Boiler system for both heating and hot water

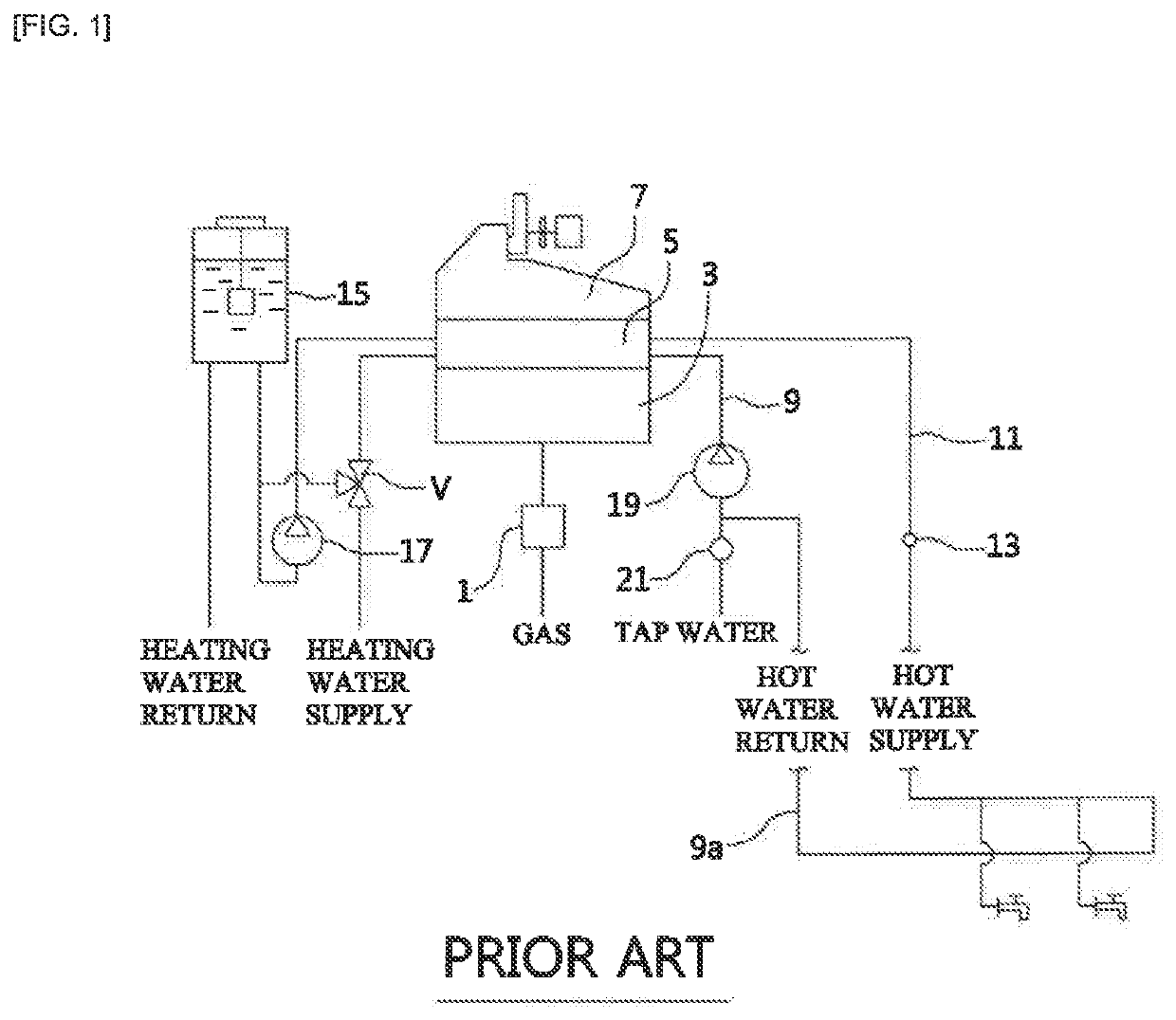

a boiler system and boiler technology, applied in space heating and ventilation, heating types, lighting and heating apparatus, etc., can solve the problems of reducing the ease of installation and increasing the purchase cost of pumps, and achieve the effect of smooth preheating and circulating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

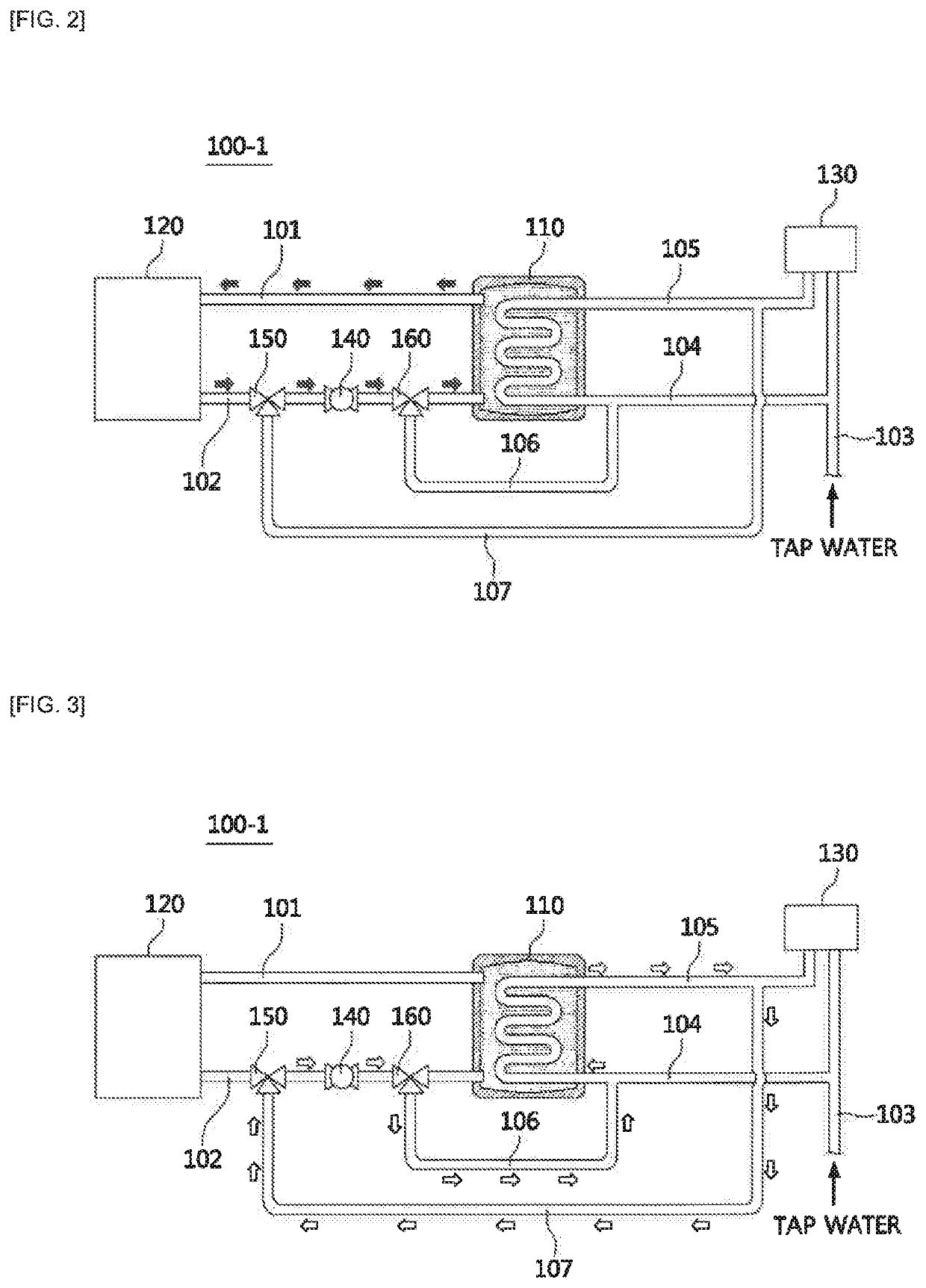

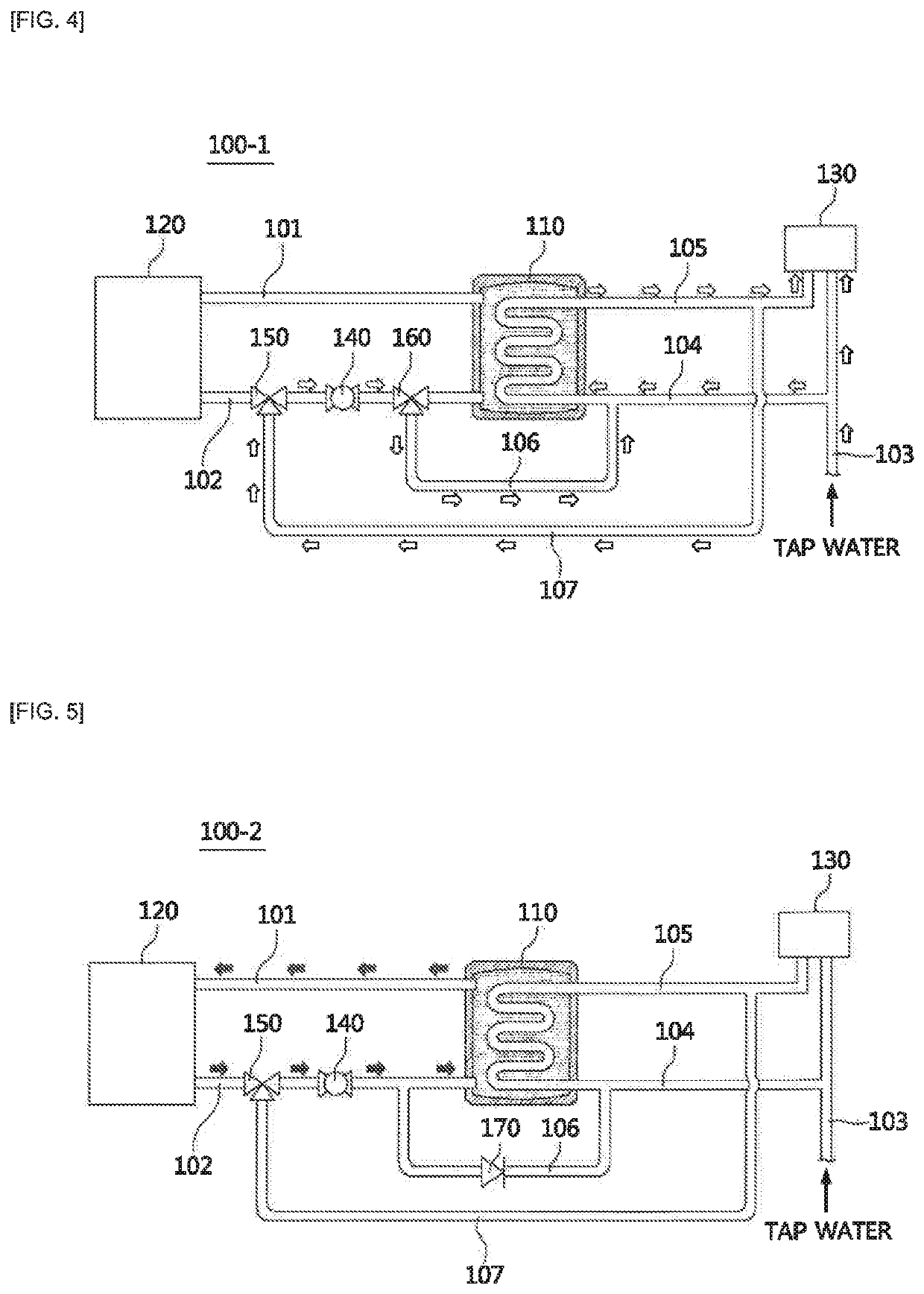

[0038]Referring to FIGS. 2 to 4, a boiler system 100-1 for both heating and hot water according to the present invention includes a hot water storage type heat exchanger 110 which stores heating water supplied to a heating destination 120, heats the heating water using a heat source (not shown), and generates hot water through a heat exchange between the heated heating water and tap water.

[0039]A heating water supply pipe 101 and a heating water return pipe 102 are connected between the hot water storage type heat exchanger 110 and the heating destination 120 to form a heating water channel.

[0040]A tap water pipe 103 and a hot water supply pipe 105 are connected to a hot water destination 130.

[0041]A tap water supply pipe 104 is branched from the tap water pipe 103 and is connected to pass through the inside of the hot water storage type heat exchanger 110. The tap water supply pipe 104 inside the hot water storage type heat exchanger 110 is connected to the hot water supply pipe 105.

third embodiment

[0067]Referring to FIGS. 8 to 11, a boiler system 200-1 for both heating and hot water according to the present invention includes a main heat exchanger 210 which heats heating water supplied for heating or supplied for exchanging heat by using combustion heat and a hot water heat exchanger 220 which generates hot water by exchanging heat between the heated heating water, which is heated by the main heat exchanger 210, and tap water. Reference symbol “F” denotes an air blower configured to supply combustion air, and reference symbol “B” denotes a burner configured to burn a mixture gas of combustion air and a gas.

[0068]A heating water supply pipe 201 and a heating water return pipe 202 are connected between the main heat exchanger 210 and a heating destination 230 to form a heating water channel.

[0069]A heating water bypass pipe 203 is connected to the heating water supply pipe 201 such that heating water supplied from the main heat exchanger 210 flows toward the heating water return p

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap