Calcium salt of citric acid, and preparation method thereof, and preparation containing calcium salt of citric acid

A technology of citric acid and calcium salt, which is applied in the field of calcium salt of citric acid and its preparation, can solve the problems of filtration and concentrated crystallization, and achieve the effects of increased solubility, high purity, and expanded application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0012] In the first aspect, the present invention provides a method for preparing a calcium salt of citric acid, the method comprising: in a molar ratio, the basic calcium-containing compound, citric acid and water are adjusted to a ratio of 1:2-2.2:4.5-11.5 Mix in proportions, then stir and let stand.

[0013] In the method of the present invention, the basic calcium-containing compound is not particularly limited, and it can be various basic calcium-containing compounds commonly used in the art that can react with citric acid to form a calcium salt of citric acid. Preferably, the basic calcium-containing compound is one or more of calcium carbonate, calcium oxide and calcium hydroxide.

[0014] In the method of the present invention, citric acid is not particularly limited, and can be various citric acids commonly used in the art. For example, the citric acid may be citric acid monohydrate and / or anhydrous citric acid.

[0015] In the method of the present invention, preferably, t

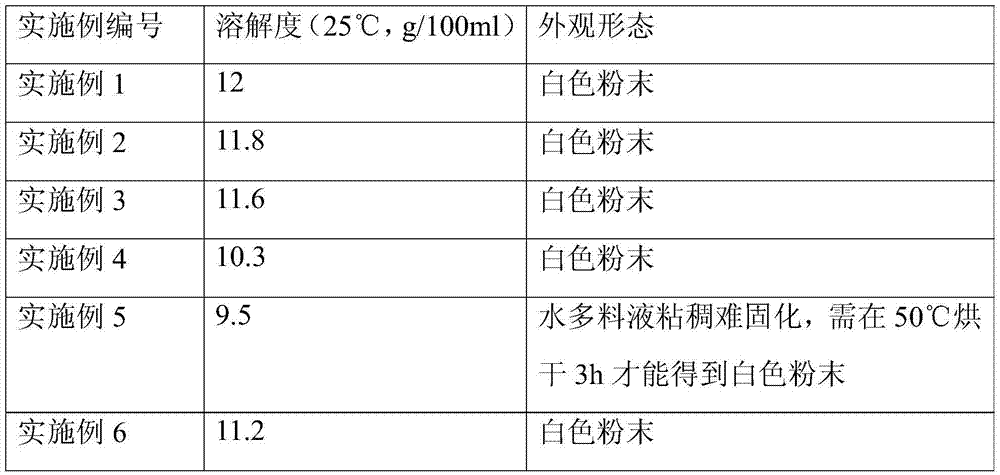

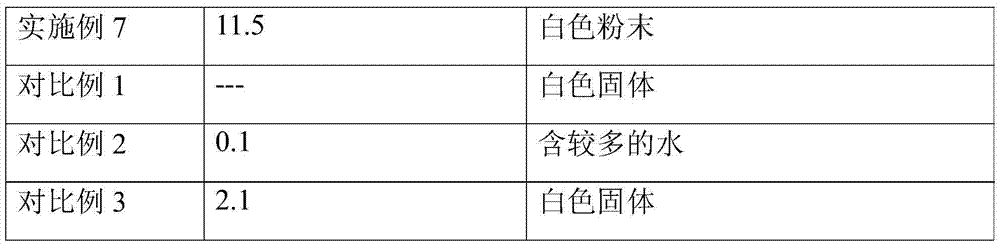

Embodiment 1

[0034] This example is used to illustrate the calcium salt of citric acid and the preparation method of the present invention.

[0035] After mixing 20.2 g of anhydrous citric acid and 5.0 g of calcium carbonate at 25° C., 7.2 g of water was added, and then stirred at a stirring speed of 90 rpm for 40 minutes, and then left to stand for 2 hours. The appearance of the obtained product is shown in Table 1.

Embodiment 2

[0037] This example is used to illustrate the calcium salt of citric acid and the preparation method of the present invention.

[0038] After mixing 22.6 g of citric acid monohydrate and 2.8 g of calcium oxide at 25° C., 7.1 g of water was added, and then stirred at a stirring speed of 100 rpm for 30 minutes, and then allowed to stand for 4 hours. The appearance of the obtained product is shown in Table 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap