Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6 results about "Fine chemical" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fine chemicals are complex, single, pure chemical substances, produced in limited quantities in multipurpose plants by multistep batch chemical or biotechnological processes. They are described by exacting specifications, used for further processing within the chemical industry and sold for more than $10/kg (see the comparison of fine chemicals, commodities and specialties). The class of fine chemicals is subdivided either on the basis of the added value (building blocks, advanced intermediates or active ingredients), or the type of business transaction, namely standard or exclusive products.

Synthesis method of 2-(2-chloroethoxy) acetic acid

InactiveCN101844978AZero costSimple and fast operationOrganic compound preparationCarboxylic compound preparationAcetic acidOrganic solvent

The invention relates to a synthesis method of 2-(2-chloroethoxy) acetic acid, which belongs to the technical field of the preparation and the application of fine chemical engineering products. The invention particularly belongs to the synthesis method of 2-(2-chloroethoxy) acetic acid. The invention uses 2-chloroethoxy ethanol as starting materials, uses water as solvents, and uses nitric acid for direct oxidization to obtain products. The reaction process is shown as the accompanying drawing. The invention adopts water as the solvents, and uses the nitric acid as oxidizing agents for efficiently oxidizing the 2-chloroethoxy ethanol into corresponding acids. The method has the advantages of simple operation, low price of raw materials, easy acquisition of raw materials, simple requirement on equipment, simple after treatment and the like. In addition, the use of the organic solvent has nearly zero cost, and the invention conforms to the environmental protection industrial production requirements, so the invention has wide application prospects.

Owner:NANKAI UNIV

Down feather detergent composition

InactiveCN107723129AImprove decontamination abilityExtended service lifeInorganic/elemental detergent compounding agentsCationic surface-active compoundsTriglycerideGlycol stearate

Owner:安徽玉龙羽绒服饰集团有限公司

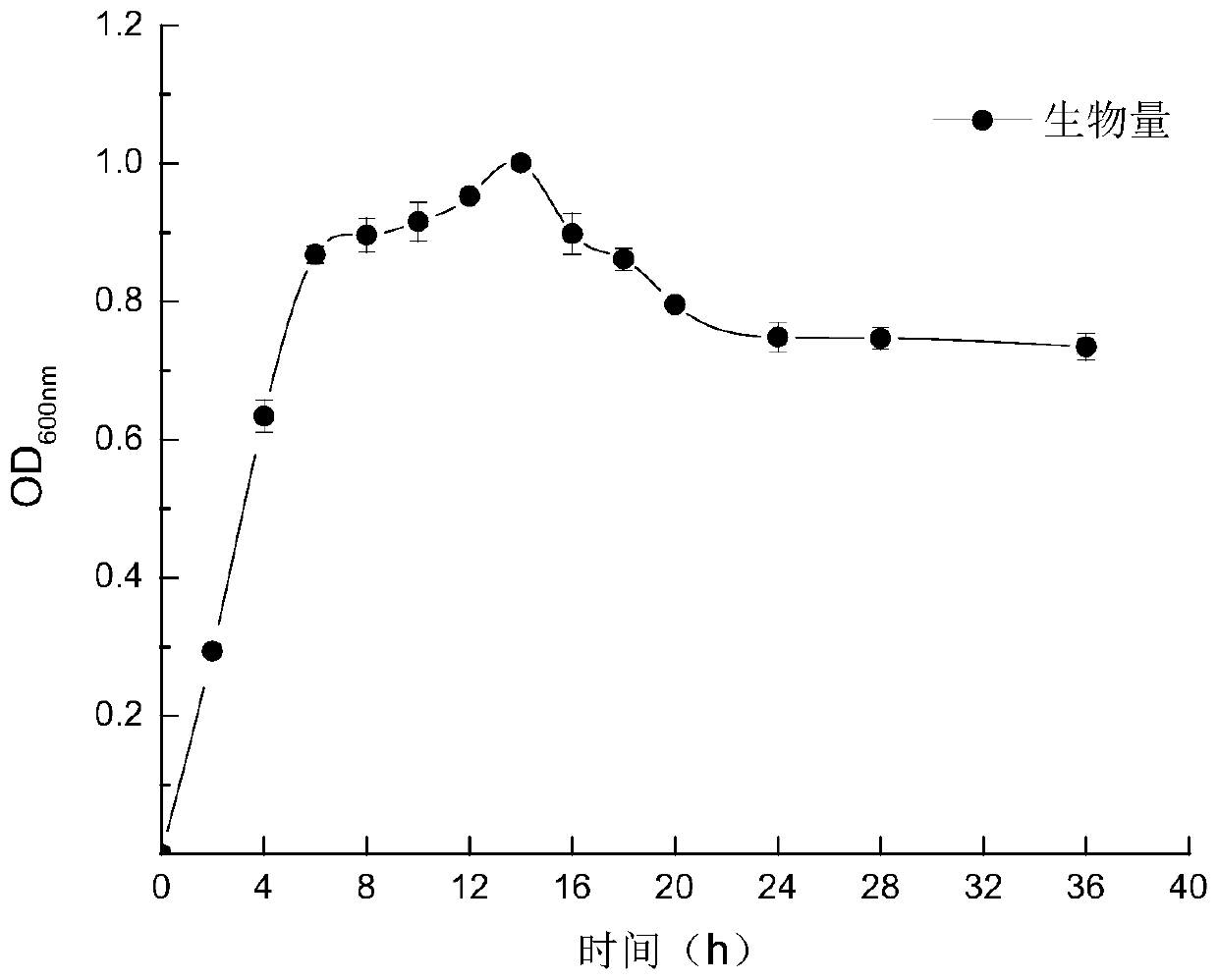

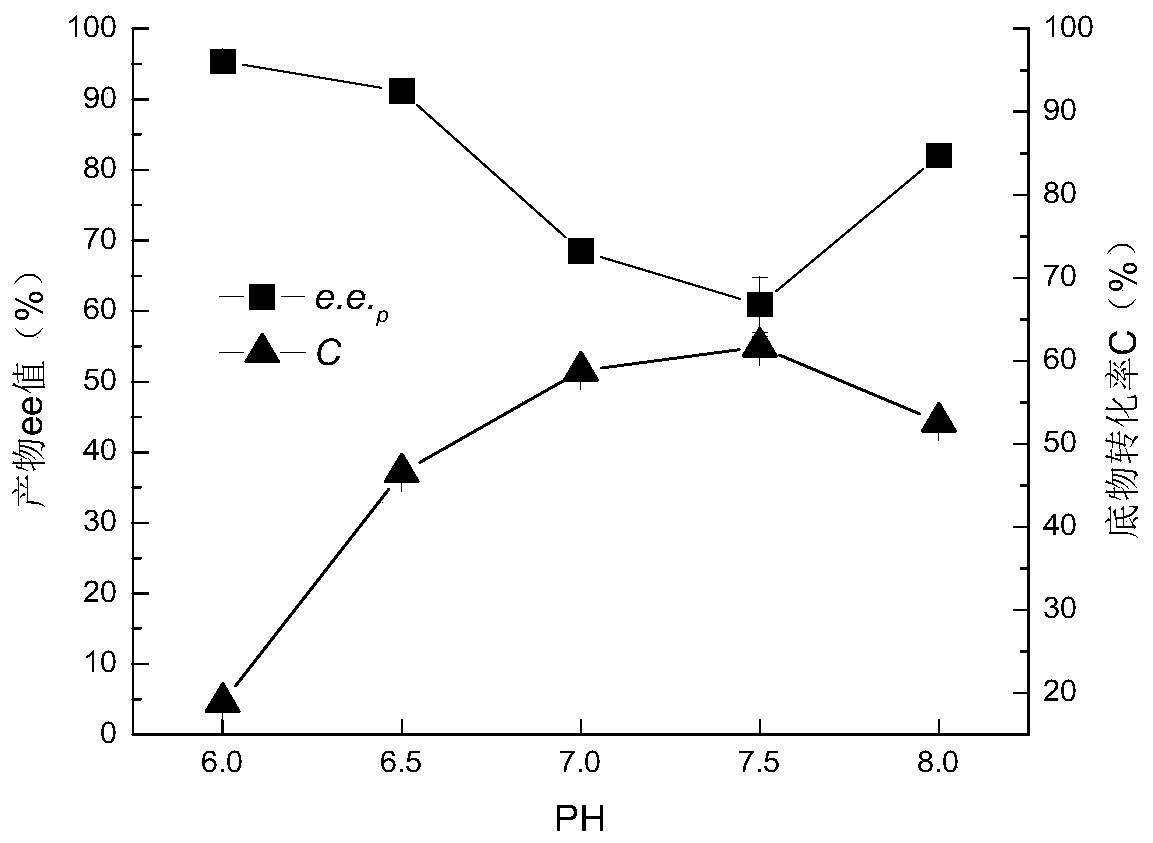

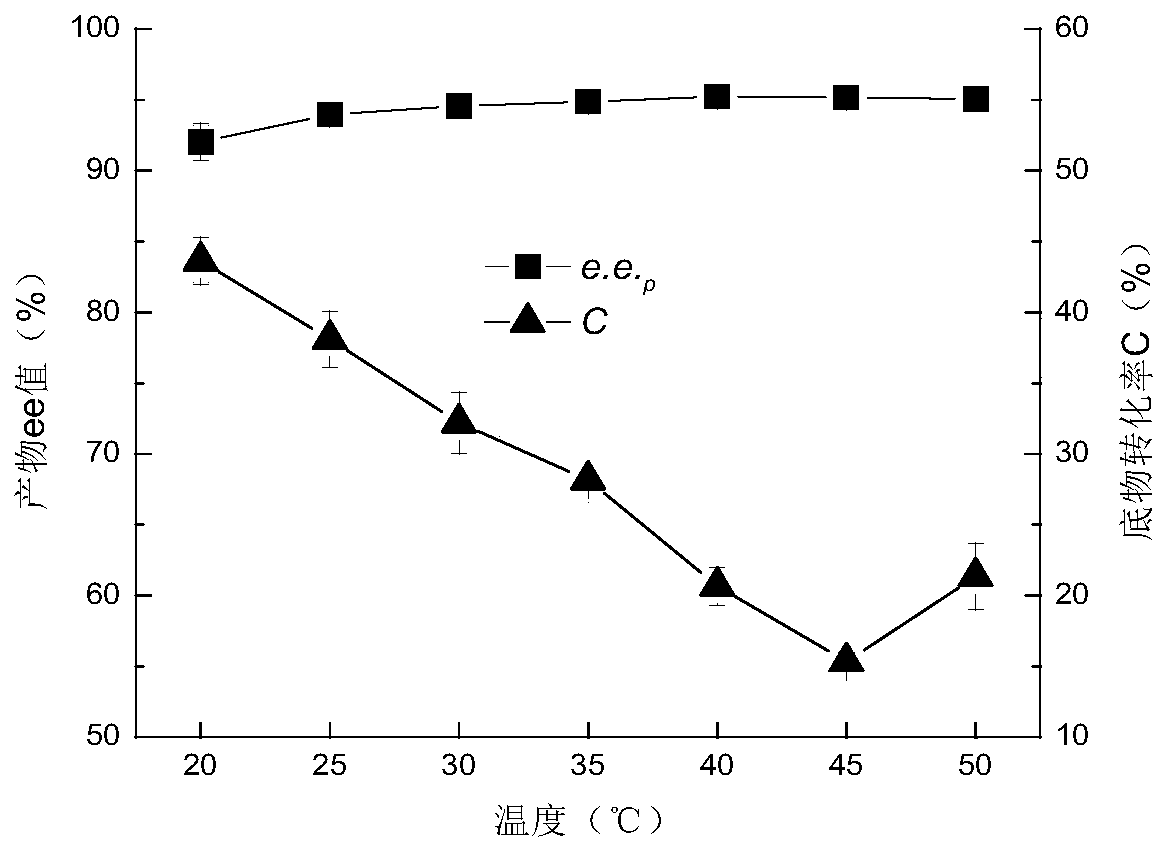

Application of whole cells of Bacillus DL-2 in catalyzing asymmetric hydrolysis in (+/-)-styralyl acetate

InactiveCN109797185AHigh catalytic efficiencySimple production processMicroorganism based processesFermentationAcetic acidHydrolysis

Owner:SOUTH CHINA SEA INST OF OCEANOLOGY - CHINESE ACAD OF SCI

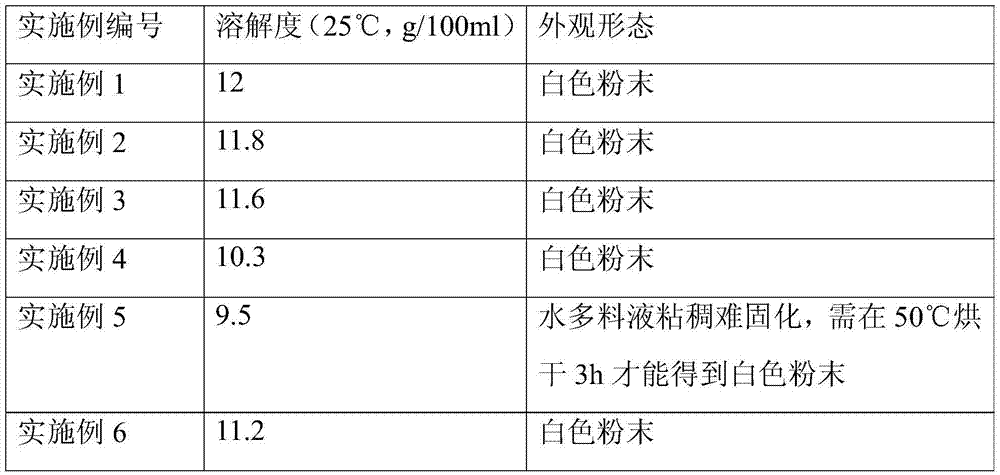

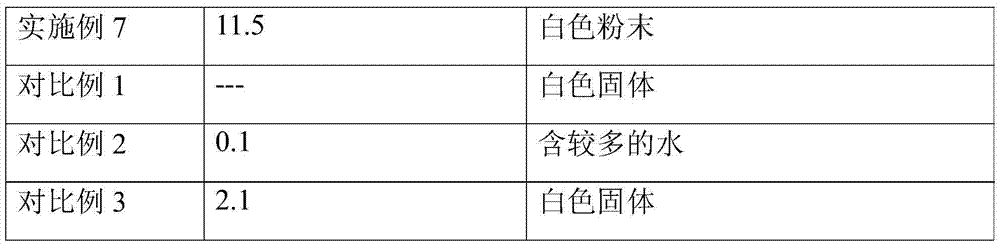

Calcium salt of citric acid, and preparation method thereof, and preparation containing calcium salt of citric acid

InactiveCN106854153AHigh puritySuitable for mass production applicationsOrganic compound preparationCarboxylic acid salt preparationSolubilityFiltration

Owner:COFCO BIOTECHNOLOGY CO LTD

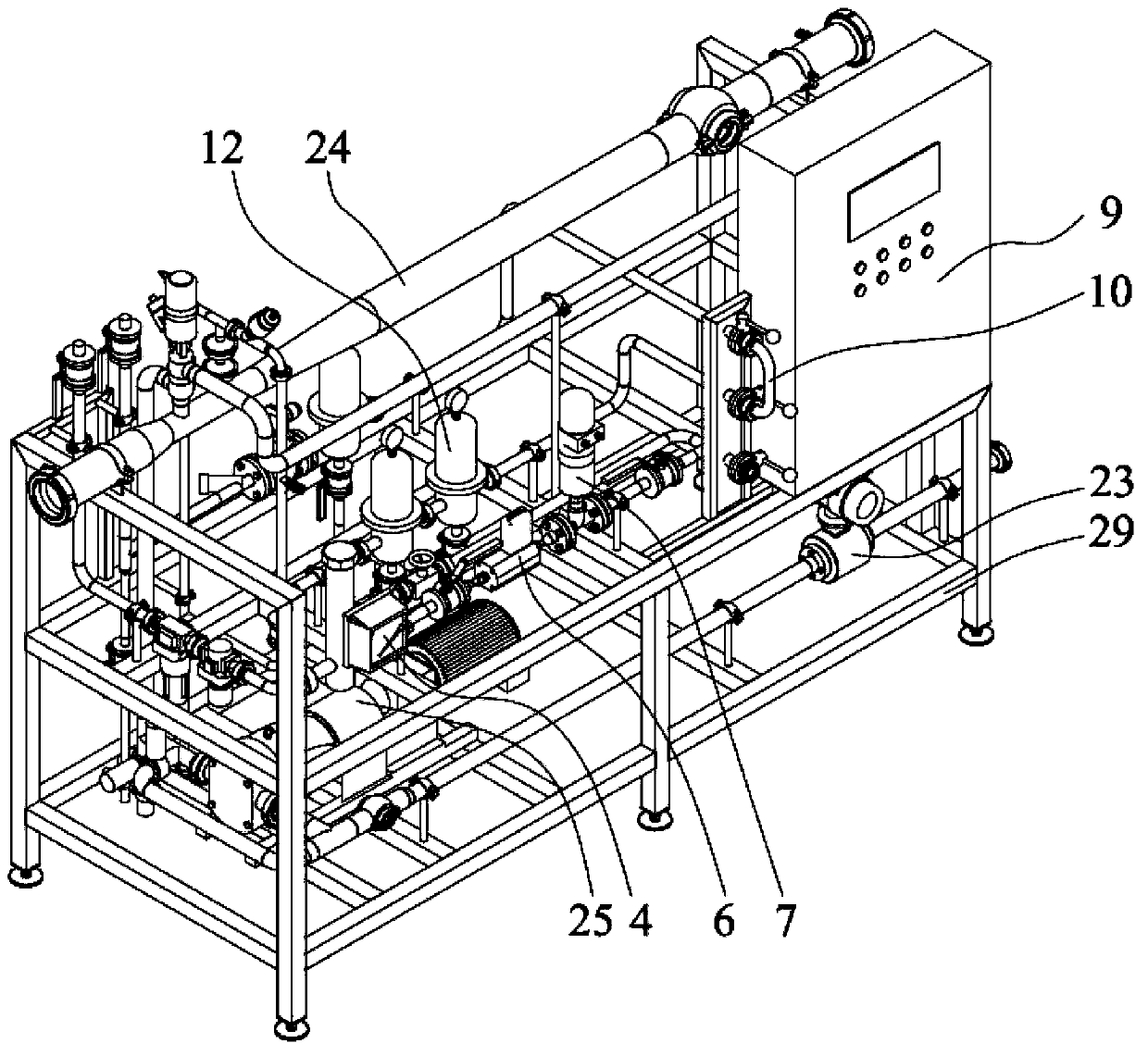

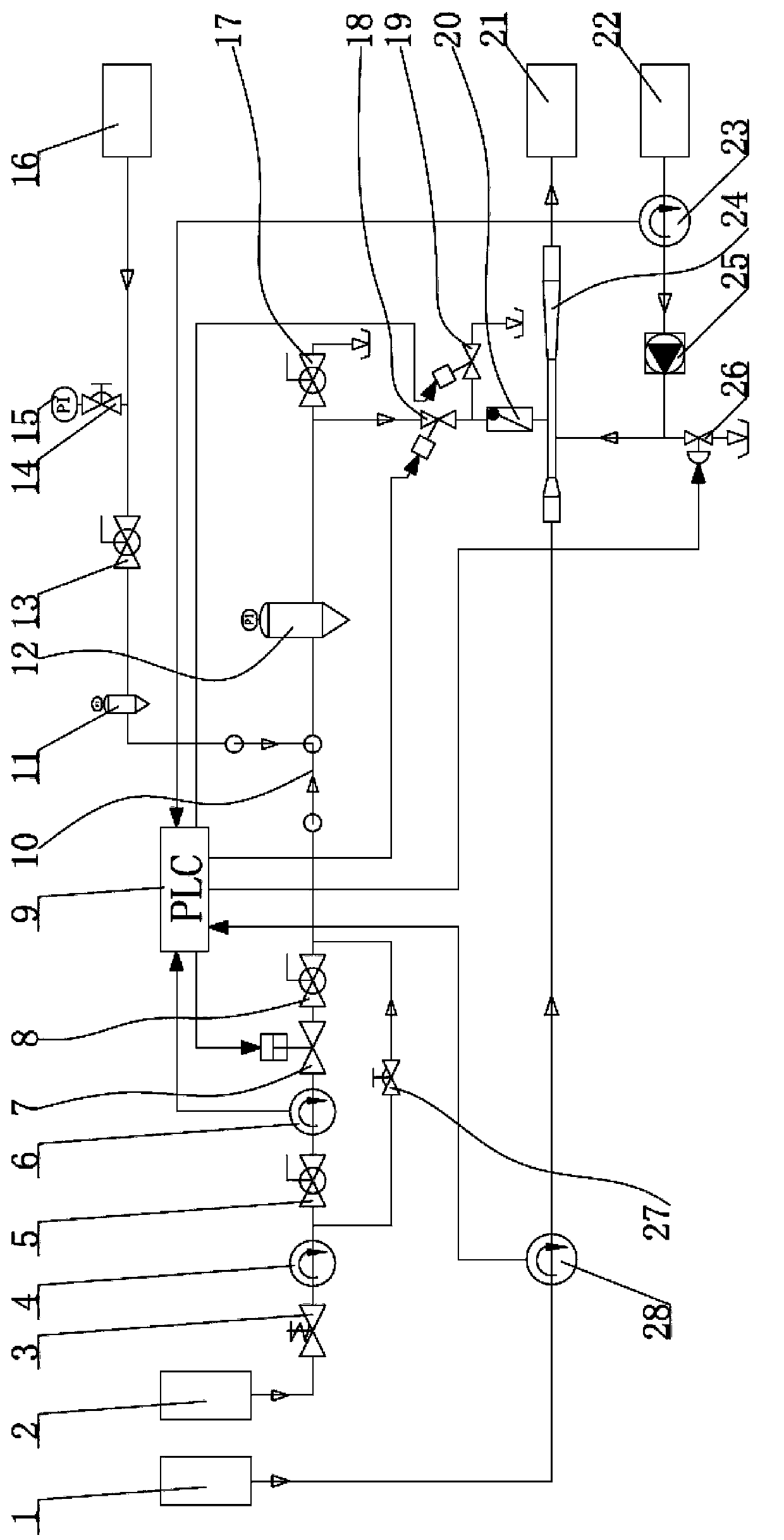

Full-automatic wort oxygenated yeast adding machine and wort oxygenated yeast adding method

InactiveCN102816662BAvoiding problems with feedback regulation hysteresisMethod is feasibleWort preparationHuman error probabilityLoop control

Owner:ANHUI HUAYI BIOLOGICAL EQUIP TECH

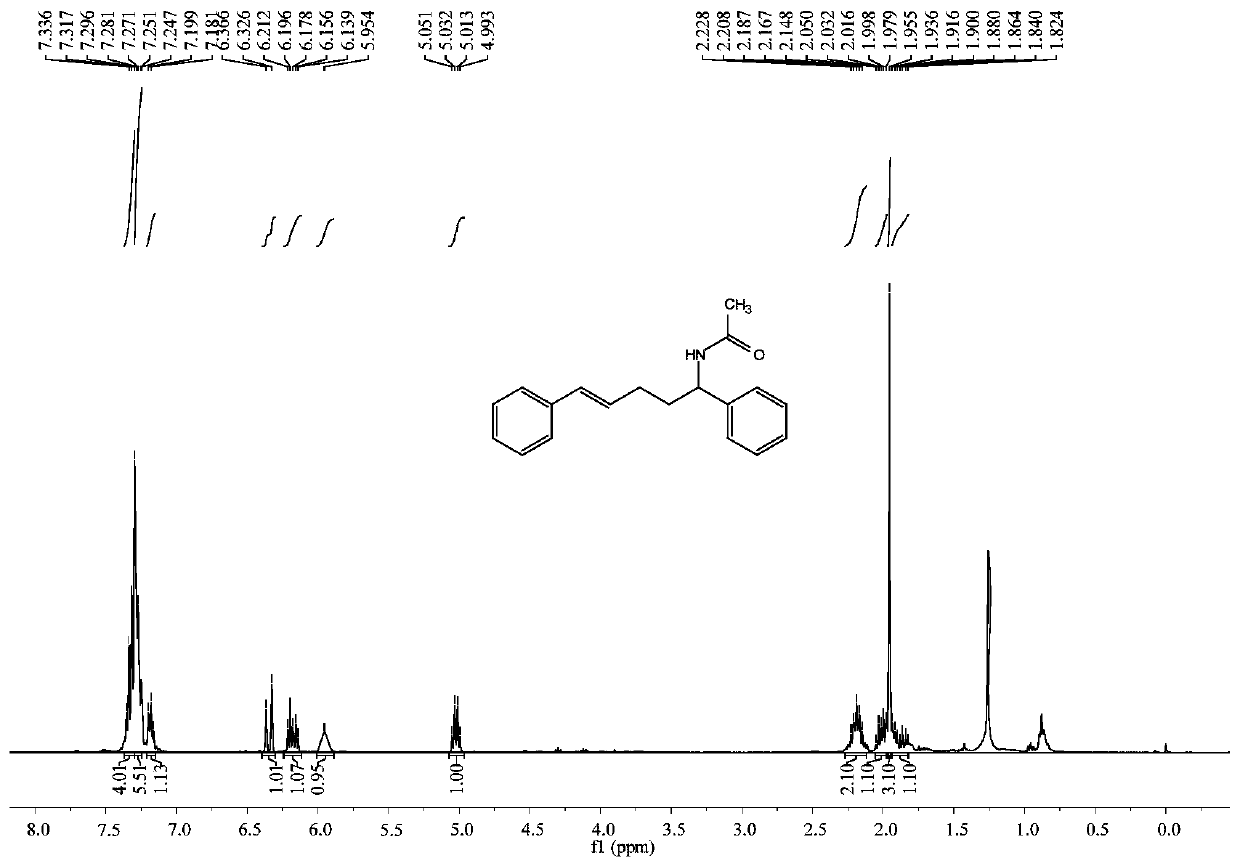

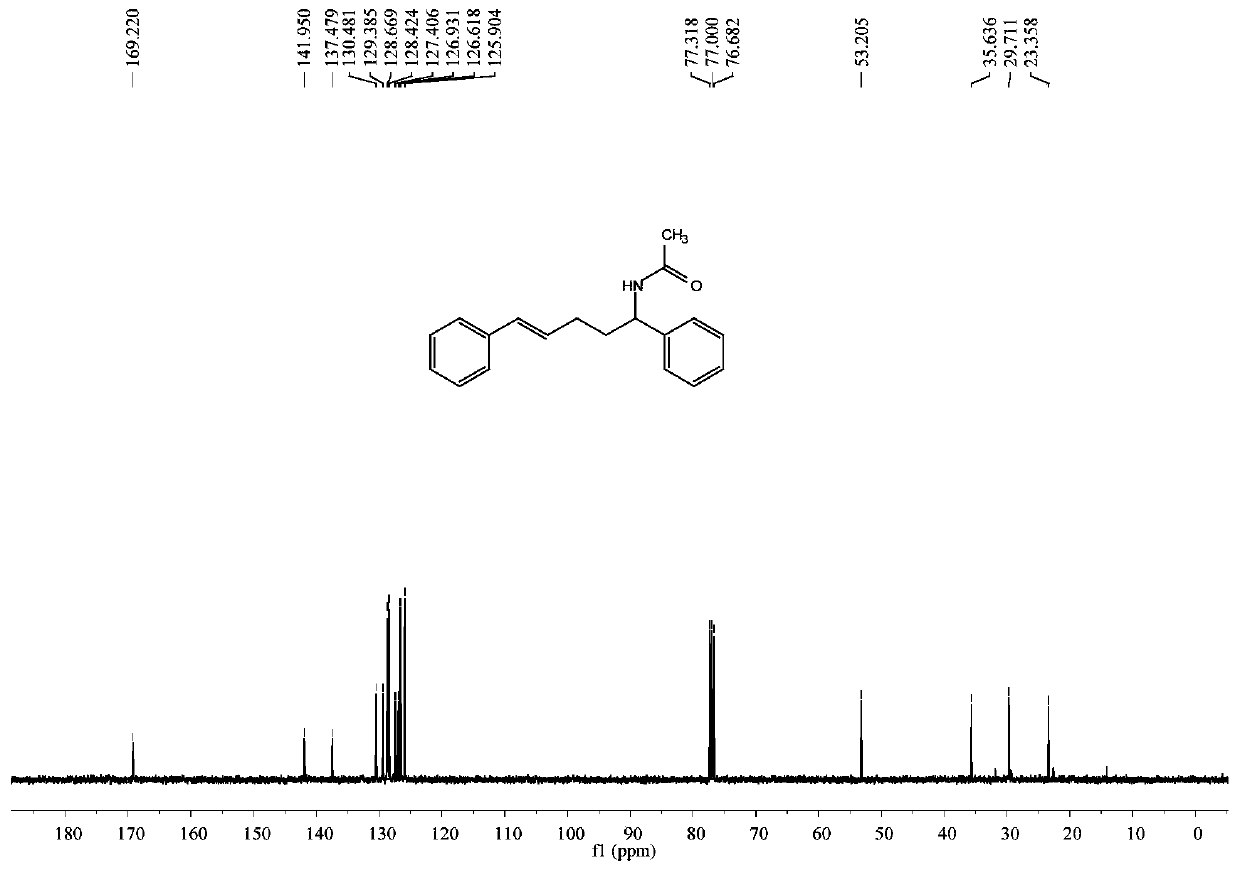

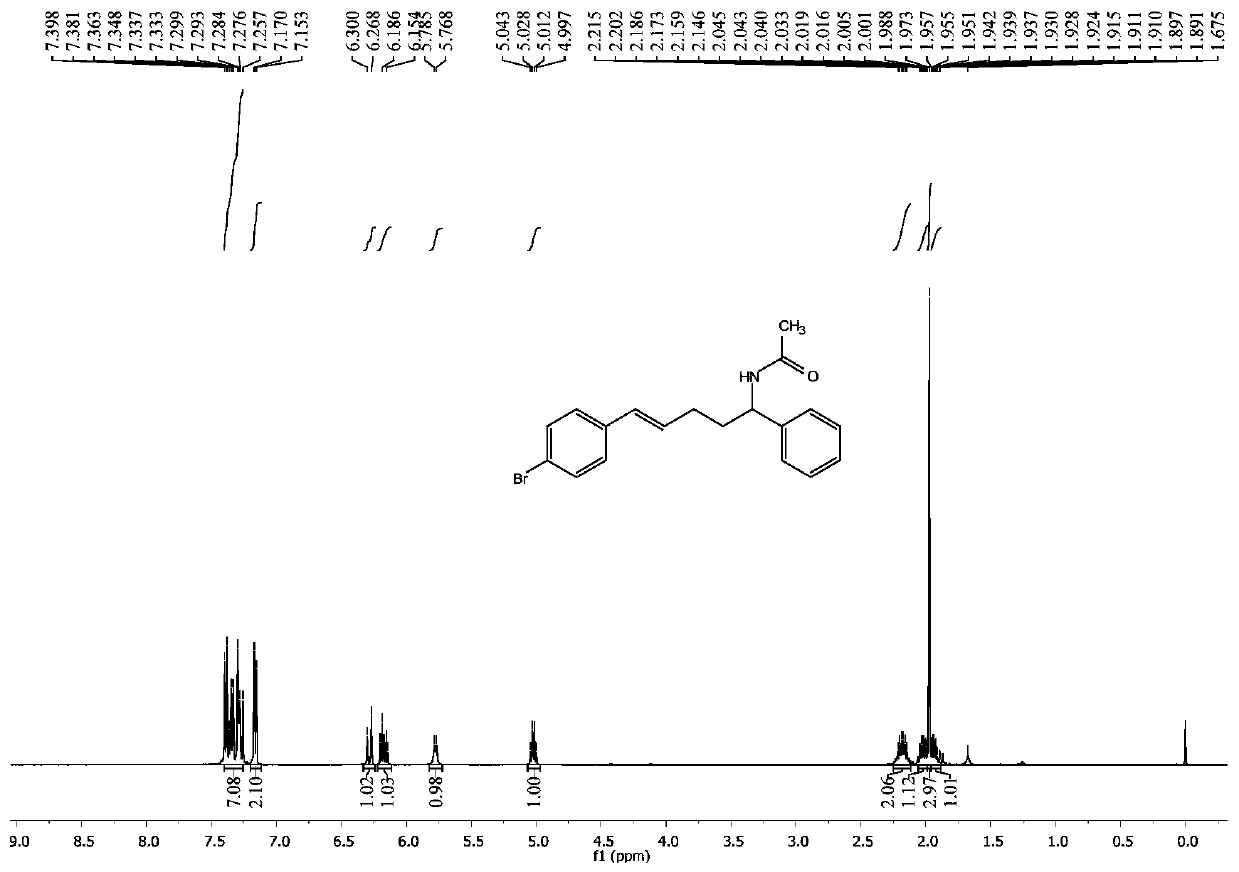

Method for preparing N-1, 5-diaryl-4-pentene-1-acetamide compound

ActiveCN109734620ANo generationSimple and fast operationOrganic compound preparationCarboxylic acid amides preparationArylNatural product

Owner:DALIAN UNIV OF TECH

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap