Pressure balance system of automatic ELISA (Enzyme-Linked Immunosorbent Assay) plate washer and automatic ELISA plate washer

A technology of balance system and plate washer, which is applied to chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., and can solve problems such as excessive residual liquid, damage, orifice plate washing is not clean, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

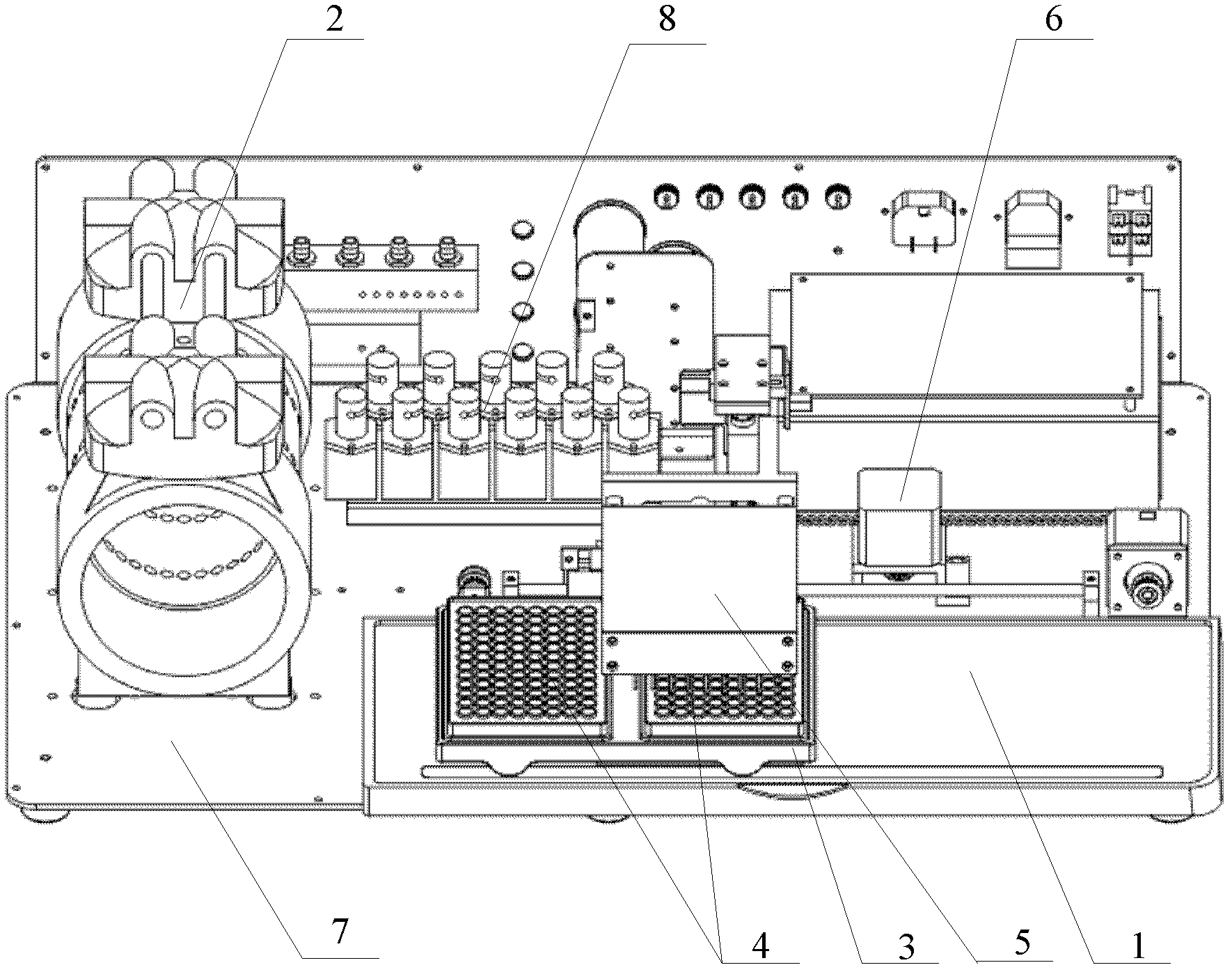

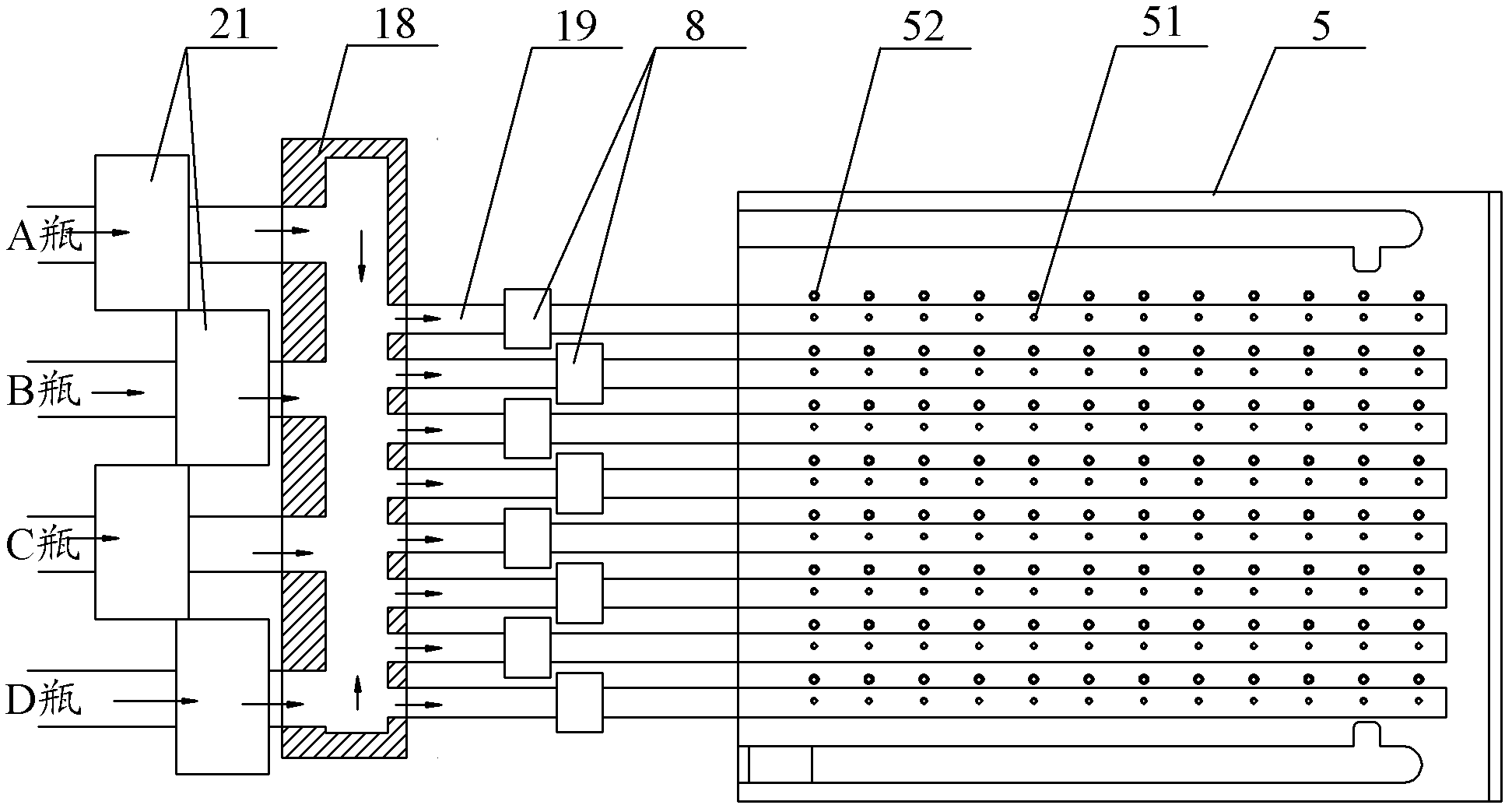

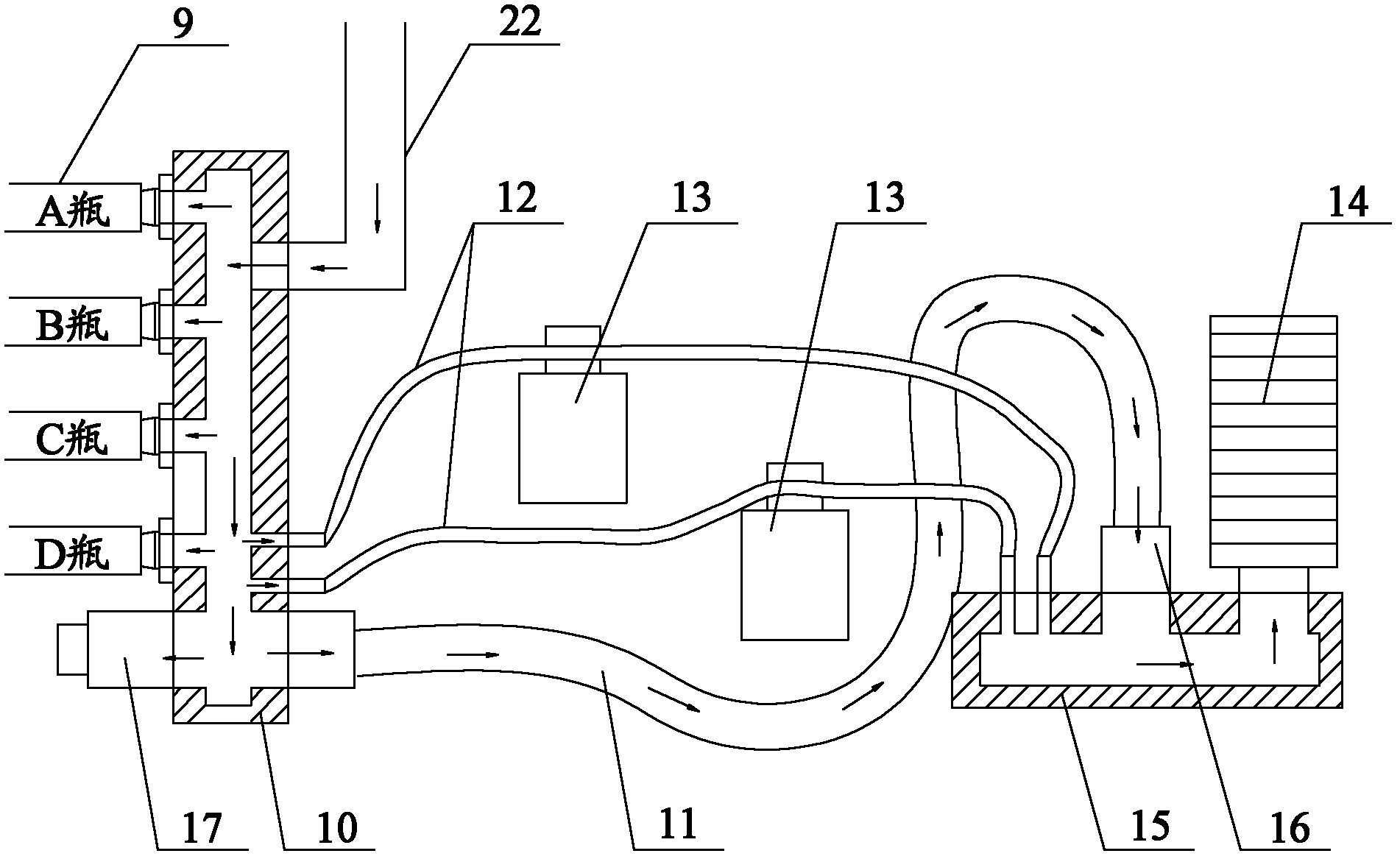

Embodiment Construction

[0022] The main solution of the embodiment of the present invention is: by setting a pressure balance system in the microplate washer, the pipeline pressure in the microplate washer can be automatically adjusted, so that the pressure generated by the vacuum pump is the same as that of the lotion needle on the cleaning head. The flow rate is automatically matched to prevent the large plate washer with a large number of holes from washing fewer orifice plates, due to closing part of the washing channel, the excessive overflow liquid overflows the tray and enters the inside of the machine, causing damage to the instrument.

[0023] The embodiment of the present invention is described by taking a large plate washer with 96 well cleaning heads as an example, but it is not limited to this case.

[0024] In order for the plate washer to work normally, it is very important to match the pressure generated by the vacuum pump in the plate washer with the flow rate of the lotion needle on the

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap