Application of whole cells of Bacillus DL-2 in catalyzing asymmetric hydrolysis in (+/-)-styralyl acetate

A technology based on styroyl acetate and bacillus, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of harsh reaction conditions, large pollution, expensive reagents, etc., and achieve simple production process and high catalytic efficiency , the effect of great development potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Example 1: Identification of Bacillus species

[0034] The screened and purified Bacillus sp.DL-2 strain used its conservative 16S rRNA gene sequence to identify its strains. Using 16S rRNA universal primer 27F: 5'-AGAGTTTATCCTGGCTCAG-3'; and 1492R: 5'-GGTTACCTTGTTACGACTT-3', PCR amplification was carried out using Bacillus sp.DL-2 bacterial solution as a DNA template. Establish the reaction system shown in Table 1:

[0035] Table 1 PCR reaction system

[0036]

[0037] PCR amplification conditions: pre-denaturation at 94°C for 10min, then denaturation at 94°C for 30s, annealing at 56°C for 30s, extension at 72°C for 2min30s, cycle 30 times; finally extension at 72°C for 10min, and cooling to 18°C. The amplified products were subjected to 1% agarose gel electrophoresis for detection, and then sent to Mega Biotech Co., Ltd. for two-way sequencing. After the 16S rRNA gene sequence of the bacteria was spliced (the nucleotide sequence is shown in SEQ ID NO. 1), the strain was id

Embodiment 2

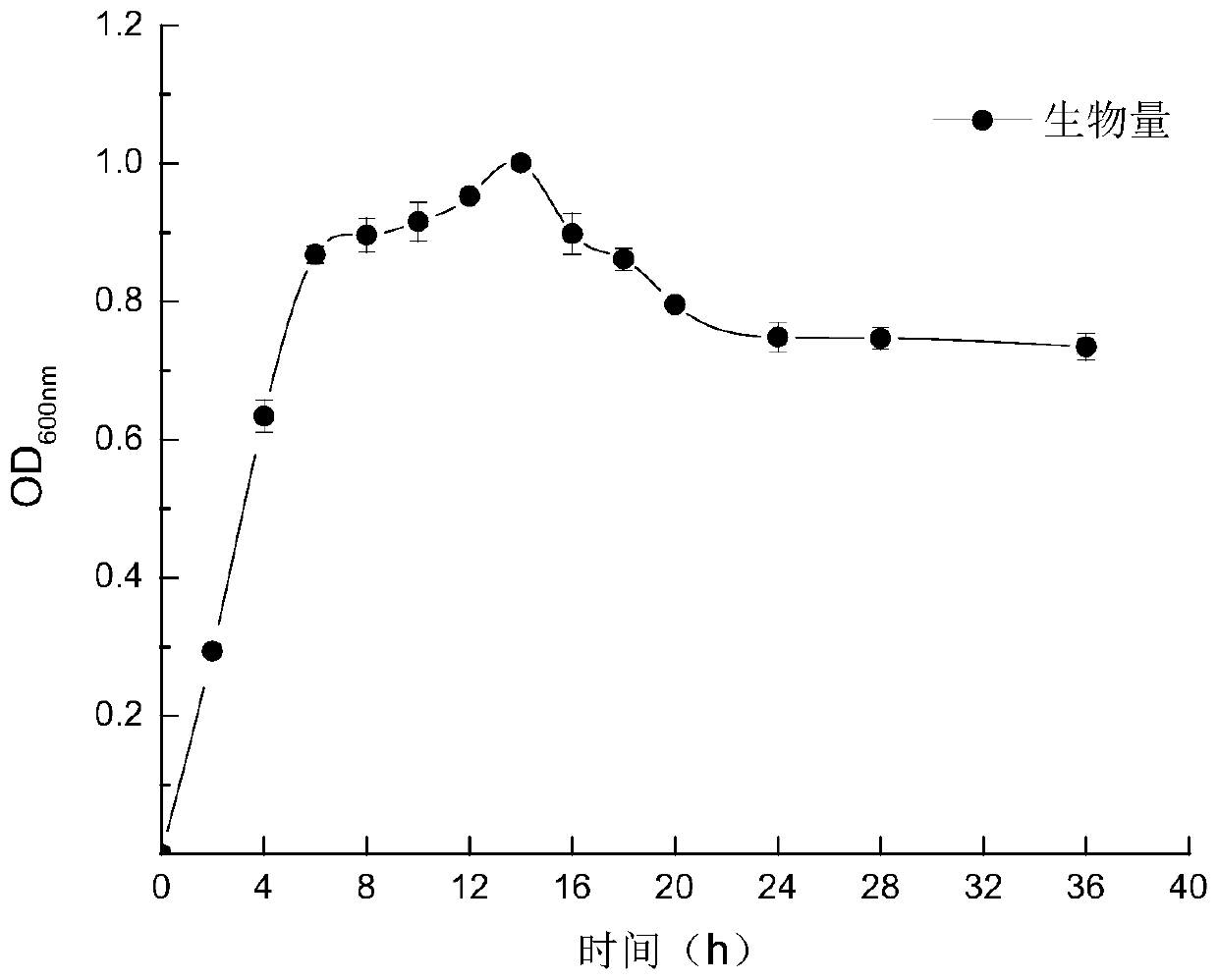

[0038] Example 2: Growth curve of Bacillus sp.DL-2

[0039] Streak the stored Bacillus sp.DL-2 on LB solid medium (1% tryptone, 0.5% yeast powder, 1% NaCl, 1.5% agar powder), culture at 37°C for 16 hours, and then pick a single colony Inoculate 100mL of LB liquid medium (1% tryptone, 0.5% yeast powder, 1% NaCl), 200r / min, 37°C for 12h to obtain seed liquid, inoculate 1% of the inoculum into LB liquid medium Cultivate in medium, 200r / min, 37℃, measure the biomass OD-600nm every 2h, the results are as follows figure 1 Shown.

Embodiment 3

[0040] Example 3: Preparation of Bacillus sp.DL-2 whole cells

[0041] The seed solution of Bacillus sp.DL-2 was inoculated into a non-fat milk powder liquid medium at an inoculum of 1% for fermentation and culture, 200r / min, 37°C for 24h (the medium became clear), the fermentation broth was obtained, and the supernatant was centrifuged The cell pellet was washed three times with Tris / HCl buffer after sterilization at pH=7.2, and the cell pellet was collected by centrifugation to obtain Bacillus sp.DL-2 whole cells.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap