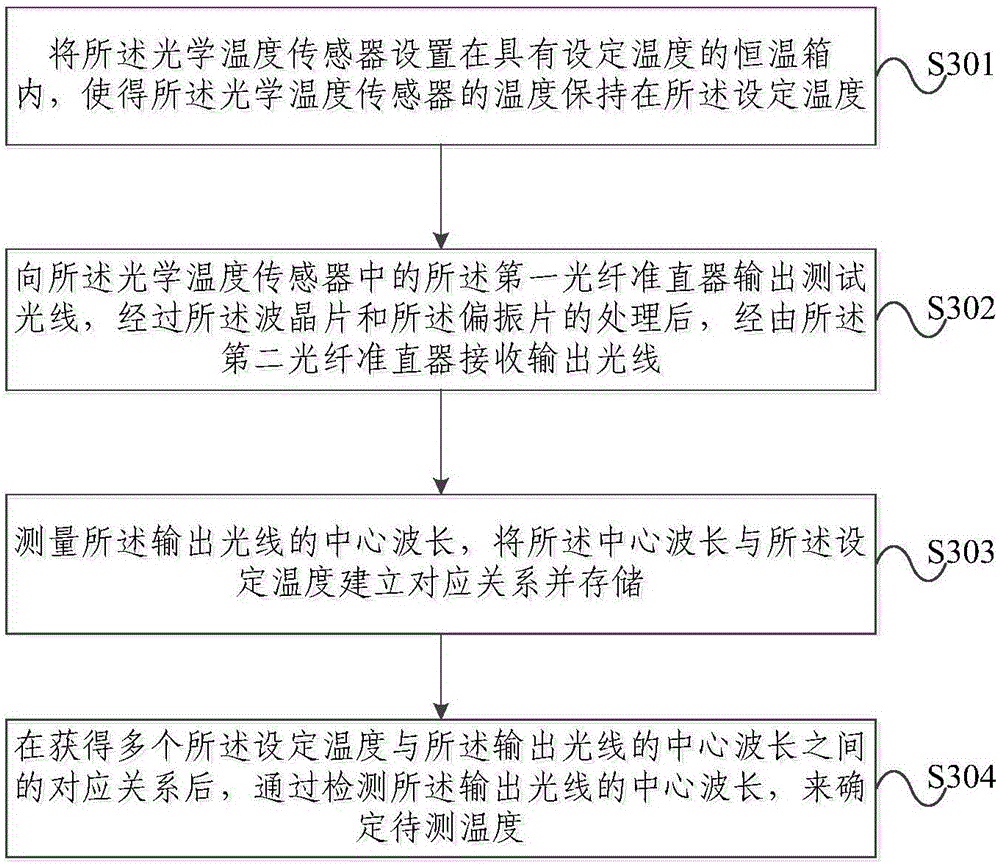

Optical temperature sensor and temperature measurement method

InactiveCN106500866AImprove stabilityThermometers using physical/chemical changesPolarizerLength wave

Owner:STATE GRID CORP OF CHINA +2

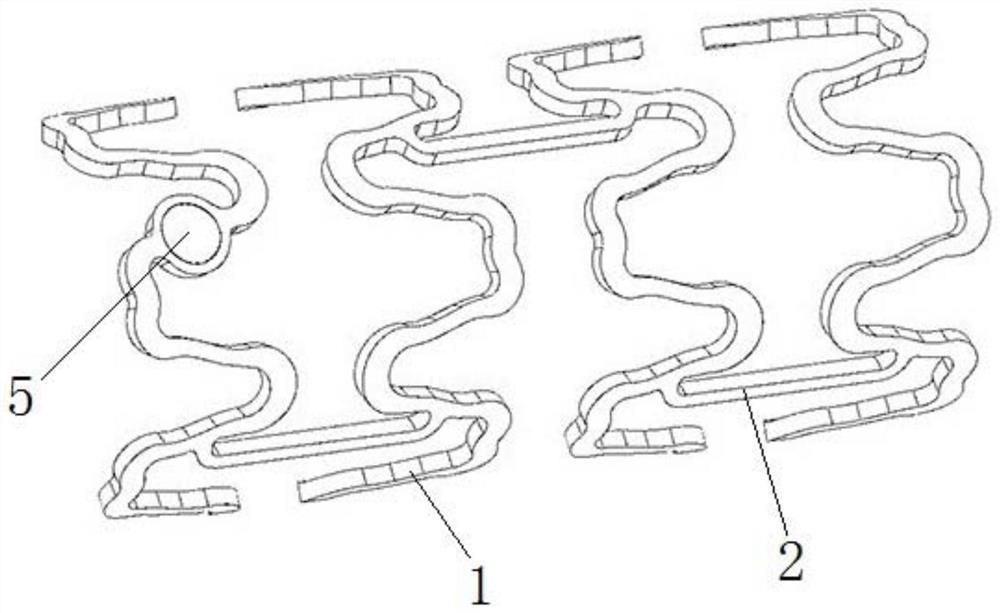

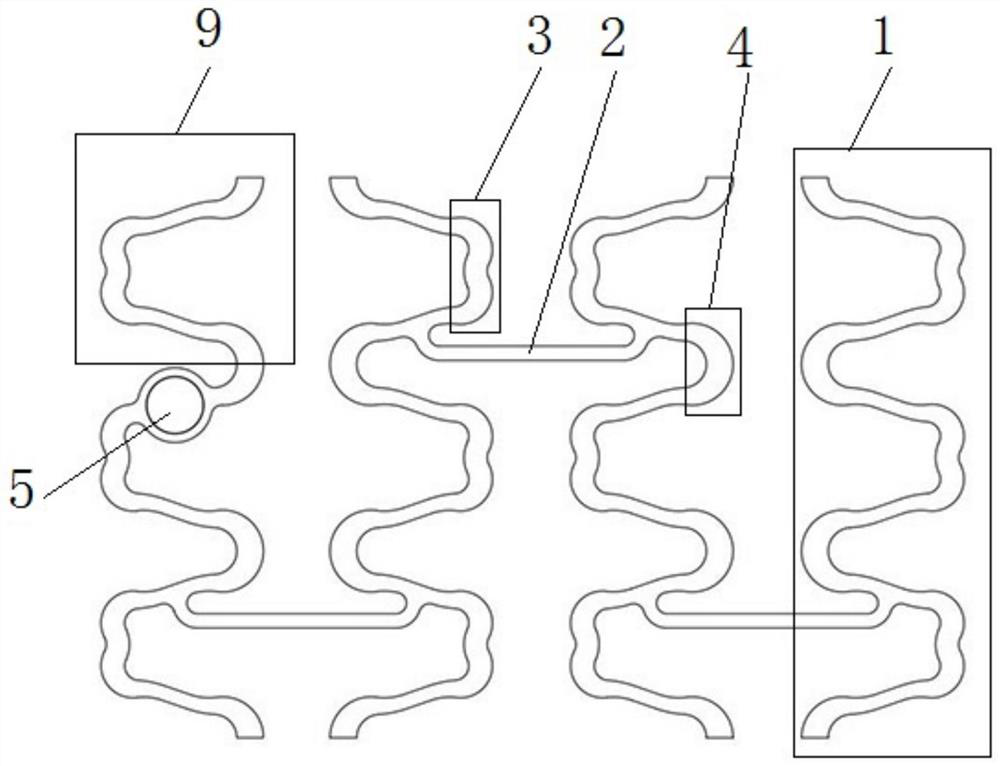

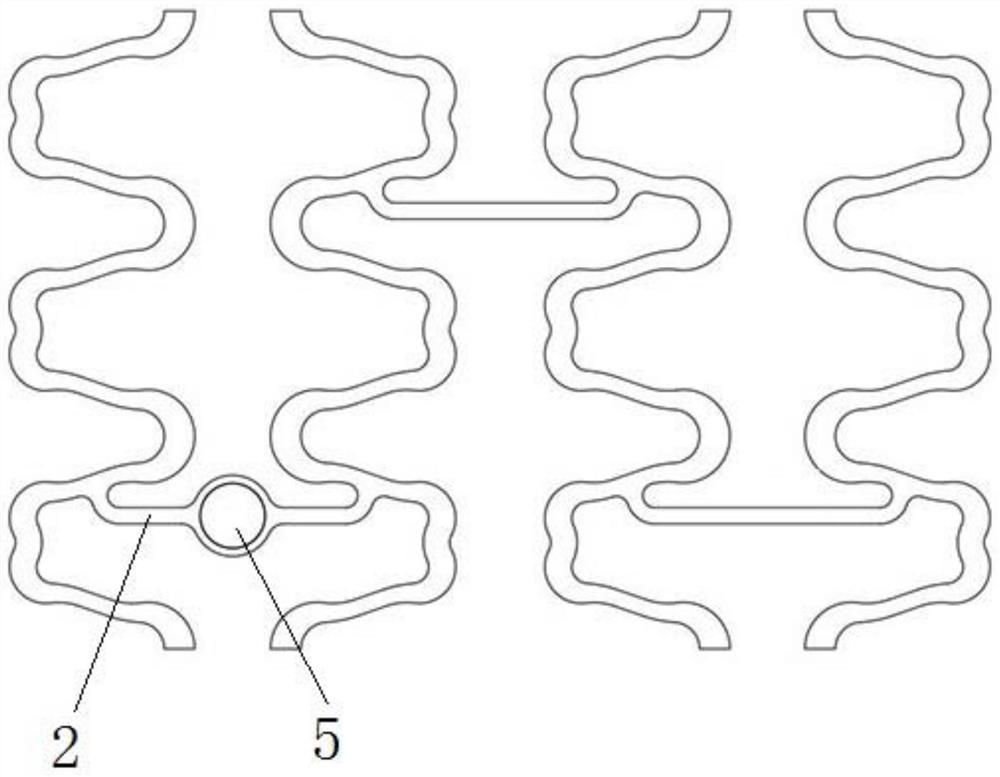

Degradable magnesium alloy stent

Owner:SHANGHAI KINDLY MEDICAL INSTR CO LTD +1

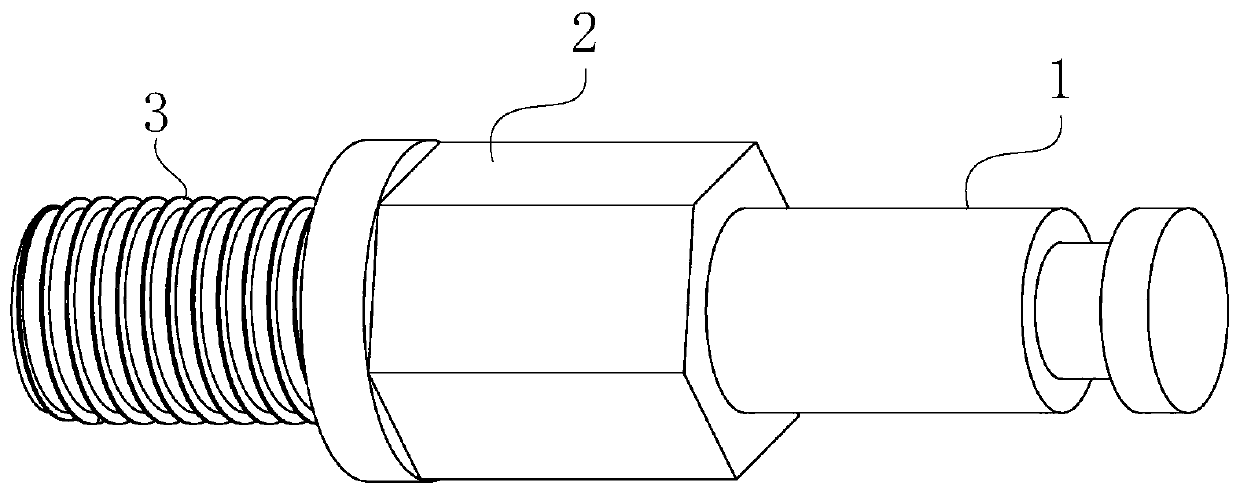

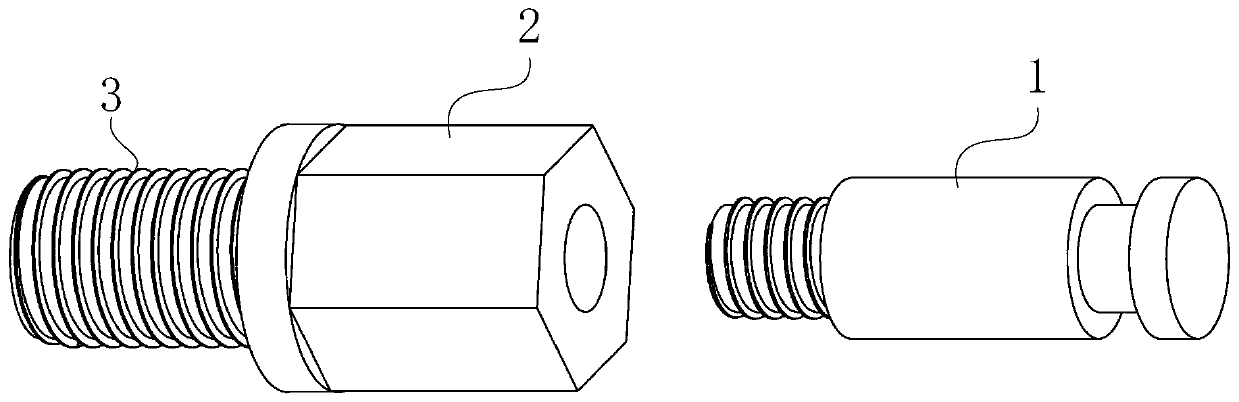

High-pressure micro-frog nozzle assembly special disassembling and assembling tool

Owner:CHINA TOBACCO HENAN IND

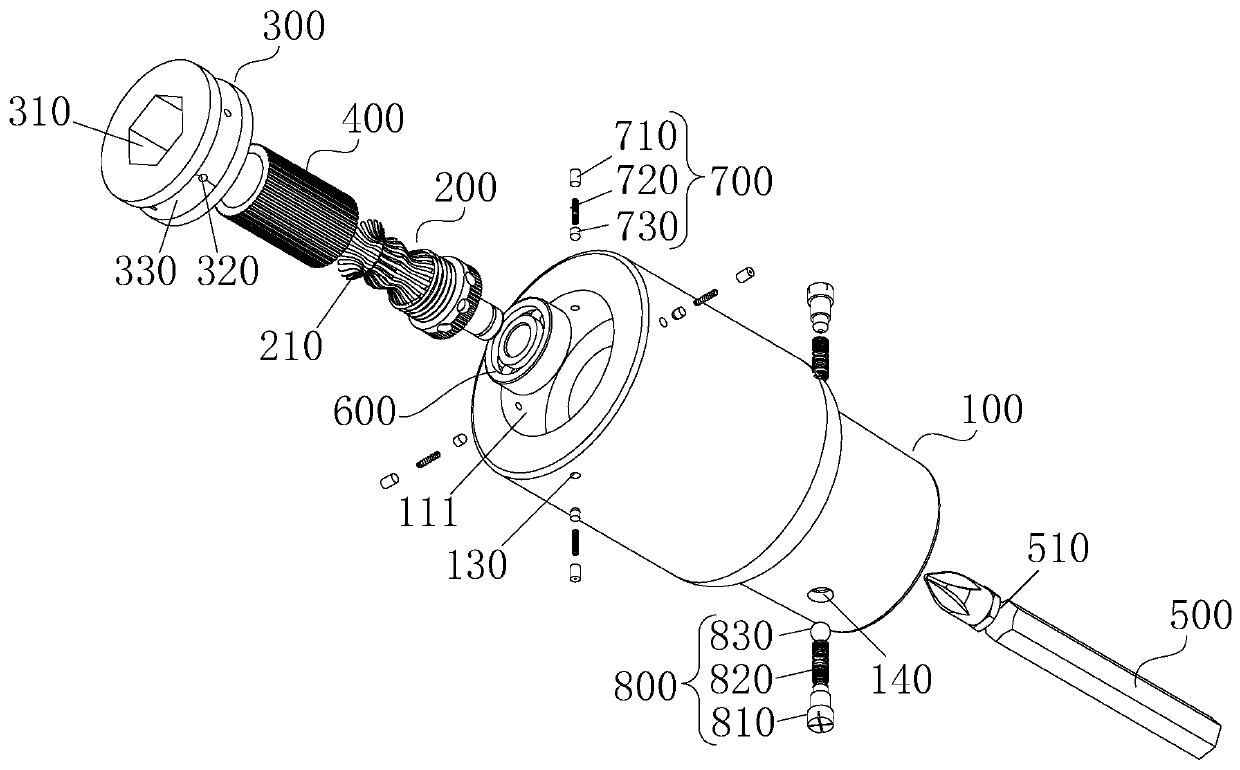

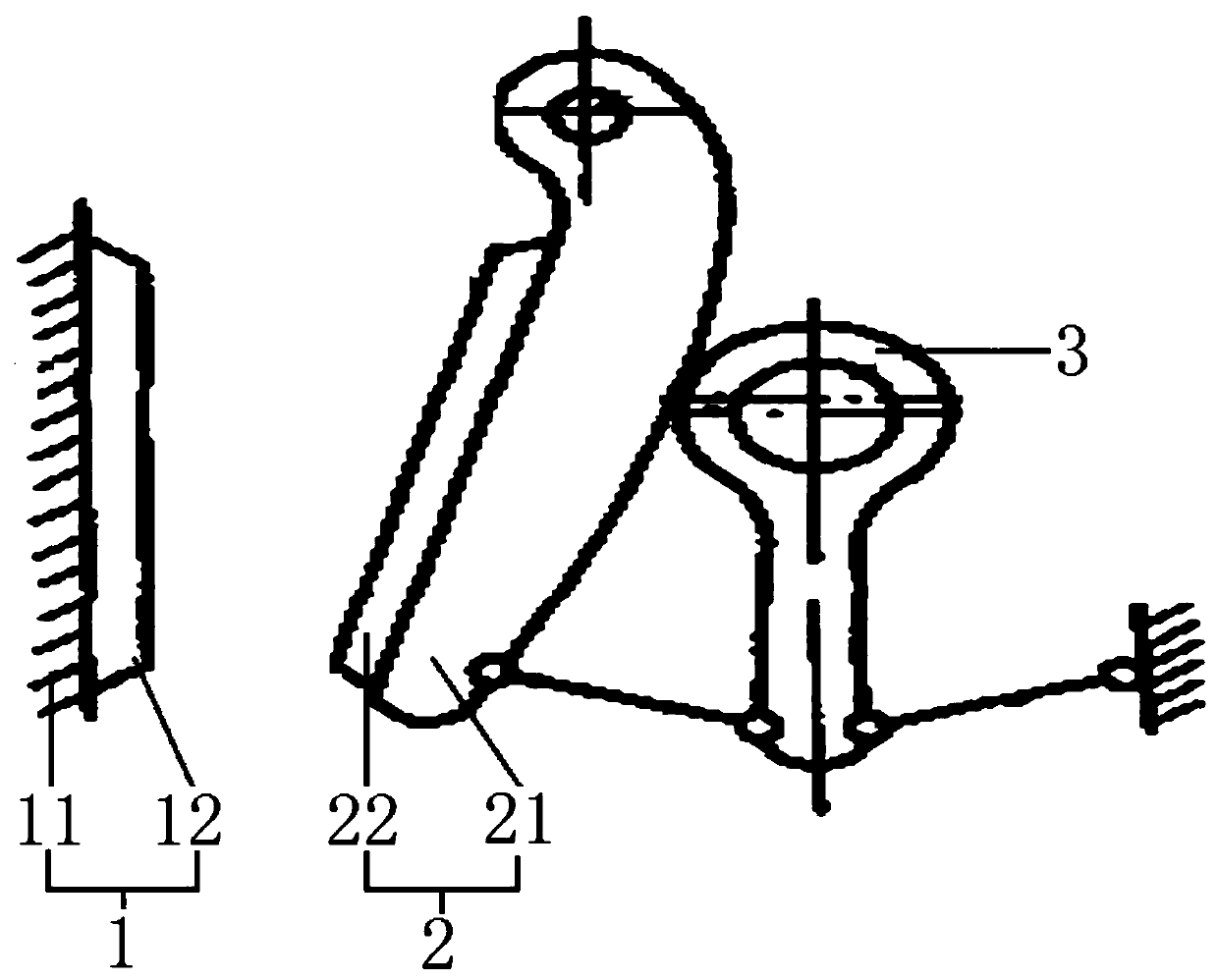

Circuit board wave crest soldering carrier cleaning device

ActiveCN108526113AAvoid breakingSmooth rotationGas treatmentDispersed particle filtrationEngineeringSoldering

The invention discloses a circuit board wave crest soldering carrier cleaning device. The cleaning device comprises a case; a lead rail is mounted on a side of the case; a bracket is slidably connected with the lead rail; a lower end of the bracket is located in a groove in the middle of the case; support plates are mounted on the bottom of the bracket; support rods are connected with the side edge of the case; a displacement device is arranged in the middle of the support rods; a motor is mounted in the middle of the displacement device; the lower end of the displacement device is connected with a roll shaft which is connected with the motor through a belt in a transmission manner; and the roll shaft is evenly covered with fur brushes corresponding to the support plates. According to theinvention, the roll shaft equipped with the fur brushes is driven to rotate by the motor through the belt, so that the manual brushing is replaced; the cleaning device is high in cleaning efficiency,uniform in cleaning force, not easy to destroy a carrier, no need to manually move the carrier, and can adapt to the cleaning work of carriers of different thickness; a filter is used to absorb the odor of a cleaning liquid, thereby reducing the pollution to the outside air, and lowering the impact on the staff body.

Owner:ZHONG SHAN SHI BAO YUE JIA DIAN ZI YOU XIAN GONG SI

Method for improving ore crushing efficiency of jaw crusher

Owner:TAIYUAN IRON & STEEL GROUP

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap