Construction method for sealing slurry at bottom of PC component

A construction method and component technology, applied in building structure, building material processing, construction, etc., can solve problems such as hidden quality problems, achieve the effects of improving compactness, improving quality and efficiency, and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0025] Embodiment one

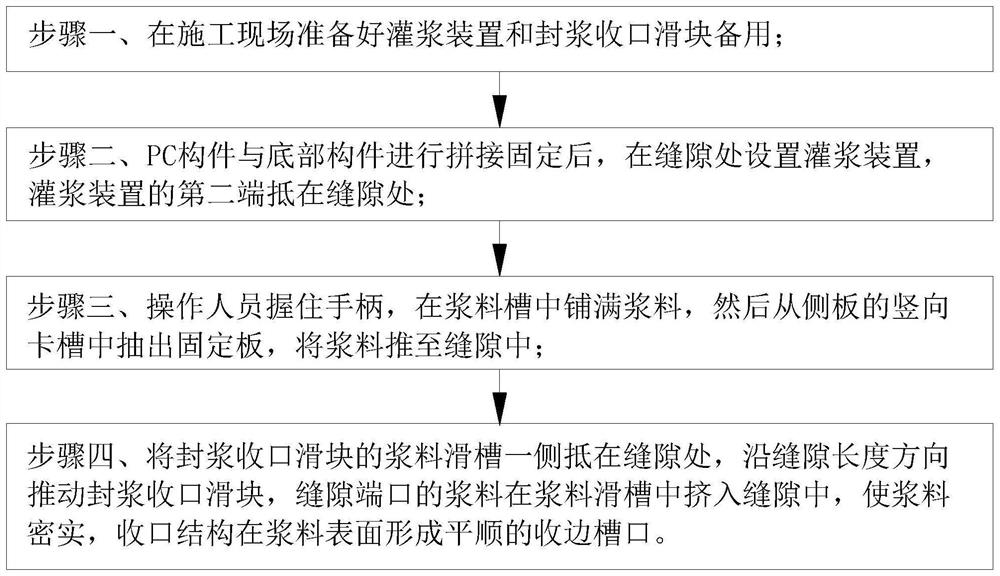

[0026] like figure 1 As shown, the construction method for the bottom grouting of a PC component provided in this embodiment includes the following steps:

[0027] Step 1: Prepare the grouting device and the grout sealing slider at the construction site for spare use.

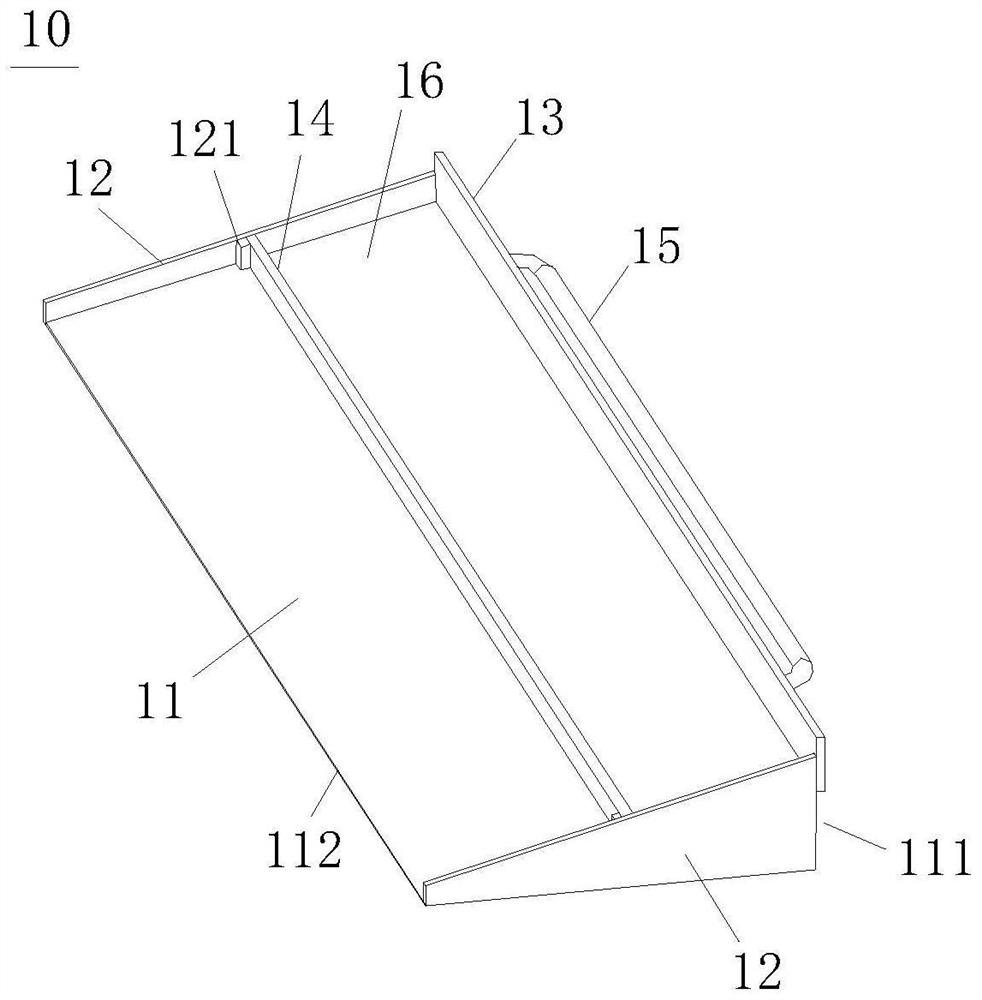

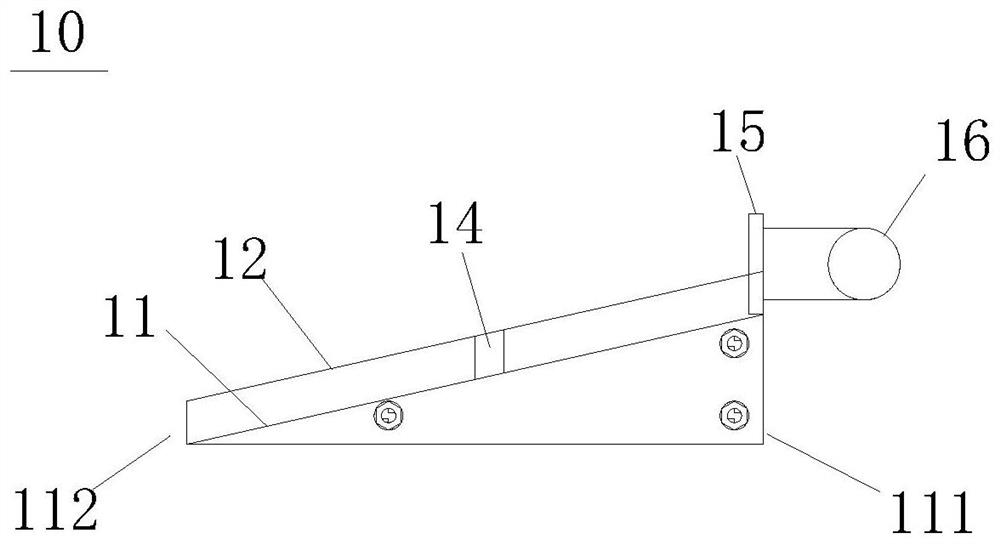

[0028] to combine figure 2 and image 3 As shown, the grouting device 10 includes an inclined support 11 , two side plates 12 , an end plate 13 , a fixing plate 14 and a handle 15 . The first end 111 of the inclined support 11 is higher than the second end 112, and the upper surface forms an inclined surface. The end plate 13 is arranged on the top of the first end 111 of the inclined surface, and the side plates 12 are fixed on both sides of the inclined support 11 by screws. The top of the side plate 12 protrudes from the upper surface of the inclined support 11 , preferably the top of the side plate 12 is parallel to the upper surface of the inclined support 11 . The side plate 12

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap