Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3 results about "Surface oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface oxidation process is used to create a gate insulator film of the transistor or oxide films which required forming insulation between wiring layers.

Porous high-entropy alloy self-supporting electrode for electrolyzing water and preparation method thereof

ActiveCN112725818AExcellent decomposabilityLow costNon-noble metal oxide coatingsHigh entropy alloysSurface oxidation

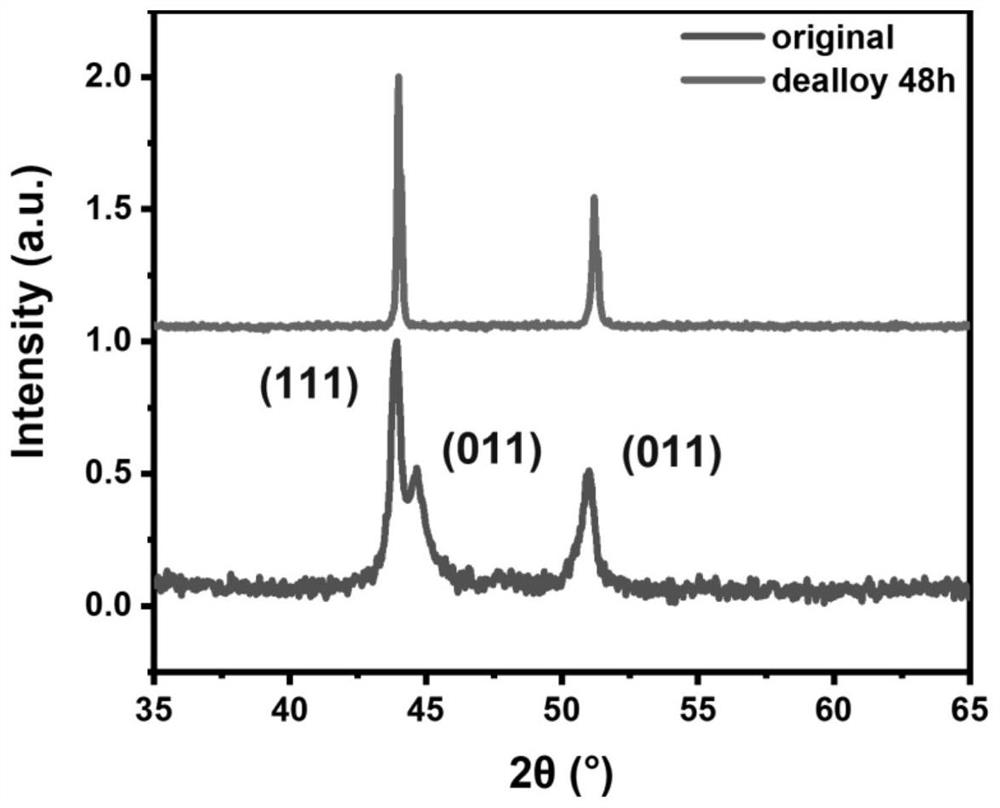

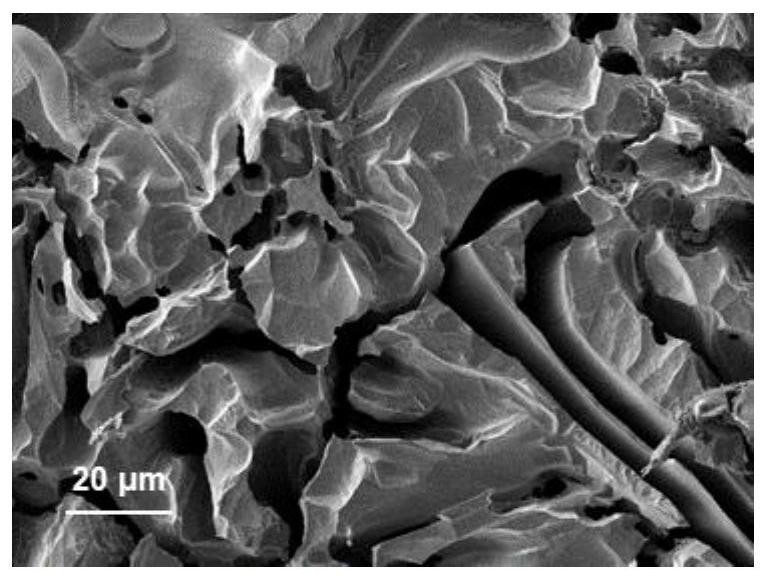

The invention discloses a porous high-entropy alloy self-supporting electrode for electrolyzing water and a preparation method thereof. The preparation method comprises the following steps: smelting, mixing and melting nickel powder, cobalt powder, chromium powder, iron powder, aluminum powder and tungsten powder, and conducting cooling to form a high-entropy alloy with an eutectic structure; cutting the high-entropy alloy into an alloy sheet, and conducting polishing to remove surface oxide skins; then carrying out dealloying treatment; and after dealloying treatment is completed, taking out the alloy sheet and carrying out ultrasonic treatment so as to obtain the self-supporting electrode. The invention provides a simple, efficient and controllable dealloying means for treating the high-entropy alloy sheet to obtain the sheet-shaped high-entropy alloy self-supporting catalytic electrode with a multi-scale pore structure, and the sheet-shaped high-entropy alloy self-supporting catalytic electrode is proved to have excellent electro-catalytic hydrogen evolution / oxygen evolution reaction activity and stability.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Spray method for preparing oxidation-resisting phosphorous copper alloy powder

InactiveCN106048298AGood sphericityUniform compositionTransportation and packagingMetal-working apparatusSurface oxidationIntermediate frequency

Owner:安徽旭晶粉体新材料科技有限公司

Diaphragm for efficient lithium ion secondary battery and preparation method thereof

ActiveCN111341975AImprove flame retardant performanceReduce the risk of explosionSecondary cellsCell component detailsActivated carbonSurface oxidation

The invention discloses a diaphragm for an efficient lithium ion secondary battery. The diaphragm comprises polyethylene microporous layers and a composite material coating. The thickness of each polyethylene microporous layer is 5-10 [mu]m, the pore diameter is 0.03-0.12 [mu]m, and the porosity is 40-50%. The thickness of each composite material coating is 5-10 [mu]m. The material coating comprises the following raw materials in parts by weight: 90-95 parts of organic silicon resin, 5-10 parts of modified activated carbon and 20-30 parts of a curing agent, wherein the water content of the organic silicon resin is 0.5-1%, the modified activated carbon is modified activated carbon obtained by surface oxidation, and the modified activated carbon is nano modified activated carbon. The diaphragm comprises the polyethylene microporous layers and the composite material coating, and is specifically of a polyethylene-composite material-polyethylene layered structure, and organic silicon resinin the composite material layer has good flame retardance, so that the explosion risk of the battery is reduced.

Owner:SICHUAN YOUYUAN NEW ENERGY CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap