Water-based alkyd-acrylate dispersion as well as preparation method and application thereof

An acrylate and water-based alkyd technology, used in coatings, anti-corrosion coatings, etc., can solve the problems of poor film adhesion, hardness and anti-corrosion, wide molecular weight distribution, and high molecular weight, and achieve improved density and leveling. The molecular weight distribution is uniform and the effect of improving the hardness of the paint film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

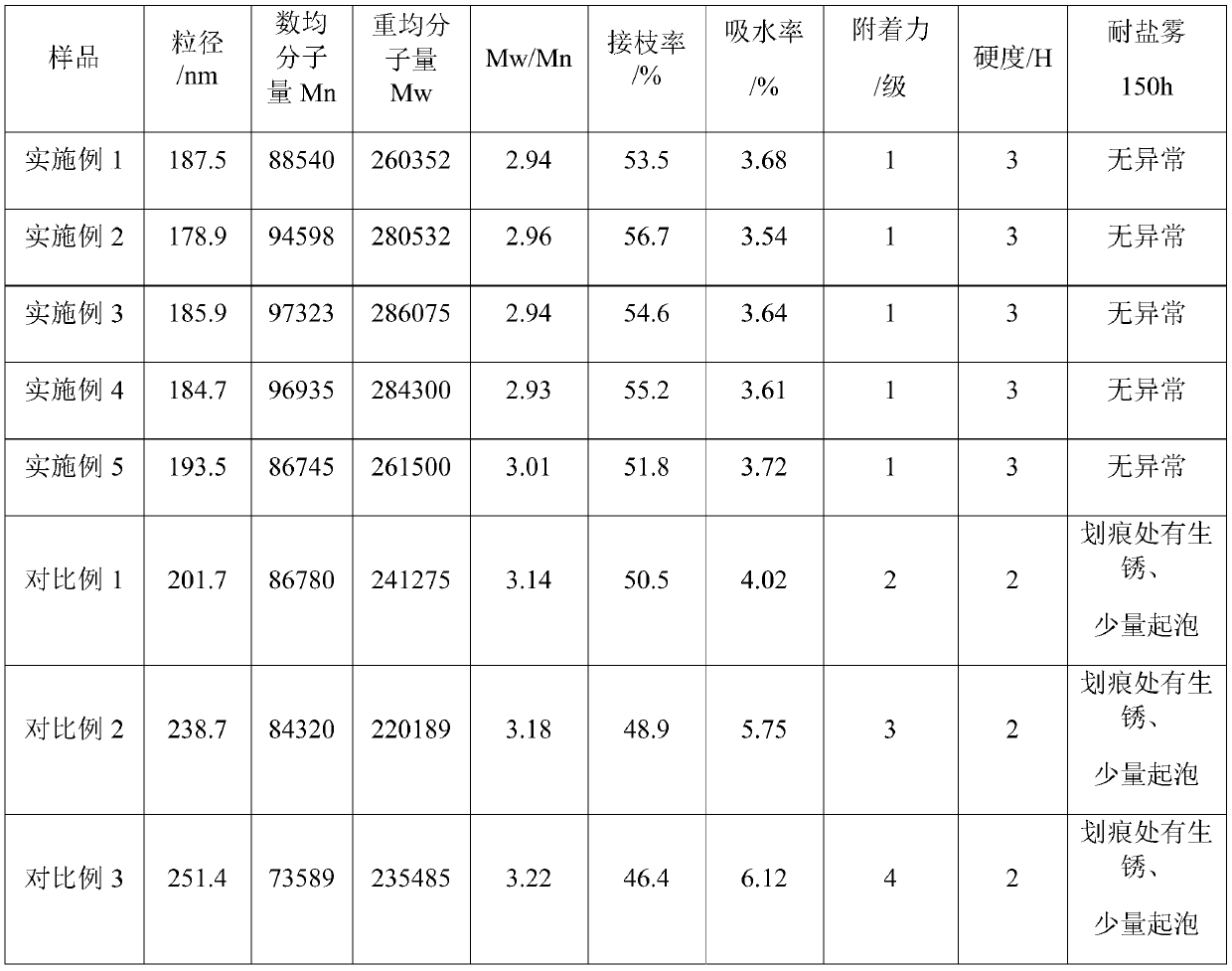

Examples

Embodiment 1

[0038] The embodiment of the present invention provides a water-based alkyd-acrylate dispersion, the raw materials of which include the following components in parts by mass: 45 parts of alkyd resin, 30 parts of acrylate monomer, 2,2,4-trimethyl- 10 parts of 1,3-pentanediol monoisobutyrate, 5 parts of initiator and 8 parts of neutralizer;

[0039] Wherein, the raw material of the alkyd resin includes the following components in parts by mass: 3 parts of rosin, 110 parts of vegetable oil, 45 parts of polyol, 55 parts of phthalic anhydride, 6 parts of maleic anhydride, 18 parts of trimellitic anhydride , 5 parts of D40 mineral spirits, 0.06 parts of alcoholysis catalyst, 0.07 parts of esterification catalyst and 23 parts of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate.

[0040] Wherein, the acrylate monomer is dimethylaminoethyl methacrylate; the initiator is benzoyl peroxide; the neutralizer is N,N-dimethylethanolamine; the vegetable oil is linseed oil ; The polyol is a mixtur

Embodiment 2

[0046] The embodiment of the present invention provides a water-based alkyd-acrylate dispersion, whose raw materials include the following components in parts by mass: 50 parts of alkyd resin, 45 parts of acrylate monomer, 2,2,4-trimethyl- 8 parts of 1,3-pentanediol monoisobutyrate, 4 parts of initiator and 7 parts of neutralizer;

[0047] Wherein, the acrylate monomer is dimethylaminoethyl methacrylate and methyl methacrylate with a mass ratio of 1:1; the raw material of the alkyd resin includes the following components in parts by mass: 4 parts of rosin, 105 parts of vegetable oil, 50 parts of polyol, 60 parts of phthalic anhydride, 7 parts of maleic anhydride, 20 parts of trimellitic anhydride, 6 parts of D40 solvent oil, 0.06 parts of alcoholysis catalyst, 0.08 parts of esterification catalyst and 2,2 , 20 parts of 4-trimethyl-1,3-pentanediol monoisobutyrate.

[0048] Wherein, the initiator is dicumyl peroxide; the neutralizer is triethanolamine; the vegetable oil is soybean

Embodiment 3

[0054] The embodiment of the present invention provides a water-based alkyd-acrylate dispersion, the raw materials of which include the following components in parts by mass: 55 parts of alkyd resin, 40 parts of acrylate monomer, 2,2,4-trimethyl- 8 parts of 1,3-pentanediol monoisobutyrate, 8 parts of initiator and 9 parts of neutralizer;

[0055] Wherein, the raw material of the alkyd resin includes the following components in parts by mass: 5 parts of rosin, 115 parts of vegetable oil, 48 parts of polyol, 58 parts of phthalic anhydride, 7.5 parts of maleic anhydride, 19 parts of trimellitic anhydride , 6.5 parts of D40 mineral spirits, 0.08 parts of alcoholysis catalyst, 0.07 parts of esterification catalyst and 30 parts of 2,2,4-trimethyl-1,3-pentanediol monoisobutyrate.

[0056] Wherein, the acrylate monomer is dimethylaminoethyl methacrylate and butyl (meth)acrylate with a mass ratio of 1:1; the acrylate monomer is dimethylaminoethyl methacrylate; The initiator is tert-butyl

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap