Method for recovering fluorescent material from faulty glass bodies of discharge lamps

a technology of glass bodies and discharge lamps, which is applied in the manufacture of electric discharge tubes/lamps, discharge tubes luminescnet screens, electrode systems, etc., can solve the problems of laborious process and achieve the effect of efficient good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

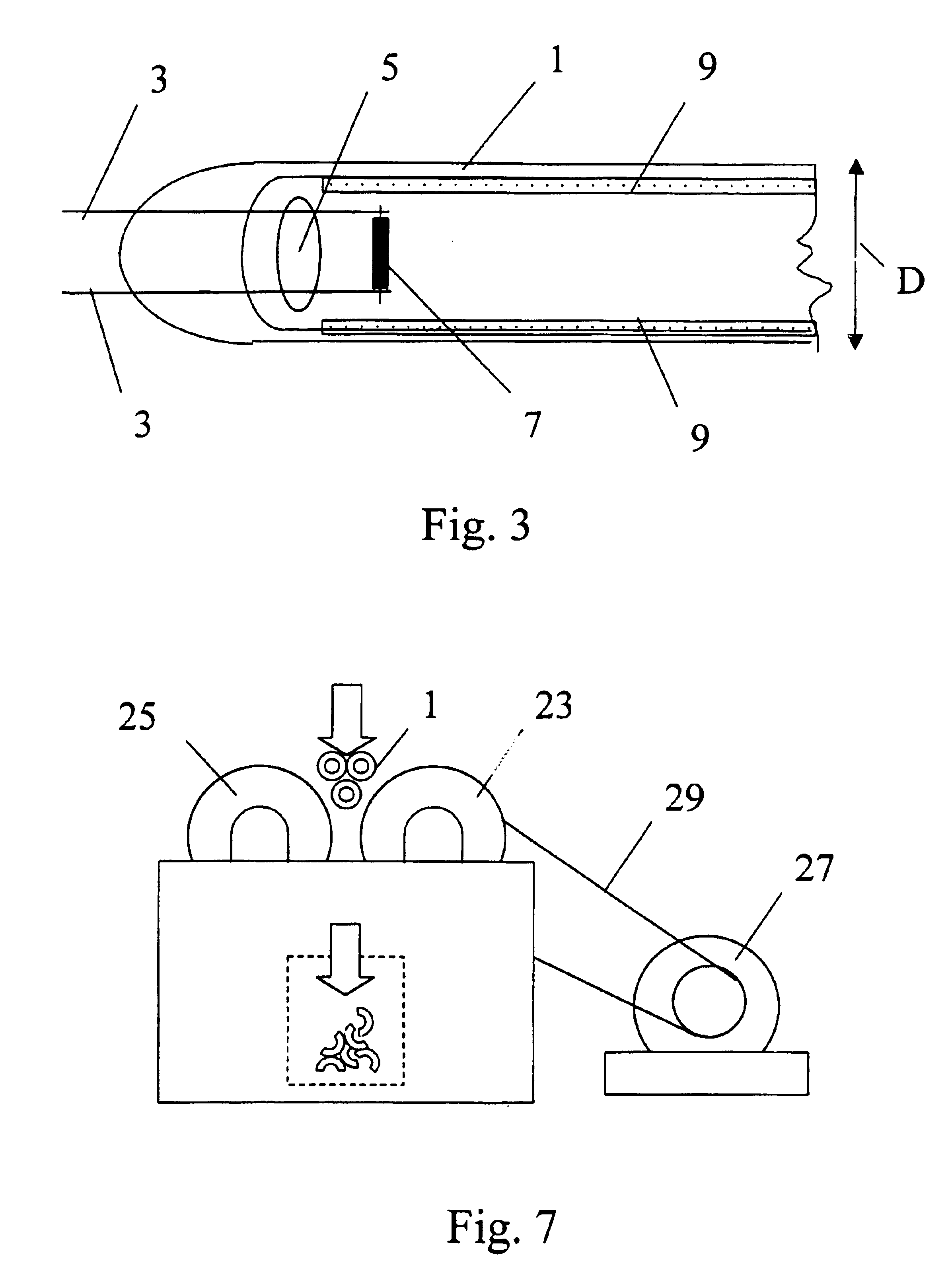

Image

Examples

Embodiment Construction

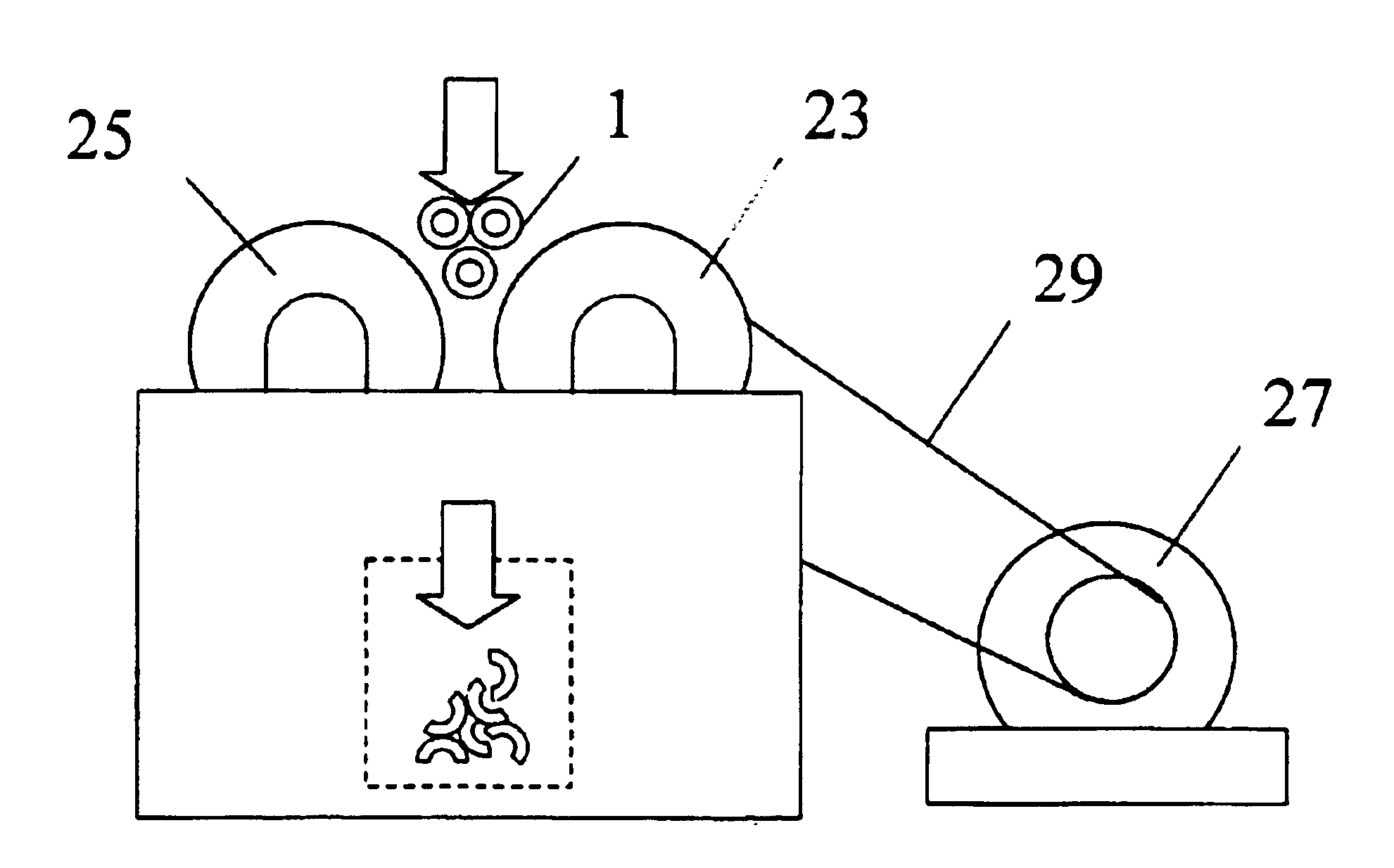

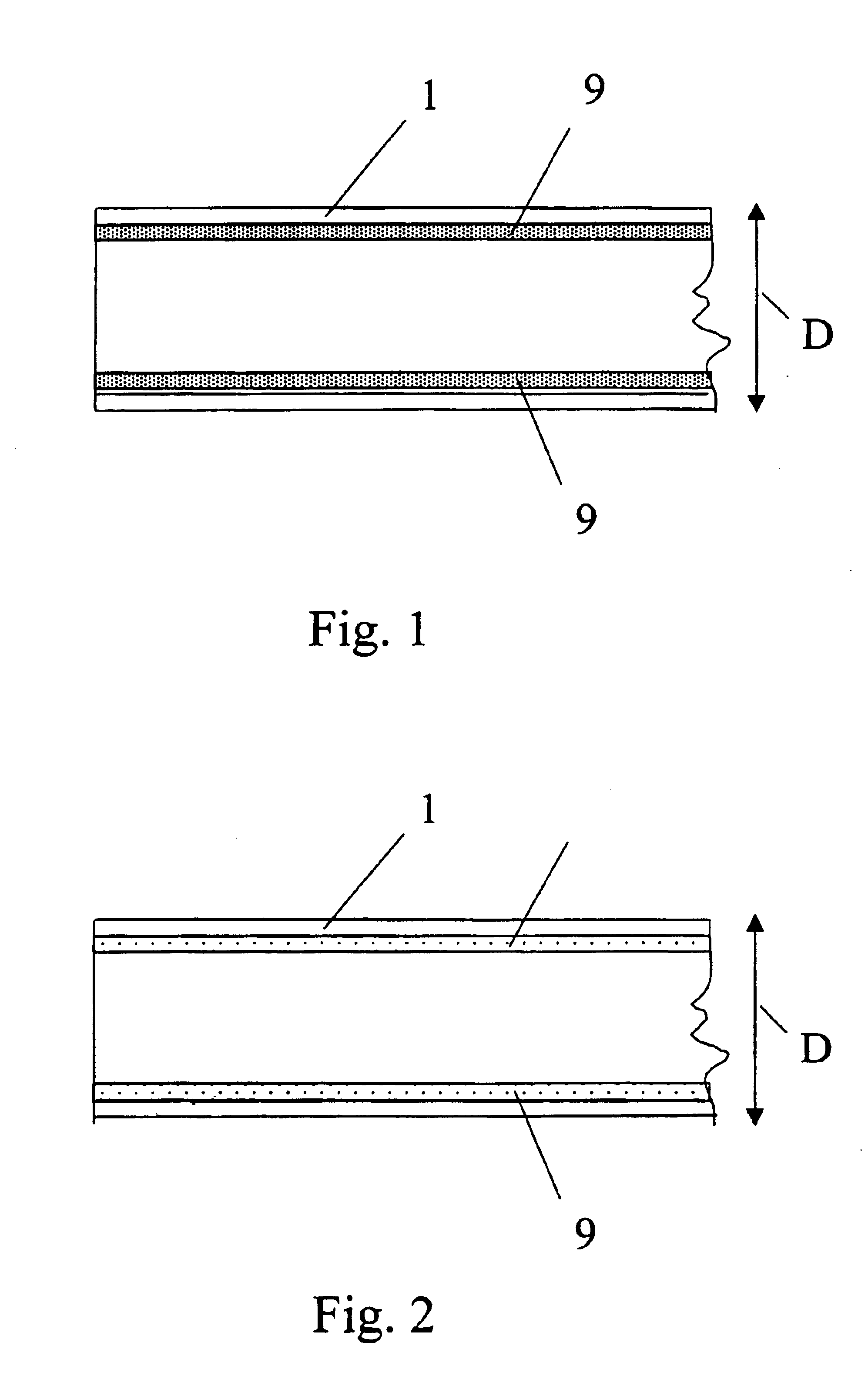

Referring now to FIG. 1, that shows an end of a faulty rod-shaped fluorescent lamp taken from the production line just after coating by a suspension of fluorescent material, the fluorescent coating 9 on the inside wall of the glass body 1 comprises binding material beside the fluorescent material in a mixture of suspension. At this stage of the lamp making process, the binding material has not been burned out from the fluorescent coating 9 yet. The fluorescent material itself can be a large variety of expensive rare-earth materials such as yttrium-oxide activated with europium, lanthanum phosphate activated with cerium and terbium and / or barium-magnesium-aluminate activated with europium. The diameter D of glass body 1 is unique at a particular type of fluorescent lamps and the glass body 1 is normally made from soda—lime glass.

FIG. 2 shows an end of a faulty rod-shaped fluorescent lamp taken from the production line just after burning out the fluorescent coating 9. At this stage of

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap